Reinforcing Efficiency of Micro and Macro Continuous Polypropylene Fibers in Cementitious Composites

Abstract

:1. Introduction

2. Experimental Program

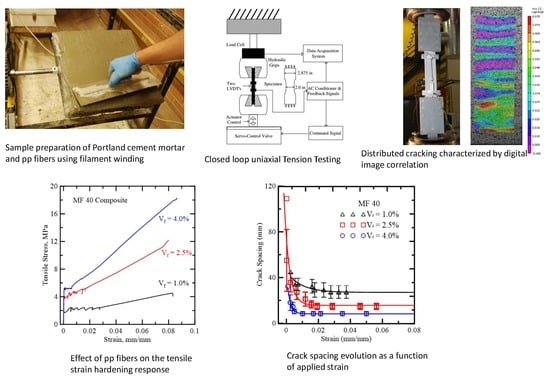

2.1. Sample Preparation Using Filament Winding

2.2. Mix Design

3. Testing Program

3.1. Tensile Response of Fibers

3.2. Tension Tests on Continuous Fiber Composites

3.3. Digital Image Correlation

3.4. Correlation of Fiber Size and Type on Crack Width and Spacing

3.5. Optical Microscopy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Peled, A.; Mob asher, B.; Bentur, A. Modern concrete technology. In Textile Reinforced Concrete; Taylor and Francis: London, UK, 2017; p. 473. [Google Scholar]

- Mechtcherine, V.; Silva, F.A.; Butler, M.; Zhu, D.; Mobasher, B.; Gao, S.L.; Mäder, E. Behaviour of strain-hardening cement-based composites under high strain rates. J. Adv. Concr. Technol. 2011, 9, 51–62. [Google Scholar] [CrossRef]

- Dey, V.; Zani, G.; Colombo, M.; di Prisco, M.; Mobasher, B. Flexural impact response of textile-reinforced aerated concrete sandwich panels. Mater. Design 2015, 86, 187–197. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H. Crack-damage mitigation and flexural behavior of flexure-dominant reinforced concrete beams repaired with strain-hardening cement-based composite. Compos. Part B Eng. 2011, 42, 645–656. [Google Scholar] [CrossRef]

- Kim, S.W.; Park, W.S.; Jang, Y.I.; Feo, L.; Yun, H.D. Crack damage mitigation and shear behavior of shear-dominant reinforced concrete beams repaired with strain-hardening cement-based composite. Compos. Part B Eng. 2015, 79, 6–19. [Google Scholar] [CrossRef]

- Esmaeeli, E.; Barros, J.A. Flexural strengthening of RC beams using Hybrid Composite Plate (HCP): Experimental and analytical study. Compos. Part B Eng. 2015, 79, 604–620. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Silva, F.A.; Butler, M.; Mechtcherine, V.; Mobasher, B. Tension stiffening in textile-reinforced concrete under high speed tensile loads. Cem. Concr. Compos. 2015, 64, 49–61. [Google Scholar] [CrossRef]

- Ghasemi, S.; Zohrevand, P.; Mirmiran, A.; Xiao, Y.; Mackie, K. A super lightweight UHPC-HSS deck panel for movable bridges. Eng. Struct. 2016, 113, 186–193. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; Parra-Montesinos, G.J. Ultra-high performance concrete with compressive strength exceeding 150 MPa (22 ksi): A simpler way. ACI Mater. J. 2011, 108, 46–54. [Google Scholar]

- Xu, M.; Wille, K. Fracture energy of UHP-FRC under direct tensile loading applied at low strain rates. Compos. Part B Eng. 2015, 80, 116–125. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Lee, B.Y.; Bang, J.W.; Han, B.C.; Feo, L.; Cho, C.G. Flexural performance of reinforced concrete beams strengthened with strain-hardening cementitious composite and high strength reinforcing steel bar. Compos. Part B Eng. 2014, 56, 512–519. [Google Scholar] [CrossRef]

- Wille, K.; Xu, M.; El-Tawil, S.; Naaman, A.E. Dynamic impact factors of strain hardening UHP-FRC under direct tensile loading at low strain rates. Mater. Struct. 2016, 49, 1351–1365. [Google Scholar] [CrossRef]

- Mobasher, B.; Pivacek, A. A filament winding technique for cement based cross-ply laminates. Cement Concr. Compos. 1998, 20, 405–415. [Google Scholar] [CrossRef]

- Mobasher, B.; Peled, A.; Pahilajani, J. Distributed cracking and stiffness degradation in fabric-cement composites. Mater. Struct. 2006, 39, 317–331. [Google Scholar] [CrossRef]

- Mobasher, B. Mechanics of Fiber and Textile Reinforced Concrete 2011, 473.

