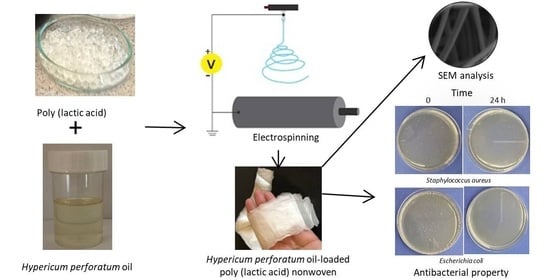

An In Vitro Study of Antibacterial Properties of Electrospun Hypericum perforatum Oil-Loaded Poly(lactic Acid) Nonwovens for Potential Biomedical Applications

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Study

2.1. Materials

2.2. Methods

2.2.1. Preparation of Solutions for Electrospinning

2.2.2. Preparation of Electrospun Nonwoven Fabrics

2.2.3. Measurements and Characterizations

2.2.4. In Vitro Antibacterial Activity

3. Results and Discussion

3.1. Morphology of the Electrospun Nonwoven Fabrics

3.2. ATR-FTIR Analysis of the Electrospun Nonwoven Fabrics

3.3. Thermal Properties of the Electrospun Nonwoven Fabrics

3.4. Thickness and Air Permeability of the Electrospun Nonwoven Fabrics

3.5. In Vitro Antibacterial Activity of the Electrospun Nonwoven Fabrics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hagen, R. Polylactic Acid. In Polymer Science: A Comprehensive Reference, 1st ed.; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 231–236. [Google Scholar]

- Puchalski, M.; Kwolek, S.; Szparaga, G.; Chrzanowski, M.; Krucińska, I. Investigation of the influence of PLA molecular structure on the crystalline Forms (α’ and α) and mechanical properties of wet spinning fibres. Polymers 2017, 9, 18. [Google Scholar] [CrossRef] [PubMed]

- Giełdowska, M.; Puchalski, M.; Szparaga, G.; Krucińska, I. Investigation of the Influence of PLA molecular and supramolecular structure on the kinetics of thermal-supported hydrolytic degradation of wet spinning fibres. Materials 2020, 13, 2111. [Google Scholar] [CrossRef] [PubMed]

- Połowiński, S.; Jantas, R.; Szumilewicz, J.; Stawski, D.; Herczyńska, L.; Draczyński, Z. Modification of PLA Fibers with Bioacceptable Hydrophilic Polymers. Fibres Text. East. Eur. 2012, 20, 78–85. [Google Scholar]

- Szuman, K.; Krucińska, I.; Boguń, M.; Draczyński, Z. PLA/PHA- biodegradable blends for pneumothermic fabrication of nonwovens. Autex Res. J. 2016, 16, 119–127. [Google Scholar] [CrossRef] [Green Version]

- Herrero-Herrero, M.; Gómez-Tejedor, J.; Vallés Lluch, A. PLA/PCL electrospun membranes of tailored fibres diameter as drug delivery systems. Eur. Polym. J. 2018, 99, 445–455. [Google Scholar] [CrossRef] [Green Version]

- Lascano, D.; Moraga, G.; Ivorra-Martinez, J.; Rojas-Lema, S.; Torres-Giner, S.; Balart, R.; Boronat, T.; Quiles-Carrillo, L. Development of Injection-Molded Polylactide Pieces with High Toughness by the Addition of Lactic Acid Oligomer and Characterization of Their Shape Memory Behavior. Polymers 2019, 11, 2099. [Google Scholar] [CrossRef] [Green Version]

- Ramakrishna, S.; Fujihara, K.; Teo, W.; Lim, T.; Ma, Z. An Introduction to Electrospinning and Nanofibers; World Scientific Publishing, Co.: Singapore, 2005. [Google Scholar]

- Huang, C.; Thomas, N.L. Fabrication of porous fibers via electrospinning: Strategies and applications. Polym. Rev. 2020, 60, 595–647. [Google Scholar] [CrossRef]

