Ignition of Deposited Wood Dust Layer by Selected Sources

Abstract

:1. Introduction

- Spontaneous ignition due to an external source of radiant heat;

- Initiation by external source of ignition (open flame, spark);

- Spontaneous ignition without an effect of an external heat source (autoignition, chemical reaction).

2. Materials and Methods

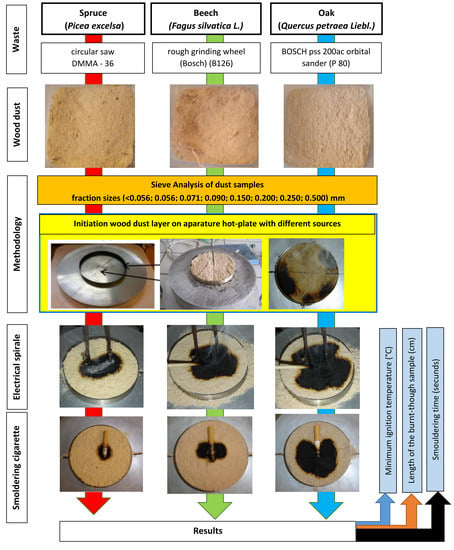

2.1. Wood Dust Samples—Preparation Process

2.2. Physical Properties of Wood Dusts and Sieve Analysis

2.3. Determining the Minimum Ignition Temperature According to EN 50281 of Waste Wood Dust Layer Samples from Hot Surfaces

- (a)

- Glowing or flame combustion was observed;

- (b)

- Measured temperature of dust have reached 450 °C;

- (c)

- Measured temperature of dust exceeded 250 K (the temperature of the furnace plate).

- Glowing, smouldering or flaming combustion;

- The temperature–time curve obtained by the thermocouple placed in the centre of the dust layer increases steadily along with the temperature of the isothermal hot plate.

- There is visible evidence of combustion such as a red glow or a flame;

- The temperature in the dust layer at the position of the thermocouple rises at least 50 °C above the hot plate temperature.

2.4. Ignition of Waste Wood Dust Samples by an Electric Coil

3. Results and Discussion

3.1. Determination of Moisture Content of Waste Wood Dust

3.2. Sieve Analysis

3.3. Ignition of Waste Wood Dust

3.3.1. Monitoring of Hot Surface Ignition

3.3.2. Monitoring of Waste Wood Dust Ignition by Electric Coil

3.3.3. Monitoring of Waste Wood Dust Ignition by a Smouldering Cigarette

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Marková, I.; Hroncová, E.; Tomaskin, J.; Turekova, I. Thermal analysis of granulometry selected wood dust particles. Bioresources 2018, 13, 8041–8060. [Google Scholar] [CrossRef]

- Holla, K.; Ristvej, J.; Moricova, V.; Novak, L. Results of survey among SEVESO establishments in the Slovak Republic. J. Chem. Health Saf. 2016, 23, 9–17. [Google Scholar] [CrossRef]

- Tureková, I.; Balog, K.; Slabá, I. Determination of ignition temperatures of wood dust. In Fire Protection, Ostrava, Czech Republic; SPBI: Ostrava, Czech Republic, 2005; CD rom. (In Slovak) [Google Scholar]

- Tureková, I.; Kuracina, R. Dust and Dust Mixtures, 1st ed.; AlumniPress: Trnava, Slovakia, 2011; p. 112. (In Slovak) [Google Scholar]

- Vested, A.; Schlünssen, V.; Burdorf, A.; Andersen, J.H.; Christoffersen, J.; Daugaard, S.; Flachs, E.M.; Garde, A.H.; Hansen, Å.M.; Markvart, J.; et al. A quantitative general population job exposure matrix for occupational daytime light exposure. Ann. Work. Expo. Health 2019, 63, 666–678. [Google Scholar] [CrossRef] [PubMed]