- Li, C.Y. Mechanical Behavior of Cementitious Composites Reinforced with High Volume Content of Fibers. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, May 1995. [Google Scholar]

- Pivacek, A.; Haupt, G.J.; Mobasher, B. Cement based cross-ply laminates. Adv. Cement Based Mater. 1997, 6, 144–152. [Google Scholar] [CrossRef]

- BASF–Master Builders Solutions, Technical Document, MasterFiber MAC 2200CB Synthetic Macrofiber with Chemical Bond for Low Deflection Applications. Available online: https://assets.master-builders-solutions.basf.com/en-us/basf-masterfiber-mac-2200-cb-tds.pdf (accessed on 5 May 2019).

- Peled, A.; Mobasher, B. Tensile behavior of fabric cement-based composites: Pultruded and cast, ASCE. J. Mater. Civil Eng. 2007, 19, 340–348. [Google Scholar] [CrossRef]

- Sutton, M.A.; Wolters, W.J.; Peters, W.H.; Ranson, W.F.; McNeil, S.R. Determination of displacements using an improved digital correlation method. Image Vision Comput. 1983, 1, 133–139. [Google Scholar] [CrossRef]

- Bruck, H.A.; McNeil, S.R.; Sutton, M.A.; Peters, W.H. Digital image correlation using newton-raphson method of partial differential correction. Exp.Mech. 1989, 29, 261–267. [Google Scholar] [CrossRef]

- Destrebecq, J.-F.; Toussaint, E.; Ferrier, E. Analysis of cracks and deformations in a full scale reinforced concrete beam using a digital image correlation technique. Exp.Mech. 2011, 51, 879–890. [Google Scholar] [CrossRef]

- Koerber, H.; Xavier, J.; Camanho, P.P. High strain rate characterisation of unidirectional carbon-epoxy IM7-8552 in transverse compression and in-plane shear using digital image correlation. Mech. Mater. 2010, 42, 1004–1019. [Google Scholar] [CrossRef]

- Gao, G.; Huang, S.; Xia, K.; Li, Z. Application of digital image correlation (DIC) in dynamic notched semi-circular bend (NSCB) tests. Exp. Mech. 2015, 55, 95–104. [Google Scholar] [CrossRef]

- VIC-3D 8 Manual, Correlated Solutions. Available online: http://www.correlatedsolutions.com/supportcontent/VIC-3D-8-Manual.pdf (accessed on 24 May 2019).

- Das, S.; Aguayo, M.; Dey, V.; Kachala, R.; Mobasher, B.; Sant, G.; Neithalath, N. The fracture response of blended formulations containing limestone powder: Evaluations using two-parameter fracture model and digital image correlation. Cem. Concr. Compos. 2014, 53, 316–326. [Google Scholar] [CrossRef]

| Test Type | Yarn Type | Sample Variables | Curing | Yarn Vf% |

|---|---|---|---|---|

| Fiber Tension | MAC | 150, 200, and 250 mm | N/A | |

| Fiber Tension | MF40 | 150, 200, and 250 mm | N/A | |

| Composite Tension | MAC | Volume fraction | 28 days | 1.0, 2.5, 4.0 |

| Composite Tension | MF40 | Volume fraction | 7, 28 days | 1.0, 2.5, 4.0 |

| Fiber | Max Load | Max Elongation | Tensile Strength | Elastic Modulus, E1 | Post-Yield Modulus, E2 | Work to Fracture | |

|---|---|---|---|---|---|---|---|

| N | mm | MPa | MPa | MPa | J | ||

| MAC | Avg. | 245.3 | 4.4 | 394 | 9239 | 4566 | 0.70 |

| Std Dev. | 20.0 | 0.9 | 32.8 | 1813 | 918.3 | 0.25 | |

| MF | Average | 293.8 | 6.3 | 405 | 4985 | 3058 | 1.59 |

| Std Dev. | 33.0 | 0.7 | 45.5 | 1112 | 479.3 | 0.21 |

| Fiber Type, Vf | Replicate ID | Stress at First Crack | Strain at First Crack | UTS | Strain at UTS | Ultimate Strain | Young’s Modulus (LVDT) | Post-Crack Modulus | Work to Fracture (Stroke) | Toughness at 5% Strain | Toughness at 10% Strain |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MPa | mm/mm | MPa | mm/mm | mm/mm | GPa | MPa | N∙ms | MPa | MPa | ||

| MAC | |||||||||||

| MAC 1% | #1 | 1.6 | 1.1 × 10−3 | 7.4 | 0.12 | 0.16 | 1.4 | 94 | 90 | 0.16 | 0.43 |

| #2 | 1.5 | 1.0 × 10−3 | 7.3 | 0.13 | 0.16 | 1.5 | 70 | 89 | 0.14 | 0.41 | |

| #6 | 1.5 | 1.1 × 10−4 | 8.3 | 0.13 | 0.15 | 13.6 | 80 | 65 | 0.09 | 0.37 | |

| Avg | 1.5 | 7.4 × 10−4 | 7.4 | 0.13 | 0.16 | 2.8 | 81 | 89 | 0.15 | 0.42 | |

| MAC 2.5% | #2c | 1.7 | 1.4 × 10−3 | 8.6 | 0.13 | 0.17 | 1.2 | 88 | 143 | 0.16 | 0.48 |

