Effect of Different Types of Recycled Concrete Aggregates on Equivalent Concrete Strength and Drying Shrinkage Properties

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Program

3. Experimental Tests

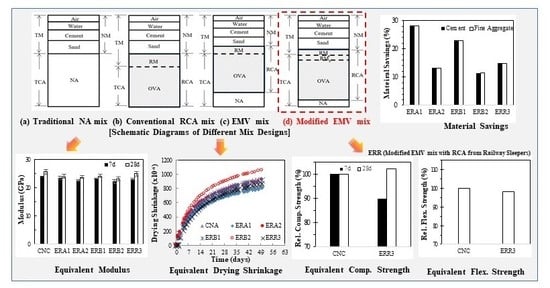

3.1. Mix Design

3.2. Test Preparation

4. Experimental Test Results

4.1. Results of Slump, Air Content and Density

4.2. Compressive Strength

4.3. Young’s Modulus

4.4. Flexural Strength

4.5. Split Tensile Strength

4.6. Drying Shrinkage

5. Conclusions

- (1)

- Due to the nature of a lower slump problem that often occurs in the modified EMV method, all the mixture slump values were controlled by using a superplasticizer to range between 140–155 mm and air contents values with 3.7–5.8%.

- (2)

- Except for the split tensile strength, test results showed that the ERR mix with 100% RCA replacement, which was produced from old PC sleepers mixed by the revised EMV mix method, exhibited equivalent compressive strength, Young’s modulus, and flexural strength values to the companion reference mix of natural aggregate. In addition, the relative drying shrinkage increased only 2% to the companion control mix.

- (3)

- In other mixes (except for ERR mix), compared to the drop of 11–20% of the compressive strength, the modulus of the modified EMV mixes resulted in only a 6–10% decrease to the companion control mix, which is the result of the characteristic in the revised EMV method.

- (4)

- In the modified EMV mixes with RCA replacement of 100%, the flexural strength of concretes decreased by 8–16%. However, with 50% replacement of RCA mixes, the strength increased by 4–10% and thus may be preferred for concrete pavements, which are loaded in bending.

- (5)

- Although a 7–11% decrease was observed in the modified EMV mixes, the split tension to compressive strength of concrete lineally follows the compressive strength trend.

- (6)

- At 50 days, test results revealed that drying shrinkage of the modified RMV mixes with RCA exhibited a 4% drop to only an 8% increase. There was one, except for the ERB2 mix with a 24% increase, and this might be affected by relatively higher fine aggregate ratio and cement content, compared to the other EMV mixes.

Funding

Conflicts of Interest

References

- Tegguer, A. Determining the water absorption of recycled aggregates utilizing hydrostatic weighing approach. Constr. Build. Mater. 2012, 27, 113–116. [Google Scholar]

- Pauw, P.; Thomas, P.; Vyncke, J.; Desmyter, J. Shrinkage and creep of concrete with recycled materials as coarse aggregates. Sustainable Construction: Use of recycled concrete aggregate. In Proceedings of the International Symposium, London, UK, 11–12 November 1998; pp. 213–225. [Google Scholar]

- Maultzch, M.; Mellmann, G. Properties of large scale processed building rubble with respect to the reuse as aggregate in concrete. Sustainable Construction: Use of recycled concrete aggregate. In Proceedings of the International Symposium, London, UK, 11–12 November 1998; pp. 99–107. [Google Scholar]

- Abbas, A. Durability of Green Concrete as a Structural Material. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, March 2007. [Google Scholar]

- Fathifazl, G. Structural Performance of Steel Reinforced Recycled Concrete Members. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, January 2008. [Google Scholar]

- Snyder, M. Recycling concrete pavements. In Proceedings of the ACPA Pennsylvania Chapter Presentation, Harrisburg, PA, USA, 27 January 2010. [Google Scholar]

- FHWA. Recycled Concrete Aggregate Federal Highway Administration National Review. Available online: http://www.fhwa.dot.gov/Pavement/recycling/rca.cfm (accessed on 27 June 2017).