- Sundhari, D.; Dhineshbabu, N.R.; Sutha, S.; Saravanan, M.E.R. Encapsulation of bioactive agent (Curcumin, Moringa) in electrospun nanofibers—Some insights into recent research trends. Mater. Today-Proc. 2021, 46, 7–2682. [Google Scholar]

- Pakolpakçıl, A.; Draczynski, Z. Preparation and characterization of the advanced alginate-based nanofibrous nonwoven using EDC/NHS coupling agent by electrospinning. J. Text. Inst. 2021, 1–9. [Google Scholar] [CrossRef]

- Zafar, M.; Najeeb, S.; Khurshid, Z.; Vazirzadeh, M.; Zohaib, S.; Najeeb, B.; Sefat, F. Potential of Electrospun Nanofibers for Biomedical and Dental Applications. Materials 2016, 9, 73. [Google Scholar] [CrossRef] [PubMed]

- Qasim, S.B.; Zafar, M.S.; Najeeb, S.; Khurshid, Z.; Shah, A.H.; Husain, S.; Rehman, I.U. Electrospinning of Chitosan-Based Solutions for Tissue Engineering and Regenerative Medicine. Int. J. Mol. Sci. 2018, 19, 407. [Google Scholar] [CrossRef] [Green Version]

- Kakoria, A.; Sinha-Ray, S. A Review on Biopolymer-Based Fibers via Electrospinning and Solution Blowing and Their Applications. Fibers 2018, 6, 45. [Google Scholar] [CrossRef] [Green Version]

- Nagam Hanumantharao, S.; Rao, S. Multi-Functional Electrospun Nanofibers from Polymer Blends for Scaffold Tissue Engineering. Fibers 2019, 7, 66. [Google Scholar] [CrossRef] [Green Version]

- Chiu, C.-M.; Nootem, J.; Santiwat, T.; Srisuwannaket, C.; Pratumyot, K.; Lin, W.-C.; Mingvanish, W.; Niamnont, N. Enhanced Stability and Bioactivity of Curcuma comosa Roxb. Extract in Electrospun Gelatin Nanofibers. Fibers 2019, 7, 76. [Google Scholar] [CrossRef] [Green Version]

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Michalska-Pożoga, I.; Thakur, V.K. Biopolymers for Biomedical and Pharmaceutical Applications: Recent Advances and Overview of Alginate Electrospinning. Nanomaterials 2019, 9, 404. [Google Scholar] [CrossRef] [Green Version]

- Fattahi, F.S.; Khoddami, A.; Avinc, O.O. Poly(Lactic Acid) Nano Structure Mats as Potential Wound Dressings. Pamukkale Univ Muh Bilim Derg. 2020, 26, 1193–1203. [Google Scholar]

- Mozaffari, A.; Parvinzadeh Gashti, M.; Mirjalili, M.; Parsania, M. Argon and Argon–Oxygen Plasma Surface Modification of Gelatin Nanofibers for Tissue Engineering Applications. Membranes 2021, 11, 31. [Google Scholar] [CrossRef] [PubMed]

- Quoc Pham, L.; Uspenskaya, M.V.; Olekhnovich, R.O.; Olvera Bernal, R.A. A Review on Electrospun PVC Nanofibers: Fabrication, Properties, and Application. Fibers 2021, 9, 12. [Google Scholar] [CrossRef]

- Pakolpakçıl, A.; Karaca, E.; Becerir, B. Investigation of a natural pH-indicator dye for nanofibrous wound dressings. IOP Conf. Ser. Mater. Sci. Eng. 2018, 460, 012020. [Google Scholar] [CrossRef]

- Pakolpakçıl, A.; Osman, B.; Özer, E.T.; Şahan, Y.; Becerir, B.; Göktalay, G.; Karaca, E. Halochromic composite nanofibrous mat for wound healing monitoring. Mater. Res. Express 2019, 6, 1250c3. [Google Scholar] [CrossRef]

- Pakolpakçıl, A.; Osman, B.; Göktalay, G.; Özer, E.T.; Şahan, Y.; Becerir, B.; Karaca, E. Design and in vivo evaluation of alginate-based pH-sensing electrospun wound dressing containing anthocyanins. J. Polym. Res. 2021, 28, 50. [Google Scholar] [CrossRef]

