1. Introduction

Additive manufacturing (AM) has emerged as a breakthrough processing technology owing to its various advantages, such as ease of fabrication of complex geometry parts, improvement of expensive raw materials’ yield [

1,

2,

3,

4,

5]. AM has a short lead time, but not always. AM parts (made from the AM process) can be applied in diverse fields and contribute in various ways to the system to which they belong. For example, the total performance of the system is increased by high-performance AM parts, while lightweight AM parts can reduce energy consumption [

6,

7,

8,

9,

10].

The final product of the continuous annealing process is a finished cold-rolled steel strip. In this process, the strips are annealed in a reheating furnace, with an atmosphere stabilized and maintained without chemical change. This type of annealing is done in a continuous annealing line (CAL), commonly referred to as CAL in the steelmaking industry.

POSCO has been searching processes that could reduce fuel consumption by applying AM because of the implementation of stricter regulations on the air environment [

11]. The CAL consumes a large amount of fuel to maintain pre-set heat treatment temperatures (approximately 800~1000 °C). Depending on the size of the CAL, approximately 100~500 radiant tubes are in operation in the CAL, and about 300 million m

3 of coke oven gas (COG) and liquefied natural gas (LNG) are consumed every year. Radiant heat is continuously released from the outside surface of radiant tubes, whereas combustion heat is charged and then continuously released through the inside surface radiant tubes.

A radiant tube (RT) consists of a burner, recuperator, and tube made of either high-temperature steel or nickel-based alloys. In the burner, the fuel (LNG or COG) ignites and quickly enters the inlet of the RT. The generated high-temperature heat in the tube is transmitted by radiation from the outer surface of the tube to the steel strip. Lastly, the heat is exhausted through the outlet. The hot exhaust gas recovered by the recuperator is then used to reheat the cold air flowing through the burner. RTs appear in diverse shapes: double P, straight, W, and U [

12].

Many studies have focused on improving the radiant heat efficiency of the burner and reheating system of the RT. Flamme et al. in 2010 argued that increasing fuel efficiency depends on an effective reheating of the cold air flowing through the burner [

12]. Thus, they emphasized on the importance of RT designs that can use internal air preheating technologies, such as plug-in recovery, and regenerative and recuperative burners. Zhong et al. in 2015 used a double regenerative RT burner to improve the unstable combustion, gas pressure, and flow changes that often occur in conventional burners [

13]. They reported that using low heat gases capable of burning at lower temperatures could reduce fuel costs, thus increasing fuel efficiency. Scribano et al. in 2006 tried to find the best operating conditions of RT in terms of optimum equivalence ratio, thermal power, and lower pollutant emissions [

14]. They introduced a self-induced exhaust gas recirculation mechanism and reduced NOx emissions by up to 50%, for a wide range of thermal power and equivalence ratios, compared to the original burner design without compromising the thermal efficiency, CO emissions, and surface temperature uniformity of the RT.

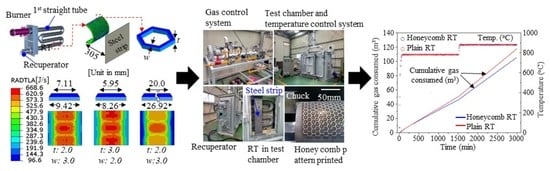

This paper presents a way to improve the radiant heat efficiency of W-type RT in CAL using AM. The RT surface area was increased by printing a series of honeycomb patterns on the RT surface. A three-dimensional (3D) elastic-thermal finite element (FE) analysis was carried out to calculate the time-integrated radiation per unit area (hereafter, referred to as radiant heat (J/s) and determine the appropriate dimensions (width, length, and thickness) of the honeycomb printed on the RT surface.

An RT is large (the size of a straight tube is Φ190 × 2000 mm) and has a curved surface. Consequently, the printing of a set of honeycomb patterns is impossible using the powder bed fusion (PBF) method. Therefore, in this study, the directed energy deposition (DED) method was selected. This method can be used even on objects with large and curved surfaces. Commercially available DED printers and powders (INCONEL 718 alloy) were used.