- Rohr, A.C.; Campleman, S.L.; Long, C.M.; Peterson, M.K.; Weatherstone, S.; Quick, W.; Lewis, A.S. Potential occupational exposures and health risks associated with biomass-based power generation. Int. J. Environ. Res. Public Health 2015, 12, 8542–8605. [Google Scholar] [CrossRef] [Green Version]

- Hatina, T.; Kordošová, M.; Matulová, S.; Perichtová, B.; Škvarková, V. Terminological Dictionary of Safety and Health Protection at Work; Institute for Research on Work and Family in Slovakia: Bratislava, Slovakia, 2006; (nonpublic). (In Slovak) [Google Scholar]

- Amyotte, P. An Introduction to Dust Explosions; Elsevier: Woburn, MA, USA, 2013. [Google Scholar]

- Amyotte, P.R.; Eckhoff, R.K. Dust explosion causation, prevention and mitigation: An overview. J. Chem. Health Saf. 2010, 17, 15–28. [Google Scholar] [CrossRef]

- Huang, C.; Chen, X.; Yuan, B.; Zhang, H.; Shang, S.; Zhao, Q.; Dai, H.; He, S.; Zhang, Y.; Niu, Y. Insight into suppression performance and mechanisms of ultrafine powders on wood dust deflagration under equivalent concentration. J. Hazard. Mater. 2020, 394, 122584. [Google Scholar] [CrossRef]

- Vaughn, S.F.; Winkler-Moser, J.K.; Berhow, M.A.; Byars, J.A.; Liu, S.X.; Jackson, M.A.; Peterson, S.C.; Eller, F.J. An odor-reducing, low dust-forming, clumping cat litter produced from Eastern red cedar (Juniperus virginiana L.) wood fibers and biochar1. Ind. Crop. Prod. 2020, 147, 112224. [Google Scholar] [CrossRef]

- Tureková, I. Industrial dust risk. In Proceedings of the 9th International Conference, Bratislava, Slovakia, 5–6 January 2008; Rusko, M., Ed.; Strix et VeV: Žilina, Slovakia, 2008; pp. 167–175. (In Slovak). [Google Scholar]

- Lidén, G. Dustiness testing of materials handled at workplaces. Ann. Occup. Hyg. 2006, 50, 437–439. [Google Scholar] [CrossRef]

- Tian, Z.F.; Inthavong, K.; Tu, J. Deposition of inhaled wood dust in the nasal cavity. Inhal. Toxicol. 2007, 19, 1155–1165. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Krišťák, Ľ.; Igaz, R.; Réh, R. Occupational exposure to dust produced when milling thermally modified wood. Int. J. Environ. Res. Public Health 2020, 17, 1478. [Google Scholar] [CrossRef] [Green Version]

- CEN Standard EN 481. Workplace Atmospheres. Size Fraction Definitions for Measurement of Airborne Particles; European Committe for Standartion: Brussels, Belgium, 1998. [Google Scholar]

- Top, Y. Relationship between employees’ perception of airborne wood dust and ventilation applications in micro-scale enterprises producing furniture. BioRes 2020, 15, 1252–1264. [Google Scholar]

- Vandličková, M.; Marková, I.; Osvaldová, L.M.; Gašpercová, S.; Svetlík, J. Evaluation of African padauk (Pterocarpus soyauxii) explosion dust. BioRes 2020, 15, 401–414. [Google Scholar]

- Mračková, E. Microscopic analysis of spruce and beech wood dust. Ochrana Przed Korozja 5s/A/; SIGMA-NOT Spolka Zoo: Opole, Poland, 2004. [Google Scholar]

- Marková, I.; Mračková, E.; Očkajová, A.; Ladomerský, J. Granulomerty of selectes wood dust species of dust from orbital sanders. Wood Res. 2016, 61, 983–992. [Google Scholar]

- Mračková, E.; Marková, I. Microscopic Analysis of Spruce Wood, Beech Wood and Pacticle Board—Wood Dust. WPP—Chemical Technology—Wood Pulp Paper (Natural—Renewable—Biocompatible); Slovak National Library: Bratislava, Slovakia, 2003; pp. 263–268. [Google Scholar]

