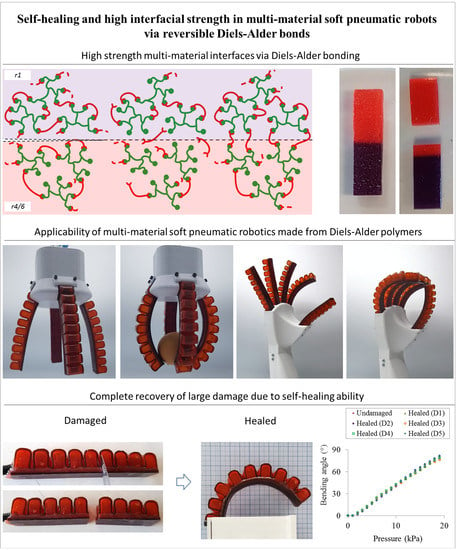

Self-Healing and High Interfacial Strength in Multi-Material Soft Pneumatic Robots via Reversible Diels–Alder Bonds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Synthesis

2.3. Diels–Alder Network Characteristics

2.4. Healing in Diels–Alder Networks

2.5. Merging of Diels–Alder Parts, Possibly with Different Properties

2.6. Manufacturing Through Folding and Covalently Binding

3. Results

3.1. Validation of the Merging Principle

3.2. Design of the Prototype

3.3. Manufacturing

- A.

- r4/6 and r1 are synthesized by solvent-casting thin sheets with dimensions: 100 × 100 × 0.75 mm3.

- B.

- A 3D printed, polylactic acid (PLA) mold is used to fold a r4/6 sheet. The mold consists of several different parts: a large bottom part containing the square wave shape of the top layer of the actuator, and nine smaller individual molds with the shape of the air chambers.

- C.

- First thin strips of 100 × 16.5 × 0.75 mm3 of r4/6 are cut from the synthesized sheets. The ends of four of these strips are merged, using a local heating procedure of 120 °C using a soldering tool, to form a strip of 400 × 16.5 × 0.75 mm3. This strip is placed on the large bottom mold. By pressing the small molds one by one on the strip, a square wave shape is formed in the strip. The mold is thereafter placed in a preheated oven at 80 °C (for 1 h). Because of the faster reaction dynamics of the DA reaction at higher temperatures, stresses induced by the pressing the strip in the mold are relaxed, and the strip takes on the square wave shape.

- D.

- A thin r4/6-strip of 105 × 17 × 0.75 mm3 is placed on a Teflon plate and the mold is placed on top, such that the square wave strip makes contact with the sheet. This sheet acts as the vertical side membrane of the actuator. The two r4/6-parts are connected through a merging procedure at 80 °C (1 h). The procedure is repeated for a second vertical side membrane on the other side.

- E.

- The r4/6-part is de-molded from the large bottom mold.

- F.

- The small molds can be removed.

- G.

- A strip of 100x16.5x1.5 mm3 is cut from a synthesized r1-sheet. The air chambers are sealed from the surroundings by placing the r4/6-part (red) on top of this r1 strip (purple) and heating it to 80 °C for 1 h.

- H.

- A hole is made at the back of the actuator in which a Tygon R3603 tube (outer diameter 6.5 mm, inner diameter 5.5 mm) is inserted. The connection between the membrane and this tube is made airtight through another local heating procedure using the hot soldering tool (120 °C).

- I.

- The entire actuator is placed for at last one hour at 80 °C, to form strong interfacial bonds between the different sheets. After this last heating stage, the actuator is left untouched for 24 h at 25 °C. The actuator is airtight and ready to use.

3.4. Validation of the Mechanical Properties

3.5. Validation of the Healing Properties

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef] [Green Version]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [Green Version]

- Marchese, A.D.; Katzschmann, R.K.; Rus, D. A Recipe for Soft Fluidic Elastomer Robots. Soft Robot. 2015, 2, 7–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Walker; Zidek; Harbel; Yoon; Strickland; Kumar; Shin Soft Robotics: A Review of Recent Developments of Pneumatic Soft Actuators. Actuators 2020, 9, 3. [CrossRef] [Green Version]