- Fathifazl, G.; Abbas, A.; Razaqpur, A.G.; Isgor, O.B.; Fournire, B.; Foo, S. New mixture proportioning method for concrete made with coarse recycled concrete aggregate. J. Mater. Civ. Eng. ASCE 2009, 21, 601–611. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournire, B.; Foo, S. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cem. Concr. Compos. 2009, 31, 555–563. [Google Scholar] [CrossRef]

- Fathifazl, G.; Razaqpur, A.G.; Isgor, O.B.; Abbas, A.; Fournire, B.; Foo, S. Flexural performance of steel-reinforced recycled concrete beams. ACI Struct. J. 2009, 106, 858–867. [Google Scholar]

- Fathifazl, G.; Razaqpur, A.G.; Isgor, O.B.; Abbas, A.; Fournire, B.; Foo, S. Shear capacity evaluation of steel reinforced recycled concrete (RRC) beams. Eng. Struct. 2011, 33, 1025–1033. [Google Scholar] [CrossRef]

- Mathew, P.; Baby, V.; Sahoo, D.K.; Joseph, G. Manually recycled coarse aggregate from concrete waste—A sustainable substitute for customary coarse aggregate. Am. J. Eng. Res. 2013, 3, 34–38. [Google Scholar]

- Yang, S.; Lee, H. Mechanical properties of recycled aggregate concrete proportioned with modified equivalent mortar volume method for paving applications. Constr. Build. Mater. 2017, 136, 9–17. [Google Scholar] [CrossRef]

- Desai, S. Sustainable concrete construction: An engineer’s views. In Proceedings of the Technical Meeting, Institution of Structural Engineers: South Eastern Countries Branch, London, UK, 2 November 2010. [Google Scholar]

- Thomas, C.; Setien, J.; Polanco, J. Structural recycled aggregate concrete made with precast wastes. Constr. Build. Mater. 2016, 124, 536–546. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem. Concr. Compos. 2000, 24, 269–279. [Google Scholar] [CrossRef]

- Gomez-Soberon, J. Porosity of recycled concrete with substitution of recycled concrete aggregate-an experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C. Effect of the quality of parent concrete on the properties of high performance recycled aggregate concrete. Constr. Build. Mater. 2015, 77, 501–508. [Google Scholar] [CrossRef]

- Hall, K.; Dawood, D.; Vanikar, S.; Tally, R., Jr.; Cackler, T.; Correa, A.; Deem, P.; Duit, J.; Geary, G.; Gisi, A.; et al. Long-Life Concrete Pavement in Europe and Canada; FHWA-PL-07-027; Federal Highway Administration: Alexandria, VA, USA, 2007; p. 80.

- Hu, J.; Siddiqui, M.S.; Fowler, D.W.; Whitney, D. Two-lift concrete paving-case studies and reviews from sustainability, cost effectiveness and construction perspectives. In Proceedings of the 93rd Annual Transportation Research Board Meeting, Washington, DC, USA, 12–16 January 2014. [Google Scholar]

- Gerhardt, T. Two-lift Paving: Contractor’s Perspective. In National Open for House Two Lift Concrete Paving; FHWA: Austin, TX, USA, 2013. [Google Scholar]

- Shi, X.; Mukhopadhyay, A.; Zollinger, D. Sustainability assessment for portland cement concrete pavement containing reclaimed asphalt pavement aggregates. J. Clean. Prod. 2018, 192, 569–581. [Google Scholar] [CrossRef]

- Tam, V.; Tam, C. Assessment of durability of recycled aggregate concrete produced by two-stage mixing approach. J. Mater Sci. 2007, 42, 3592–3602. [Google Scholar] [CrossRef] [Green Version]

