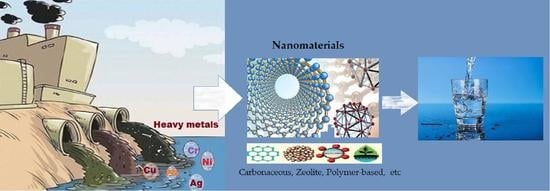

Function of Nanomaterials in Removing Heavy Metals for Water and Wastewater Remediation: A Review

Abstract

:1. Introduction

| Process | Description | Advantages | Limitations | Reference |

|---|---|---|---|---|

| Coagulation and Flocculation | Positively charged chemicals are added to the water. These chemicals neutralize the negative charge of contaminants and other dissolved particles in the water. When this occurs, the particles bind with the chemicals and form larger particles, called floc. Floc settles to the bottom of the water supply due to its weight, and this settling process is called sedimentation. | Relatively affordable since alum is a cheap coagulant Simple to operate | Ineffective for heavy metals removal To achieve efficient removal, it is frequently combined with a precipitation approach. Sludge production | [20] |

| Precipitation | Chemical agents are used in this procedure to convert metal ions to insoluble precipitates of hydroxide, sulfide, carbonate, or phosphate. Later, the solid precipitate is separated using a filtering procedure. | A simple approach with remarkable selectivity Low-cost precipitants | Low-efficiency treatment for polluted water with high heavy metals concentrations. Consumes huge quantities of precipitate agents Results in large amounts of toxic sludge Chemical stabilization and efficient precipitant disposal are required. Metal precipitation and sedimentation at a slow rate | [21] |

| Ion exchange | Ion exchange removes ions from the aqueous phase by exchanging cations or anions between the contaminants and the exchange medium. Ion exchange materials may consist of resins made from synthetic organic materials that contain ionic functional groups to which exchangeable ions are attached. They also may be inorganic and natural polymeric materials. After the resin capacity has been exhausted, resins can be regenerated for re-use. | Easy procedure Low-cost materials and re-usable resin Fast process kinetic | Highly sensitive to pH The presence of free acids may result in low binding affinity. Fouling of metal ions on ion exchange mediaOnly suitable for low concentration of metals | [22] |

| Membrane technologies | The membrane technologies use a physical barrier (usually a porous membrane or filter) to separate particles and microorganisms suspended in water. | High removal efficiency Ease of fabrication, operation No need for chemical additives Scale-up and control, space-saving | Severe foulingHigh energy consumption due to the pressure-driven inherent process May need pretreatment process Probability generation of secondary pollutants and requirement of post-treatment | [23] |

| Electrochemical technologies | Using anodic and cathodic reactions In an electrochemical cell | This process is easy to operate, does not require chemicals, and has reduced sludge production and saves energy. | Large capital investments, expensive electricity supply Ineffective when metal ion concentrations in aqueoussolutions are low | [24] |

| Adsorption | This mechanism entraps metal ions in materials with adsorptive features (i.e., highly porous, large surface area, active functional groups) through physical or chemical interactions. The adsorbents are then filtered from the solution and regenerated. | Wide range of adsorbents Low cost Easy to use | Time-consuming post-treatment procedure For maximal binding capacity, some adsorbents must be hybridized. | [25] |

2. Mechanisms for the Removal of Heavy Metal

3. Nanomaterials for Heavy Metals Removal

3.1. Carbon-Based Nanomaterials

3.2. Zeolites Nanoparticle

3.3. Polymer-Based Nanomaterials

3.3.1. Cellulose-Based Nanomaterials

3.3.2. Dendrimer-Based Nanomaterials

3.3.3. Chitosan-Based Nanomaterials

3.4. Magnetic Nanomaterials

3.4.1. Polymers Functionalized Magnetic Nanoparticles

3.4.2. Nanocomposite Magnetic Nanoparticles

3.4.3. Inorganic Functionalized Magnetic Nanoparticles

3.5. Carbon Materials Magnetic Nanoparticles

3.5.1. Organic Functionalized Magnetic Nanoparticles

3.5.2. Biomolecules Functionalized Magnetic Nanoparticles

3.6. Metal Oxides and Metal-Based Nanomaterials

3.7. Silica-Based Nanomaterials

4. Factors Affecting Adsorption

4.1. Impact of Initial Ion Concentration

4.2. Temperature

4.3. Contact Time

4.4. Effect of Adsorbent Dosage

4.5. Effect of Solution pH

4.6. Effect of Ionic Strength

5. Conclusions and Future Prospective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ethaib, S.; Zubaidi, S.L. Removal of methylene blue dye from aqueous solution using kaolin. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 2nd International Scientific Conference of Al-Ayen University, Nasiriyah, Iraq, 15-16 July 2020; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Khudhair, Z.S.; Zubaidi, S.; Ortega-Martorell, S.; Al-Ansari, N.; Ethaib, S.; Hashim, K. A Review of Hybrid Soft Computing and Data Pre-Processing Techniques to Forecast Freshwater Quality’s Parameters: Current Trends and Future Directions. Environments 2022, 9, 85. [Google Scholar] [CrossRef]

- Ethaib, S.; Zubaidi, S.L.; Al-Ansari, N. Evaluation water scarcity based on GIS estimation and climate-change effects: A case study of Thi-Qar Governorate. Iraq. Cogent Eng. 2022, 9, 2075301. [Google Scholar] [CrossRef]

- Bolisetty, S.; Peydayesh, M.; Mezzenga, R. Sustainable technologies for water purification from heavy metals: Review and analysis. Chem. Soc. Rev. 2019, 48, 463–487. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, S.; Priya, T.; Khoo, K.S.; Hoang, T.; Ng, H.S.; Munawaroh, H.; Karaman, C.; Orooji, Y.; Show, P.L. A critical review on various remediation approaches for heavy metal contaminants removal from contaminated soils. Chemosphere 2022, 287, 132369. [Google Scholar] [CrossRef]

- Srivastava, N.; Majumder, C. Novel biofiltration methods for the treatment of heavy metals from industrial wastewater. J. Hazard. Mater. 2008, 151, 1–8. [Google Scholar] [CrossRef]

- Ilyas, M.; Ahmad, W.; Khan, H.; Yousaf, S.; Yasir, M.; Khan, A. Environmental and health impacts of industrial wastewater effluents in Pakistan: A review. Rev. Environ. Health 2019, 34, 171–186. [Google Scholar] [CrossRef]

- Ethaib, S. Solid waste situation in Thi-Qar governorate. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Civil and Environmental Engineering Technologies, Najaf, Iraq, 23–24 April 2019; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Erabee, I.K.; Ethaib, S. Performane of Activated Carbon Adsorption in Removing of Organic Pollutants from River Water. Int. J. Eng. Technol. 2018, 7, 356–358. [Google Scholar] [CrossRef]

- Priyadharshini, S.D.; Suresh Babu, P.; Manikandan, S.; Subbaiya, R.; Govarthanan, M.; Karmegam, N. Phycoremediation of wastewater for pollutant removal: A green approach to environmental protection and long-term remediation. Environ. Pollut. 2021, 290, 117989. [Google Scholar] [CrossRef]

- Chan, B.; Dudeney, A. Reverse osmosis removal of arsenic residues from bioleaching of refractory gold concentrates. Miner. Eng. 2008, 21, 272–278. [Google Scholar] [CrossRef]

- Rashid, R.; Shafiq, I.; Akhter, P.; Iqbal, M.J.; Hussain, M. A state-of-the-art review on wastewater treatment techniques: The effectiveness of adsorption method. Environ. Sci. Pollut. Res. 2021, 28, 9050–9066. [Google Scholar] [CrossRef]

- Elgarahy, A.; Al-wakeel, K.; Mohammad, S.; Shoubaky, G. A critical review of biosorption of dyes, heavy metals and metalloids from wastewater as an efficient and green process. Clean. Eng. Technol. 2021, 4, 100209. [Google Scholar] [CrossRef]

- Ethaib, S.; Erabee, I.K.; Abdulsahib, A.A. Removal of methylene blue dye from synthetic wastewater using kenaf core and activated carbon. Int. J. Eng. Technol. 2018, 7, 909–913. [Google Scholar] [CrossRef]

- Qasem, N.A.; Mohammed, R.H.; Lawal, D.U. Removal of heavy metal ions from wastewater: A comprehensive and critical review. Npj Clean Water 2021, 4, 36. [Google Scholar] [CrossRef]

- Almomani, F.; Bhosale, R.; Khraisheh, M.; Kumar, A.; Almomani, T. Heavy metal ions removal from industrial wastewater using magnetic nanoparticles (MNP). Appl. Surf. Sci. 2020, 506, 144924. [Google Scholar] [CrossRef]