The radiant heat efficiency of an RT with honeycomb patterns printed was evaluated in the pilot furnace. The RT was supported by the refractory support at the far-off end of the test furnace, while two ambient temperatures (780 °C and 880 °C) commonly adopted in the CAL are maintained. For comparison purposes, RTs with and without honeycomb patterns were sequentially mounted in the pilot furnace. Instead of measuring the radiant heat, the variations in the amount of gaseous fuel consumed to maintain specified ambient temperature in the pilot furnace were measured. Finally, the soundness of the prototype RT with honeycomb patterns printed was tested on-site on the actual CAL of No. 3 CGL in POSCO Gwangyang Steel Works, Korea.

3. Experiment

3.1. Material Used to Print the Honeycomb Pattern

The INCONEL 718 alloy powder (CarTech

® 718, UNS N07718), with its chemical composition given in

Table 2 (supplied by Carpenter Technology Corporation), was used to print a set of honeycomb patterns on the RT made of INCONEL 601. Ideally, the pattern’s metal should be the same as the RT metal to achieve high bonding strength between the pattern and the RT’s surface and prevent the separation of patterns from the RT when the pattern-printed RTs are heated and cooled repeatedly. However, the selected pattern material was the INCONEL 718 as an alternative because INCONEL 601 powder for 3D printing is not commercially available.

Table 3 shows that INCONEL 718 has higher tensile and yield strength than INCONEL 625 at elevated temperatures. A higher strength pattern can support the RT and prevent collapse at high temperatures.

Table 4 shows that the difference between the thermal expansion coefficients of INCONEL 601 and INCONEL 718 is smaller than that between INCONEL 601 and INCONEL 625. Therefore, INCONEL 718 is more effective in preventing the separation of the patterns from the RT when the pattern-printed RTs is heated and cooled repeatedly.

The particle size distribution of INCONEL 718 powder was performed using a Malvern Mastersizer 3000, and the particle morphology was observed via scanning electron microscopy (SEM).

Figure 7a shows the particle size distributions for D10, D50, and D90 are 57.1 μm, 95.5 μm, and 155 μm, respectively. Unlike in PBF method, powders with a wide range of particle sizes can be used in the DED process, which is an advantage contributing to the reduction of DED’s manufacturing cost. The powder particle sizes for DED method are similar to those used in powder metallurgy processes, 50–150 μm, and the powder used has a comparable size.

Figure 7b shows SEM images of the INCONEL 718 powders. The overall shape is nearly spherical (

Figure 7c), and individual powder particles have a dendritic microstructure, typical results of rapid solidification while some satellites are sticking on the surface of larger particles (

Figure 7c).

3.2. DED Printing Machine

Directed energy deposition (DED) is one of AM processes in which a focused energy source (laser beam, electron beam, and plasma arc) is used to form a deposit layer with metal powder or wire. DED offers faster building speed and larger printing size compared to powder bed fusion (PBF) and can bond additional material directly to existing parts.

An InssTek MX-Grande machine (Korea) was used to print the honeycomb patterns. The process parameters required to operate the machine given in

Table 5. The laser power was adjusted automatically between 500 and 800 W. The height of the melt pool was analyzed and controlled in real-time using two cameras mounted on the nozzle head. Printing was confined to the surface of the four straight tubes of the RT except for 20 mm at the end of each straight tubes to secure the space needed to weld the straight tubes and U-bends.

3.3. Printing of the Honeycomb Patterns on Prototype (Actual) RT

A commercially available DED printer was used since it can print them on the straight tube with large and curved surfaces. In DED process, powder is laid down in successive layers on the surfaces and melted by varied heat source of powder to produce any shape. In this study, a layer is defined as an individually generated planar and a thin honeycomb shape.

There are two ways to print a set of honeycomb patterns on the surfaces. The first way divides the target height of the honeycomb shapes on the straight tube into a certain number of layers and then each layer is sequentially stacked on top of the printed layers. In this study, the thickness of one layer of the honeycomb shape was 500 μm and therefore, six layers were stacked sequentially to build a 3 mm-high honeycomb. Each layer adhered to the previous layer repeatedly until the target height (3 mm) of the honeycomb was reached. Hereafter, this method is referred to as the ‘layer-priority method’.