- Orémusová, E. Comparison of flammability polymethylmethacrylate and polycarbonate. In Proceedings of the Advances in Fire and Safety Engineering, T Zvolen, Slovakia, 18–19 October 2018; pp. 223–234. [Google Scholar]

- Gašparík, M.; Makovická Osvaldová, L.; Čekovská, H.; Potůček, D. Flammability characteristics of thermally modified oak wood treated with a fire retardant. BioRes 2017, 12, 8451–8467. [Google Scholar]

- Čekovská, H.; Gaff, M.; Osvald, A.; Kačík, F.; Kubš, J.; Kaplan, L. Fire resistance of thermally modified spruce wood. Bioresources 2016, 12, 947–959. [Google Scholar] [CrossRef]

- Serafín, J. Stanovení Teplotních Mezí Výbušnosti. Fire Protecton—Scientific Processing; Technical University in Ostrava: Ostrava, Czech Republic, 2007; pp. 542–546. (In Czech) [Google Scholar]

- Cheng, Q.; Via, B.; Wang, J.; Zondlo, J. Primary study of woody biomass and coal for energy production investigated by TGA-FTIR analysis. Bioresources 2014, 9, 2899–2906. [Google Scholar] [CrossRef] [Green Version]

- Osvald, A.; Bučko, J. Degradation of wood by heat and fire. In Monography, 1st ed.; Technical University in Zvolen: Zvolen, Slovakia, 1998; p. 125. (In Slovak) [Google Scholar]

- Kačík, F.; Osvald, A.; Marková, I.; Giertlová, Z.; Čunderlík, I. Chemische und mikrostrukturelle Veränderungen des Holzes infolge Brandbelastung; Buchverlag Gräfelfing: München, Germany, 2001; p. 136. [Google Scholar]

- Troitzsch, J. International Plastics Flammability Handbook, 1st ed.; Hanser Publishers: Munich, Germany, 1990; p. 517. [Google Scholar]

- Šimandl, L. Electric spark initiation. ARPOS 2004, 14–15, 21–23. [Google Scholar]

- Bond, J. Sources of Ignition. Flammability Characteristics of Chemicals and Products, 1st ed.; Butterworth-Heinemann Ltd.: Oxford, UK, 2017. [Google Scholar]

- Balog, K.; Kvarčák, M. Dynamic Fire, 1st ed.; EDICE SPBI SPEKTRUM: Ostrava, Czech Republic, 1999; p. 118. (In Czech) [Google Scholar]

- Gann, R.G.; Babrauskas, V.; Peacock, R.D.; Hall, J.R. Fire conditions for smoke toxicity measurement. Fire Mater. 1994, 18, 193–199. [Google Scholar] [CrossRef]

- Young, S.A.; Clancy, P. Compression mechanical properties of wood at temperatures simulating fire conditions. Fire Mater. 2001, 25, 83–93. [Google Scholar] [CrossRef]

- Damec, J. Explosion Prevention in Food and Agriculture, 1st ed.; EDICE SPBI SPEKTRUM: Ostrava, Czech Republic, 1999; p. 252. (In Czech) [Google Scholar]

- Ševda, M. Efect of Firing Process on Properties of Brick Body with Organic Combustible Admixture, 1st ed.; Monography; Slovak Technical University in Bratislava: Bratislava, Slovakia, 2005; p. 64. [Google Scholar]

- Turns, S.R. An Introduction to Combustion; The Pensylvania State University: PA, USA, 1996; p. 555. [Google Scholar]

- Šimorová, T. The chosen methods of determination of ignition temperature of the wood dusts. In New Trends in Research of Energetic Materials; Slovak Technical University in Bratislava: Bratislava, Slovakia, 2007; pp. 985–994. [Google Scholar]