- Sadegh, H.; Ali, G.A. Potential applications of nanomaterials in wastewater treatment: Nanoadsorbents performance. In Research Anthology on Synthesis, Characterization, and Applications of Nanomaterials; Information Resources Management Association, Ed.; IGI Global: Hershey, PA, USA, 2021; pp. 1230–1240. [Google Scholar]

- Wu, Y.; Pang, H.; Liu, Y.; Wang, X.; Yu, S.; Fu, D.; Chen, J.; Wang, X. Environmental remediation of heavy metal ions by novel-nanomaterials: A review. Environ. Pollut. 2019, 246, 608–620. [Google Scholar] [CrossRef]

- Kanel, S.R.; Greneche, J.-M.; Choi, H. Arsenic (V) removal from groundwater using nano scale zero-valent iron as a colloidal reactive barrier material. Environ. Sci. Technol. 2006, 40, 2045–2050. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, J.; Yan, Y.; Yang, L.; Xing, G.; Li, H.; Wu, P.; Wang, M.; Zheng, H. Application of coagulation/flocculation in oily wastewater treatment: A review. Sci. Total Environ. 2021, 765, 142795. [Google Scholar] [CrossRef]

- Gunatilake, S. Methods of removing heavy metals from industrial wastewater. Methods 2015, 1, 14. [Google Scholar]

- Hubicki, Z.; Kołodyńska, D. Selective removal of heavy metal ions from waters and waste waters using ion exchange methods. Ion Exch. Technol. 2012, 7, 193–240. [Google Scholar]

- Sadr, S.M.; Saroj, D.P. Membrane technologies for municipal wastewater treatment. In Advances in Membrane Technologies for Water Treatment; Basile, A., Cassano, A., Rastogi, N.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 443–463. [Google Scholar]

- Lee, J.; Lee, J.K.; Uhm, S.; Lee, H.J. Electrochemical technologies: Water treatment. Appl. Chem. Eng. 2011, 22, 235–242. [Google Scholar]

- Gupta, A.; Sharma, V.; Sharma, K.; Kumar, V.; Choudhary, S.; Mankotia, P.; Kumar, B.; Mishra, H.; Moulick, A.; Ekielski, A.; et al. A review of adsorbents for heavy metal decontamination: Growing approach to wastewater treatment. Materials 2021, 14, 4702. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; Wang, W.; Tan, F.; Luo, F.; Chen, J.; Qiao, X. Investigation on the efficiency and mechanism of Cd (II) and Pb (II) removal from aqueous solutions using MgO nanoparticles. J. Hazard. Mater. 2015, 299, 664–674. [Google Scholar] [CrossRef] [PubMed]

- Zamora-Ledezma, C.; Negrete-Bolagay, D.; Figueroa, F.; Zamora, L.E.; Ni, M.; Alexis, F.; Guerrero, V. Heavy metal water pollution: A fresh look about hazards, novel and conventional remediation methods. Environ. Technol. Innov. 2021, 22, 101504. [Google Scholar] [CrossRef]

- Yang, X.; Wan, Y.; Zheng, Y.; He, F.; Yu, Z.; Huang, J.; Wang, H.; Ok, Y.S.; Jiang, Y.; Gao, B. Surface functional groups of carbon-based adsorbents and their roles in the removal of heavy metals from aqueous solutions: A critical review. Chem. Eng. J. 2019, 366, 608–621. [Google Scholar] [CrossRef]

- Ettre, L.S. Nomenclature for chromatography (IUPAC Recommendations 1993). Pure Appl. Chem. 1993, 65, 819–872. [Google Scholar] [CrossRef]

- Hu, J.; Chen, G.; Lo, I.M. Removal and recovery of Cr (VI) from wastewater by maghemite nanoparticles. Water Res. 2005, 39, 4528–4536. [Google Scholar] [CrossRef]

- Alharbi, N.S.; Hu, B.; Hayat, T.; Rabah, S.; Alsaedi, A.; Zhuang, L.; Wang, X. Efficient elimination of environmental pollutants through sorption-reduction and photocatalytic degradation using nanomaterials. Front. Chem. Sci. Eng. 2020, 14, 1124–1135. [Google Scholar] [CrossRef]

- Hu, B.; Boyd, K.G.; Taggart, M.A.; Turk Sekulic, M. Efficient elimination of organic and inorganic pollutants by biochar and biochar-based materials. Biochar 2020, 2, 47–64. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Q.; Jia, F.; Song, S. Adsorption of heavy metals on molybdenum disulfide in water: A critical review. J. Mol. Liq. 2019, 292, 111390. [Google Scholar] [CrossRef]

- Shukor, S.A.A.; Hamzah, R.; Bakar, M.A.; Noriman, N.Z.; Al-Rashdi, A.A.; Razlan, Z.M.; Shahriman, A.B.; Zunaidi, I.; Khairunizam, W. Metal oxide and activated carbon as photocatalyst for waste water treatment. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 1st International Conference on Mechanical Electronic and Biosystem Engineering (MEBSE 2018), Bogor, Indonesia,15–16 December 2018; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Cheng, L.; Liu, S.; He, G.; Hu, Y. The simultaneous removal of heavy metals and organic contaminants over a Bi2WO6/mesoporous TiO2 nanotube composite photocatalyst. RSC Adv. 2020, 10, 21228–21237. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Wang, J.; Zhu, H. Recent advances in carbon nitride-based nanomaterials for the removal of heavy metal ions from aqueous solution. J. Inorg. Mater. 2020, 35, 260. [Google Scholar]

- Le, A.T.; Pung, S.Y.; Sreekantan, S.; Matsuda, A.; Huynh, D.P. Mechanisms of removal of heavy metal ions by ZnO particles. Heliyon 2019, 5, e01440. [Google Scholar] [CrossRef]

- Qu, X.; Alvarez, P.J.; Li, Q. Applications of nanotechnology in water and wastewater treatment. Water Res. 2013, 47, 3931–3946. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, B.; Rezania, S. Carbon-based sorbents and their nanocomposites for the enrichment of heavy metal ions: A review. Microchim. Acta 2019, 186, 578. [Google Scholar] [CrossRef] [PubMed]

- Nasrollahzadeh, M.; Sajjadi, M.; Iravani, S.; Varma, R. Carbon-based sustainable nanomaterials for water treatment: State-of-art and future perspectives. Chemosphere 2021, 263, 128005. [Google Scholar] [CrossRef] [PubMed]

- Hoang, A.T.; Nižetić, S.; Cheng, C.K.; Luque, R.; Thomas, S.; Banh, T.L.; Pham, V.V.; Nguyen, X.P. Heavy metal removal by biomass-derived carbon nanotubes as a greener environmental remediation: A comprehensive review. Chemosphere 2022, 287, 131959. [Google Scholar] [CrossRef]

- Kosa, S.A.; Al-Zhrani, G.; Salam, M.A. Removal of heavy metals from aqueous solutions by multi-walled carbon nanotubes modified with 8-hydroxyquinoline. Chem. Eng. J. 2012, 181, 159–168. [Google Scholar] [CrossRef]

- Wang, J.; Ma, X.; Fang, G.; Pan, M.; Ye, X.; Wang, S. Preparation of iminodiacetic acid functionalized multi-walled carbon nanotubes and its application as sorbent for separation and preconcentration of heavy metal ions. J. Hazard. Mater. 2011, 186, 1985–1992. [Google Scholar] [CrossRef]

- Taghizadeh, M.; Asgharinezhad, A.A.; Samkhaniany, N.; Tadjarodi, A.; Abbaszadeh, A.; Pooladi, M. Solid phase extraction of heavy metal ions based on a novel functionalized magnetic multi-walled carbon nanotube composite with the aid of experimental design methodology. Microchim. Acta 2014, 181, 597–605. [Google Scholar] [CrossRef]

- Zhang, C.; Sui, J.; Li, J.; Tang, Y.; Cai, W. Efficient removal of heavy metal ions by thiol-functionalized superparamagnetic carbon nanotubes. Chem. Eng. J. 2012, 210, 45–52. [Google Scholar] [CrossRef]

- Chen, C.; Hu, J.; Shao, D.; Li, J.; Wang, X. Adsorption behavior of multiwall carbon nanotube/iron oxide magnetic composites for Ni (II) and Sr (II). J. Hazard. Mater. 2009, 164, 923–928. [Google Scholar] [CrossRef] [PubMed]

- Rao, G.P.; Lu, C.; Su, F. Sorption of divalent metal ions from aqueous solution by carbon nanotubes: A review. Sep. Purif. Technol. 2007, 58, 224–231. [Google Scholar] [CrossRef]

- Ren, X.; Chen, C.; Nagatsu, M.; Wang, X. Carbon nanotubes as adsorbents in environmental pollution management: A review. Chem. Eng. J. 2011, 170, 395–410. [Google Scholar] [CrossRef]