- Parin, F.N.; Terzioğlu, P.; Sicak, Y.; Yildirim, K.; Öztürk, M. Pine honey–loaded electrospun poly (vinyl alcohol)/gelatin nanofibers with antioxidant properties. J. Text. Inst. 2021, 112, 628–635. [Google Scholar] [CrossRef]

- Ulag, S.; Ilhan, E.; Demirhan, R.; Sahin, A.; Yilmaz, B.K.; Aksu, B.; Sengor, M.; Ficai, D.; Titu, A.M.; Ficai, A.; et al. Propolis-Based Nanofiber Patches to Repair Corneal Microbial Keratitis. Molecules 2021, 26, 2577. [Google Scholar] [CrossRef] [PubMed]

- Pakolpakçıl, A.; Draczynski, Z. Green approach to develop bee pollen-loaded alginate based nanofibrous mat. Materials 2021, 14, 2775. [Google Scholar] [CrossRef]

- Zare, M.R.; Khorram, M.; Barzegar, S.; Asadian, F.; Zareshahrabadi, Z.; Saharkhiz, M.J.; Ahadian, S.; Zomorodian, K. Antimicrobial core–shell electrospun nanofibers containing Ajwain essential oil for accelerating infected wound healing. Int. J. Pharm. 2021, 603, 120698. [Google Scholar] [CrossRef] [PubMed]

- Mele, E. Electrospinning of Essential Oils. Polymers 2020, 12, 908. [Google Scholar] [CrossRef] [Green Version]

- De Luca, I.; Pedram, P.; Moeini, A.; Cerruti, P.; Peluso, G.; Di Salle, A.; Germann, N. Nanotechnology development for formulating essential oils in wound dressing materials to promote the wound-healing process: A Review. Appl. Sci. 2021, 11, 1713. [Google Scholar] [CrossRef]

- Ozturk, N.; Korkmaz, S.; Ozturk, Y. Wound-healing activity of St. John’s Wort (Hypericum perforatum L.) on chicken embryonic fibroblasts. J. Ethnopharmacol. 2007, 111, 33–39. [Google Scholar] [CrossRef]

- Süntar, I.P.; Akkol, E.K.; Yilmazer, D.; Baykal, T.; Kirmizibekmez, H.; Alper, M.; Yeşilada, E. Investigations on the in vivo wound healing potential of Hypericum perforatum L. J. Ethnopharmacol. 2010, 27, 468–477. [Google Scholar] [CrossRef]

- Kiyan, G.S.; Uyanikgil, Y.; Altunci, Y.A.; Çavuşoğlu, T.; Uyanikgil, E.Ö.Ç.; Karabey, F. Investigation of acute effects of Hypericum perforatum (St. John’s Wort-Kantaron) treatment in experimental thermal burns and comparison with silver sulfadiazine treatment. Ulus. Travma ve Acil Cerrahi Derg. 2015, 21, 323–336. [Google Scholar]

- Altan, A.; Aras, M.H.; Damlar, İ.; Gökçe, H.; Özcan, O.; Alpaslan, C. The effect of Hypericum Perforatum on wound healing of oral mucosa in diabetic rats. Eur Oral Res. 2018, 52, 143–149. [Google Scholar] [CrossRef]

- Pourhojat, F.; Sohrabi, M.; Shariati, S.; Asadpour, L. Evaluation of poly ε-caprolactone electrospun nanofibers loaded with Hypericum perforatum extract as a wound dressing. Res. Chem. Intermed. 2017, 43, 297–320. [Google Scholar] [CrossRef]

- Pourhojat, F.; Shariat, S.; Sohrabi, M.; Mahdavi, H.; Asadpour, L. Preparation of antibacterial electrospun Poly lactic-co–glycolic acid nanofibers containing Hypericum Perforatum with bedsore healing property and evaluation of its drug release performance. Int. J. Nano Dimens. 2018, 9, 286–297. [Google Scholar]