- Sicakova, A.; Urban, K. The influence of discharge time, kind of additive and kind of aggregate on the properties of three-stage mixed concrete. Sustainability 2018, 10, 3862. [Google Scholar] [CrossRef]

- Tam, V.; Gao, X.; Tam, C. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Gupta, P.; Khaudhair, Z.; Ahuja, A. A new method for proportioning recycled concrete. Struct. Concr. 2016, 4, 677–687. [Google Scholar] [CrossRef]

- Kim, N.; Kim, J.; Yang, S. Mechanical strength properties of RCA concrete made by a modified EMV method. Sustainability 2016, 8, 924. [Google Scholar] [CrossRef]

- Yang, S.; Lim, Y. Mechanical strength and drying shrinkage properties of RCA concretes produced from old railway concrete sleepers using by a modified EMV method. Constr. Build. Mater. 2018, 185, 499–507. [Google Scholar] [CrossRef]

- Yang, S.; Lee, H. Freeze-thaw resistance and drying shrinkage of recycled aggregate concrete proportioned by the modified equivalent mortar volume method. Int. J. Concr. Struct. Mater. 2017, 11, 617–626. [Google Scholar] [CrossRef]

- Fathifazl, G.; Razaqpur, A.G.; Isgor, O.B.; Abbas, A.; Fournire, B.; Foo, S. Creep and drying shrinkage characteristics of concrete produced with coarse recycled concrete. Cem. Concr. Compos. 2011, 33, 1026–1037. [Google Scholar] [CrossRef]

- ASTM C127: Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C131: Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; ASTM International: West Conshohocken, PA, USA, 2014.

- Juan, M.S.; Gutierrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.; Zhang, M.H.; Tam, C.T. Acid treatment technique for determining the mortar content of recycled concrete aggregates. J. Test. Eval. 2013, 41, 1–10. [Google Scholar] [CrossRef]

- Korea Expressway Corporation Research Institute. Highway Construction Guide Specification; Korea Expressway Corporation: Gyungbuk, Korea, 2011. (In Korean) [Google Scholar]

- Ministry of Land, Infrastructure and Transportation. Concrete Structure Specification; Ministry of Land, Infrastructure and Transportation: Sejong, Korea, 2009. (In Korean)

- Incheon International Airport Corporation. Concrete Construction Guidelines; Incheon International Airport Corporation: Incheon, Korea, 2012. (In Korean) [Google Scholar]

- ASTM C39: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C469: Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2014.

- KS F 2424: Standard Test Method for Length Change of Mortar and Concrete; KATS: Seoul, Korea, 2015.

- ASTM C157: Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete; ASTM International: West Conshohocken, PA, USA, 2012.

- Ho, N.; Lee, Y.; Lim, W.; Zayed, T.; Chew, K.; Low, G.; Ting, S. Efficient Utilization of Recycled Concrete Aggregate in Structural Concrete. J. Mater. Civ. Eng. 2013, 25, 318–327. [Google Scholar] [CrossRef]

- Paul, S.; Panda, B.; Garg, A. A novel approach in modelling of concrete made with recycled aggregates. Measurement 2018, 115, 64–72. [Google Scholar] [CrossRef]

- Paul, S. Data on optimum recycle aggregate content in production of new structural concrete. Data Brief 2017, 15, 987–992. [Google Scholar] [CrossRef] [PubMed]

- Brito, J.; Saikia, N. Recycled Aggregate in Concrete, Use of Industrial, Construction and Demolished Waste; Springer: London, UK, 2013; pp. 379–426. [Google Scholar]

- Salam, M.; Jumaat, M.; Jaafar, F.; Saad, H. Properties of high-workability concrete with recycled concrete aggregate. Mater. Res. 2011, 14, 248–255. [Google Scholar] [Green Version]

- Price, W.H. Factors influencing concrete strength. J. ACI Proc. 1951, 47, 429. [Google Scholar]

