Two-Stage Optimal Scheduling of Large-Scale Renewable Energy System Considering the Uncertainty of Generation and Load

Abstract

:1. Introduction

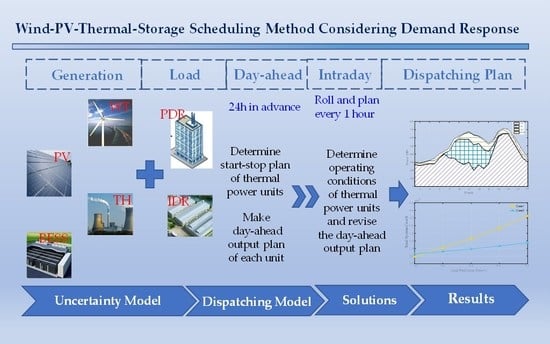

2. Wind-PV-Thermal-Storage Scheduling Mode Considering Demand Response

3. Generation-Load Uncertainty Model

3.1. Uncertain Models of Renewable Energy Output

3.1.1. PV Output Uncertainty Model

3.1.2. Wind Power Output Uncertainty Model

3.2. Load Uncertainty Model Considering Demand-Side Management

3.2.1. Uncertainty Model of Day-Ahead Price Demand Response Virtual Unit

3.2.2. Uncertainty Model of Intraday IDR Virtual Unit

4. A Two-Stage Optimal Scheduling Model for Wind-PV-Thermal-Storage System

4.1. Day-Ahead Optimal Scheduling Model

4.1.1. Low-Carbon Economy Scheduling Objective Function

4.1.2. Economy Scheduling Objective Function

4.1.3. Day-Ahead Dispatching Model Constraints

4.2. Intraday Optimal Dispatching Model

4.2.1. Thermal Units Power Output Correction Model

4.2.2. Intraday Low-Carbon Economic Scheduling Model

4.3. Solutions

4.3.1. Bat Algorithm and Individual Coding

4.3.2. Algorithm Steps

5. Example Simulation and Analysis

5.1. Different Scheduling Scenarios

5.2. Basic Data

5.3. Algorithm Testing

5.4. Results Analysis

5.4.1. Different Scheduling Scenes Analysis

5.4.2. The Effect of Uncertainty on Scheduling Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Li, X.; Zhang, R.F.; Bai, L.Q. Stochastic low-carbon scheduling with carbon capture power plants and coupon-based demand response. Appl. Energy 2018, 210, 1219–1228. [Google Scholar] [CrossRef]

- Hemmati, R.; Saboori, H.; Jirdehi, M.A. Stochastic planning and scheduling of energy storage systems for congestion management in electric power systems including renewable energy resources. Energy 2017, 133, 380–387. [Google Scholar] [CrossRef]

- Shen, J.J.; Cao, R.; Su, C.J. Big data platform architecture and key techniques of power generation scheduling for hydro-thermal-wind-solar hybrid system. Proc. CSEE 2019, 39, 43–55. [Google Scholar]

- Dui, X.W.; Zhu, G.P.; Yao, L.Z. Two-stage optimization of battery energy storage capacity to decrease wind power curtailment in grid-connected wind farms. IEEE Trans. Power Syst. 2018, 33, 3296–3305. [Google Scholar] [CrossRef]

- An, L.; Wang, M.B.; Qi, X. Optimal dispatching of multi-power sources containing wind/photovoltaic/thermal/hydro-pumped and battery storage. Renew. Energy Res. 2018, 33, 1492–1498. [Google Scholar]

- Reddy, S.S.; Vuddanti, S.; Babu, B.C.; Jung, C. Multi-objective based optimal generation scheduling considering wind and solar energy systems. Int. J. Emerg. Electr. Power Syst. 2018, 19, 1553–1779X. [Google Scholar]

- Reddy, S.S. Optimal scheduling of thermal-wind-solar power system with storage. Renew. Energy 2017, 101, 1357–1368. [Google Scholar] [CrossRef]

- Eissa, M.M. First time real time incentive demand response program in smart grid with “i-Energy” management system with different resources. Appl. Energy 2018, 212, 607–621. [Google Scholar] [CrossRef]

- Zhang, M.L.; Ai, X.M.; Fang, J.K. A systematic approach for the joint dispatch of energy and reserve incorporating demand response. Appl. Energy 2018, 230, 1279–1291. [Google Scholar] [CrossRef]