- Eğri, O.; Erdemir, N. Production of Hypericumperforatum oil loaded membranes for wound dressing material and in vitro tests. Artif. Cells Nanomed. Biotechnol. 2019, 47, 1404–1415. [Google Scholar] [CrossRef] [Green Version]

- Avci, H.; Gergeroglu, H. Synergistic effects of plant extracts and polymers on structural and antibacterial properties for wound healing. Polym. Bull. 2019, 76, 3709–3731. [Google Scholar] [CrossRef]

- Akşit, N.N.; Gürdap, S.; İşoğlu, S.D.; İşoğlu, İ.A. Preparation of antibacterial electrospun poly(D, L-lactide-co-glycolide)/gelatin blend membranes containing Hypericumcapitatum var. capitatum. Int. J. Polym. Mater. 2020, 70, 797–809. [Google Scholar] [CrossRef]

- Gunes, S.; Tamburaci, S.; Tihminlioglu, F. A novel bilayer zein/MMT nanocomposite incorporated with H. perforatum oil for wound healing. J. Mater. Sci. Mater. Med. 2020, 31, 7. [Google Scholar] [CrossRef] [PubMed]

- Maver, T.; Kurečič, M.; Pivec, T.; Maver, U.; Gradisnik, L.; Gasparic, P.; Kaker, B.; Bratusa, A.; Hribernik, S.; Kleinschek, K.S. Needleless electrospun carboxymethyl cellulose/polyethylene oxide mats with medicinal plant extracts for advanced wound care applications. Cellulose 2020, 27, 4487–4508. [Google Scholar] [CrossRef]

- Mouro, C.; Gomes, A.P.; Gouveia, I.C. Double-layer PLLA/PEO_Chitosan nanofibrous mats containing Hypericum perforatum L. as an effective approach for wound treatment. Polym. Adv. Technol. 2021, 32, 1493–1506. [Google Scholar] [CrossRef]

- Guleken, Z.; Depciuch, J.; Ege, H.; İlbay, G.; Kalkandelen, C.; Ozbeyli, D.; Bulut, H.; Sener, G.; Tarhan, N.; Kuruca, S.E. Spectrochemical and biochemical assay comparison study of the healing effect of the Aloe vera and Hypericum perforatum loaded nanofiber dressings on diabetic wound. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 254, 119639. [Google Scholar] [CrossRef] [PubMed]

- Au, H.T.; Pham, L.N.; Vu, T.H.T.; Park, J.S. Fabrication of an antibacterial non-woven mat of a poly(lactic acid)/chitosan blend by electrospinning. Macromol. Res. 2012, 20, 51–58. [Google Scholar] [CrossRef]

- Karami, Z.; Rezaeian, I.; Zahedi, P.; Abdollahi, M. Preparation and performance evaluations of electrospun poly(ε-caprolactone), poly(lactic acid), and their hybrid (50/50) nanofibrous mats containing thymol as an herbal drug for effective wound healing. J. Appl. Polym. Sci. 2013, 129, 756–766. [Google Scholar] [CrossRef]

- Sutjarittangtham, K.; Sanpa, S.; Tunkasiri, T.; Chantawannakul, P.; Intatha, U.; Eitssayeam, S. Bactericidial effects of propolis/PLA nanofibres obtained via electrospinning. J. Apic. Res. 2014, 53, 109–115. [Google Scholar] [CrossRef]

- Munteanu, B.S.; Aytac, Z.; Pricope, G.M.; Uyar, T.; Vasile, C. Polylactic acid (PLA)/Silver-NP/VitaminE bionanocomposite electrospun nanofibers with antibacterial and antioxidant activity. J. Nanopart. Res. 2014, 16, 2643. [Google Scholar] [CrossRef] [Green Version]