- Marková, I. Influence of Burning on Chemical and Microscopic Changes of Spruce Wood, 1st ed.; Monography 10/2000/ A; Technical Universita in Zvolen: Zvolen, Slovakia, 2001; p. 85. (In Slovak) [Google Scholar]

- Balog, K. Autoinitiation; EDICE SPBI SPEKTRUM: Ostrava, Czech Republic, 1999; p. 133. (In Slovak) [Google Scholar]

- Tureková, I. Study of initiating sources of wood dust. Sborník Vědeckých Prác; VŠB-TU: Ostrava, Czech Republic, 2009; Volume 4, pp. 105–116. (In Slovak) [Google Scholar]

- Damec, J. Anti-Explosion Prevention, 1st ed.; EDICE SPBI SPEKTRUM: Ostrava, Czech Republic, 1998; p. 188. (In Czech) [Google Scholar]

- Samák, M. Consideration of Initiating Sources for Inflammability of Dusts. Master’s Thesis, Slovak Technical University, Bratislava, Slovakia, 2009; p. 77. (In Slovak). [Google Scholar]

- Mračková, E.; Tureková, I. The dimensional characteristics of the particles of wood dust of selected deciduous trees considering to explosion. Key Eng. Mater. 2016, 688, 182–189. [Google Scholar] [CrossRef]

- Siklienka, M.; Mišura, Ľ. Influence of Selected Factors on Cutting Power When Cutting with a Circular Saw; Chip and Chipless Woodworking A: Zvolen, Slovakia, 2006; pp. 265–270. [Google Scholar]

- STN 49 0103. Wood. Determination of Moisture Content at Physical and Mechanical Testing; Slovak Technical Normalisation: Bratislava, Slovakia, 1979. (In Slovak) [Google Scholar]

- Dastidar, A.G. Chapter Four—Dust Explosions: Test Methods; Fauske and Associates LLC: Burr Ridge, IL, USA, 2019; Volume 3, pp. 71–122. [Google Scholar]

- Pastier, M.; Tureková, I.; Turňová, Z.; Harangozó, J. Minimum ignition tmperature of wood dust layer. Res. Pap. Mater. Sci. Technol. 2003, 21, 127–131. [Google Scholar]

- Slabá, I.; Tureková, I. Smouldering and Flaming Combustion of Dust Layer on Hot Surface, 1st ed.; Scientific Monographs: Dresden, Germany, 2012; p. 88. [Google Scholar]

- ISO 2591-1. Test Sieving—Part 1: Methods Using Test Sieves of Woven Wire cloth and Perforated Metal Plate; International Organization for Standardization: Geneva, Switzerland, 1988. [Google Scholar]

- EN 50281-2-1. Electrical Apparatus for Use in the Presence of Combustible Dust. Part 2–1: Test Methods. Methods for Determining the Minimum Ignition Temperatures of Dust; European Committe for Standartion: Brussels, Belgium, 2002. [Google Scholar]

- Bono, R.; Capacci, F.; Cellai, F.; Sgarrella, C.; Bellisario, V.; Trucco, G.; Tofani, L.; Peluso, A.; Poli, C.; Arena, L.; et al. Wood dust and urinary 15-F2t isoprostane in Italian industry workers. Environ. Res. 2019, 173, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Rostami, A.; Murthy, J.; Hajaligol, M.R. Modeling of a smoldering cigarette. J. Anal. Appl. Pyrolysis 2003, 66, 281–301. [Google Scholar] [CrossRef]

- Yi, S.C.; Song, E.S.; Oh, S.G.; Bae, S.Y.; Moon, S.K.; Hajaligol, M.R. Theoretical analysis of the effects of cigarette design parameters on the smoldering rates, heat flux, and total heat released during smoldering of a cigarette. J. Fire Sci. 2001, 19, 18–30. [Google Scholar] [CrossRef]

