Design and Optimization of Origami-Inspired Orthopyramid-Like Core Panel for Load Damping

Abstract

:1. Introduction

2. Experimental Work

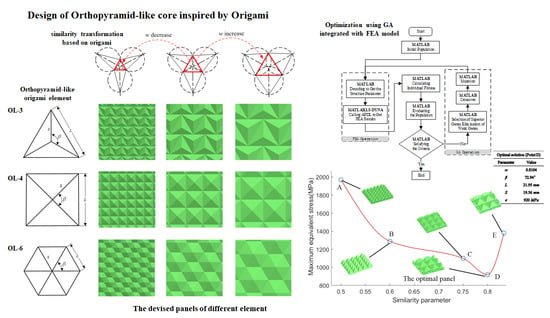

2.1. Orthopyramid-Like Origami Element Geometry

2.2. Orthopyramid-Like Origami Element and Panel Configurations

3. Fabrication of the Panel

4. Mechanical Testing Procedure

4.1. Compression Test

4.2. Impact Test

5. Finite Element Simulation

5.1. Material Properties

5.2. Simulation of Compression Test

5.3. Simulation of Impact Test

6. Result and Discussion

6.1. Result of Compression Test

6.2. Result of Impact Test

6.3. Simulation Result and Comparison

6.4. Optimize the Best Geometric Parameters

7. Conclusions and Prospect

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, X.; Wang, H.; You, Z. Mechanical properties of Miura-based folded cores under quasi-static loads. Thin Wall. Struct. 2014, 82, 296–310. [Google Scholar] [CrossRef]

- Florence, A.; Jaswin, M.A. Vibration and flexural characterization of hybrid honeycomb core sandwich panels filled with different energy absorbing materials. Mater. Res. Express. 2019, 6, 075326. [Google Scholar] [CrossRef]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- Sebaey, T.A.; Mandi, E. Crushing behavior of a unit cell of CFRP lattice core for sandwich structures’ application. Thin Wall. Struct. 2017, 116, 91–95. [Google Scholar] [CrossRef]

- Wang, Y.P.; Gong, X.L.; Xuan, S.H. Study of low-velocity impact response of sandwich panels with shear-thickening gel cores. Smart Mater. Struct. 2018, 27, 065008. [Google Scholar] [CrossRef] [Green Version]

- Yu, B.; Han, B.; Su, P.; Ni, C.; Zhang, Q.; Lu, T. Graded square honeycomb as sandwich core for enhanced mechanical performance. Mater. Des. 2016, 89, 642–652. [Google Scholar] [CrossRef]

- Kumar, S.; Renji, K. Estimation of strains in composite honeycomb sandwich panels subjected to low frequency diffused acoustic field. J. Sound Vib. 2019, 449, 84–97. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Z.; Xiong, W. Experimental investigation on bending behavior of honeycomb sandwich panel with ceramic tile face-sheet. Compos. Part B Eng. 2019, 164, 280–286. [Google Scholar] [CrossRef]

- Pan, G.; Zhang, P.; Liu, J. Experimental and numerical analyses on the dynamic response of aluminum foam core sandwich panels subjected to localized air blast loading. Mar. Struct. 2019, 65, 343–361. [Google Scholar]

- Yin, H.; Wen, G. Crashworthiness optimization design of honeycomb based on simplified basic folding element method. J. Mech. Eng. 2011, 47, 93–100. [Google Scholar] [CrossRef]

- Hao, J.; Wu, X.; Liu, W. Modeling and verification of sandwich beam with wooden skin and honey-comb core subjected to transverse loading. Sci. Silvae Sin. 2019, 50, 128–137. [Google Scholar]

- Seeliger, H.W. Aluminium foam sandwich (AFS) ready for market introduction. Adv. Eng. Mater. 2010, 6, 448–451. [Google Scholar] [CrossRef]

- Xin, F.; Lu, T. Analytical modeling of fluid loaded orthogonally rib-stiffened sandwich structures: Sound transmission. J. Mech. Phys. Sol. 2010, 58, 1374–1396. [Google Scholar] [CrossRef]

- Hýsek, Š.; Frydrych, M.; Herclík, M.; Louda, P.; Fridrichová, L.; Le Van, S.; Le Chi, H. Fire-Resistant Sandwich-Structured Composite Material Based on Alternative Materials and Its Physical and Mechanical Properties. Materials 2019, 12, 1432. [Google Scholar] [CrossRef] [PubMed]