- Bonan, R.F.; Bonan, P.R.F.; Batista, A.U.D.; Sampaio, F.C.; Albuquerque, A.J.R.; Moraes, M.C.B.; Mattoso, L.H.C.; Glenn, G.M.; Medeiros, E.S.; Oliveira, J.E. In vitro antimicrobial activity of solution blow spun poly(lactic acid)/polyvinylpyrrolidone nanofibers loaded with Copaiba (Copaifera sp.) oil. Mater. Sci. Eng. C 2015, 48, 372–377. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Lv, J.; Ding, M.; Li, Y.; Wang, H.; Jiang, S. Release behavior of tetracycline hydrochloride loaded chitosan/poly(lactic acid) antimicrobial nanofibrous membranes. Mater. Sci. Eng. C 2016, 59, 86–91. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Zhang, R.; Lan, W.; Qin, W. Development of poly(lactic acid)/chitosan fibers loaded with essential oil for antimicrobial applications. Nanomaterials 2017, 7, 194. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gomaa, S.F.; Madkour, T.M.; Moghannem, S.; El-Sherbiny, I.M. New polylactic acid/ cellulose acetate-based antimicrobial interactive single dose nanofibrous wound dressing mats. Int. J. Biol. Macromol. 2017, 105, 1148–1160. [Google Scholar] [CrossRef]

- Zhang, W.; Huang, C.; Kusmartseva, O.; Thomas, N.L.; Mele, E. Electrospinning of polylactic acid fibres containing tea tree and manuka oil. React. Funct. Polym. 2017, 117, 106–111. [Google Scholar] [CrossRef]

- Scaffaro, R.; Lopresti, F.; D’Arrigo, M.; Marino, A.; Nostro, A. Efficacy of poly(lactic acid)/carvacrol electrospun membranes against Staphylococcus aureus and Candida albicans in single and mixed cultures. Appl. Microbiol. Biotechnol. 2018, 102, 4171–4181. [Google Scholar] [CrossRef]

- Wang, P.; Mele, E. Effect of Antibacterial Plant Extracts on the Morphology of Electrospun Poly(Lactic Acid) Fibres. Materials 2018, 11, 923. [Google Scholar] [CrossRef] [Green Version]

- Nepomuceno, N.C.; Barbosa, M.A.; Bonan, R.F.; Oliveira, J.E.; Sampaio, F.C.; Medeiros, E.S. Antimicrobial activity of PLA/PEG nanofibers containing terpinen-4-ol against Aggregatibacter actinomycetemcomitans. J. Appl. Polym. Sci. 2018, 135, 1–9. [Google Scholar] [CrossRef]

- Xu, F.; Wang, H.; Zhang, J.; Jiang, L.; Zhang, W.; Hu, Y. A facile design of EGF conjugated PLA/gelatin electrospun nanofibers for nursing care of in vivo wound healing applications. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Kost, B.; Svyntkivska, M.; Brzeziński, M.; Makowski, T.; Piorkowska, E.; Rajkowska, K.; Kunicka-Styczyńska, A.; Biela, T. PLA/β-CD-based fibres loaded with quercetin as potential antibacterial dressing materials. Colloids Surf. B 2020, 190, 110949. [Google Scholar] [CrossRef] [PubMed]

- Sharifi, M.; Bahrami, S.H.; Nejad, N.H.; Milan, P.B. Electrospun PCL and PLA hybrid nanofibrous scaffolds containing Nigella sativa herbal extract for effective wound healing. J. Appl Polym Sci. 2020, 137, e49528. [Google Scholar] [CrossRef]

- Argui, H.; Suner, S.C.; Periz, Ç.D.; Ulusoy, S.; Ben-Attia, M.; Oral, A.; Coşkun, Y.; Oral, A.; Said, H. Fabrication, Characterization, In Vitro Release, and Some Biological Activities of Eucalyptus Essential Oil Loaded Poly (Lactic Acid) Nanofibers. ASMI 2021, 4, 54–63. [Google Scholar]

- Alisir, S.H.; Ozdemir, N.; Burgaz, E.; Dege, N.; Canavar, Y.E. Fabrication and Antimicrobial Activity of Poly(lactic acid) Nanofibers Containing Firstly Synthesized Silver Diclofenac Complex with (2-methylimidazole) for Wound Dressing Applications. Fibers Polym. 2021, 1–12. [Google Scholar] [CrossRef]