- Rawat, D.S.; Calbi, M.M.; Migone, A.D. Equilibration time: Kinetics of gas adsorption on closed-and open-ended single-walled carbon nanotubes. J. Phys. Chem. C 2007, 111, 12980–12986. [Google Scholar] [CrossRef]

- Abbas, A.; Abbas, A.; Al-Amer, A.; Laoui, T.; Almarri, M.; Nasser, M.; Khraisheh, M.; Atieh, A.M. Heavy metal removal from aqueous solution by advanced carbon nanotubes: Critical review of adsorption applications. Sep. Purif. Technol. 2016, 157, 141–161. [Google Scholar]

- Pyrzyńska, K.; Bystrzejewski, M. Comparative study of heavy metal ions sorption onto activated carbon, carbon nanotubes, and carbon-encapsulated magnetic nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2010, 362, 102–109. [Google Scholar] [CrossRef]

- Mubarak, M.; Sahu, J.; Abdullah, E.; Natesan, J. Removal of heavy metals from wastewater using carbon nanotubes. Sep. Purif. Rev. 2014, 43, 311–338. [Google Scholar] [CrossRef]

- Moghaddam, H.K.; Pakizeh, M. Experimental study on mercury ions removal from aqueous solution by MnO2/CNTs nanocomposite adsorbent. J. Ind. Eng. Chem. 2015, 21, 221–229. [Google Scholar] [CrossRef]

- Liang, J.; Liu, J.; Yuan, X.; Dong, H.; Zeng, G.; Wu, H.; Wang, H.; Liu, J.; Hua, S.; Zhang, S.; et al. Facile synthesis of alumina-decorated multi-walled carbon nanotubes for simultaneous adsorption of cadmium ion and trichloroethylene. Chem. Eng. J. 2015, 273, 101–110. [Google Scholar] [CrossRef]

- Liu, D.; Zhu, Y.; Li, Z.; Tian, D.; Chen, L.; Chen, P. Chitin nanofibrils for rapid and efficient removal of metal ions from water system. Carbohydr. Polym. 2013, 98, 483–489. [Google Scholar] [CrossRef]

- Zhu, K.; Jia, H.; Wang, F.; Zhu, Y.; Wang, C.; Ma, C. Efficient removal of Pb (II) from aqueous solution by modified montmorillonite/carbon composite: Equilibrium, kinetics, and thermodynamics. J. Chem. Eng. Data 2017, 62, 333–340. [Google Scholar] [CrossRef]

- Sun, J.; Liang, Q.; Han, Q.; Zhang, X.; Ding, M. One-step synthesis of magnetic graphene oxide nanocomposite and its application in magnetic solid phase extraction of heavy metal ions from biological samples. Talanta 2015, 132, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Gollavelli, G.; Chang, C.-C.; Ling, Y.-C. Facile synthesis of smart magnetic graphene for safe drinking water: Heavy metal removal and disinfection control. ACS Sustain. Chem. Eng. 2013, 1, 462–472. [Google Scholar] [CrossRef]

- Zeng, T.; Yu, Y.; Li, Z.; Zuo, J.; Kuai, Z.; Jin, Y.; Wang, Y.; Wu, A.; Peng, C. 3D MnO2 nanotubes@reduced graphene oxide hydrogel as reusable adsorbent for the removal of heavy metal ions. Mater. Chem. Phys. 2019, 231, 105–108. [Google Scholar] [CrossRef]

- Zhao, G.; Li, J.; Ren, X.; Chen, C.; Wang, X. Few-layered graphene oxide nanosheets as superior sorbents for heavy metal ion pollution management. Environ. Sci. Technol. 2011, 45, 10454–10462. [Google Scholar] [CrossRef] [PubMed]

- Mahmodi, G.; Zarrintaj, P.; Taghizadeh, A.; Taghizadeh, M.; Manouchehri, S.; Dangwal, S.; Ronte, A.; Ganjali, M.R.; Ramsey, J.D.; Kim, S.J.; et al. From microporous to mesoporous mineral frameworks: An alliance between zeolite and chitosan. Carbohydr. Res. 2020, 489, 107930. [Google Scholar] [CrossRef] [PubMed]

- Mahdavi Far, R.; Van der Bruggen, B.; Verliefde, A.; Cornelissen, E. A review of zeolite materials used in membranes for water purification: History, applications, challenges and future trends. J. Chem. Technol. Biotechnol. 2022, 97, 575–596. [Google Scholar] [CrossRef]

- Yoldi, M.; Fuentes-Ordoñez, E.G.; Korili, S.A.; Gil, A. Zeolite synthesis from industrial wastes. Microporous Mesoporous Mater. 2019, 287, 183–191. [Google Scholar] [CrossRef]

- Ribeiro, F.R. Zeolites: Science and Technology; Springer Science & Business Media: Dordrecht, The Netherlands, 2012; Volume 80. [Google Scholar]

- Guisnet, M.; Gilson, J.-P. Introduction to zeolite science and technology. Catal. Sci. Ser. 2002, 3, 1–28. [Google Scholar]

- Aghel, B.; Gouran, A.; Razmegir, M.H. Use of modified Iranian clinoptilolite zeolite for cadmium and lead removal from oil refinery wastewater. Int. J. Environ. Sci. Technol. 2020, 17, 1239–1250. [Google Scholar] [CrossRef]

- Mahmoodi, N.M.; Saffar-Dastgerdi, M.H. Zeolite nanoparticle as a superior adsorbent with high capacity: Synthesis, surface modification and pollutant adsorption ability from wastewater. Microchem. J. 2019, 145, 74–83. [Google Scholar] [CrossRef]

- Rad, L.R.; Momeni, A.; Ghazani, B.; Irani, M.; Mahmoudi, M.; Noghreh, B. Removal of Ni2+ and Cd2+ ions from aqueous solutions using electrospun PVA/zeolite nanofibrous adsorbent. Chem. Eng. J. 2014, 256, 119–127. [Google Scholar] [CrossRef]

- Charkhi, A.; Kazemeini, M.; Ahmadi, S.; Kazemian, H. Fabrication of granulated NaY zeolite nanoparticles using a new method and study the adsorption properties. Powder Technol. 2012, 231, 1–6. [Google Scholar] [CrossRef]

- Malamis, S.; Katsou, E. A review on zinc and nickel adsorption on natural and modified zeolite, bentonite and vermiculite: Examination of process parameters, kinetics and isotherms. J. Hazard. Mater. 2013, 252, 428–461. [Google Scholar] [CrossRef]

- Sprynskyy, M.; Buszewski, B.; Terzyk, A.P.; Namieśnik, J. Study of the selection mechanism of heavy metal (Pb2+, Cu2+, Ni2+, and Cd2+) adsorption on clinoptilolite. J. Colloid Interface Sci. 2006, 304, 21–28. [Google Scholar] [CrossRef]

- Alvarez-Ayuso, E.; Garcıa-Sánchez, A.; Querol, X. Purification of metal electroplating waste waters using zeolites. Water Res. 2003, 37, 4855–4862. [Google Scholar] [CrossRef]

- Lee, M.-G.; Yi, G.; Ahn, B.; Roddick, F. Conversion of coal fly ash into zeolite and heavy metal removal characteristics of the products. Korean J. Chem. Eng. 2000, 17, 325–331. [Google Scholar] [CrossRef]

- Yurekli, Y. Removal of heavy metals in wastewater by using zeolite nano-particles impregnated polysulfone membranes. J. Hazard. Mater. 2016, 309, 53–64. [Google Scholar] [CrossRef]

- Deravanesiyan, M.; Beheshti, M.; Malekpour, A. The removal of Cr (III) and Co (II) ions from aqueous solution by two mechanisms using a new sorbent (alumina nanoparticles immobilized zeolite)—Equilibrium, kinetic and thermodynamic studies. J. Mol. Liq. 2015, 209, 246–257. [Google Scholar] [CrossRef]

- Abdelrahman, E.A.; Tolan, D.A.; Nassar, M.Y. A tunable template-assisted hydrothermal synthesis of hydroxysodalite zeolite nanoparticles using various aliphatic organic acids for the removal of zinc (II) ions from aqueous media. J. Inorg. Organomet. Polym. Mater. 2019, 29, 229–247. [Google Scholar] [CrossRef]

- Al-Jubouri, S.M.; Holmes, S.M. Immobilization of cobalt ions using hierarchically porous 4A zeolite-based carbon composites: Ion-exchange and solidification. J. Water Process Eng. 2020, 33, 101059. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, W.; Cai, J.; Cheng, S.Y.; Ding, W.P. Citric acid-incorporated cellulose nanofibrous mats as food materials-based biosorbent for removal of hexavalent chromium from aqueous solutions. Int. J. Biol. Macromol. 2020, 149, 459–466. [Google Scholar] [CrossRef] [PubMed]

