Finding Minimal Optimal Indent Separation for Polystyrene via Instrumental Nanoindentation and FEA Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Nanoindentation Experiment

2.2. Modeling Plastic Behavior/Region During Indentation

2.2.1. Determination of Plastic Properties for FEA

2.2.2. Finite Element Modeling

3. Results and Discussion

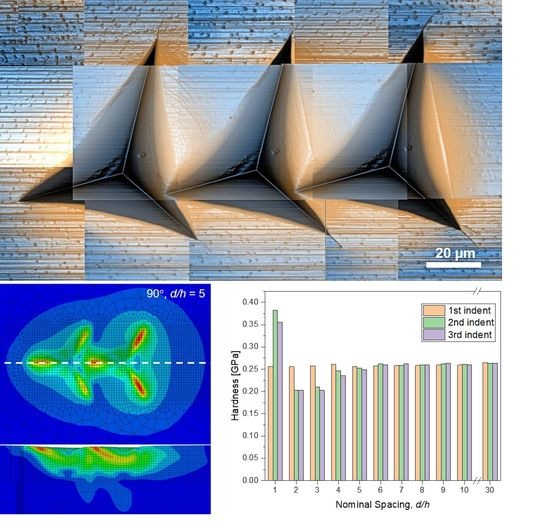

3.1. Experimental Analysis for Indents in a Row with Orientations 0° and 90°

3.2. Experimental Analysis of Indents in a Matrix

3.3. Finite Element Analysis for h = 1 µm with Three Different Orientations

4. Conclusions

- The Tabor’s method allows to obtain the stress–strain through the loading–unloading curve from the nanoindentation experiment directly using the finite element method. The material properties will change according to the maximum indentation depth.

- Berkovich tip orientation does not influence modulus or hardness values at separation above 5, thus removing the importance of the alignment.

- Experimentally and through FEA, it was shown that for PS, the minimum required spacing to measure properties accurately is d/h ~ 10–15, depending if indents are performed in a single line or matrix. When indents are executed in a single line or column, the nominal spacing of 10 is sufficient for separate indents to have similar hardness and modulus values and is independent on indentation depth. When a matrix set-up is used, d/h > 15 is required for a depth of 1 µm, and at least 10 for deeper indents.

- At separations below 10–15, hardness and modulus values were lower when compared to those obtained at larger separations or with the first indent. PS tends to form pile-up and crazes when it is plastically deformed, as well as strain harden. The properties will depend on the location of the next indent: the areas having “softer” regions are those close to the pile-up, the “hardest” areas are close to the apex of the first indent. No or little difference in properties is observed when the indent takes place on optically undamaged surface, even though indents edges and plastic zones overlap.

- Taking into account the viscoelastic nature of polymer materials and their time-dependent behavior that may increase the indent area for up to 40%, separation of at least 15 is recommended for polymers at all indentation depths for single line or column, or matrix arrangement. Overall, the required minimum spacing is lower than the original 30 times maximum depth rule.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Fischer-Cripps, A.C. Nanoindentation. In Mechanical Engineering Series, 3rd ed.; Springer: New York, NY, USA, 2011; Volume 2. [Google Scholar]

- Bull, S.J. Nanoindentation of coatings. J. Phys. D. Appl. Phys. 2005, 38, R393–R413. [Google Scholar] [CrossRef]

- Tiwari, A.; Natarajan, S. (Eds.) Applied Nanoindentation in Advanced Materials; John Wiley & Sons, Ltd.: Chichester, UK, 2017. [Google Scholar]

- Ebenstein, D.M.; Pruitt, L.A. Nanoindentation of biological materials. Nano Today 2006, 1, 26–33. [Google Scholar] [CrossRef]

- Beake, B.D.; Chen, S.; Hull, J.B.; Gao, F. Nanoindentation Behavior of Clay/Poly (Ethylene Oxide) Nanocomposites. J. Nanosci. Nanotechnol. 2002, 2, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Beake, B.D.; Goodes, S.R.; Smith, J.F.; Gao, F. Nanoscale repetitive impact testing of polymer films. J. Mater. Res. 2004, 19, 237–247. [Google Scholar] [CrossRef]

- Indentation Rules of Thumb—Applications and Limits; Application Note 5990-5700EN; Agilent Technologies Inc.: Santa Clara, CA, USA, 2010.

