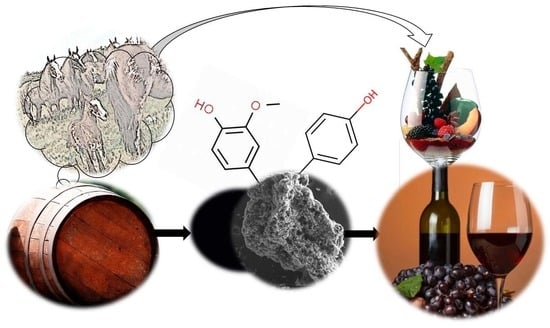

Removal of 4-Ethylphenol and 4-Ethylguaiacol, from Wine-like Model Solutions, by Commercial Modified Activated Carbons Produced from Coconut Shell

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Adsorbents’ Textural and Chemical Characterisation

2.2.2. Textural and Chemical Modification

2.2.3. AC Modification with Nitric Acid

2.2.4. AC Modification with Sodium Hydroxide

2.2.5. Kinetic and Adsorption Studies of 4-Ethylphenol and 4-Ethylguaiacol

3. Results and Discussion

3.1. Textural and Chemical Characterisation of Activated Carbons

3.2. Adsorption of 4-Ethylphenol and 4-Ethylguaiacol

3.2.1. Kinetic Studies of 4-Ethylphenol and 4-Ethylguaiacol

3.2.2. Kinetic Studies of 4-Ethylphenol and 4-Ethylguaiacol on Granular and Powder ACs

3.2.3. 4-Ethylphenol and 4-Ethylguaiacol Removals from Like-Wine Solutions

3.2.4. Joint Removal of 4-Ethylphenol and 4-Ethylguaiacol from Like-Wine Solutions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Milheiro, J.; Filipe-Ribeiro, L.; Vilela, A.; Cosme, F.; Nunes, F.M. 4-Ethylphenol, 4-ethylguaiacol and 4-ethylcatechol in red wines: Microbial formation, prevention, remediation and overview of analytical approaches. Crit. Rev. Food Sci. Nutr. 2019, 59, 1367–1391. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Gong, Q.; Chen, Z.; Wang, W.D.; Huang, Q.; Song, S.; Wang, X. Adsorption and competition investigation of phenolic compounds on the solid-liquid interface of three-dimensional foam-like graphene oxide. Chem. Eng. J. 2019, 378, 122085. [Google Scholar] [CrossRef]

- Ferrer-Gallego, R.; Hernández-Hierro, J.M.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T. Sensory evaluation of bitterness and astringency sub-qualities of wine phenolic compounds: Synergistic effect and modulation by aromas. Food Res. Int. 2022, 62, 1100–1107. [Google Scholar] [CrossRef] [Green Version]

- Paissoni, M.A.; Bitelli, G.; Vilanova, M.; Montanini, C.; Segade, S.R.; Rolle, L.; Giacosa, S. Relative impact of oenological tannins in model solutions and red wine according to phenolic, antioxidant, and sensory traits. Food Res. Int. 2022, 157, 111203. [Google Scholar] [CrossRef]

- Malfeito-Ferreira, M. Two Decades of “Horse Sweat” Taint and Brettanomyces Yeasts in Wine: Where do We Stand Now? Beverages 2018, 4, 32. [Google Scholar] [CrossRef] [Green Version]

- Schumaker, M.R.; Chandra, M.; Malfeito-Ferreira, M.; Ross, C.F. Influence of Brettanomyces ethylphenols on red wine aroma evaluated by consumers in the United States and Portugal. Food Res. Int. 2017, 100, 161–167. [Google Scholar] [CrossRef] [Green Version]

- Aliakbarian, B.; Casazza, A.A.; Perego, P. Kinetic and isotherm modelling of the adsorption of phenolic compounds from olive mill water onto activated carbon. Food Technol. Biotechnol. 2015, 53, 207–214. [Google Scholar] [CrossRef]