- Milanesi, G.; Vigani, B.; Rossi, S.; Sandri, G.; Mele, E. Chitosan-Coated Poly(lactic acid) Nanofibres Loaded with Essential Oils for Wound Healing. Polymers 2021, 13, 2582. [Google Scholar] [CrossRef]

- Ciftci, F.; Ayan, S.; Duygulu, N.; Yilmazer, Y.; Karavelioglu, Z.; Vehapi, M.; Koc, R.C.; Sengor, M.; Yılmazer, H.; Ozcimen, D.; et al. Selenium and clarithromycin loaded PLA-GO composite wound dressings by electrospinning method. Int. J. Polym. Mater. 2021, 1–12. [Google Scholar] [CrossRef]

- Hajikhani, M.; Emam-Djomeh, Z.; Askari, G. Fabrication and characterization of mucoadhesive bioplastic patch via coaxial polylactic acid (PLA) based electrospun nanofibers with antimicrobial and wound healing application. Int. J. Biol. Macromol. 2021, 172, 143–153. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Cheng, X.; Xiao, L.; Wang, Q.; Yan, K.; Su, Z.; Wang, L.; Ma, C.; Wang, Y. Inside-outside Ag nanoparticles-loaded polylactic acid electrospun fiber for long-term antibacterial and bone regeneration. Int. J. Biol. Macromol. 2021, 167, 1338–1348. [Google Scholar] [CrossRef]

- Zhang, R.; Lan, W.; Ji, T.; Sameen, D.E.; Ahmed, S.; Qin, W.; Liu, Y. Development of polylactic acid/ZnO composite membranes prepared by ultrasonication and electrospinning for food packaging. LWT 2021, 135, 110072. [Google Scholar] [CrossRef]

- Maroufi, L.Y.; Ghorbani, M.; Mohammadi, M.; Pezeshki, A. Improvement of the physico-mechanical properties of antibacterial electrospun poly lactic acid nanofibers by incorporation of guar gum and thyme essential oil. Colloids Surf. A Physicochem Eng. Asp. 2021, 622, 126659. [Google Scholar] [CrossRef]

- Aman, M.M.; Ramezani, S.; Hosseini, H.; Mortazavian, A.M.; Hosseini, S.M.; Ghorbani, M. Electrospun Antibacterial and Antioxidant Zein/Polylactic Acid/Hydroxypropyl Methylcellulose Nanofibers as an Active Food Packaging System. Food Bioprocess. Technol. 2021, 14, 1529–1541. [Google Scholar] [CrossRef]

- Fan, T.; Daniels, R. Preparation and Characterization of Electrospun Polylactic Acid (PLA) Fiber Loaded with Birch Bark Triterpene Extract for Wound Dressing. AAPS PharmSciTech 2021, 22, 205. [Google Scholar] [CrossRef]

- Zhu, P.; Zhang, X.; Wang, Y.; Li, C.; Wang, X.; Tie, J.; Wang, Y. Electrospun polylactic acid nanofiber membranes containing Capparis spinosa L. extracts for potential wound dressing applications. J. Appl Polym Sci. 2021, 138, e50800. [Google Scholar] [CrossRef]

- Ibili, H.; Dasdemir, M.; Çankaya, İ.İ.T.; Orhan, M.; Güneşoğlu, C.; Arabacı, A.S. Investigation of poly(lactic acid) nanocapsules containing the plant extract via coaxial electrospraying method for functional nonwoven applications. J. Ind. Text. 2021. [Google Scholar] [CrossRef]

- Jahanmardi, Y.; Tavanaie, M.A.; Tehrani-Bagha, A.R. Curcumin release from blended polycaprolactone/polylactic acid electrospun nanofibrous meshes. J. Ind. Text. 2021, 50, 1065–1078. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Barbosa, W.S.; Rangel, W.S.P.; Valle, I.M.M.; Matos, A.P.S.; Melgaço, F.G.; Dias, M.L.; Júnior, E.R.; Silva, L.C.P.; Abreu, L.C.L.; et al. Polymeric membrane based on polylactic acid and babassu oil for wound healing. Mater. Today Commun. 2021, 26, 102173. [Google Scholar] [CrossRef]