| #4 | 1.7 | 2.7 × 10−4 | 5.0 | 0.07 | 0.12 | 6.4 | 110 | 57 | 0.10 | 0.32 | |

| #5 | 2.0 | 2.2 × 10−4 | 8.8 | 0.12 | 0.16 | 9.1 | 180 | 131 | 0.17 | 0.51 | |

| Avg | 1.7 | 6.3 × 10−4 | 7.5 | 0.11 | 0.15 | 7.6 | 126 | 110 | 0.15 | 0.44 | |

| MAC 4% | #5 | 2.8 | 8.8 × 10−5 | 12.7 | 0.08 | 0.09 | 32.0 | 170 | 146 | 0.31 | 0.78 |

| #6 | 3.6 | 1.1 × 10−4 | 12.9 | 0.08 | 0.11 | 33.6 | 170 | 205 | 0.35 | 0.89 | |

| #7 | 3.0 | 7.1 × 10−5 | 14.1 | 0.10 | 0.10 | 42.2 | 250 | 160 | 0.31 | 0.79 | |

| Avg | 3.1 | 9.0 × 10−5 | 13.2 | 0.08 | 0.10 | 16.9 | 197 | 170 | 0.32 | 0.82 | |

| MF40 | |||||||||||

| MF40 1% | #2 | 2.1 | 1.8 × 10−4 | 5.3 | 0.13 | 0.14 | 11.7 | 36 | 96 | 0.13 | 0.33 |

| #3 | 2.7 | 1.6 × 10−4 | 5.5 | 0.13 | 0.14 | 16.4 | 38 | 102 | 0.14 | 0.34 | |

| Avg | 2.4 | 1.7 × 10−4 | 5.4 | 0.13 | 0.14 | 3.4 | 37 | 99 | 0.14 | 0.34 | |

| MF40 2.5% | #3 | 3.1 | 1.3 × 10−4 | 8.6 | 0.13 | 0.17 | 24.5 | 120 | 170 | 0.23 | 0.66 |

| #5 | 4.5 | 1.1 × 10−4 | 15.1 | 0.12 | 0.13 | 42.0 | 140 | 211 | 0.29 | 0.82 | |

| #8 | 5.2 | 1.2 × 10−4 | 9.9 | 0.08 | 0.12 | 43.6 | 206 | 168 | 0.25 | 0.69 | |

| Avg | 4.3 | 1.2 × 10−4 | 12.5 | 0.10 | 0.13 | 27.7 | 156 | 190 | 0.27 | 0.76 | |

| MF40 4% | #3 | 4.7 | 1.5 × 10−4 | 19.1 | 0.11 | 0.12 | 30.6 | 190 | 259 | 0.33 | 1.04 |

| #5 | 5.1 | 1.2 × 10−4 | 16.4 | 0.10 | 0.12 | 41.7 | 200 | 220 | 0.32 | 0.99 | |

| #7 | 5.2 | 1.1 × 10−4 | 16.9 | 0.13 | 0.14 | 47.6 | 200 | 271 | 0.27 | 0.89 | |

| Avg | 5.0 | 1.3 × 10−4 | 17.5 | 0.11 | 0.13 | 23.5 | 197 | 250 | 0.31 | 0.97 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mobasher, B.; Dey, V.; Bauchmoyer, J.; Mehere, H.; Schaef, S. Reinforcing Efficiency of Micro and Macro Continuous Polypropylene Fibers in Cementitious Composites. Appl. Sci. 2019, 9, 2189. https://doi.org/10.3390/app9112189

Mobasher B, Dey V, Bauchmoyer J, Mehere H, Schaef S. Reinforcing Efficiency of Micro and Macro Continuous Polypropylene Fibers in Cementitious Composites. Applied Sciences. 2019; 9(11):2189. https://doi.org/10.3390/app9112189

Chicago/Turabian StyleMobasher, Barzin, Vikram Dey, Jacob Bauchmoyer, Himai Mehere, and Steve Schaef. 2019. "Reinforcing Efficiency of Micro and Macro Continuous Polypropylene Fibers in Cementitious Composites" Applied Sciences 9, no. 11: 2189. https://doi.org/10.3390/app9112189

APA StyleMobasher, B., Dey, V., Bauchmoyer, J., Mehere, H., & Schaef, S. (2019). Reinforcing Efficiency of Micro and Macro Continuous Polypropylene Fibers in Cementitious Composites. Applied Sciences, 9(11), 2189. https://doi.org/10.3390/app9112189