- Khandaker, S.; Toyohara, Y.; Saha, G.; Saha, D.; Awual, M.; Kuba, T. Development of synthetic zeolites from bio-slag for cesium adsorption: Kinetic, isotherm and thermodynamic studies. J. Water Process Eng. 2020, 33, 101055. [Google Scholar] [CrossRef]

- Rondón, W.; Freire, D.; Benzo, Z.; Sifontes, A.; González, Y.; Valero, M.; Brito, J. Application of 3A zeolite prepared from Venezuelan kaolin for removal of Pb (II) from wastewater and its determination by flame atomic absorption spectrometry. Am. J. Anal. Chem. 2013, 4, 584–593. [Google Scholar] [CrossRef]

- Fanta, F.T.; Dubale, A.A.; Bebizuh, D.F.; Atlabachew, M. Copper doped zeolite composite for antimicrobial activity and heavy metal removal from waste water. BMC Chem. 2019, 13, 44. [Google Scholar] [CrossRef]

- Meng, Q.; Chen, H.; Lin, J.; Lin, Z.; Sun, J. Zeolite A synthesized from alkaline assisted pre-activated halloysite for efficient heavy metal removal in polluted river water and industrial wastewater. J. Environ. Sci. 2017, 56, 254–262. [Google Scholar] [CrossRef]

- Nosike, E.I.; Jiang, Z.; Miao, L.; Akakuru, O.U.; Yuan, B.; Wu, S.; Zhang, Y.; Zhang, Y.; Wu, A. A novel hybrid nanoadsorbent for effective Hg2+ adsorption based on zeolitic imidazolate framework (ZIF-90) assembled onto poly acrylic acid capped Fe3O4 nanoparticles and cysteine. J. Hazard. Mater. 2020, 392, 122288. [Google Scholar] [CrossRef]

- Luo, C.; Wang, J.; Jia, P.; Liu, Y.; An, J.; Cao, B.; Pan, K. Hierarchically structured polyacrylonitrile nanofiber mat as highly efficient lead adsorbent for water treatment. Chem. Eng. J. 2015, 262, 775–784. [Google Scholar] [CrossRef]

- Ethaib, S.; Omar, R.; Mazlina, M.S.; Radiah, A.D.; Zubaidi, S.L. Toward sustainable processes of pretreatment technologies of lignocellulosic biomass for enzymatic production of biofuels and chemicals: A review. BioResources 2020, 15, 1006. [Google Scholar] [CrossRef]

- Mautner, A.; Maples, H.; Kobkeatthawin, T.; Kokol, V.; Karim, Z.; Li, K.; Bismarck, A. Phosphorylated nanocellulose papers for copper adsorption from aqueous solutions. Int. J. Environ. Sci. Technol. 2016, 13, 1861–1872. [Google Scholar] [CrossRef]

- Abou-Zeid, R.E.; Dacrory, S.; Ali, K.A.; Kamel, S. Novel method of preparation of tricarboxylic cellulose nanofiber for efficient removal of heavy metal ions from aqueous solution. Int. J. Biol. Macromol. 2018, 119, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.Y.; Bae, J.H.; Hasegawa, Y.; An, S.; Kim, I.S.; Lee, H.; Kim, M. Thiol-functionalized cellulose nanofiber membranes for the effective adsorption of heavy metal ions in water. Carbohydr. Polym. 2020, 234, 115881. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, E.; Aval, S.F.; Akbarzadeh, A.; Milani, M.; Nasrabadi, H.T.; Joo, S.W.; Hanifehpour, Y.; Nejati-Koshki, K.; Pashaei-Asl, R. Dendrimers: Synthesis, applications, and properties. Nanoscale Res. Lett. 2014, 9, 247. [Google Scholar] [CrossRef] [PubMed]

- Viltres, H.; Odio, O.F.; Reguera, E. Dendrimer-based hybrid nanomaterials for water remediation: Adsorption of inorganic contaminants. In Nanohybrids in Environmental & Biomedical Applications; Sharma, S.K., Ed.; CRC Press: Boca Raton, FL, USA, 2019; pp. 279–298. [Google Scholar]

- Shah, S.N.; Mo, K.H.; Soon, P.Y.; Yang, J.; Ling, T.-C. Lightweight foamed concrete as a promising avenue for incorporating waste materials: A review. Resour. Conserv. Recycl. 2021, 164, 105103. [Google Scholar] [CrossRef]

- Efome, J.E.; Rana, D.; Matsuura, T.; Lan, C. Effects of operating parameters and coexisting ions on the efficiency of heavy metal ions removal by nano-fibrous metal-organic framework membrane filtration process. Sci. Total Environ. 2019, 674, 355–362. [Google Scholar] [CrossRef] [PubMed]

- Lide, D.R. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2004; Volume 85. [Google Scholar]

- Martín, D.M.; Faccini, M.; García, M.A.; Amantia, D. Highly efficient removal of heavy metal ions from polluted water using ion-selective polyacrylonitrile nanofibers. J. Environ. Chem. Eng. 2018, 6, 236–245. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Moghadam, P.N.; Samadi, N. Synthesis and application of modified poly (styrene-alt-maleic anhydride) networks as a nano chelating resin for uptake of heavy metal ions. Polym. Adv. Technol. 2013, 24, 34–41. [Google Scholar] [CrossRef]

- Cegłowski, M.; Gierczyk, B.; Frankowski, M.; Popenda, L. A new low-cost polymeric adsorbents with polyamine chelating groups for efficient removal of heavy metal ions from water solutions. React. Funct. Polym. 2018, 131, 64–74. [Google Scholar] [CrossRef]

- Hirano, S.; Seino, H.; Akiyama, Y.; Nonaka, I. A biocompatible material for oral and intravenous administrations. In Progress in Biomedical Polymers; Gebelein, C.G., Dunn, R.L., Eds.; Plenum Press: New York, NY, USA, 1990; pp. 283–289. [Google Scholar]

- Suh, J.-K.F.; Matthew, H.W. Application of chitosan-based polysaccharide biomaterials in cartilage tissue engineering: A review. Biomaterials 2000, 21, 2589–2598. [Google Scholar]

- Kumar, N.; Ravikumar, M.N.; Domb, A. Biodegradable block copolymers. Adv. Drug Deliv. Rev. 2001, 53, 23–44. [Google Scholar] [CrossRef]

- Mima, S.; Miya, M.; Iwamoto, R.; Yoshikawa, S. Highly deacetylated chitosan and its properties. J. Appl. Polym. Sci. 1983, 28, 1909–1917. [Google Scholar] [CrossRef]

- Dubey, R.; Bajpai, J.; Bajpai, A. Chitosan-alginate nanoparticles (CANPs) as potential nanosorbent for removal of Hg (II) ions. Environ. Nanotechnol. Monit. Manag. 2016, 6, 32–44. [Google Scholar] [CrossRef]

- Saad, A.H.A.; Azzam, A.; El-Wakeel, S.; Mostafa, B.; El-latif, M. Removal of toxic metal ions from wastewater using ZnO@Chitosan core-shell nanocomposite. Environ. Nanotechnol. Monit. Manag. 2018, 9, 67–75. [Google Scholar] [CrossRef]

- Razzaz, A.; Ghorban, S.; Hosseini, L.; Irani, M.; Aliabadi, M. Chitosan nanofibers functionalized by TiO2 nanoparticles for the removal of heavy metal ions. J. Taiwan Inst. Chem. Eng. 2016, 58, 333–343. [Google Scholar] [CrossRef]

- Esmaeili, A.; Khoshnevisan, N. Optimization of process parameters for removal of heavy metals by biomass of Cu and Co-doped alginate-coated chitosan nanoparticles. Bioresour. Technol. 2016, 218, 650–658. [Google Scholar] [CrossRef]

- Yuan, X.; An, N.; Zhu, Z.; Sun, H.; Zheng, J.; Jia, M.; Lu, C.; Zhang, W.; Liu, N. Hierarchically porous nitrogen-doped carbon materials as efficient adsorbents for removal of heavy metal ions. Process Saf. Environ. Prot. 2018, 119, 320–329. [Google Scholar] [CrossRef]

- Shukla, S.K.; Mishra, A.K.; Arotiba, O.A.; Mamba, B.B. Chitosan-based nanomaterials: A state-of-the-art review. Int. J. Biol. Macromol. 2013, 59, 46–58. [Google Scholar] [CrossRef]

- Nassar, N.N. Rapid removal and recovery of Pb (II) from wastewater by magnetic nanoadsorbents. J. Hazard. Mater. 2010, 184, 538–546. [Google Scholar] [CrossRef]

- Iconaru, S.L.; Guegan, R.; Popa, C.; Motelica-Heino, M.; Carmen, C.; Predoi, D. Magnetite (Fe3O4) nanoparticles as adsorbents for As and Cu removal. Appl. Clay Sci. 2016, 134, 128–135. [Google Scholar] [CrossRef]

