Surface Plasmon Nanolaser: Principle, Structure, Characteristics and Applications

Abstract

:Featured Application

Abstract

1. Introduction

2. Basic Principle of Surface Plasmons

3. Structures and Characteristics of Plasmonic Nanolasers

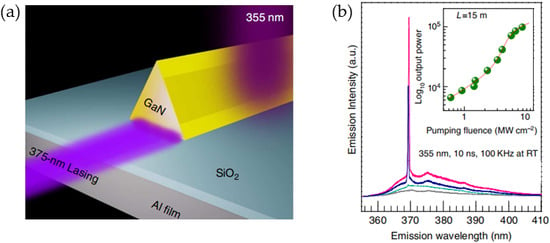

3.1. Plasma Nanolaser Based on a Single Semiconductor Nanowire

3.2. Plasmonic Nanolaser Based on Single Perovskite Nanowires

3.3. Nanowire Array Plasmonic Nanolaser

3.4. LSP-Based Nanolaser

3.5. Nanolaser Based on Whisper-Gallery Effect

4. Existing Problems and Development Trends

- 1)

- Developing from a single operating wavelength to a range of coordinated wavelengths;

- 2)

- Changing pumping methods from optical pumping to electric pumping;

- 3)

- Developing the gain medium of the resonator from cylindrical to polygonal core-shell composite nanowires in structure, from single nanowires to regular array nanowires in quantity, and from traditional semiconductors to new materials such as organic dye molecules and perovskite;

- 4)

- Developing the type of resonator from the F-P cavity composed of nanowires to the metal nanoparticle cavity to the echo wall cavity based on the W-G effect;

- 5)

- Increasing the working temperature from ultra-low temperature (T < 10K) to room temperature and developing towards higher temperatures;

- 6)

- Developing from an independent monomer structure to an integrated array.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergman, D.J.; Stockman, M.I. Surface Plasmon Amplification by Stimulated Emission of Radiation: Quantum Generation of Coherent Surface Plasmons in Nanosystems. Phys. Rev. Lett. 2003, 90, 027402. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Tong, C.; Li, Q.; Wang, L.; Zhang, J. Progress in surface plasmon polariton nano-laser technologies and applications. Chin. Opt. 2012, 5, 453–463. [Google Scholar] [CrossRef]

- Stockman, M.I. Spaser Action, Loss Compensation, and Stability in Plasmonic Systems with Gain. Phys. Rev. Lett. 2011, 106, 156802. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Lan, P.; Liu, X.; He, L.; Zhu, X.; Mücke, O.D.; Lu, P. Method for direct observation of Bloch oscillations in semiconductors. Opt. Express 2018, 26, 23844. [Google Scholar] [CrossRef] [PubMed]

- Lan, P.F.; Ruhmann, M.; He, L.X.; Zhai, C.Y.; Wang, F.; Zhu, X.S.; Zhang, Q.; Zhou, Y.; Li, M.; Lein, M.; et al. Attosecond Probing of Nuclear Dynamics with Trajectory-Resolved High-Harmonic Spectroscopy. Phys. Rev. Lett. 2017, 119, 033201. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.Q.; Wang, B.; Long, H.; Wang, K.; Lu, P.X. Surface Plasmonic Lattice Solitons in Semi-Infinite Graphene Sheet Arrays. J. Lightwave Technol. 2017, 35, 2960–2965. [Google Scholar] [CrossRef] [Green Version]

- Solowan, H.-P.; Kryschi, C. Facile Design of a Plasmonic Nanolaser. Condens. Matter 2017, 2, 8. [Google Scholar] [CrossRef]

- Kong, W.; Wan, Y.; Zheng, Z.; Zhao, X.; Liu, Y.; Bian, Y. High-sensitivity sensing based on intensity-interrogated bloch surface wave sensors. Sens. Actuators B Chem. 2014, 193, 467–471. [Google Scholar] [CrossRef]

- Montanari, R.; Pakhomova, E.; Pizzoferrato, R.; Richetta, M.; Varone, A. Laser Pulse Effects on Plasma-Sprayed and Bulk Tungsten. Metals 2017, 7, 454. [Google Scholar] [CrossRef]

- Giannini, V.; Fernandez-Domínguez, A.I. Plasmonic Nanoantennas: Fundamentals and Their Use in Controlling the Radiative Properties of Nanoemitters. Chem. Rev. 2011, 111, 3888–3912. [Google Scholar] [CrossRef] [PubMed]