- Polygerinos, P.; Correll, N.; Morin, S.A.; Mosadegh, B.; Onal, C.; Petersen, K.H.; Cianchetti, M.; Tolley, M.T.; Shepherd, R.F. Soft Robotics: Review of Fluid-Driven Intrinsically Soft Devices; Manufacturing, Sensing, Control, and Applications in Human-Robot Interaction. Adv. Eng. Mater. 2017, 19, 1700016. [Google Scholar] [CrossRef]

- Gorissen, B.; Reynaerts, D.; Konishi, S.; Yoshida, K.; Kim, J.; Volder, M. De Elastic Inflatable Actuators for Soft Robotic Applications. Adv. Mater. 2017, 29, 1604977. [Google Scholar] [CrossRef] [PubMed]

- Van Damme, M.; Beyl, P.; VanderBorght, B.; Versluys, R.; Van Ham, R.; Vanderniepen, I.; Daerden, F.; Lefeber, D. The Safety of a Robot Actuated by Pneumatic Muscles—A Case Study. Int. J. Soc. Robot. 2010, 2, 289–303. [Google Scholar] [CrossRef]

- Choi, T.-Y.; Choi, B.-S.; Seo, K.-H. Position and Compliance Control of a Pneumatic Muscle Actuated Manipulator for Enhanced Safety. IEEE Trans. Control. Syst. Technol. 2010, 19, 832–842. [Google Scholar] [CrossRef]

- VanderBorght, B.; Verrelst, B.; Van Ham, R.; Van Damme, M.; Beyl, P.; Lefeber, D. Development of a compliance controller to reduce energy consumption for bipedal robots. Auton. Robot. 2008, 24, 419–434. [Google Scholar] [CrossRef]

- Ranzani, T.; Gerboni, G.; Cianchetti, M.; Menciassi, A. A bioinspired soft manipulator for minimally invasive surgery. Bioinspiration Biomim. 2015, 10, 35008. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Gafford, J.B. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef] [Green Version]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft Manipulators and Grippers: A Review. Front. Robot. AI 2016, 3, 20. [Google Scholar] [CrossRef] [Green Version]

- Available online: http://www.softroboticsinc.com/ (accessed on 25 April 2020).

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Scharff, R.B.; Wu, J.; Geraedts, J.M.; Wang, C.C. Reducing Out-of-Plane Deformation of Soft Robotic Actuators for Stable Grasping. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 265–270. [Google Scholar]

- Scharff, R.B.; Wu, J.; Geraedts, J.M.; Wang, C.C. A soft exoskeleton for hand assistive and rehabilitation application using pneumatic actuators with variable stiffness. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4967–4972. [Google Scholar]

- Manti, M.; Hassan, T.; Passetti, G.; D’Elia, N.; Laschi, C.; Cianchetti, M. A Bioinspired Soft Robotic Gripper for Adaptable and Effective Grasping. Soft Robot. 2015, 2, 107–116. [Google Scholar] [CrossRef]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9, 878. [Google Scholar] [CrossRef] [PubMed]

- Hughes, J.; Maiolino, P.; Iida, F. An anthropomorphic soft skeleton hand exploiting conditional models for piano playing. Sci. Robot. 2018, 3, eaau3098. [Google Scholar] [CrossRef] [Green Version]

- Chubb, K.; Berry, D.; Burke, T. Towards an ontology for soft robots: What is soft? Bioinspiration Biomim. 2019, 14, 063001. [Google Scholar] [CrossRef]

- Beyl, P.; Van Damme, M.; Van Ham, R.; VanderBorght, B.; Lefeber, D. Pleated Pneumatic Artificial Muscle-Based Actuator System as a Torque Source for Compliant Lower Limb Exoskeletons. IEEE/ASME Trans. Mechatron. 2014, 19, 1046–1056. [Google Scholar] [CrossRef]

- Brancart, J.; Verhelle, R.; Mangialetto, J.; Van Assche, G. Coupling the Microscopic Healing Behaviour of Coatings to the Thermoreversible Diels-Alder Network Formation. Coatings 2018, 9, 13. [Google Scholar] [CrossRef] [Green Version]

- Diaz, M.M.; Brancart, J.; Van Assche, G.; Mele, B. Van Room-temperature versus heating-mediated healing of a Diels-Alder crosslinked polymer network. Polymer 2018, 153, 453–463. [Google Scholar] [CrossRef]

- Brancart, J.; Scheltjens, G.; Muselle, T.; Van Mele, B.; Terryn, H.; Van Assche, G. Atomic force microscopy–based study of self-healing coatings based on reversible polymer network systems. J. Intell. Mater. Syst. Struct. 2012, 25, 40–46. [Google Scholar] [CrossRef]