- Leonel, A.G.; Mansur, A.A.; Mansur, H.S. Advanced functional nanostructures based on magnetic iron oxide nanomaterials for water remediation: A review. Water Res. 2021, 190, 116693. [Google Scholar] [CrossRef]

- Wang, X. Nanomaterials as sorbents to remove heavy metal ions in wastewater treatment. J. Environ. Anal. Toxicol. 2012, 2, 154–158. [Google Scholar] [CrossRef]

- Patwardhan, S.V.; Emami, F.S.; Berry, R.J.; Jones, S.E.; Naik, R.R.; Deschaume, O.; Heinz, H.; Perry, C.C. Chemistry of aqueous silica nanoparticle surfaces and the mechanism of selective peptide adsorption. J. Am. Chem. Soc. 2012, 134, 6244–6256. [Google Scholar] [CrossRef]

- Pratt, A. Environmental applications of magnetic nanoparticles. In Frontiers of Nanoscience; Lead, J.R., Valsami-Jones, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 259–307. [Google Scholar]

- Hassan, M.; Naidu, R.; Du, J.; Liu, Y.; Qi, F. Critical review of magnetic biosorbents: Their preparation, application, and regeneration for wastewater treatment. Sci. Total Environ. 2020, 702, 134893. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Guan, J.; Lai, G.; Xu, Q.; Bai, X.; Wang, Z.; Cui, S. Stimuli-responsive adsorption behavior toward heavy metal ions based on comb polymer functionalized magnetic nanoparticles. J. Clean. Prod. 2020, 253, 119915. [Google Scholar] [CrossRef]

- Huang, S.-H.; Chen, D.-H. Rapid removal of heavy metal cations and anions from aqueous solutions by an amino-functionalized magnetic nano-adsorbent. J. Hazard. Mater. 2009, 163, 174–179. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Cabanas, M.; López-García, M.; Barriada, J.; Herrero, R.; Sastre de Vicente, M. Green synthesis of iron oxide nanoparticles. Development of magnetic hybrid materials for efficient As (V) removal. Chem. Eng. J. 2016, 301, 83–91.

- Hasanzadeh, R.; Moghadam, P.N.; Bahri-Laleh, N.; Sillanpää, M. Effective removal of toxic metal ions from aqueous solutions: 2-Bifunctional magnetic nanocomposite base on novel reactive PGMA-MAn copolymer@Fe3O4 nanoparticles. J. Colloid Interface Sci. 2017, 490, 727–746. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.-J.; Lee, C.S.; Chang, Y.Y.; Chang, Y.S. Hierarchically structured manganese oxide-coated magnetic nanocomposites for the efficient removal of heavy metal ions from aqueous systems. ACS Appl. Mater. Interfaces 2013, 5, 9628–9634. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.-J.; You, C.-F.; Chen, M.-H.; Duan, Y.-P. Efficient removal/recovery of Pb onto environmentally friendly fabricated copper ferrite nanoparticles. J. Taiwan Inst. Chem. Eng. 2017, 71, 197–205. [Google Scholar] [CrossRef]

- Tu, Y.J.; Chan, T.S.; Tu, H.W.; Wang, S.L.; You, C.F.; Chang, C.K. Rapid and efficient removal/recovery of molybdenum onto ZnFe2O4 nanoparticles. Chemosphere 2016, 148, 452–458. [Google Scholar] [CrossRef]

- Tu, Y.-J.; You, C.-F.; Chang, C.-K. Conversion of waste Mn–Zn dry battery as efficient nano-adsorbents for hazardous metals removal. J. Hazard. Mater. 2013, 258, 102–108. [Google Scholar] [CrossRef]

- Asadi, R.; Abdollahi, H.; Gharabaghi, M.; Boroumand, Z. Effective removal of Zn (II) ions from aqueous solution by the magnetic MnFe2O4 and CoFe2O4 spinel ferrite nanoparticles with focuses on synthesis, characterization, adsorption, and desorption. Adv. Powder Technol. 2020, 31, 1480–1489. [Google Scholar] [CrossRef]

- Vamvakidis, K.; Kostitsi, T.M.; Makridis, A.; Dendrinou-Samara, C. Diverse surface chemistry of cobalt ferrite nanoparticles to optimize copper (II) removal from aqueous media. Materials 2020, 13, 1537. [Google Scholar] [CrossRef] [PubMed]

- Ghaemi, N.; Madaeni, S.S.; Daraei, P.; Rajabi, H.; Zinadini, S.; Alizadeh, A.; Heydari, R.; Beygzadeh, M.; Ghouzivand, S. Polyethersulfone membrane enhanced with iron oxide nanoparticles for copper removal from water: Application of new functionalized Fe3O4 nanoparticles. Chem. Eng. J. 2015, 263, 101–112. [Google Scholar] [CrossRef]

- Guo, L.; Li, J.; Zhang, L.; Li, J.; Li, Y.; Yu, C.; Shi, J.; Ruan, M.; Feng, J. A facile route to synthesize magnetic particles within hollow mesoporous spheres and their performance as separable Hg2+ adsorbents. J. Mater. Chem. 2008, 18, 2733–2738. [Google Scholar] [CrossRef]

- Mokadem, Z.; Mekki, S.; Saïdi-Besbes, S.; Agusti, G.; Elaissari, A.; Derdour, A. Triazole containing magnetic core-silica shell nanoparticles for Pb2+, Cu2+ and Zn2+ removal. Arab. J. Chem. 2017, 10, 1039–1051. [Google Scholar] [CrossRef]

- Calvo, B.; Canoira, L.; Morante, F.; Martínez-Bedia, J.M.; Vinagre, C.; García-González, J.E.; Elsen, J.; Alcantara, R. Continuous elimination of Pb2+, Cu2+, Zn2+, H+ and NH4+ from acidic waters by ionic exchange on natural zeolites. J. Hazard. Mater. 2009, 166, 619–627. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, D.; Chang, Y.; Xing, S.; Wu, Y.; Gao, Y. Synthesis of MnFe2O4@Mn–Co oxide core–shell nanoparticles and their excellent performance for heavy metal removal. Dalton Trans. 2013, 42, 14261–14267. [Google Scholar] [CrossRef]

- Wang, P.; Shen, T.; Li, X.; Tang, Y.; Li, Y. Magnetic mesoporous calcium carbonate-based nanocomposites for the removal of toxic Pb (II) and Cd (II) ions from water. ACS Appl. Nano Mater. 2020, 3, 1272–1281. [Google Scholar] [CrossRef]

- Islam, M.S.; Choi, W.; Nam, B.; Yoon, C.; Lee, H.-J. Needle-like iron oxide@CaCO3 adsorbents for ultrafast removal of anionic and cationic heavy metal ions. Chem. Eng. J. 2017, 307, 208–219. [Google Scholar] [CrossRef]

- Danesh, N.; Hosseini, M.; Ghorbani, M.; Marjani, A. Fabrication, characterization and physical properties of a novel magnetite graphene oxide/Lauric acid nanoparticles modified by ethylenediaminetetraacetic acid and its applications as an adsorbent for the removal of Pb (II) ions. Synth. Met. 2016, 220, 508–523. [Google Scholar] [CrossRef]

- Ghasemi, E.; Heydari, A.; Sillanpää, M. Superparamagnetic Fe3O4@EDTA nanoparticles as an efficient adsorbent for simultaneous removal of Ag (I), Hg (II), Mn (II), Zn (II), Pb (II) and Cd (II) from water and soil environmental samples. Microchem. J. 2017, 131, 51–56. [Google Scholar] [CrossRef]

- Li, N.; Li, Z.; Zhang, L.; Shi, H.; Li, J.; Zhang, J.; Zhang, Z.; Dang, F. One-step fabrication of bifunctional self-assembled oligopeptides anchored magnetic carbon nanoparticles and their application in copper (II) ions removal from aqueous solutions. J. Hazard. Mater. 2020, 382, 121113. [Google Scholar] [CrossRef] [PubMed]

- Ge, F.; Li, M.-M.; Ye, H.; Zhao, B.-X. Effective removal of heavy metal ions Cd2+, Zn2+, Pb2+, Cu2+ from aqueous solution by polymer-modified magnetic nanoparticles. J. Hazard. Mater. 2012, 211, 366–372. [Google Scholar] [CrossRef] [PubMed]

- Girginova, P.I.; Daniel-da-Silva, A.L.; Lopes, C.; Figueira, P.; Otero, M.; Amaral, V.; Pereira, E.; Trindade, T. Silica coated magnetite particles for magnetic removal of Hg2+ from water. J. Colloid Interface Sci. 2010, 345, 234–240. [Google Scholar] [CrossRef]

- Xu, P.; Zeng, G.; Huang, D.; Yan, M.; Chen, M.; Lai, C.; Jiang, H.; Wu, H.; Chen, G.; Wan, J. Fabrication of reduced glutathione functionalized iron oxide nanoparticles for magnetic removal of Pb (II) from wastewater. J. Taiwan Inst. Chem. Eng. 2017, 71, 165–173. [Google Scholar] [CrossRef]