- Argui, H.; Suner, S.; Periz, Ç.; Ulusoy, S.; Türker, G.; Ben-Attia, M.; Büyükkaya, F.; Oral, A.; Coşkun, Y.; Said, H. Preparation of cypress (Cupressus sempervirens L.) essential oil loaded poly(lactic acid) nanofibers. Open Chem. 2021, 19, 796–805. [Google Scholar] [CrossRef]

- Štular, D.; Kruse, M.; Župunski, V.; Kreinest, L.; Medved, J.; Gries, T.; Blaeser, A.; Jerman, I.; Simončič, B.; Tomšič, B. Smart Stimuli-Responsive Polylactic Acid-Hydrogel Fibers Produced via Electrospinning. Fibers Polym. 2019, 20, 1857–1868. [Google Scholar] [CrossRef]

- Mao, Y.; Guidoin, R.; Li, Y.; Brochu, G.; Zhang, Z.; Wang, L. Soybean-derived phospholipids complexed poly (lactic-co-glycolic acid) nanofibrous scaffolds for tissue engineering applications. Mater. Des. 2021, 205, 109737. [Google Scholar] [CrossRef]

- İçoğlu, H.; Oğulata, R. Effect of ambient parameters on morphology of electrospun poly (trimethylene terephthalate) (PTT) fibers. Tekstil ve Konfeksiyon 2017, 27, 215–223. [Google Scholar]

- Kim, M.S.; Kim, D.; Kang, J.K.; Lee, J.H.; Kim, H.L.; Koo, M.A.; Lee, M.H.; Park, J.C. Migration of human dermal fibroblast is affected by the diameter of the electrospun PLGA fiber. Biomater Res. 2012, 16, 135–139. [Google Scholar]

- Silverajah, V.S.G.; Ibrahim, N.A.; Zainuddin, N.; Yunus, W.M.Z.W.; Hassan, H.A. Mechanical, thermal and morphological properties of poly(lactic acid)/epoxidized palm olein blend. Molecules 2012, 17, 11729–11747. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kister, G.; Cassanas, G.; Vert, M.; Pauvert, B.; Térol, A. Vibrational analysis of poly(Llactic acid). J. Raman Spectrosc. 1995, 26, 307–311. [Google Scholar] [CrossRef]

- Alharbi, H.F.; Luqman, M.; Khalil, K.A.; Elnakady, Y.A.; Abd-Elkader, O.H.; Rady, A.M.; Alharthi, N.H.; Karim, M.R. Fabrication of core-shell structured nanofibers of poly (lactic acid) and poly (vinyl alcohol) by coaxial electrospinning for tissue engineering. Eur. Polym. J. 2018, 98, 483–491. [Google Scholar] [CrossRef]

- Restrepo, I.; Medina, C.; Meruane, V.; Fakhrabadi, A.A.; Flores, P.; Llamazare, S.R. The effect of molecular weight and hydrolysis degree of poly(vinyl alcohol)(PVA) on the thermal and mechanical properties of poly(lactic acid)/PVA blends. Polímeros 2018, 28, 2. [Google Scholar] [CrossRef] [Green Version]

- Burkov, A.; Kraev, A.; Grishin, M.; Vesnin, R.; Fomin, S.; Iordanskii, A. Structural Features and Properties’ Characterization of Polylactic Acid/Natural Rubber Blends with Epoxidized Soybean Oil. Polymers 2021, 13, 1101. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Hu, H. Spacer fabric-based exuding wound dressing—Part II: Comparison with commercial wound dressings. Text. Res. J. 2017, 87, 1481–1493. [Google Scholar] [CrossRef]

- Rodriguez, P.G.; Felix, F.N.; Woodley, D.T.; Shim, E.K. The role of oxygen in wound healing: A review of the literature. Dermatol Surg. 2008, 34, 1159–1169. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Feng, J.W.; Zhang, C.C.; Teng, Y.; Liu, Z.; He, J.H. Air permeability of nanofiber membrane with hierarchical structure. Therm. Sci. 2018, 22, 1637–1643. [Google Scholar] [CrossRef]