- Caboni, P.; Sarais, G.; Cabras, M.; Angioni, A. Determination of 4-ethylphenol and 4-ethylguaiacol in wines by LC-MS-MS and HPLC-DAD-fluorescence. J. Agric. Food Chem. 2007, 55, 7288–7293. [Google Scholar] [CrossRef]

- Filipe-Ribeiro, L.; Cosme, F.; Nunes, F.M. Reducing the negative sensory impact of volatile phenols in red wine with different chitosans: Effect of structure on efficiency. Food Chem. 2017, 242, 591–600. [Google Scholar] [CrossRef]

- Schumaker, M.R.; Diako, C.; Castura, J.C.; Edwards, C.G.; Ross, C.F. Influence of wine composition on consumer perception and acceptance of Brettanomyces metabolites using temporal check-all-that-apply methodology. Food Res. Int. 2019, 116, 963–972. [Google Scholar] [CrossRef]

- Šućur, S.; Čadež, N.; Košmerl, T. Volatile phenols in wine: Control measures of Brettanomyces/Dekkera yeasts. Acta Agric. Slov. 2016, 107, 453–472. [Google Scholar] [CrossRef] [Green Version]

- Oelofse, A.; Malherbe, S.; Pretorius, I.S.; Du Toit, M. Preliminary evaluation of infrared spectroscopy for the differentiation of Brettanomyces bruxellensis strains isolated from red wines. Int. J. Food Microbiol. 2010, 143, 136–142. [Google Scholar] [CrossRef] [PubMed]

- Steensels, J.; Daenen, L.; Malcorps, P.; Derdelinckx, G.; Verachtert, H.; Verstrepen, K.J. Brettanomyces yeasts—From spoilage organisms to valuable contributors to industrial fermentations. Int. J. Food Microbiol. 2015, 206, 24–35. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Filipe-Ribeiro, L.; Milheiro, J.; Matos, C.C.; Cosme, F.; Nunes, F.M. Reduction of 4-ethylphenol and 4-ethylguaiacol in red wine by activated carbons with different physicochemical characteristics: Impact on wine quality. Food Chem. 2017, 229, 242–251. [Google Scholar] [CrossRef] [PubMed]

- Malfeito-Ferreira, M. Yeasts and wine off-flavours: A technological perspective. Ann. Microbiol. 2011, 61, 95–102. [Google Scholar] [CrossRef]

- Larcher, R.; Puecher, C.; Rohregger, S.; Malacarne, M.; Nicolini, G. 4-Ethylphenol and 4-ethylguaiacol depletion in wine using esterified cellulose. Food Chem. 2012, 132, 2126–2130. [Google Scholar] [CrossRef]

- Carrasco-Sánchez, V.; John, A.; Marican, A.; Santos, L.S.; Laurie, V.F. Removal of 4-ethylphenol and 4-ethylguaiacol with polyaniline-based compounds in wine-like model solutions and red Wine. Molecules 2015, 20, 14312–14325. [Google Scholar] [CrossRef] [Green Version]

- Suárez, R.; Suárez-Lepe, J.A.; Morata, A.; Calderón, F. The production of ethylphenols in wine by yeasts of the genera Brettanomyces and Dekkera: A review. Food Chem. 2007, 102, 10–21. [Google Scholar] [CrossRef]

- Madureira, J.; Melo, R.; Verde, S.C.; Matos, I.; Bernardo, M.; Noronha, J.P.; Fonseca, I.M. Recovery of phenolic compounds from multi-component solution by a synthesized activated carbon using resorcinol and formaldehyde. Water Sci. Technol. 2018, 77, 456–466. [Google Scholar] [CrossRef]

- Da̧browski, A.; Podkościelny, P.; Hubicki, Z.; Barczak, M. Adsorption of phenolic compounds by activated carbon—A critical review. Chemosphere 2005, 58, 1049–1070. [Google Scholar] [CrossRef]