- Shen, H.; Pan, S.; Zhang, Y.; Huang, X.; Gong, H. A new insight on the adsorption mechanism of amino-functionalized nano-Fe3O4 magnetic polymers in Cu (II), Cr (VI) co-existing water system. Chem. Eng. J. 2012, 183, 180–191. [Google Scholar] [CrossRef]

- Zhang, H.; Tan, X.; Qiu, T.; Zhou, L.; Li, R.; Deng, Z. A novel and biocompatible Fe3O4 loaded chitosan polyelectrolyte nanoparticles for the removal of Cd2+ ion. Int. J. Biol. Macromol. 2019, 141, 1165–1174. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Xiao, C.; Zhao, H.; Zhang, M.; Zheng, N.; Kong, W.; Zhang, L.; Yuan, H.; Zhang, L. Triethylenetetramine-modified hollow Fe3O4/SiO2/chitosan magnetic nanocomposites for removal of Cr (VI) ions with high adsorption capacity and rapid rate. Microporous Mesoporous Mater. 2020, 297, 110041. [Google Scholar] [CrossRef]

- Shen, H.; Chen, J.; Dai, H.; Wang, L.; Hu, M.; Xia, Q.-H. New insights into the sorption and detoxification of chromium (VI) by tetraethylenepentamine functionalized nanosized magnetic polymer adsorbents: Mechanism and pH effect. Ind. Eng. Chem. Res. 2013, 52, 12723–12732. [Google Scholar] [CrossRef]

- Verma, R.; Asthana, A.; Singh, A.; Prasad, S.; Susan, M. Novel glycine-functionalized magnetic nanoparticles entrapped calcium alginate beads for effective removal of lead. Microchem. J. 2017, 130, 168–178. [Google Scholar] [CrossRef]

- Xu, P.; Zeng, G.; Huang, D.; Lai, C.; Zhao, M.; Wei, Z.; Li, N.; Huang, C.; Xie, G. Adsorption of Pb (II) by iron oxide nanoparticles immobilized Phanerochaete chrysosporium: Equilibrium, kinetic, thermodynamic and mechanisms analysis. Chem. Eng. J. 2012, 203, 423–431. [Google Scholar] [CrossRef]

- Abdolmaleki, A.; Mallakpour, S.; Borandeh, S. Efficient heavy metal ion removal by triazinyl-β-cyclodextrin functionalized iron nanoparticles. RSC Adv. 2015, 5, 90602–90608. [Google Scholar] [CrossRef]

- Fan, H.; Ma, X.; Zhou, S.; Huang, J.; Liu, Y.; Liu, Y. Highly efficient removal of heavy metal ions by carboxymethyl cellulose-immobilized Fe3O4 nanoparticles prepared via high-gravity technology. Carbohydr. Polym. 2019, 213, 39–49. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Li, N.; Li, P.Y.; Liu, B.; Lai, H.J.; Jin, T. One-step preparation of chitosan-based magnetic adsorbent and its application to the adsorption of inorganic arsenic in water. Molecules 2021, 26, 1785. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, N.M.; Hamouda, A.; Kader, S.; Khalil, M. Removal of cadmium from aqueous solution using modified magnetic glycine modified cross-linked chitosan resin. Egypt. J. Aquat. Biol. Fish. 2021, 25, 555–570. [Google Scholar] [CrossRef]

- Lian, Z.; Li, Y.; Xian, H.; Ouyang, X.K.; Lu, Y.; Peng, X.; Hu, D. EDTA-functionalized magnetic chitosan oligosaccharide and carboxymethyl cellulose nanocomposite: Synthesis, characterization, and Pb (II) adsorption performance. Int. J. Biol. Macromol. 2020, 165, 591–600. [Google Scholar] [CrossRef] [PubMed]

- Hua, M.; Hua, M.; Zhang, S.; Pan, B.; Zhang, W.; Lv, L.; Zhang, Q. Heavy metal removal from water/wastewater by nanosized metal oxides: A review. J. Hazard. Mater. 2012, 211, 317–331. [Google Scholar] [CrossRef]

- Fan, M.; Boonfueng, T.; Xu, Y.; Axe, L.; Tyson, T. Modeling Pb sorption to microporous amorphous oxides as discrete particles and coatings. J. Colloid Interface Sci. 2005, 281, 39–48. [Google Scholar] [CrossRef]

- Mahdavian, A.R.; Mirrahimi, M.A.-S. Efficient separation of heavy metal cations by anchoring polyacrylic acid on superparamagnetic magnetite nanoparticles through surface modification. Chem. Eng. J. 2010, 159, 264–271. [Google Scholar] [CrossRef]

- Wang, X.; Cai, W.; Lin, Y.; Wang, G.; Liang, C. Mass production of micro/nanostructured porous ZnO plates and their strong structurally enhanced and selective adsorption performance for environmental remediation. J. Mater. Chem. 2010, 20, 8582–8590. [Google Scholar] [CrossRef]

- Recillas, S.; Colón, J.; Casals, E.; González, E.; Puntes, V.; Sánchez, A.; Font Segura, X. Chromium VI adsorption on cerium oxide nanoparticles and morphology changes during the process. J. Hazard. Mater. 2010, 184, 425–431. [Google Scholar] [CrossRef] [PubMed]

- Mahdavi, S.; Jalali, M.; Afkhami, A. Heavy metals removal from aqueous solutions using TiO2, MgO, and Al2O3 nanoparticles. Chem. Eng. Commun. 2013, 200, 448–470. [Google Scholar] [CrossRef]

- Wang, H.-Q.; Yang, G.; Li, Q.Y.; Zhong, X.X.; Wang, F.P.; Li, Z.-S.; Li, Y. Porous nano-MnO2: Large scale synthesis via a facile quick-redox procedure and application in a supercapacitor. New J. Chem. 2011, 35, 469–475. [Google Scholar] [CrossRef]

- Pakarinen, J.; Koivula, R.; Laatikainen, M.; Laatikainen, K.; Paatero, E.; Harjula, R. Nanoporous manganese oxides as environmental protective materials—Effect of Ca and Mg on metals sorption. J. Hazard. Mater. 2010, 180, 234–240. [Google Scholar] [CrossRef]

- Shao, L.; Liu, L.; Cheng, S.X.; Huang, Y.D.; Ma, J. Comparison of diamino cross-linking in different polyimide solutions and membranes by precipitation observation and gas transport. J. Membr. Sci. 2008, 312, 174–185. [Google Scholar] [CrossRef]

- Xiao, Z.; Zhang, H.; Xu, Y.; Yuan, M.; Jing, X.; Huang, J.; Li, Q.; Sun, D. Ultra-efficient removal of chromium from aqueous medium by biogenic iron based nanoparticles. Sep. Purif. Technol. 2017, 174, 466–473. [Google Scholar] [CrossRef]

- Sikder, M.T.; Yoshihiro, M.; Islam, M.; Saito, T.; Tanaka, S.; Kurasaki, M. Preparation and characterization of chitosan–caboxymethyl-β-cyclodextrin entrapped nanozero-valent iron composite for Cu (II) and Cr (IV) removal from wastewater. Chem. Eng. J. 2014, 236, 378–387. [Google Scholar] [CrossRef] [Green Version]

- Cai, X.; Gao, Y.; Sun, Q.; Chen, Z.; Mallavarapu, M.; Naidu, R. Removal of co-contaminants Cu (II) and nitrate from aqueous solution using kaolin-Fe/Ni nanoparticles. Chem. Eng. J. 2014, 244, 19–26. [Google Scholar] [CrossRef]

- Sounthararajah, D.; Loganathan, P.; Kandasamy, J.; Vigneswaran, S. Adsorptive removal of heavy metals from water using sodium titanate nanofibres loaded onto GAC in fixed-bed columns. J. Hazard. Mater. 2015, 287, 306–316. [Google Scholar] [CrossRef]

- Gupta, V.K.; Chandra, R.; Tyagi, I.; Verma, M. Removal of hexavalent chromium ions using CuO nanoparticles for water purification applications. J. Colloid Interface Sci. 2016, 478, 54–62. [Google Scholar] [CrossRef]

- Verma, M.; Tyagi, I.; Chandra, R.; Gupta, V. Adsorptive removal of Pb (II) ions from aqueous solution using CuO nanoparticles synthesized by sputtering method. J. Mol. Liq. 2017, 225, 936–944. [Google Scholar] [CrossRef]

- Zhu, X.; Song, T.; Lv, Z.; Ji, G. High-efficiency and low-cost α-Fe2O3 nanoparticles-coated volcanic rock for Cd (II) removal from wastewater. Process Saf. Environ. Prot. 2016, 104, 373–381. [Google Scholar] [CrossRef]