- Afshari, M. Electrospun Nanofibers, 1st ed.; Woodhead Publishing: Cambridge, UK, 2016; p. 162. [Google Scholar]

- Saddiqe, Z.; Naeem, I.; Maimoona, A. A review of the antibacterial activity of Hypericum perforatum L. J. Ethnopharmacol. 2010, 131, 511–521. [Google Scholar] [CrossRef] [PubMed]

- Crockett, S.L. Essential oil and volatile components of the genus Hypericum (Hypericaceae). Nat. Prod. Commun. 2010, 5, 1493–1506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alebachew, T.; Yismaw, G.; Derabe, A.; Sisay, Z. Staphylococcus aureus burn wound infection among patients attending yekatit 12 hospital burn unit, addis ababa, ethiopia. Ethiop J. Health Sci. 2012, 22, 209–213. [Google Scholar] [PubMed]

- Forson, O.A.; Ayanka, E.; Olu-Taiwo, M.; Pappoe-Ashong, P.J.; Ayeh-Kumi, P.J. Bacterial infections in burn wound patients at a tertiary teaching hospital in Accra, Ghana. Ann. Burns Fire Disasters 2017, 30, 116–120. [Google Scholar]

- Cetik, Y.S.; Demir, C.; Cengiz, M.; Ayhanci, A. Protective properties of kefir on burn wounds of mice that were infected with S. aureus, P. auroginasa and E. coli. Cell Mol. Biol. 2019, 65, 60–65. [Google Scholar] [CrossRef]

| Samples | Reduction Rate (%) | |

|---|---|---|

| Staphylococcus aureus | Escherichia coli | |

| Cotton gauze | No Reduction | No Reduction |

| PLA | No Reduction | No Reduction |

| 5HPO/PLA | ˃99.99 | ˃99.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pakolpakçıl, A.; Draczyński, Z.; Szulc, J.; Stawski, D.; Tarzyńska, N.; Bednarowicz, A.; Sikorski, D.; Hernandez, C.; Sztajnowski, S.; Krucińska, I.; et al. An In Vitro Study of Antibacterial Properties of Electrospun Hypericum perforatum Oil-Loaded Poly(lactic Acid) Nonwovens for Potential Biomedical Applications. Appl. Sci. 2021, 11, 8219. https://doi.org/10.3390/app11178219

Pakolpakçıl A, Draczyński Z, Szulc J, Stawski D, Tarzyńska N, Bednarowicz A, Sikorski D, Hernandez C, Sztajnowski S, Krucińska I, et al. An In Vitro Study of Antibacterial Properties of Electrospun Hypericum perforatum Oil-Loaded Poly(lactic Acid) Nonwovens for Potential Biomedical Applications. Applied Sciences. 2021; 11(17):8219. https://doi.org/10.3390/app11178219

Chicago/Turabian StylePakolpakçıl, Ayben, Zbigniew Draczyński, Justyna Szulc, Dawid Stawski, Nina Tarzyńska, Anna Bednarowicz, Dominik Sikorski, Cesar Hernandez, Sławomir Sztajnowski, Izabella Krucińska, and et al. 2021. "An In Vitro Study of Antibacterial Properties of Electrospun Hypericum perforatum Oil-Loaded Poly(lactic Acid) Nonwovens for Potential Biomedical Applications" Applied Sciences 11, no. 17: 8219. https://doi.org/10.3390/app11178219

APA StylePakolpakçıl, A., Draczyński, Z., Szulc, J., Stawski, D., Tarzyńska, N., Bednarowicz, A., Sikorski, D., Hernandez, C., Sztajnowski, S., Krucińska, I., & Gutarowska, B. (2021). An In Vitro Study of Antibacterial Properties of Electrospun Hypericum perforatum Oil-Loaded Poly(lactic Acid) Nonwovens for Potential Biomedical Applications. Applied Sciences, 11(17), 8219. https://doi.org/10.3390/app11178219