- Taillandier, P.; Joannis-Cassan, C.; Jentzer, J.B.; Gautier, S.; Sieczkowski, N.; Granes, D.; Brandam, C. Effect of a fungal chitosan preparation on Brettanomyces bruxellensis, a wine contaminant. J. Appl. Microbiol. 2015, 118, 123–131. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elmacı, S.B.; Gulgor, G.K.; Tokatlı, M.; Erten, H.; Isci, A.; Ozcelik, F. Effectiveness of chitosan against wine-related microorganisms. Antonie Van Leeuwenhoek 2015, 107, 675–686. [Google Scholar] [CrossRef] [PubMed]

- Colangelo, D.; Torchio, F.; De Faveri, D.M.; Lambri, M. The use of chitosan as alternative to bentonite for wine fining: Effects on heat-stability, proteins, organic acids, colour, and volatile compounds in an aromatic white wine. Food Chem. 2018, 264, 301–309. [Google Scholar] [CrossRef] [PubMed]

- European Union (EU). Commission regulation (EU) 53/2011 of 21 January 2011. Off. J. Eur. Union. 2011, 22, L19/1–L19/6. [Google Scholar]

- Milheiro, J.; Filipe-Ribeiro, L.; Cosme, F.; Nunes, F.M. A simple, cheap and reliable method for control of 4-ethylphenol and 4-ethylguaiacol in red wines. Screening of fining agents for reducing volatile phenols levels in red wines. J. Chromatogr. B: Anal. Technol. Biomed. Life Sci. 2017, 1041–1042, 183–190. [Google Scholar] [CrossRef]

- Belo, C.R.; Cansado, I.; Mourão, P. Synthetic polymers blend used in the production of high activated carbon for pesticides removals from liquid phase. Environ. Technol. 2017, 38, 285–296. [Google Scholar] [CrossRef]

- Mourão, P.A.M.; Cansado, I.P.P.; Carrott, P.J.M.; Ribeiro Carrott, M.M.L. Designing activated carbons from natural and synthetic raw materials for pollutants adsorption. Mater. Sci. Forum 2010, 636–637, 1404–1409. [Google Scholar] [CrossRef] [Green Version]

- Cansado, I.P.P.; Belo, C.R.; Mourão, P.A.M. Valorisation of Tectona Grandis tree sawdust through the production of high activated carbon for environment applications. Bioresour. Technol. 2018, 249, 328–333. [Google Scholar] [CrossRef] [Green Version]

- Cansado, I.P.P.; Galacho, C.; Nunes, A.S.; Carrott, M.L.R.; Carrott, P.J.M. Adsorption properties of activated carbons prepared from recycled pet in the removal of organic pollutants from aqueous solutions. Adsorpt. Sci. Technol. 2010, 28, 807–821. [Google Scholar] [CrossRef]

- Gokce, Y.; Aktas, Z. Nitric acid modification of activated carbon produced from waste tea and adsorption of methylene blue and phenol. Appl. Surf. Sci. 2014, 313, 352–359. [Google Scholar] [CrossRef]

- Lorenc-Grabowska, E. Effect of micropore size distribution on phenol adsorption on steam activated carbons. Adsorption 2016, 22, 599–607. [Google Scholar] [CrossRef]

- Cansado, I.P.P.; Mourão, P.A.M.; Falcão, A.I.; Ribeiro Carrott, M.L.; Carrott, P.J.M. The influence of the activated carbon post-treatment on the phenolic compounds removal. Fuel Process. Technol. 2012, 103, 64–70. [Google Scholar] [CrossRef] [Green Version]

- Sulaymon, A.H.; Ahmed, K.W. Competitive adsorption of furfural and phenolic compounds onto activated carbon in fixed bed column. Environ. Sci. Technol. 2008, 42, 392–397. [Google Scholar] [CrossRef] [PubMed]