- Hay, J. Introduction to instrumented indentation testing. Exp. Tech. 2009, 33, 66–72. [Google Scholar] [CrossRef]

- Zhang, W.; Chou, X.; Shi, T.; Ma, Z.; Bao, H.; Chen, J.; Chen, L.; Li, D.; Xue, C. Mechanical Characteristics Measurements. In Measurement Technology for Micro-Nanometer Devices; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; pp. 121–190. [Google Scholar]

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Kietzke, T.; Neher, D.; Landfester, K.; Montenegro, R.; Güntner, R.; Scherf, U. Novel approaches to polymer blends based on polymer nanoparticles. Nat. Mater. 2003, 2, 408–412. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. On the relationship between plastic zone radius and maximum depth during nanoindentation. Surf. Coatings Technol. 2006, 201, 4289–4293. [Google Scholar] [CrossRef]

- Xiao, Y.; Shi, W.; Wan, Q.; Luo, J. Evaluation of failure properties of a DLC/steel system using combined nanoindentation and finite element approach. Diam. Relat. Mater. 2019, 93, 159–167. [Google Scholar] [CrossRef]

- Liu, S.; Huang, H.; Gu, Y. Deconvolution of mechanical properties of thin films from nanoindentation measurement via finite element optimization. Thin Solid Film. 2012, 526, 183–190. [Google Scholar] [CrossRef]

- Li, Y.G.; Kanouté, P.; François, M.; Chen, D.; Wang, H.W. Inverse identification of constitutive parameters with instrumented indentation test considering the normalized loading and unloading P-h curves. Int. J. Solids Struct. 2019, 156–157, 163–178. [Google Scholar] [CrossRef]

- Mojumder, S.; Mahboob, M.; Motalab, M. Atomistic and finite element study of nanoindentation in pure aluminum. Mater. Today Commun. 2020, 23, 100798. [Google Scholar] [CrossRef]

- Tao, P.; Gong, J.M.; Wang, Y.F.; Jiang, Y.; Li, Y.; Cen, W.W. Characterization on stress-strain behavior of ferrite and austenite in a 2205 duplex stainless steel based on nanoindentation and finite element method. Results Phys. 2018, 11, 377–384. [Google Scholar] [CrossRef]

- Long, X.; Jia, Q.P.; Li, Z.; Wen, S.X. Reverse analysis of constitutive properties of sintered silver particles from nanoindentations. Int. J. Solids Struct. 2020, 191–192, 351–362. [Google Scholar] [CrossRef]

- Basu, S.; Moseson, A.; Barsoum, M.W. On the determination of spherical nanoindentation stress-strain curves. J. Mater. Res. 2006, 21, 2628–2637. [Google Scholar] [CrossRef] [Green Version]

- Charvátová Campbell, A.; Buršíková, V.; Martinek, J.; Klapetek, P. Modeling the influence of roughness on nanoindentation data using finite element analysis. Int. J. Mech. Sci. 2019, 161–162. [Google Scholar] [CrossRef]

- Zhao, Y.; Ovaert, T.C. Error estimation of nanoindentation mechanical properties near a dissimilar interface via finite element analysis and analytical solution methods. J. Mater. Res. 2010, 25, 2308–2316. [Google Scholar] [CrossRef] [Green Version]

- Sudharshan Phani, P.; Oliver, W.C. A critical assessment of the effect of indentation spacing on the measurement of hardness and modulus using instrumented indentation testing. Mater. Des. 2019, 164, 107563. [Google Scholar] [CrossRef]

- Xu, B.; Chen, X. Determining engineering stress-strain curve directly from the load-depth curve of spherical indentation test. J. Mater. Res. 2010, 25, 2297–2307. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Tabor, D. The hardness of solids. Rev. Phys. Technol. 1970, 1, 145–179. [Google Scholar] [CrossRef]

- Van Melick, H.G.H.; Govaert, L.E.; Meijer, H.E.H. On the origin of strain hardening in glassy polymers. Polymer 2003, 44, 2493–2502. [Google Scholar] [CrossRef] [Green Version]