- Hýsek, Š.; Frydrych, M.; Herclík, M.; Fridrichová, L.; Louda, P.; Knížek, R.; Le Van, S.; Le Chi, H. Permeable Water-Resistant Heat Insulation Panel Based on Recycled Materials and Its Physical and Mechanical Properties. Molecules 2019, 24, 3300. [Google Scholar] [CrossRef]

- Herrmann, A.S.; Zahlen, P.C.; Zuardy, I. Sandwich structures technology in commerical aviation: Present applications and future trends. J. Sandw. Struct. Mater. 2005, 7, 13–26. [Google Scholar]

- Sab, K.; Lebée, A. Transverse shear stiffness of a chevron folded core used in sandwich construction. Int. J. Sol. Struct. 2010, 47, 2620–2629. [Google Scholar] [Green Version]

- Elder, T.; Rozairo, D.; Croll, A.B. Origami inspired mechanics: Measuring modulus and force recovery with bent polymer films. Macromolecules 2019, 52, 690–699. [Google Scholar] [CrossRef]

- Peraza-Hernandez, E.A.; Hartl, D.J.; Malak, R.J., Jr.; Lagoudas, D.C. Origami-inspired active structures: A synthesis and review. Smart Mater. Struct. 2014, 23, 094001. [Google Scholar] [CrossRef]

- Turner, N.; Goodwine, B.; Sen, M. A review of origami applications in mechanical engineering. Proc Inst. Mech. Eng. C 2016, 230, 2345–2362. [Google Scholar] [CrossRef]

- Ma, J.; Hou, D.; Chen, Y. Quasi-static axial crushing of thin-walled tubes with a kite-shape rigid origami pattern: Numerical simulation. Thin Wall. Struct. 2016, 100, 38–47. [Google Scholar] [CrossRef]

- Schenk, M. Folded Shell Structures. Ph.D. Thesis, Clare College University of Cambridge, Cambridge, UK, 2011. [Google Scholar]

- Schenk, M.; Guest, S.D. Geometry of Miura-folded metamaterials. Proc. Natl. Acad. Sci. USA 2013, 110, 3276–3281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eidini, M.; Paulino, G.H. Unraveling metamaterial properties in zigzag-base folded sheets. Sci. Adv. 2015, 1, e1500224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hernandez, E.A.P.; Hartl, D.J.; Lagoudas, D.C. Design of origami structures with smooth folds. In Proceedings of the ASME 2016 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Stove, VT, USA, 28–30 September 2016. [Google Scholar]

- Tachi, T. Designing freeform origami tessellations by generalizing Resch’s patterns. J. Mech. Design. 2013, 135, 111006. [Google Scholar] [CrossRef]

- Feng, H.; Ma, J.; Chen, Y.; You, Z. Twist of tubular mechanical metamaterials based on waterbomb origami. Sci. Rep. 2018, 8, 9522. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Deng, X.; Xu, Y.; Feng, J. Motion analysis of a foldable barrel vault based on regular and irregular yoshimura origami. J. Mech. Robot. 2016, 8, 021017. [Google Scholar] [CrossRef]

- Zakirov, I.I. Study of creasing parameters at shaping of folded cores in sandwich panels. Russ. Aeronaut. 2013, 56, 191–193. [Google Scholar] [CrossRef]

- Zakirov, I.M.; Alekseev, K.A.; Kayumov, R.A.; Gainutdinov, I.R. Some possible techniques for improving the strength characteristics of folded cores from sheet composite materials. Russ. Aeronaut. 2009, 52, 347–350. [Google Scholar] [CrossRef]

- Kayumov, R.A.; Zakirov, I.M.; Alekseev, K.P.; Alekseev, K.A.; Zinnurov, R.A. Determination of load-carrying capacity in panels with chevron-type cores. Russ. Aeronaut. 2007, 50, 357–361. [Google Scholar] [CrossRef]

- Wang, F.; Guo, X.; Xu, J.; Zhang, Y.; Chen, C.Q. Patterning curved three-dimensional structures with programmable kirigami designs. Int. J. Appl. Mech. 2017, 84, 061007. [Google Scholar] [CrossRef]