- Mohammad, N.; Yateendra, M. Coordination of wind generation and demand response to minimise operation cost in day-ahead electricity markets using bi-level optimization framework. IET Gener. Transm. Distrib. 2018, 22, 3793–3802. [Google Scholar] [CrossRef]

- Geng, K.L.; Ai, X.; Liu, B. A Two-Stage Scheduling Optimization Model and Corresponding Solving Algorithm for Power Grid Containing Wind Farm and Energy Storage System Considering Demand Response. In Proceedings of the International Conference on Applied Mechanics and Mechanical Automation (AMMA), Hong Kong, China, 22–24 June 2017; pp. 139–145. [Google Scholar]

- Sun, Y.J.; Wang, Y.; Wang, B.B. Multi-time scale decision method for source-load interaction considering demand response uncertainty. Autom. Electr. Power Syst. 2018, 42, 106–113. [Google Scholar]

- Najafi, G.A.; Pashaei, F.A.; Sayyad, N. A stochastic self-scheduling program for compressed air energy storage (CAES) of renewable energy sources (RESs) based on a demand response mechanism. Energy Convers. Manag. 2016, 120, 388–396. [Google Scholar]

- Zhang, Y.C.; Liu, K.P.; Liao, X.B. Multi-time scale source-load coordination dispatch model for power system with large-scale wind power. High Volt. Eng. 2019, 45, 600–608. [Google Scholar]

- Liu, J.C.; Wen, Z.G. An optimal scheduling method to hybrid wind-solar-hydro power generation system with data center in demand side. Power Syst. Technol. 2019, 43, 2449–2460. [Google Scholar]

- Ju, L.W.; Yu, C.; Tan, Z.F. A two-stage scheduling optimization model and corresponding solving algorithm for power grid containing wind farm and energy storage system considering demand response. Power Syst. Technol. 2015, 39, 1287–1293. [Google Scholar]

- Lin, L.; Zou, Q.L.; Zhou, P. Multi-angle economic analysis on deep peak regulation of thermal units with large-scale wind power integration. Autom. Electr. Power Syst. 2017, 41, 21–27. [Google Scholar]

- Lu, R.Z.; Ding, T.; Qin, B.Y.; Ma, J.; Bo, R.; Zhao, Y.D. Reliability based min-max regret stochastic optimization model for capacity market with renewable energy and practice in China. IEEE Trans. Sustain. Energy 2018, 10, 2065–2074. [Google Scholar] [CrossRef]

- Lu, R.Z.; Ding, T.; Qin, B.Y.; Ma, J.; Dong, Z.Y. Multi-Stage Stochastic Programming to Joint Economic Dispatch for Energy and Reserve with Uncertain Renewable Energy. IEEE Trans. Sustain. Energy 2019, 1. [Google Scholar] [CrossRef]

- Luo, C.J.; Li, Y.W.; Xu, H.P. Influence of demand response uncertainty on day-ahead optimization. Autom. Electr. Power Syst. 2017, 41, 22–29. [Google Scholar]

- Liu, B.D.; Zhao, R.Q.; Wang, G. Uncertainty Programming with Application; Tsinghua University Press: Beijing, China, 2003; pp. 213–217. [Google Scholar]

- Li, Y.R. Modeling of Demand Response Considering the Uncertainty and Its Applications in Power System Operation. Master’s Thesis, Southeast University, Nanjing, China, 2015. [Google Scholar]

- Che, Q.H.; Wu, Y.W.; Zhu, Z.G. Carbon trading based optimal scheduling of hybrid energy storage in power systems with large-scale photovoltaic power generation. Autom. Electr. Power Syst. 2019, 43, 76–82. [Google Scholar]

- Liu, X.D.; Chen, H.Y.; Yao, C. Economic dispatch considering deep peak-regulation and interruptible loads for power system incorporated with wind farms. Electr. Power Autom. Equip. 2019, 32, 95–99. [Google Scholar]

- Cui, Y.; Yang, Z.W.; Zhong, W.Z. A joint scheduling strategy of CHP with thermal energy storage and wind power to reduce sulfur and nitrate emission. Power Syst. Technol. 2018, 42, 1063–1070. [Google Scholar]

- Kong, X.Y.; Xiao, J.; Wang, C.S.; Cui, K.; Jin, Q.; Kong, D. Bi-level multi-time scale scheduling method based on bidding for multi-operator virtual power plant. Appl. Energy 2019, 249, 178–189. [Google Scholar] [CrossRef]