- Marková, I.; Očkajová, A. Assessing the Risk of Wood Dust in the Work and Environment, 1st ed.; Monography, Banská Bystrica: Belainum, Slovakia, 2018; p. 124. (In Slovak) [Google Scholar]

- Dado, M.; Mikusova, L.; Hnilica, R. Laboratory Investigations applied to wood dust emmited by electrical hand-held belt sander. Manag Syst. Prod. Eng. 2018, 26, 133–136. [Google Scholar] [CrossRef] [Green Version]

- Majka, J.; Rogoziński, T.; Olek, W. Water sorption and diffusion properties of beech wood dust. Powder Technol. 2019, 346, 109–115. [Google Scholar] [CrossRef]

- ISO 9276-1. Representation of Results of Particle Size Analysis—Part 1: Graphical Representation; International Organization for Standardization: Geneva, Switzerland, 1988. [Google Scholar]

- Wolfrom, R.L. The language of particle size. As published in GXP. Spring 2011, 15, 2. [Google Scholar]

- Dzurenda, L.; Orlowski, K.A. The effect of thermal modification of ash wood on granularity and homogeneity of sawdust in the sawing process on a sash gang saw PRW 15-M in view of its technological usefulness. Drewno 2011, 54, 27–37. [Google Scholar]

- Kucerka, M. Analysis of sawdust fractions from wood sawing processes. Acta Univ. Matthiae Belii 2014, 14, 36–43. [Google Scholar]

- Janssens, M. Rate of heat release of wood products. Fire Saf. J. 1991, 17, 217–238. [Google Scholar] [CrossRef]

- Lowden, L.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef] [Green Version]

- Hehar, G.; Fasina, O.; Adhikari, S.; Fulton, J. Ignition and volatilization behavior of dust from loblolly pine wood. Fuel Process. Technol. 2014, 127, 117–123. [Google Scholar] [CrossRef]

- Beljaková, A.; Očkajová, A.; Jobbagy, J. Determination of the minimum ignition temperature of beech dust depending on the grinding model. Acta Univ. Matthiae Belii 2009, 9, 36–43. [Google Scholar]

- Hosseinzadeh, S.; Norman, F.; Verplaetsen, F.; Berghmans, J.; Bulck, E.V.D. Minimum ignition energy of mixtures of combustible dusts. J. Loss Prev. Process. Ind. 2015, 36, 92–97. [Google Scholar] [CrossRef]

- Fernandez-Anez, N.; Slatter, D.J.; Saeed, M.A.; Phylaktou, H.N.; Andrews, G.E.; García-Torrent, J. Ignition sensitivity of solid fuel mixtures. Fuel 2018, 223, 451–461. [Google Scholar] [CrossRef]

- Danzi, E.; Marmo, L.; Riccio, D. Minimum Ignition Temperature of layer and cloud dust mixtures. J. Loss Prev. Process. Ind. 2015, 36, 326–334. [Google Scholar] [CrossRef]

- Rockwell, S.R.; Rangwala, A. Modeling of dust air flames. Fire Saf. J. 2013, 59, 22–29. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Dust Explosions in the Process Industries, 1st ed.; Gulf Professional Publishing: Boston, MA, USA, 2003; p. 719. [Google Scholar]

- Zima, V.P.; Kasymov, D.P. Experimental investigation of the effect extended by a natural fire on wood materials. J. Eng. Phys. Thermophys 2018, 91, 913–917. [Google Scholar] [CrossRef]

- Krentowski, J.R. Disaster of an industrial hall caused by an explosion of wood dust and fire. Eng. Fail. Anal. 2015, 56, 403–411. [Google Scholar] [CrossRef]

- Mračková, E.; Krišťák, Ľ.; Kučerka, M.; Gaff, M.; Gajtanska, M. Creation of wood dust during wood processing: Size analysis, dust separation, and occupational health. Bioresources. 2015, 11, 209–222. [Google Scholar] [CrossRef]