- Gu, P.; Birch, D.J.S.; Chen, Y. Dye-Doped Polystyrene-Coated Gold Nanorods: Towards Wavelength Tuneable SPASER. Methods Appl. Fluoresc. 2014, 2, 024004. [Google Scholar] [CrossRef] [PubMed]

- Eustis, S.; El-Sayed, M.A. Why Gold Nanoparticles are More Precious than Pretty Gold: Noble Metal Surface Plasmon Resonance and its Enhancement of the Radiative and Nonradiative Properties of Nanocrystals of Different Shapes. J. Phys. Chem. C 2008, 112, 3216–3222. [Google Scholar]

- Long, H.; Bao, L.J.; Habeeb, A.A.; Lu, P.X. Effects of doping concentration on the surface plasmonic resonances and optical nonlinearities in AGZO nano-triangle arrays. Opt. Quantum Electron. 2017, 49, 345. [Google Scholar] [CrossRef]

- Olivieri, A.; Lisickaskrzek, E.; Northfield, H.; Liscidini, M.; Menotti, M.; Tait, N.; Fong, N.; Berini, P. Bloch long-range surface plasmon polaritons in metallic stripe waveguides. Cleo Sci. Innov. 2017. [Google Scholar]

- Wan, Y.H.; Zheng, Z.; Kong, W.J.; Zhao, X.; Liu, J.S. Fiber-to-fiber optical switching based on gigantic bloch-surface-wave-induced goos–hanchen shifts. IEEE Photonics J. 2013, 5, 7200107. [Google Scholar]

- Wan, Y.H.; Zheng, Z.; Shi, X.G.; Bian, Y.S.; Liu, J.S. Hybrid plasmon waveguide leveraging Bloch surface polaritons for sub-wavelength confinement. Sci. China Technol. Sci. 2013, 56, 567–572. [Google Scholar] [CrossRef]

- Wang, F.; Ke, S.L.; Qin, C.Z.; Wang, B.; Long, H.; Wang, K.; Lu, P.X. Topological interface modes in graphene multilayer arrays. Opt. Laser Technol. 2018, 103, 272–278. [Google Scholar] [CrossRef]

- Ke, S.L.; Liu, J.X.; Liu, Q.J.; Zhao, D.; Liu, W.W. Strong absorption near exceptional points in plasmonic waveguide arrays. Opt. Quantum Electron. 2018, 50, 318. [Google Scholar] [CrossRef]

- Ke, S.L.; Zhao, D.; Liu, Q.J.; Liu, W.W. Adiabatic transfer of surface plasmons in non-Hermitian graphene waveguides. Opt. Quantum Electron. 2018, 50, 393. [Google Scholar] [CrossRef]

- Fornasari, L.; Floris, F.; Patrini, M.; Canazza, G.; Guizzetti, G.; Comoretto, D. Fluorescence excitation enhancement by bloch surface wave in all-polymer one-dimensional photonic structure. Appl. Phys. Lett. 2014, 105, 117. [Google Scholar] [CrossRef]

- Kong, W.; Wan, Y.; Ni, X.; Zhao, W.; Li, S.; Zheng, Z. Optimizing loss of the dielectric stack for Bloch-surface-wave sensors under different interrogation schemes. J. Mod. Opt. 2017, 64, 407–412. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, S.P.; Tian, X.R.; Xu, H.X. Highly Tunable Propagating Surface Plasmons on Supported Silver Nanowires. Proc. Natl. Acad. Sci. USA 2013, 110, 4494–4499. [Google Scholar] [CrossRef] [PubMed]

- Fornasari, L.; Floris, F.; Patrini, M.; Comoretto, D.; Marabelli, F. Demonstration of fluorescence enhancement via bloch surface waves in all-polymer multilayer structures. Phys. Chem. Chem. Phys. 2016, 18, 14086–14093. [Google Scholar] [CrossRef] [PubMed]

- Toma, K.; Descrovi, E.; Toma, M.; Ballarini, M.; Mandracci, P.; Giorgis, F. Bloch surface wave-enhanced fluorescence biosensor. Biosens. Bioeletron. 2013, 43, 108–114. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Y.; Chen, J.; Zhang, D.; Wang, R.; Kuai, Y.; Lu, F.; Tang, X.; Wang, P.; Ming, H.; Rosenfeld, M.; et al. Manipulating Propagation Constants of Silver Nanowire Plasmonic Waveguide Modes Using a Dielectric Multilayer Substrate. Appl. Sci. 2018, 8, 144. [Google Scholar] [CrossRef]