- Soudani, N.; Souissi-Najar, S.; Ouederni, A. Influence of nitric acid concentration on characteristics of olive stone based activated carbon. Chin. J. Chem. Eng. 2013, 21, 1425–1430. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

| Activated Carbon | ABET/ m2 g−1 | As/ m2 g−1 | Vs/ cm3 g−1 | VDR/ cm3 g−1 | L0/ nm | C/% | H/% | S/% | pHpcz |

|---|---|---|---|---|---|---|---|---|---|

| Norit 1240X | 975 | 60 | 0.43 | 0.23 | 1.04 | 84.4 | 0.19 | 0.49 | 9.73 |

| Norit 1240W | 971 | 38 | 0.43 | 0.22 | 1.11 | 86.7 | 0.07 | 0.54 | 10.49 |

| Panreac | 941 | 223 | 0.41 | 0.23 | 0.97 | 89.3 | 0.53 | 0.38 | 8.12 |

| Merck | 927 | 170 | 0.36 | 0.23 | 1.02 | 85.2 | 0.22 | 0.32 | 7.27 |

| Merck-NaOH-0.5 | 994 | 194 | 0.38 | 0.25 | 1.02 | 84.9 | 0.43 | 0.59 | 7.76 |

| Merck-NaOH-2.5 | 976 | 162 | 0.40 | 0.24 | 1.02 | 84.1 | 0.47 | 0.57 | 8.67 |

| Merck-NaOH-5 | 968 | 188 | 0.37 | 0.24 | 1.00 | -- | -- | -- | 8.06 |

| Merck-HNO3-10 | 979 | 175 | 0.40 | 0.25 | 1.08 | 71.8 | 1.47 | 0.41 | 2.88 |

| Merck-HNO3-20 | 966 | 177 | 0.38 | 0.24 | 1.09 | 70.4 | -- | -- | 2.69 |

| Maximum Adsorption Capacity/mmol g−1 | ||||

|---|---|---|---|---|

| Activated Carbon | 4-Ethylphenol | 4-Ethylguaiacol | ||

| without Ethanol | with Ethanol | without Ethanol | with Ethanol | |

| Merck | 1.59 | 1.06 | 2.02 | 0.96 |

| Panreac | 1.85 | 1.16 | 1.91 | 1.21 |

| Norit 1240X | 1.01 | 0.71 | 1.12 | 0.21 |

| Norit 1240W | 1.03 | 0.87 | 0.96 | 0.16 |

| Maximum Adsorption Capacity/mmol g−1 | ||||

|---|---|---|---|---|

| Activated Carbon | 4-Ethylphenol | 4-Ethylguaiacol | ||

| without Ethanol | with Ethanol | without Ethanol | with Ethanol | |

| Merck CA | 1.59 | 1.06 | 2.02 | 0.96 |

| Merck-NaOH-0.5 | 1.62 | 1.10 | 1.47 | 1.11 |

| Merck-NaOH-2.5 | 1.70 | 1.07 | 1.42 | 1.16 |

| Merck-NaOH-5 | 1.73 | 1.10 | 1.60 | 1.15 |

| Merck-HNO3-10 | 1.51 | 0.66 | 1.28 | 0.53 |

| Merck-HNO3-20 | 0.96 | 0.66 | 0.92 | 0.76 |

| System | nmax | nmL | KL | KF | nF | ||

|---|---|---|---|---|---|---|---|

| Panreac | isolated | 4-EG | 1.91 | 1.77 | 49.6 | 1.98 | 6.09 |

| 4-EP | 1.85 | 1.99 | 9.1 | 1.92 | 4.25 | ||

| mixture | 4-EG | 1.27 | 1.20 | 41.3 | 1.34 | 5.67 | |

| 4-EP | 0.73 | 0.64 | 104.2 | 0.71 | 8.53 | ||

| isolated with ethanol | 4-EG | 1.21 | 1.38 | 7.8 | 1.29 | 5.07 | |

| 4-EP | 1.16 | 1.29 | 8.8 | 1.21 | 5.0 | ||

| mixture with ethanol | 4-EG | 0.89 | 0.86 | 23.6 | 0.92 | 5.98 | |

| 4-EP | 0.55 | 0.58 | 21.8 | 0.56 | 9.86 | ||

| System | nmax | nmL | KL | KF | nF | ||