- Niknam, T.; Azizipanah-Abarghooee, R.; Zare, M.; Bahmani-Firouzi, B. Reserve constrained dynamic environmental/economic dispatch: A new multi-objective self-adaptive learning bat algorithm. IEEE Syst. J. 2013, 7, 763–776. [Google Scholar] [CrossRef]

- Guo, D.D.; Song, J.G.; Wang, X.Z. Research on indoor coverage optimization strategy of electric wireless private network based on improved bat algorithm. Distrib. Util. 2019, 36, 23–28. [Google Scholar]

- Wang, T. Bat Algorithm Based on Hybrid Strategy. Master’s Thesis, Department of Software Engineering Guangxi University, Guangxi, China, 2015. [Google Scholar]

- Bie, Z.H.; Hu, G.W.; Xie, H.P.; Li, G.F. Optimal dispatch for wind power integrated systems considering demand response. Autom. Electr. Power Syst. 2014, 38, 115–120. [Google Scholar]

- Zhang, G.; Zhang, F.; Zhang, L. Two-stage robust optimization model of day-ahead scheduling considering carbon emissions trading. Proc. CSEE 2018, 38, 5490–5499. [Google Scholar]

- Song, Y.H.; Tan, Z.F.; Li, H.H. An optimization model combining generation side and energy storage system with demand side to promote accommodation of wind power. Power Syst. Technol. 2014, 38, 610–615. [Google Scholar]

- Dong, C.; Zhang, Y.T.; Liu, J.N.; Wu, B.X. Real-time generation scheduling model and its application considering deep peak regulation of thermal power units. Electr. Power Autom. Equip. 2018, 39, 108–113. [Google Scholar]

| Symbol | Capacity (MW) | Cost Coefficient ($/MW∙h) |

|---|---|---|

| Wind Power | 45 | 3.25 |

| PV | 40 | 3.5 |

| Symbol | Parameter Value | Symbol | Parameter Value |

|---|---|---|---|

| 100 | 0.05 | ||

| [0,100] | 0.25 | ||

| 0.5 | 0.95 |

| Algorithm | Average/$ | Standard Deviation | Simulation Time |

|---|---|---|---|

| BA | 409,459.88 | 4.2719 | 2.04 |

| GA | 396,102.31 | 3.2481 | 2.43 |

| Improved BA | 389,024.49 | 1.9625 | 2.96 |

| Cost/$ | Case1 | Case2 | Case3 | Case4 | Case5 |

|---|---|---|---|---|---|

| Thermal | 262,140 | 257,343 | 147,004 | 237,406 | 139,512 |

| Storage | - | 14,828 | - | - | 16,871 |

| DR | - | - | 109118 | - | 118356 |

| Adjustment | 81,735 | 60,138 | 42,031 | 73,021 | 21,362 |

| Limit | 39,005 | 36,710 | 18,493 | 59,204 | 30,048 |

| Total | 38,2880 | 369,019 | 316,646 | 369,631 | 326,149 |

| Cost/$ | Case1 | Case2 | Case3 | Case4 | Case5 |

|---|---|---|---|---|---|

| Adjustment | 87,120 | 65,024 | 45,317 | 78,352 | 23,824 |

| Total | 421,551 | 396,069 | 332,716 | 401,899 | 337,597 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, X.; Quan, S.; Sun, F.; Chen, Z.; Wang, X.; Zhou, Z. Two-Stage Optimal Scheduling of Large-Scale Renewable Energy System Considering the Uncertainty of Generation and Load. Appl. Sci. 2020, 10, 971. https://doi.org/10.3390/app10030971

Kong X, Quan S, Sun F, Chen Z, Wang X, Zhou Z. Two-Stage Optimal Scheduling of Large-Scale Renewable Energy System Considering the Uncertainty of Generation and Load. Applied Sciences. 2020; 10(3):971. https://doi.org/10.3390/app10030971

Chicago/Turabian StyleKong, Xiangyu, Shuping Quan, Fangyuan Sun, Zhengguang Chen, Xingguo Wang, and Zexin Zhou. 2020. "Two-Stage Optimal Scheduling of Large-Scale Renewable Energy System Considering the Uncertainty of Generation and Load" Applied Sciences 10, no. 3: 971. https://doi.org/10.3390/app10030971

APA StyleKong, X., Quan, S., Sun, F., Chen, Z., Wang, X., & Zhou, Z. (2020). Two-Stage Optimal Scheduling of Large-Scale Renewable Energy System Considering the Uncertainty of Generation and Load. Applied Sciences, 10(3), 971. https://doi.org/10.3390/app10030971