- Tripura, D.D.; Raj, S.; Mohammad, S.; Das, R. Suitability of recycled aggregate as a replacement for natural aggregate in construction. In Journal of the ACI Conference; SP-326; American Concrete Institute: Farmington Hills, MI, USA, 2018; pp. 1–10. [Google Scholar]

- ACI Manual of Concrete Practice 209R-92. Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 1997; pp. 1–47. [Google Scholar]

| Test Items | RA | RB | RR | KS Specification [38] |

|---|---|---|---|---|

| Specific gravity | 2.52 | 2.34 | 2.48 | >2.5 |

| Absorption ratio (%) | 3.82 | 6.61 | 4.53 | <3.0 |

| LA abrasion coef. (%) 1 | - | - | 32.2 | <25(paving), 40(others) |

| RMC 2,3 | 25.0 2 | 46.8 2 | 39.9 2 (40.1 3) | - |

| Test Items | Specific Gravity | Absorption Ratio (%) |

|---|---|---|

| Fine aggregate | 2.60 | 0.95 |

| Natural coarse aggregate | 2.71 | 0.37 |

| Number | Mix-ID 1 | W/C | FA/a | RCA, % | S | Materials (kg) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| W | C | FA | NCA | RCA | Admixture 2 (%) | ||||||

| I | CNC | 0.39 | 45.0 | 0 | - | 187 | 480 | 742 | 907 | 0 | 0.5 |

| II | ERA1 | 0.39 | 32.4 | 100 | 1 | 146 | 374 | 579 | 0 | 1210 | 0.7 |

| III | ERA2 | 0.39 | 38.7 | 100 | 2 | 165 | 424 | 656 | 0 | 1037 | 0.5 |

| IV | ERB1 | 0.39 | 34.3 | 50 | 1 | 152 | 390 | 604 | 622 | 537 | 0.65 |

| V | ERB2 | 0.39 | 39.5 | 50 | 2 | 168 | 431 | 666 | 546 | 472 | 0.5 |

| VI | ERR3 | 0.39 | 38.2 | 100 | 3 | 163 | 418 | 646 | 0 | 1046 | 0.5 |

| Mix-Id | Average Strength of Concrete (MPa) | Ratio (%) | |||

|---|---|---|---|---|---|

| Compression | Flexure | Split Tension | Flexure to Compression | Split Tension to Compression | |

| CNC | 38.7 | 5.36 | 3.72 | 13.9 | 9.6 |

| ERA1 | 34.4 | 4.95 | 3.40 | 14.4 | 9.9 |

| ERA2 | 29.3 | 4.50 | 3.05 | 15.3 | 10.4 |

| ERB1 | 32.4 | 5.91 | 3.47 | 18.3 | 10.7 |

| ERB2 | 31.0 | 5.55 | 3.31 | 17.9 | 10.7 |

| ERR3 | 39.5 | 5.27 | 3.30 | 13.4 | 8.4 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S. Effect of Different Types of Recycled Concrete Aggregates on Equivalent Concrete Strength and Drying Shrinkage Properties. Appl. Sci. 2018, 8, 2190. https://doi.org/10.3390/app8112190

Yang S. Effect of Different Types of Recycled Concrete Aggregates on Equivalent Concrete Strength and Drying Shrinkage Properties. Applied Sciences. 2018; 8(11):2190. https://doi.org/10.3390/app8112190

Chicago/Turabian StyleYang, Sungchul. 2018. "Effect of Different Types of Recycled Concrete Aggregates on Equivalent Concrete Strength and Drying Shrinkage Properties" Applied Sciences 8, no. 11: 2190. https://doi.org/10.3390/app8112190

APA StyleYang, S. (2018). Effect of Different Types of Recycled Concrete Aggregates on Equivalent Concrete Strength and Drying Shrinkage Properties. Applied Sciences, 8(11), 2190. https://doi.org/10.3390/app8112190