- Nasser, H.; Lebee, A.; Monasse, L. Curvature, metric and parametrization of origami tessellations: Theory and application to the eggbox pattern. Proc. R. Soc. A Math. Phys. Eng. Sci. 2017, 473, 20160705. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Li, X.; Wang, Z.; Zhao, L.; Yan, X. Dynamic blast loading response of sandwich beam with origami-inspired core. Res. Phys. 2018, 10, 946–955. [Google Scholar] [CrossRef]

- Kshad, M.A.E.; Naguib, H.E. Development and modeling of multi-phase polymeric origami inspired architecture by using pre-molded geometrical features. Smart Mater. Struct. 2017, 26, 025012. [Google Scholar] [CrossRef]

- Kshad, M.A.E.; Popinigis, C.; Naguib, H.E. 3D printing of Ron-Resch-like origami cores for compression and impact load damping. Smart Mater. Struct. 2019, 28, 015027. [Google Scholar] [CrossRef]

- Saito, K.; Nojima, T.; Hagiwara, I. Relation between geometrical patterns and mechanical properties in newly developed light-weight core panels. Trans. JSME. A 2008, 74, 1580–1586. [Google Scholar] [CrossRef]

- Li, D.; Dai, N.; Tang, Y.; Dong, G.; Zhao, Y. Design and optimization of graded cellular structures with triply periodic level surface-based topological shapes. J. Mech. Des. 2019, 141, 071402. [Google Scholar] [CrossRef]

- Liu, J.T.; Feng, Y.X.; Zheng, H.; Tan, J.R. Innovative design of regular unit-cell and energy-absorbing features under impact of polyhedron sandwich structure. Chin. J. Mech. 2017, 53, 147–156. [Google Scholar] [CrossRef]

- Qiu, H.; Gao, Y.C.; Feng, Y.X.; Zheng, H.; Tan, J.R. The evolutionary mechanism of unit cell: Parameterizations of polyhedron sandwich structure based on rigid origami. In Proceedings of the 18th International Conference on Geometry and Graphics, Milan, Italy, 3–7 August 2018; pp. 701–710. [Google Scholar]

- Yap, Y.L.; Yeong, W.Y. Shape recovery effect of 3D printed polymeric honeycomb. Virt. Phys. Prototyp. 2015, 10, 91–99. [Google Scholar] [CrossRef]

- Li, S.; Fang, H.; Sadeghi, S.; Bhovad, P.; Wang, K.W. Architected origami materials: How folding creates sophisticated mechanical properties. Adv. Mater. 2019, 31, 1805282. [Google Scholar] [CrossRef]

- Zadpoor, A.A. Mechanical meta-materials. Mater. Horiz. 2016, 3, 371–381. [Google Scholar] [CrossRef] [Green Version]

- Zeng, S.; Gao, Y.; Feng, Y.; Zheng, H.; Qiu, H.; Tan, J. Programming the deformation of a temperature-driven bilayer structure in 4D printing. Smart Mater. Struct. 2019, 28, 105031. [Google Scholar] [CrossRef]

- Evans, A.G.; Hutchinson, J.W.; Fleck, N.A.; Ashby, M.F.; Wadley, H.N.G. The topological design of multifunctional cellular metals. Prog. Mater. Sci. 2001, 46, 309–327. [Google Scholar] [CrossRef]

- Lahoz-Beltra, R. Quantum genetic algorithms for computer scientists. Computers 2016, 5, 24. [Google Scholar] [CrossRef]

- Gao, Y.; Feng, Y.; Wang, Q.; Zheng, H.; Tan, J. A multi-objective decision making approach for dealing with uncertainty in EOL product recovery. J. Clean. Prod. 2018, 204, 712–725. [Google Scholar] [CrossRef]

- Gao, Y.; Feng, Y.; Zhang, Z.; Tan, J. An optimal dynamic interval preventive maintenance scheduling for series systems. Reliab. Eng. Syst. Saf. 2015, 142, 19–30. [Google Scholar] [CrossRef]