- Yari, S.; Abbasizadeh, S.; Mousavi, S.E.; Saei Moghaddam, M.; Moghaddam, A. Adsorption of Pb (II) and Cu (II) ions from aqueous solution by an electrospun CeO2 nanofiber adsorbent functionalized with mercapto groups. Process Saf. Environ. Prot. 2015, 94, 159–171. [Google Scholar] [CrossRef]

- Hallaji, H.; Keshtkar, A.R.; Moosavian, M.A. A novel electrospun PVA/ZnO nanofiber adsorbent for U (VI), Cu (II) and Ni (II) removal from aqueous solution. J. Taiwan Inst. Chem. Eng. 2015, 46, 109–118. [Google Scholar] [CrossRef]

- Ren, T.; He, P.; Niu, W.; Wu, Y.; Ai, L.; Gou, X. Synthesis of α-Fe2O3 nanofibers for applications in removal and recovery of Cr (VI) from wastewater. Environ. Sci. Pollut. Res. 2013, 20, 155–162. [Google Scholar] [CrossRef] [PubMed]

- Chu, T.P.M.; Nguyen, N.; Vu, T.; Dao, H.; Dinh, L.; Nguyen, H.; Hoang, T.; Thanh Son, L.; Duc, P. Synthesis, characterization, and modification of alumina nanoparticles for cationic dye removal. Materials 2019, 12, 450. [Google Scholar] [CrossRef]

- Hojamberdiev, M.; Daminova, S.; Kadirova, Z.; Sharipov, K.; Mtalo, F.; Hasegawa, M. Ligand-immobilized spent alumina catalyst for effective removal of heavy metal ions from model contaminated water. J. Environ. Chem. Eng. 2018, 6, 4623–4633. [Google Scholar] [CrossRef]

- Ghaemi, N. A new approach to copper ion removal from water by polymeric nanocomposite membrane embedded with γ-alumina nanoparticles. Appl. Surf. Sci. 2016, 364, 221–228. [Google Scholar] [CrossRef]

- Dehghani, M.H.; Salari, M.; Heidarinejad, Z.; Sillanpää, M. Adsorptive removal of cobalt (II) from aqueous solutions using multi-walled carbon nanotubes and γ-alumina as novel adsorbents: Modelling and optimization based on response surface methodology and artificial neural network. J. Mol. Liq. 2020, 299, 112154. [Google Scholar] [CrossRef]

- Kumari, V.; Tripathi, A. Remediation of heavy metals in pharmaceutical effluent with the help of Bacillus cereus-based green-synthesized silver nanoparticles supported on alumina. Appl. Nanosci. 2020, 10, 1709–1719. [Google Scholar] [CrossRef]

- Nguyen, T.M.T.; Do, T.; Hoang, T.; Nguyen, N.; Pham, H.; Nguyen, T.; Pham, M.; Thanh Son, L.; Duc, P. Adsorption of anionic surfactants onto alumina: Characteristics, mechanisms, and application for heavy metal removal. Int. J. Polym. Sci. 2018, 2018, 2830286. [Google Scholar] [CrossRef]

- Khobragade, M.; Pal, A. Adsorptive removal of Mn (II) from water and wastewater by surfactant-modified alumina. Desalination Water Treat. 2016, 57, 2775–2786. [Google Scholar] [CrossRef]

- Li, Y.; He, J.; Zhang, K.; Liu, T.; Hu, Y.; Chen, X.; Huang, X.; Kong, L.; Liu, J. Super rapid removal of copper, cadmium and lead ions from water by NTA-silica gel. RSC Adv. 2019, 9, 397–407. [Google Scholar] [CrossRef] [PubMed]

- Kotsyuda, S.S.; Tomina, V.; Zub, Y.; Furtat, I.; Lebed-Phothisane, A.; Vaclavikova, M.; Melnyk, I. Bifunctional silica nanospheres with 3-aminopropyl and phenyl groups. Synthesis approach and prospects of their applications. Appl. Surf. Sci. 2017, 420, 782–791. [Google Scholar] [CrossRef]

- Najafi, M.; Yousefi, Y.; Rafati, A. Synthesis, characterization and adsorption studies of several heavy metal ions on amino-functionalized silica nano hollow sphere and silica gel. Sep. Purif. Technol. 2012, 85, 193–205. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, X.; Li, S.; Ma, W.; Li, Y.; He, Z.; Hu, H. Effective removal of Cr (VI) from aqueous solution based on APTES modified nanoporous silicon prepared from kerf loss silicon waste. Environ. Sci. Pollut. Res. 2020, 27, 10899–10909. [Google Scholar] [CrossRef]

- Yen, C.-H.; Lien, H.-L.; Chung, J.-S.; Yeh, H.-D. Adsorption of precious metals in water by dendrimer modified magnetic nanoparticles. J. Hazard. Mater. 2017, 322, 215–222. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, T.; Chen, C.; Wang, L.; Deng, Q.; Chen, G.; Ye, C. Synthesis of a novel magnetic nano-zeolite and its application as an efficient heavy metal adsorbent. Mater. Res. Express 2020, 7, 085007. [Google Scholar] [CrossRef]

- Ghorai, S.; Sarkar, A.; Raoufi, M.; Panda, A.; Schönherr, H.; Pal, S. Enhanced removal of methylene blue and methyl violet dyes from aqueous solution using a nanocomposite of hydrolyzed polyacrylamide grafted xanthan gum and incorporated nanosilica. ACS Appl. Mater. Interfaces 2014, 6, 4766–4777. [Google Scholar] [CrossRef]

- Aravindhan, R.; Rao, J.R.; Nair, B.U. Removal of basic yellow dye from aqueous solution by sorption on green alga Caulerpa scalpelliformis. J. Hazard. Mater. 2007, 142, 68–76. [Google Scholar] [CrossRef]

- Sarı, A.; Tuzen, M.; Soylak, M. Adsorption of Pb (II) and Cr (III) from aqueous solution on Celtek clay. J. Hazard. Mater. 2007, 144, 41–46. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.Y.; Muralidhara, H.B.; Nayaka, Y.A.; Balasubramanyam, J.; Hanumanthappa, H.H. Low-cost synthesis of metal oxide nanoparticles and their application in adsorption of commercial dye and heavy metal ion in aqueous solution. Powder Technol. 2013, 246, 125–136. [Google Scholar] [CrossRef]

- Giraldo, L.; Erto, A.; Moreno-Piraján, J.C. Magnetite nanoparticles for removal of heavy metals from aqueous solutions: Synthesis and characterization. Adsorption 2013, 19, 465–474. [Google Scholar] [CrossRef]

- Nithya, K.; Sathish, A.; Ponnusamy, S.K.; Ramachandran, T. Fast kinetics and high adsorption capacity of green extract capped superparamagnetic iron oxide nanoparticles for the adsorption of Ni (II) ions. J. Ind. Eng. Chem. 2018, 59, 230–241. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, Z. Hydrogel-supported nanosized hydrous manganese dioxide: Synthesis, characterization, and adsorption behavior study for Pb2+, Cu2+, Cd2+ and Ni2+ removal from water. Chem. Eng. J. 2015, 281, 69–80. [Google Scholar] [CrossRef]

- Pourjavadi, A.; Abedin-Moghanaki, A.; Hosseini, S. Synthesis of poly (amidoamine)-graft-poly (methyl acrylate) magnetic nanocomposite for removal of lead contaminant from aqueous media. Int. J. Environ. Sci. Technol. 2016, 13, 2437–2448. [Google Scholar] [CrossRef]

- Hayati, B.; Maleki, A.; Najafi, F.; Gharibi, F.; Mckay, G.; Gupta, V.; Shivaraju, H.P.; Marzban, N. Heavy metal adsorption using PAMAM/CNT nanocomposite from aqueous solution in batch and continuous fixed bed systems. Chem. Eng. J. 2018, 346, 258–270. [Google Scholar] [CrossRef]

- Padmavathy, K.; Madhu, G.; Haseena, P. A study on effects of pH, adsorbent dosage, time, initial concentration and adsorption isotherm study for the removal of hexavalent chromium (Cr (VI)) from wastewater by magnetite nanoparticles. Procedia Technol. 2016, 24, 585–594. [Google Scholar] [CrossRef]

- Solomon, T. The definition and unit of ionic strength. J. Chem. Educ. 2001, 78, 1691. [Google Scholar] [CrossRef]