- Scheltjens, G.; Diaz, M.M.; Brancart, J.; Van Assche, G.; Van Mele, B. Thermal evaluation of a self-healing polymer network coating based on reversible covalent bonding. Reactive and Functional. Polymers 2013, 73, 413–420. [Google Scholar]

- Terryn, S.; Brancart, J.; Lefeber, D.; Van Assche, G.; VanderBorght, B. Self-healing soft pneumatic robots. Sci. Robot. 2017, 2, eaan4268. [Google Scholar] [CrossRef]

- Roels, E.; Terryn, S.; Brancart, J.; Van Assche, G.; VanderBorght, B. A Multi-Material Self-Healing Soft Gripper. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 316–321. [Google Scholar]

- Terryn, S.; Brancart, J.; Lefeber, D.; Van Assche, G.; VanderBorght, B. A Pneumatic Artificial Muscle Manufactured Out of Self-Healing Polymers That Can Repair Macroscopic Damages. IEEE Robot. Autom. Lett. 2017, 3, 16–21. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Gafford, J.B.; Whitesides, G.M. Pneumatic Networks for Soft Robotics that Actuate Rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Martinez, R.; Fish, C.; Chen, X.; Whitesides, G.M. Elastomeric Origami: Programmable Paper-Elastomer Composites as Pneumatic Actuators. Adv. Funct. Mater. 2012, 22, 1376–1384. [Google Scholar] [CrossRef]

- Giffney, T.; Xie, M.; Yong, A.; Wong, A.; Mousset, P.; McDaid, A.; Aw, K.C. Soft Pneumatic Bending Actuator with Integrated Carbon Nanotube Displacement Sensor. Robotics 2016, 5, 7. [Google Scholar] [CrossRef] [Green Version]

- Morrow, J.; Shin, H.-S.; Phillips-Grafflin, C.; Jang, S.-H.; Torrey, J.; Larkins, R.; Dang, S.; Park, Y.-L.; Berenson, D. Improving Soft Pneumatic Actuator fingers through integration of soft sensors, position and force control, and rigid fingernails. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 5024–5031. [Google Scholar]

- Thuruthel, T.G.; Shih, B.; Laschi, C.; Tolley, M.T. Soft robot perception using embedded soft sensors and recurrent neural networks. Sci. Robot. 2019, 4, eaav1488. [Google Scholar] [CrossRef]

| DA network | r | [F0] (mol kg−1) | [M0] (mol kg−1) | Tgel (°C) | Tg (°C) | E (MPa) | σmax (MPa) | εmax (%) |

|---|---|---|---|---|---|---|---|---|

| DPBM-FT5000-r1 | 1 | 0.77 | 0.77 | 110 | −64.3 | 8.21 | 1.20 | 150 |

| DPBM-FT5000-r4/6 | 4/6 | 0.81 | 0.54 | 102 | −64.2 | 0.72 | 0.40 | 144 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terryn, S.; Roels, E.; Brancart, J.; Van Assche, G.; Vanderborght, B. Self-Healing and High Interfacial Strength in Multi-Material Soft Pneumatic Robots via Reversible Diels–Alder Bonds. Actuators 2020, 9, 34. https://doi.org/10.3390/act9020034

Terryn S, Roels E, Brancart J, Van Assche G, Vanderborght B. Self-Healing and High Interfacial Strength in Multi-Material Soft Pneumatic Robots via Reversible Diels–Alder Bonds. Actuators. 2020; 9(2):34. https://doi.org/10.3390/act9020034

Chicago/Turabian StyleTerryn, Seppe, Ellen Roels, Joost Brancart, Guy Van Assche, and Bram Vanderborght. 2020. "Self-Healing and High Interfacial Strength in Multi-Material Soft Pneumatic Robots via Reversible Diels–Alder Bonds" Actuators 9, no. 2: 34. https://doi.org/10.3390/act9020034

APA StyleTerryn, S., Roels, E., Brancart, J., Van Assche, G., & Vanderborght, B. (2020). Self-Healing and High Interfacial Strength in Multi-Material Soft Pneumatic Robots via Reversible Diels–Alder Bonds. Actuators, 9(2), 34. https://doi.org/10.3390/act9020034