The other way divides the straight tube into a certain number of rings in the circumferential direction. The area of outer ring is referred to as section. In this study, the straight tubes were partitioned into 16 sections. The 3 mm-high honeycomb patterns were printed at once in the first section and then the next section’s honeycomb pattern was printed in order. In this fashion, the honeycomb patterns in 16 sections were printed. Hereafter, this way is referred to as the ‘section-priority method’.

The honeycomb pattern shown in

Figure 8a,b was made by the section-priority method.

Figure 8a shows the first layer of the honeycomb pattern of the edge section of a 2000 mm long straight tube with a diameter of 190 mm fixed with a rotating chuck, for example. The printer’s head and the chuck move at the same time to print the honeycomb pattern.

Figure 8b shows overall view of the prototype RT with the honeycomb pattern printed, which will be installed in the pilot furnace.

3.4. Measurement of Temperature and Fuel Consumption of the Prototype RT

The radiant heat efficiency of the prototype RT with the honeycomb pattern printed was tested using a pilot furnace.

Figure 9a shows a schematic of the pilot furnace emulating the actual CAL. This pilot furnace reproduces the situation in which the radiant heat generated by the prototype RT is absorbed by the steel strip. Two full-size (prototype) RTs with and without honeycomb patterns are supported by refractory support at the far end of the chamber and the chamber, i.e., the pilot furnace has an observation window made of heat-resistant glass and an adjustable valve at the air inlet and outlet. The chamber is made of thermal insulation bricks, and its walls are covered with heat-resistant wools.

Figure 9b represents each part of the pilot furnace. The ambient temperature inside the test chamber was measured at four positions (#1, 2, 3, 4) 200 mm away from the straight tube where the steel strip is located in the actual CAL. The temperature value at position

#2 was used for fuel consumption control during the test. The temperature and gas control system control the ambient temperature by adjusting the amount of fuel consumed by the burner.

Two prototype RTs with and without honeycomb patterns were operated at the heat cycle, as shown in

Figure 10. The two soaking temperatures in the heat cycle are 780 °C and 880 °C, which are two major heat treatment temperatures commonly used in the actual CAL and the soaking time at both 780 and 880 °C was 1440 min (24 h). The variations in fuel consumption were measured while the pilot furnace ambient temperature was maintained for 24 h.

4. Results and Discussion

4.1. 3D Printed Pattern

As mentioned above, when printing a set of the honeycomb structures using the DED printer, two methods were used to prevent the thermal deformation of the thin tube (3 mm thickness) during printing.

Figure 11a shows the pattern printed by the layer-priority method. The layer-priority method prints each layer section-by-section. Each section is printed far from the previously printed section to prevent thermal concentration. This method was effective for heat dispersion; however, it caused deviations in the position of the later printed layer from the previously printed layer because the entire printing area was heated, and the tube was thermally expanded.

Figure 11b is an enlarged picture of the printed pattern using the layer-priority method. Some spatters were observed on the edge. A terraced layer structure was obtained instead of a clear honeycomb structure. This is attributable to the stacking of the printed layer at different times. The amount of thermal expansion of each layers increased as the pattern layer number increased.

Figure 11c shows the honeycomb pattern printed using the section-priority method.

Figure 11d is an enlarged picture of the pattern printed by the section-priority method. Although a slight mismatch between the first and the second layer was observed, the whole honeycomb pattern was well printed. In this method, the heat was concentrated on a relatively small area. Therefore, only the heated section was expanded. In the layer-priority method, however, the entire 16 sections were heated for the printing the first layer on all sections; these all 16 sections were expanded. Although the heat input of one section in the section-priority method is higher than that in the layer-priority method, the heated area is smaller, and the layer after the third layer is printed on a fully heated and expanded section. Consequently, the layer mismatch in the section-priority method was smaller than that in the layer-priority method.

4.2. Spatters on the Pattern

The weld spatters at the edge are shown in

Figure 11b,d. The weld spatter is a droplet of molten metal that is scattered from the melt pool during the printing. The spatter is attached to the build plate at the initial stage of printing because the position of the melt pool is close to the build plate and the scattered melt droplets are still in a liquid (outside the oxide film and inside the liquid metal) or semi-liquid state when they stick to the build plate. As the printing progresses, the position of the melt pool increases due to the stacking of the printed layer. The scattered melt droplets are solidified before they stick to the build plate as the flying distance of the melt droplets is increased. Therefore, the spatter does not present a severe problem for printing a large independent part because the spatter-attached build plate is removed once the printing is completed.