- Musso, T.B.; Parolo, M.E.; Pettinari, G.R. pH, ionic strength, and ion competition effect on Cu (II) and Ni (II) sorption by a Na-bentonite used as liner material. Pol. J. Environ. Stud. 2019, 28, 2299–2309. [Google Scholar] [CrossRef]

| Zeolite Type | Heavy Metal | Capacity Removal (mg/g) and /or Percentage Removal | Reference |

|---|---|---|---|

| Magnetic nano-zeolite | Cu2+ | 59.9 mg/g, | [78] |

| Cd+ | 188.6 mg/g | ||

| Pb2+ | 909.1 mg/g | ||

| Synthetic zeolite-based modified bio-slag | Cs2+ | 51.02 mg/g (97%) | [79] |

| 4A zeolite 4A zeolite/Almond shells carbon 4A zeolite/Walnut shells carbon | Co2+ | 99.525 mg/g | [77] |

| Co2+ | 235.175 mg/g | ||

| Co2+ | 202.887 mg/g | ||

| Hydroxysodalite zeolite nanoparticles | Zn2+ | 8.53 mg/g, 66% | [76] |

| Clinoptilolite modified by HCl | Cd2+ | 85.9% | [66] |

| Pb2+ | 98.9% | ||

| Synthesized 3A Zeolite | Pb2+ | 14.56 mg/g (98%.) | [80] |

| Copper doped zeolite | Cr3+ | 100% | [81] |

| Pb2+ | 100% | ||

| Cd2+ | 99.37% | ||

| Synthesized zeolite A | Mg2+ | 8.4 mg/g (62.6%), | [82] |

| K+ | 11.4 mg/g (50.6%) | ||

| Ca2+ | 27.0 mg/g (100%) | ||

| Cr3+ | 27.0 mg/g (100%) | ||

| Mn2+ | 34.7 mg/g (100%) | ||

| Fe3+ | 34.5 mg/g (98.4%) | ||

| Ni2+ | 38.9 mg/g (100%) | ||

| Cu2+ | 44.2 mg/g (100%) | ||

| Zn2+ | 43.6 mg/g (100%) | ||

| Ag+ | 66.3 mg/g (100%) | ||

| Pb2+ | 115.9 mg/g (100%) | ||

| Zeolitic imidazolate framework (ZIF-90) | Hg2+ | 900 mg/g (99%) | [83] |

| Zeolite Nanoparticles Impregnated Polysulfone Membranes | Cu2+ | 682 mg/g (91%) | [74] |

| Ni2+ | 122 mg/g (42%) | ||

| Synthesis of needle-like nanocrystalline zeolites from metakaolin | Cu2+ | 431.0 ± 27.5 mg/g | [84] |

| Pb2+ | 37.8 ± 19.7 mg/g |

| Adsorbent Nanomaterial | Target Ions | Temperature (K) | pH | Contact Time (min) | Ion Concentration (mg/L) | The Capacity of Adsorption and (Removal) | Reference |

|---|---|---|---|---|---|---|---|

| Magnetic-ZIF-90-Cysteine (M-ZIF-90-C) | Hg2+ | 298 | 4 | 1080 | 500 | 900 mg/g (99%) | [80] |

| Chitosan–alginate nanoparticles (CANPs) | Hg2+ | 303 | 5 | 90 | 4 | 217.39 mg/g (89%) | [98] |

| 8-hydroxyquinoline MWCNTs (8-HQ-MWCNTs) | Pb2+ | 298 | 6 | 120 | 0.05 | 0.064 mg/g (95.1%) | [40] |

| Third-generation dendrimers (MNP-G3) | Pb2+ | 298 | 6.5 | 30 | 20 | 2.71 mg/g (63%) | [178] |

| Fe3O4@APS@AA-co-CA MNPs | Pb2+ | 298 | 5.5 | 45 | 20–450 | 166.1 (98%) | [131] |

| GO/Fe3O4/LA/EDTA | Pb2+ | 293 | 5 | 105 | 280 | 120.18 mg/L (57%) | [128] |

| Magnetic nano-zeolite (MNZ@MS) | Pb2+ | 298 | 9 | 60 | 500 | 476.1 mg/g (19%) | [179] |

| Magnetic nanocomposite particles (MNCPs) | Pb2+ | 298 | 5 | 29 | 10 | 53.33 mg/g 100% | [114] |

| 1,2,3-triazole functionalized magnetic nanoparticles (MNP-Trz) | Pb2+ | 298 | 5.5 | 240 | 400 | 167.78 mg/g (66%) | [123] |

| 1,2,3-triazole functionalized magnetic nanoparticles and silica coated MNP homologous (MNPS-Trz) | Pb2+ | 298 | 5.5 | 240 | 400 | 145.1 mg/g (64%) | [123] |

| Carboxymethyl cellulose-immobilized Fe3O4 nanoparticles (CMC-Fe3O4) | Pb2+ | 298 | 6 | 720 | 200 | 152.0 mg/g (68.4%), | [141] |

| MWCNTs–IDA | Cd2+ | 298 | 8 | 60 min | 1–6 | 32 mg/g (34%) | [41] |

| 8-HQ-MWCNTs | Cd2+ | 298 | 6 | 120 | 0.05 | 0.011 mg/g (40%) | [40] |

| Fe3O4/MnO2 | Cd2+ | 298 | 6.3 | 30 | 10 | 53.2 mg/g (95%) | [115] |

| MNZ@MS | Cd2+ | 298 | 9 | 60 | 180 | 188.9 mg/g (70%) | [179] |

| MNCPs | Cd2+ | 298 | 5 | 20 | 10 | 48.53 mg/g (91%) | [114] |

| Fe3O4@APS@AA-co-CA MNPs | Cd2+ | 298 | 5.5 | 45 | 20–450 | 29.6 mg/g (78%) | [131] |

| 8-HQ-MWCNTs) | Cu2+ | 298 | 6 | 120 | 0.05 | 0.080 mg/g (99.53%) | [40] |

| (MNZ@MS) | Cu2+ | 298 | 9 | 60 | 500 | 59.9 mg/g (44%) | [179] |

| Fe3O4@APS@AA-co-CA MNPs | Cu2+ | 298 | 5.5 | 45 | 20–450 | 126.6 mg/g (83%) | [131] |

| MNP-Trz | Cu2+ | 298 | 5.5 | 240 | 400 | 87.87 mg/g (78%) | [123] |

| CS–NZVI–CMβ-CD | Cu2+ | 298 | 6 | 360 | 100 | 250 mg/g (95.8%) | [155] |

| 8-HQ-MWCNTs | Zn2+ | 298 | 6 | 120 | 0.05 | 0.063 mg/g (94%) | [40] |

| MnFe2O4 MNPs | Zn2+ | 298 | 6 | 120 | 100 | 454.5 mg/g (63%) | [119] |

| CoFe2O4 MNPs | Zn2+ | 298 | 6 | 120 | 100 | 384.6 mg/g (58%) | [119] |

| MNP-Trz | Zn2+ | 298 | 5.5 | 240 | 400 | 51.20 mg/g (87%) | [123] |

| Fe3O4@APS@AA-co-CA MNPs | Zn2+ | 298 | 5.5 | 45 | 20–450 | 43.3 (83%) | [131] |

| Chitosan-based magnetic adsorbent CMC@Fe3O4 | As+3 | 303 | 3 | 20 | 30 | 20.1 mg/g (33%) | [142] |

| Fe3O4/SiO2/CS-TETA | Cr6+ | 298 | 2.5 | 240 | 150 | 254.6 mg/g (96.4%) | [136] |

| CeO2 nanoparticles | Cr6+ | 298 | 7 | 180 | 80 | 1.88 mg/g (75%) | [149] |

| Biogenic SJA-Fe nanoparticles | Cr6+ | 333 | 5.5 | 120 | 50 | 983.2 mg/g (99.45%) | [154] |

| CS–NZVI–CMβ-CD | Cr6+ | 298 | 6 | 360 | 100 | 200 mg/g (79.7%) | [155] |

| CuO nanoparticles | Cr6+ | 298 | 3 | 180 | 20 | 13.1 mg/g (65.6%) | [158] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ethaib, S.; Al-Qutaifia, S.; Al-Ansari, N.; Zubaidi, S.L. Function of Nanomaterials in Removing Heavy Metals for Water and Wastewater Remediation: A Review. Environments 2022, 9, 123. https://doi.org/10.3390/environments9100123

Ethaib S, Al-Qutaifia S, Al-Ansari N, Zubaidi SL. Function of Nanomaterials in Removing Heavy Metals for Water and Wastewater Remediation: A Review. Environments. 2022; 9(10):123. https://doi.org/10.3390/environments9100123

Chicago/Turabian StyleEthaib, Saleem, Sarah Al-Qutaifia, Nadhir Al-Ansari, and Salah L. Zubaidi. 2022. "Function of Nanomaterials in Removing Heavy Metals for Water and Wastewater Remediation: A Review" Environments 9, no. 10: 123. https://doi.org/10.3390/environments9100123

APA StyleEthaib, S., Al-Qutaifia, S., Al-Ansari, N., & Zubaidi, S. L. (2022). Function of Nanomaterials in Removing Heavy Metals for Water and Wastewater Remediation: A Review. Environments, 9(10), 123. https://doi.org/10.3390/environments9100123