- Tureková, I.; Harangozó, J.; Turňová, Z.; Balog, K.; Jozef, H.; Karol, B. Assessment of functionality of aged cables at loading by heat flux. Adv. Mater. Res. 2013, 652, 508–511. [Google Scholar] [CrossRef]

- Rantuch, P. Impact of initiator placement on ignition of the vertically positioned electrical cable. SGEM 2018, 18, 419–426. [Google Scholar] [CrossRef]

- Tureková, I. Determination of the minimum ignition temperature of beech dust depending on the grinding model. In Proceedings of the 8th International Conference, Jaslovské Bohunice, Slovakia, 5–6 February 2007; Edícia ESE: Žilina, Slovakia, 2007; pp. 493–499. (In Slovak). [Google Scholar]

- Barcík, Š.; Pivolusková, E.; Kminiak, R. Granulometric Analysis of Chips from Planar Milling of Poplar Wood. Chip and Chipless Wood Processing; Vysoké Tatry, Technical University in Zvolen: Zvolen, Slovakia, 2008; pp. 39–44. (In Slovak) [Google Scholar]

- Saejiw, N.; Chaiear, N.; Sadhra, S. Exposure to wood dust and its particle size distribution in a rubberwood sawmill in Thailand. J. Occup. Environ. Hyg. 2009, 6, 483–490. [Google Scholar] [CrossRef] [PubMed]

| Ignition Sources | Samples | Dust Layer (mm) | Contact Ignition Source/Dust | Temperature of Ignition Source (°C) | Time of Experiment |

|---|---|---|---|---|---|

| Hot surface | Spruce Beech Oak | 15 | Ring area d = 185 mm | <300 | 120 min |

| Electrical coil | Spruce Beech Oak | 15 | 2 height points (7.5 ± 1) mm over the bottom of the deposited layer | 490 | 180 s |

| Smouldering cigarette | Spruce Beech Oak | 15 | 1 point in the centre of the ring area | 300–450 | 120 s |

| Moisture | Waste Wood Dust Samples | ||

|---|---|---|---|

| Spruce | Beech | Oak | |

| (%) | 6.428 ± 0.025 | 5.085 ± 0.012 | 4.793 ± 0.020 |

| Dust Samples | Minimum Ignition Temperature (°C) | Visual Observations During Measurements |

|---|---|---|

| Observations or Comments | ||

| Spruce | 300 |

|

| Beech | 290 |

|

| Oak | 280 |

|

| Ignition Source | Spruce Dust | Beech Dust | Oak Dust | |

|---|---|---|---|---|

| Hot surface | Minimum ignition temperature (°C) | 301.6 ± 2.870 | 290.8 ± 2.227 | 280 ± 0.2.280 |

| Ignition time (s) * | 2060 | 2262 | 1500 | |

| Electric coil | Charred area (%) | 18.02 ± 0.487 | 40.01 ± 0.303 | 70.02 ± 0.337 |

| Ignition time (s) * | 180 | 180 | 180 | |

| Smouldering cigarette | Charred area (%) | 5.04 ± 0.102 | 40.01 ± 0.303 | 40.06 ± 0.241 |

| Ignition time (s) * | 1200 | 1200 | 1200 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tureková, I.; Marková, I. Ignition of Deposited Wood Dust Layer by Selected Sources. Appl. Sci. 2020, 10, 5779. https://doi.org/10.3390/app10175779

Tureková I, Marková I. Ignition of Deposited Wood Dust Layer by Selected Sources. Applied Sciences. 2020; 10(17):5779. https://doi.org/10.3390/app10175779

Chicago/Turabian StyleTureková, Ivana, and Iveta Marková. 2020. "Ignition of Deposited Wood Dust Layer by Selected Sources" Applied Sciences 10, no. 17: 5779. https://doi.org/10.3390/app10175779

APA StyleTureková, I., & Marková, I. (2020). Ignition of Deposited Wood Dust Layer by Selected Sources. Applied Sciences, 10(17), 5779. https://doi.org/10.3390/app10175779