- Jia, Z.L.; Wei, H.; Pan, D.; Xu, H.X. Direction-Resolved Radiation from Polarization-Controlled Surface Plasmon Modes on Silver Nanowire Antennas. Nanoscale 2016, 8, 20118–20124. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Chen, H.Z.; Ma, R.M. High Performance Plasmonic Nanolasers with External Quantum Efficiency Exceeding 10%. Nano Lett. 2018, 18, 7942–7948. [Google Scholar] [CrossRef] [PubMed]

- Ning, C. Semiconductor nanolasers. Prog. Phys. 2011, 31, 145–160. [Google Scholar] [CrossRef]

- Dai, D.; He, S. A silicon-based hybrid plasmonic waveguide with a metal cap for a nano-scale light confinement. Opt. Express 2009, 17, 16646–16653. [Google Scholar] [CrossRef] [PubMed]

- Lv, H.B.; Liu, Y.M.; Yu, Z.Y.; Ye, C.X.; Wang, J. Hybrid plasmonic waveguides for low-threshold nanolaser applications. Chin. Opt. Lett. 2014, 12, 103–106. [Google Scholar]

- Torbatian, Z.; Asgari, R. Plasmonic Physics of 2D Crystalline Materials. Appl. Sci. 2018, 8, 238. [Google Scholar] [CrossRef]

- Liu, S.; Li, F.; Han, X.; Xu, L.; Yao, F.; Liu, Y. Preparation and Two-Photon Photoluminescence Properties of Organic Inorganic Hybrid Perovskites (C6H5CH2NH3)2PbBr4 and (C6H5CH2NH3)2PbI4. Appl. Sci. 2018, 8, 2286. [Google Scholar] [CrossRef]

- Huo, C.; Wang, Z.; Li, X.; Zeng, H. Low-Dimensional Metal Halide Perovskites:a Kind of Microcavity Laser Materials. Chin. J. Lasers 2017, 44, 120–131. [Google Scholar]

- Zhang, D.G.; Xiang, Y.F.; Chen, J.X.; Cheng, J.J.; Zhu, L.F.; Wang, R.X.; Zou, G.; Wang, P.; Ming, H.; Rosenfeld, M.; et al. Extending the Propagation Distance of a Silver Nanowire Plasmonic Waveguide with a Dielectric Multilayer Substrate. Nano Lett. 2018, 18, 1152–1158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, S.F.; Buckley, S.; Schaibley, J.R.; Feng, L.F.; Yan, J.Q.; Mandrus, D.G.; Hatami, F.; Yao, W.; Vuckovic, J.; Majumdar, A.; et al. Monolayer semiconductor nanocavity lasers with ultralow thresholds. Nature 2015, 520, 7545. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L. Study on Photoelectric Characteristics of Typical Graphene Structure Based on FDFD Method; Anhui University Press: Anhui, China, 2015. [Google Scholar]

- Xu, L.; Li, F.; Liu, S.; Yao, F.; Liu, Y. Low Threshold Plasmonic Nanolaser Based on Graphene. Appl. Sci. 2018, 8, 2186. [Google Scholar] [CrossRef]

- Xu, L.; Li, F.; Wei, L.; Zhou, J.; Liu, S. Design of Surface Plasmon Nanolaser Based on MoS2. Appl. Sci. 2018, 8, 2110. [Google Scholar] [CrossRef]

- Wang, F.; Qin, C.; Wang, B.; Long, H.; Wang, K.; Lu, P. Rabi Oscillations of Plasmonic Supermodes in Graphene Multilayer Arrays. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 125–129. [Google Scholar] [CrossRef]

- Huang, H.; Ke, S.L.; Wang, B.; Long, H.; Wang, K.; Lu, P.X. Numerical Study on Plasmonic Absorption Enhancement by a Rippled Graphene Sheet. J. Lightw. Technol. 2017, 35, 320–324. [Google Scholar] [CrossRef]

- Ke, S.; Wang, B.; Long, H.; Wang, K.; Lu, P. Topological mode switching in a graphene doublet with exceptional points. Opt. Quantum Electron. 2017, 49, 224. [Google Scholar] [CrossRef]