- Feng, Y.; Gao, Y.; Tian, G.; Li, Z.; Hu, H.; Zheng, H. Flexible Process Planning and End-of-Life Decision-Making for Product Recovery Optimization Based on Hybrid Disassembly. IEEE Trans. Autom. Sci. Eng. 2018, 99, 1–16. [Google Scholar] [CrossRef]

| Sample | H (mm) | L (mm) | S (mm) | w |

|---|---|---|---|---|

| OL-3-1/2 | 10 | 12.25 | 12.25 | 1/2 |

| OL-3-3/4 | 10 | 24.50 | 17.32 | 3/4 |

| OL-3-5/6 | 10 | 32.85 | 21.44 | 5/6 |

| OL-4-1/2 | 10 | 9.10 | 11.90 | 1/2 |

| OL-4-3/4 | 10 | 17.96 | 16.16 | 3/4 |

| OL-4-5/6 | 10 | 23.93 | 19.65 | 5/6 |

| OL-6-1/2 | 10 | 6.05 | 11.69 | 1/2 |

| OL-6-3/4 | 10 | 11.89 | 15.54 | 3/4 |

| OL-6-5/6 | 10 | 15.82 | 18.72 | 5/6 |

| Edge Number | Similarity Parameter | Young’s Modulus (MPa) |

|---|---|---|

| OL-3 | 1/2 | 2442.9 ± 160.8 |

| 3/4 | 1399.2 ± 247.3 | |

| 5/6 | 357.6 ± 117.3 | |

| OL-4 | 1/2 | 2632.6 ± 245.2 |

| 3/4 | 870.8 ± 105.9 | |

| 5/6 | 290.3 ± 93.8 | |

| OL-6 | 1/2 | 2456.5 ± 110.3 |

| 3/4 | 629.6 ± 97.8 | |

| 5/6 | 271.7 ± 63.0 |

| Edge Number | Similarity Parameter | Specific Modulus of Elasticity (MPa/kg) |

|---|---|---|

| OL-3 | 1/2 | 195,800 ± 11,340 |

| 3/4 | 128,300 ± 22,680 | |

| 5/6 | 66,150 ± 11,660 | |

| OL-4 | 1/2 | 203,500 ± 19,330 |

| 3/4 | 869,100 ± 10,570 | |

| 5/6 | 30,800± 9955 | |

| OL-6 | 1/2 | 199,700 ± 8999 |

| 3/4 | 64,230 ± 9979 | |

| 5/6 | 29,360 ± 6811 |

| Edge Number | Similarity Parameter | The Maximum Impact Forces (N) |

|---|---|---|

| OL-3 | 1/2 | 6851.8 ± 122.8 |

| 3/4 | 5128.6 ± 442.0 | |

| 5/6 | 4699.6 ± 662.6 | |

| OL-4 | 1/2 | 6911.0 ± 80.4 |

| 3/4 | 3906.4 ± 339.4 | |

| 5/6 | 3448.2 ± 767.2 | |

| OL-6 | 1/2 | 6620.8 ± 191.9 |

| 3/4 | 3627.0 ± 104.4 | |

| 5/6 | 2890.3 ± 166.2 |

| Edge Number | Similarity Parameter | Maximum Equivalent Strain | Maximum Equivalent Stress (MPa) |

|---|---|---|---|

| OL-3 | 1/2 | 0.685 | 2330 |

| 3/4 | 0.550 | 1650 | |

| 5/6 | 0.453 | 913 | |

| OL-4 | 1/2 | 446 | 1970 |

| 3/4 | 0.544 | 1100 | |

| 5/6 | 0.676 | 1380 | |

| OL-6 | 1/2 | 0.602 | 2890 |

| 3/4 | 0.692 | 1490 | |

| 5/6 | 0.422 | 1000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Li, K.; Gao, Y.; Qiu, H.; Liu, J. Design and Optimization of Origami-Inspired Orthopyramid-Like Core Panel for Load Damping. Appl. Sci. 2019, 9, 4619. https://doi.org/10.3390/app9214619

Feng Y, Li K, Gao Y, Qiu H, Liu J. Design and Optimization of Origami-Inspired Orthopyramid-Like Core Panel for Load Damping. Applied Sciences. 2019; 9(21):4619. https://doi.org/10.3390/app9214619

Chicago/Turabian StyleFeng, Yixiong, Kangjie Li, Yicong Gao, Hao Qiu, and Jiatian Liu. 2019. "Design and Optimization of Origami-Inspired Orthopyramid-Like Core Panel for Load Damping" Applied Sciences 9, no. 21: 4619. https://doi.org/10.3390/app9214619

APA StyleFeng, Y., Li, K., Gao, Y., Qiu, H., & Liu, J. (2019). Design and Optimization of Origami-Inspired Orthopyramid-Like Core Panel for Load Damping. Applied Sciences, 9(21), 4619. https://doi.org/10.3390/app9214619