In the case of printing additional structures or repairing damaged areas on existing parts, however, the position of the melt pool is very close to the parts, and the spatter-attached parts cannot be removed after printing. In this study, the height of a single-layer of the honeycomb pattern is 500 μm and therefore the pattern height is only 3 mm. Furthermore, the preprinted layer near the printing position acts as a barrier and blocks the flying spatters. The short flying distance of the melt droplets due to the low melting position and the blocking caused by the preprinted layer seems to be the main reasons for the spatters inside the honeycomb patterns. Remaining spatters, which are not strongly attached to the tube’s surface, might be detached during operation. The detached spatters can cause dent or scratch defects on the strip due to RTs’ location. The number of spatters can be reduced by controlling process variables, such as laser power and printing speed. The spatters on the tube were removed by sandblasting and manual grinding before the final assembly.

4.3. Temperature and Fuel Consumption Measurement in the Pilot Furnace

Figure 12 shows the measured temperature and cumulative gas (fuel) consumed during the entire heat cycle as shown in

Figure 10. The hollow circles indicate the temperatures at position #2 in

Figure 9b recorded to control the fuel consumption, and the solid lines denote the amount of cumulative gas consumed. The symbols and lines marked in red are for the plain RT (RT without honeycomb pattern) and those marked in blue are for the honeycomb pattern-printed RT. The temperature changes for both plain RT and honeycomb pattern printed RT follow almost the same evolution because the temperature control system worked correctly. The amount of cumulative gas consumed to maintain a given temperature, however, was different. The amount of cumulative gas consumed for the honeycomb pattern-printed RT is clearly smaller than that of the plain RT. The difference in the amount of cumulative gas consumed between plain and honeycomb pattern printed RT increased with time and soaking temperature.

Table 6 summarizes the values of the set-up temperatures, measured temperatures, gas consumed for the soaking time, and gas consumed for the entire heat cycle. When the plain surface RT was run, the average amount of gas consumed to maintain the set-up temperature (780 °C and 880 °C) for the soaking time (14,400 min) was 48 m

3 and 65 m

3, respectively. The gas consumed for the entire heat cycle (3000 min) was 118 m

3.

By contrast, when the RT with honeycomb pattern printed was run, the amount of gas consumed to maintain the set-up temperature (780 °C and 880 °C) for 14,400 min was 43 m3 and 57 m3, respectively. It was observed that the gas usage for each soaking time was reduced. The gas consumed for the entire heat cycle was 105 m3. When the gas consumption for each soaking time of the two types of RTs was compared, the RT with honeycomb pattern printed consumed 10.42% at 780 °C and 12.31% at 880 °C less gas than the plain RT, respectively. The averaged gas usage was reduced by 11.02% when comparing the gas consumption of the two RTs on the entire heat cycle basis. Both results show that the radiant heat efficiency of the RT is increased by the addition of the honeycomb patterns.

4.4. Soundness Test of the Prototype RT with Honeycomb Patterns Printed

The actual CAL consists of three zones: heating, soaking, and cooling. Hence, the metal powder used to create the honeycomb patterns should be able to maintain a high bond strength between the pattern and the RT’s surface, and prevent the separation of honeycomb patterns from the RT surface when the RTs are heated and cooled repeatedly. Each zone has tens of RTs, and almost 200 RTs are in the No. 3 CAL in POSCO Gwangyang Steel Works. To investigate soundness of the prototype RT with honeycomb patterns printed, it was installed in the No. 3 CAL in POSCO Gwangyang Steel Works and remained operational for over three years.

The separation of printed patterns and the honeycomb pattern shape were checked in an annual inspection over three years. The shapes of every honeycomb pattern at four straight tubes remained intact, and no separation of the honeycomb pattern from the prototype RT surface was observed. No pressure loss occurred during operation, and no combustion gas leaked from the inside to the outside of the RT. Thus, the integrity of prototype RT has been verified and the DED method adopted in this study for printing the honeycomb pattern on RT surface proves to be acceptable.