- Walther, C.; Scalari, G.; Amanti, M.I.; Beck, M.; Faist, J. Microcavity Laser Oscillating in a Circuit-Based Resonator. Science 2010, 327, 1495–1497. [Google Scholar] [CrossRef] [PubMed]

- Nezhad, M.P.; Simic, A.; Bondarenko, O.; Slutsky, B.; Mizrahi, A.; Feng, L.; Lomakin, V.; Fainman, Y. Room-temperature subwavelength metallo-dielectric lasers. Nat. Photonics 2010, 4, 395–399. [Google Scholar] [CrossRef]

- Lv, H. Hybrid Plasmonic Waveguides for Low Threshold Nanolasers; Beijing University of Posts and Telecommunications Press: Beijing, China, 2015. [Google Scholar]

- Zhang, S.P.; Xu, H.X. Optimizing Substrate-Mediated Plasmon Coupling toward High-Performance Plasmonic Nanowire Waveguides. ACS Nano 2012, 6, 8128–8135. [Google Scholar] [CrossRef] [PubMed]

- Drezet, A.; Hohenau, A.; Koller, D.; Stepanov, A.; Ditlbacher, H.; Steinberger, B.; Aussenegg, F.R.; Leitner, A.; Krenn, J.R. Leakage Radiation Microscopy of Surface Plasmon Polaritons. Mater. Sci. Eng. B 2008, 149, 220–229. [Google Scholar] [CrossRef]

- Pyayt, A.L.; Wiley, B.; Xia, Y.N.; Chen, A.T.; Dalton, L. Integration of Photonic and Silver Nanowire Plasmonic Waveguides. Nat. Nanotechnol. 2008, 3, 660–665. [Google Scholar] [CrossRef] [PubMed]

- Suh, J.Y.; Kim, C.H.; Zhou, W.; Huntington, M.D.; Co, D.T.; Wasielewski, M.R.; Teri, W. Plasmonic Bowtie Nanolaser Arrays. Odomnano Lett. 2012, 12, 5769–5774. [Google Scholar] [CrossRef] [PubMed]

- Yv, H. Research on Low Los Semiconductor Nanolasers Based on Surface Plasmons; Harbin Institute of Technology Press: Harbin, China, 2017. [Google Scholar]

- Raether, H. Surface Plasmons on Smooth and Rough Surfaces and on Gratings; Springer: Berlin/Heidelberg, Germany, 2013; pp. 6–8. [Google Scholar]

- Gu, B.Y. Surface plasmon subwavelength optics: Principles and novel effects. Physics 2007, 36, 280–287. [Google Scholar]

- Oulton, R.F.; Pile, D.F.; Liu, Y.; Zhang, X. Scattering of surface plasmon polaritons at abrupt surface interfaces: Implications for nanoscale cavities. Phys. Rev. B 2007, 76, 035408. [Google Scholar] [CrossRef]

- Zhao, Q.; Huang, X.; Lin, E.; Jiao, J.; Liang, G.; Chen, T. Advances of plasmonic nanolaser. Opto-Electron. Eng. 2017, 44, 140–151. [Google Scholar]

- Oulton, R.F.; Sorger, V.J.; Zentgraf, T.; Ma, R.M.; Gladden, C.; Dai, L.; Bartal, G.; Zhang, X. Plasmon Lasers at Deep Subwavelength Scale. Nature 2009, 461, 629–632. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.J.; Kim, J.; Chen, H.Y.; Wu, C.H.; Dabidian, N.; Sanders, C.E.; Wang, C.Y.; Lu, M.Y.; Li, B.; Qiu, X.; et al. Plasmonic Nanolaser Using Epitaxially Grown Silver Film. Science 2012, 337, 450–453. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, G.; Liu, X.; Qian, F.; Li, Y.; Sum, T.C.; Lieber, C.M.; Xiong, Q. A room temperature low-threshold ultraviolet plasmonic nanolaser. Nat. Commun. 2014, 5, 4953. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chou, Y.H.; Wu, Y.M.; Hong, K.B.; Chou, B.T.; Shih, J.H.; Chung, Y.C.; Chen, P.Y.; Lin, T.R.; Lin, C.C.; Lin, S.D.; et al. High-operation-temperature Plasmonic Nanolasers on Single-crystalline Aluminum. Nano Lett. 2016, 16, 3179–3186. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.H.; Mao, S.; Feick, H.; Yan, H.; Wu, Y.; Kind, H.; Weber, E.; Russo, R.; Yang, P. Room-temperature ultraviolet nanowire nanolasers. Science 2001, 292, 1897–1899. [Google Scholar] [CrossRef] [PubMed]