- Peng, C.; Zeng, F. A molecular simulation study to the deformation Behaviors and the size effect of polyethylene during nanoindentation. Comput. Mater. Sci. 2017, 137, 225–232. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Bull, S.J. Mechanical response of atomic layer deposition alumina coatings on stiff and compliant substrates. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 01A160. [Google Scholar] [CrossRef]

- Bolshakov, A.; Pharr, G.M. Influences of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. J. Mater. Res. 1998, 13, 1049–1058. [Google Scholar] [CrossRef]

- Tranchida, D.; Piccarolo, S.; Loos, J.; Alexeev, A. Mechanical characterization of polymers on a nanometer scale through nanoindentationn. A study on pile-up and viscoelasticity. Macromolecules 2007, 40, 1259–1267. [Google Scholar] [CrossRef]

- Iqbal, T.; Yasin, S.; Zafar, M.; Zahid, S.; Ishteyaque, S.; Briscoe, B.J. Nanoindentation Response of Scratched Polymeric Surfaces. Tribol. Trans. 2015, 58, 801–806. [Google Scholar] [CrossRef]

- Bonne, M.; Briscoe, B.J.; Lawrence, C.J.; Manimaaran, S.; Parsonage, D.; Allan, A. Nano-indentation of scratched poly(methyl methacrylate) surfaces. Tribol. Lett. 2005, 18, 125–133. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Fiori, L.; Pelillo, E. Nano-indentation of polymeric surfaces. J. Phys. D Appl. Phys. 1998, 31, 2395–2405. [Google Scholar] [CrossRef]

- Bucsek, A.N.; Alisafaei, F.; Han, C.S.; Lakhera, N. On thresholds in the indentation size effect of polymers. Polym. Bull. 2016, 73, 763–772. [Google Scholar] [CrossRef]

- Oyen, M.L. Analytical techniques for indentation of viscoelastic materials. Philos. Mag. 2006, 86, 5625–5641. [Google Scholar] [CrossRef]

- Flores, A. Mechanical properties of poly (ethylene terephthalate) at the near surface from depth-sensing experiments. Philos. Mag. A 1998, 78, 1283–1297. [Google Scholar] [CrossRef]

| 0 | 1 | 1 | 1 |

| 0.004 | 15 | 16 | 17 |

| 0.011 | 43 | 44 | 46 |

| 0.017 | 66 | 69 | 72 |

| 0.023 | 92 | 95 | 99 |

| 0.028 | 109 | 114 | 118 |

| 0.034 | 134 | 139 | 145 |

| 0.040 | 157 | 163 | 170 |

| 0.046 | 181 | 188 | 196 |

| 0.051 | 201 | 209 | 217 |

| 0.057 | 224 | 233 | 243 |

| 0.060 | 236 | 246 | 256 |

| Depth, h [µm] | Hardness, H, [GPa] | Reduced Modulus, Er [GPa] | Young’ s Modulus, [GPa] | Constraint Factor, α |

|---|---|---|---|---|

| 1 | 0.255 ± 0.043 | 4.924 ± 0.045 | 4.354 | 1.87 |

| 5 | 0.260 ± 0.035 | 4.886 ± 0.031 | 4.322 | 2.50 |

| 10 | 0.246 ± 0.027 | 4.342 ± 0.035 | 3.840 | 3.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Davis, M.; Zekonyte, J. Finding Minimal Optimal Indent Separation for Polystyrene via Instrumental Nanoindentation and FEA Method. Appl. Sci. 2020, 10, 4262. https://doi.org/10.3390/app10124262

Jiang C, Davis M, Zekonyte J. Finding Minimal Optimal Indent Separation for Polystyrene via Instrumental Nanoindentation and FEA Method. Applied Sciences. 2020; 10(12):4262. https://doi.org/10.3390/app10124262

Chicago/Turabian StyleJiang, Chulin, Michael Davis, and Jurgita Zekonyte. 2020. "Finding Minimal Optimal Indent Separation for Polystyrene via Instrumental Nanoindentation and FEA Method" Applied Sciences 10, no. 12: 4262. https://doi.org/10.3390/app10124262

APA StyleJiang, C., Davis, M., & Zekonyte, J. (2020). Finding Minimal Optimal Indent Separation for Polystyrene via Instrumental Nanoindentation and FEA Method. Applied Sciences, 10(12), 4262. https://doi.org/10.3390/app10124262