| Merck | isolated | 4-EG | 2.02 | 1.73 | 100 | 2.18 | 4.28 |

| 4-EP | 1.59 | 1.58 | 77.9 | 1.68 | 8.31 | ||

| mixture | 4-EG | 1.40 | 1.19 | 24.7 | 1.41 | 3.24 | |

| 4-EP | 0.79 | 0.64 | 83.5 | 0.69 | 8.55 | ||

| Isolated with ethanol | 4-EG | 1.06 | 1.16 | 12.6 | 1.33 | 8.32 | |

| 4-EP | 0.96 | 0.95 | 10.5 | 1.25 | 3.32 | ||

| mixture with ethanol | 4-EG | 0.85 | 0.83 | 25.6 | 0.93 | 4.56 | |

| 4-EP | 0.58 | 0.56 | 24.5 | 0.58 | 6.34 | ||

| System | nmax | nmL | KL | KF | nF | ||

| Merck-NaOH-2.5 | isolated | 4-EG | 1.45 | 1.50 | 41.1 | 1.60 | 7.88 |

| 4-EP | 1.70 | 1.90 | 33.1 | 2.86 | 2.15 | ||

| isolated with ethanol | 4-EG | 1.16 | 1.38 | 11.5 | 2.44 | 4.07 | |

| 4-EP | 1.07 | 1.25 | 5.41 | 1.29 | 7.12 | ||

| System | nmax | nmL | KL | KF | nF | ||

| Merck- HNO3-10 | isolated | 4-EG | 1.51 | 1.20 | 15.1 | 1.41 | 3.26 |

| 4-EP | 1.28 | 1.16 | 16.1 | 1.28 | 2.93 | ||

| mixture | 4-EG | 1.06 | 0.83 | 42.7 | 1.02 | 4.02 | |

| 4-EP | 0.49 | 0.47 | 80.1 | 0.46 | 9.63 | ||

| isolated with ethanol | 4-EG | 0.60 | 0.81 | 3.6 | 0.66 | 6.23 | |

| 4-EP | 0.53 | 0.69 | 3.2 | 0.54 | 2.51 | ||

| mixture with ethanol | 4-EG | 0.77 | 0.72 | 13.8 | 0.78 | 3.55 | |

| 4-EP | 0.41 | 0.35 | 18.5 | 0.39 | 4.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cansado, I.P.d.P.; Mourão, P.A.M.; Morais, I.D.; Peniche, V.; Janeirinho, J. Removal of 4-Ethylphenol and 4-Ethylguaiacol, from Wine-like Model Solutions, by Commercial Modified Activated Carbons Produced from Coconut Shell. Appl. Sci. 2022, 12, 11754. https://doi.org/10.3390/app122211754

Cansado IPdP, Mourão PAM, Morais ID, Peniche V, Janeirinho J. Removal of 4-Ethylphenol and 4-Ethylguaiacol, from Wine-like Model Solutions, by Commercial Modified Activated Carbons Produced from Coconut Shell. Applied Sciences. 2022; 12(22):11754. https://doi.org/10.3390/app122211754

Chicago/Turabian StyleCansado, Isabel Pestana da Paixão, Paulo Alexandre Mira Mourão, Inês Dias Morais, Victor Peniche, and João Janeirinho. 2022. "Removal of 4-Ethylphenol and 4-Ethylguaiacol, from Wine-like Model Solutions, by Commercial Modified Activated Carbons Produced from Coconut Shell" Applied Sciences 12, no. 22: 11754. https://doi.org/10.3390/app122211754

APA StyleCansado, I. P. d. P., Mourão, P. A. M., Morais, I. D., Peniche, V., & Janeirinho, J. (2022). Removal of 4-Ethylphenol and 4-Ethylguaiacol, from Wine-like Model Solutions, by Commercial Modified Activated Carbons Produced from Coconut Shell. Applied Sciences, 12(22), 11754. https://doi.org/10.3390/app122211754