- Eaton, S.W.; Lai, M.; Gibson, N.A.; Wong, A.B.; Dou, L.; Ma, J.; Wang, L.-W.; Leone, S.R.; Yang, P. Lasing in robust cesium lead halide perovskite nanowires. Proc. Natl. Acad. Sci. USA 2016, 113, 1993–1998. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, H.; Fu, Y.; Meng, F.; Wu, X.; Gong, Z.; Ding, Q.; Gustafsson, M.V.; Trinh, M.T.; Zhu, X.-Y. Lead halide perovskite nanowire lasers with low lasing thresholds and high quality factors. Nat. Mater. 2015, 14, 636–642. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhang, P.; Lin, E.; Wang, P.; Mei, M.; Huang, Q.; Jiao, J.; Zhao, Q. Fabrication and optically pumped lasing of plasmonic nanolaser with regular ZnO/GaN nanoheterojunction array. Appl. Phys. A 2017, 123, 605. [Google Scholar] [CrossRef]

- Noginov, M.A.; Zhu, G.; Belgrave, A.M.; Bakker, R.; Shalaev, V.M.; Narimanov, E.E.; Stout, S.; Herz, E.; Suteewong, T.; Wiesner, U. Demonstration of a Spaser-based Nanolaser. Nature 2009, 460, 1110–1112. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Kildishev, A.V.; Fujita, K.; Tanaka, K.; Shalaev, V.M. Wavelength-tunable Spasing in the Visible. Nano Lett. 2013, 13, 4106–4112. [Google Scholar] [CrossRef] [PubMed]

- Sanvitto, D.; Daraei, A.; Tahraoui, A.; Hopkinson, M.; Fry, P.W.; Whittaker, D.M.; Skolnick, M.S. Observation of ultrahigh quality factor in a semiconductor microcavity. Appl. Phys. Lett. 2005, 86, 191109. [Google Scholar] [CrossRef]

- Madani, A.; Ma, L.; Miao, S.; Jorgensen, M.R.; Schmidt, O.G. Luminescent nanoparticles embedded in TiO2 microtube cavities for the activation of whispering-gallery-modes extending from the visible to the near infrared. Nanoscale 2016, 8, 9498–9503. [Google Scholar] [CrossRef] [PubMed]

- Madani, A.; Harazim, S.M.; Quiñones, V.A.B.; Kleinert, M.; Finn, A.; Naz, E.S.G.; Ma, L.; Schmidt, O.G. Optical microtube cavities monolithically integrated on photonic chips for optofluidic sensing. Opt. Lett. 2017, 42, 486–489. [Google Scholar] [CrossRef] [PubMed]

- Madani, A.; Böttner, S.; Jorgensen, M.R.; Schmidt, O.G. Rolled-up TiO2 optical microcavities for telecom and visible photonics. Opt. Lett. 2014, 39, 189–192. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.M.; Oulton, R.F.; Sorger, V.J.; Bartal, G.; Zhang, X.A. Room temperature plasmon laser by total internal reflection. Nat. Mater. 2011, 10, 110–113. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Gu, Z.; Xiao, S.; Song, Q. Three-dimensional light confinement in a PT-symmetric nanocavity. RSC Adv. 2016, 6, 5792–5796. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Li, F.; Liu, Y.; Yao, F.; Liu, S. Surface Plasmon Nanolaser: Principle, Structure, Characteristics and Applications. Appl. Sci. 2019, 9, 861. https://doi.org/10.3390/app9050861

Xu L, Li F, Liu Y, Yao F, Liu S. Surface Plasmon Nanolaser: Principle, Structure, Characteristics and Applications. Applied Sciences. 2019; 9(5):861. https://doi.org/10.3390/app9050861

Chicago/Turabian StyleXu, Litu, Fang Li, Yahui Liu, Fuqiang Yao, and Shuai Liu. 2019. "Surface Plasmon Nanolaser: Principle, Structure, Characteristics and Applications" Applied Sciences 9, no. 5: 861. https://doi.org/10.3390/app9050861

APA StyleXu, L., Li, F., Liu, Y., Yao, F., & Liu, S. (2019). Surface Plasmon Nanolaser: Principle, Structure, Characteristics and Applications. Applied Sciences, 9(5), 861. https://doi.org/10.3390/app9050861