3D Printing of Functional Strawberry Snacks: Food Design, Texture, Antioxidant Bioactive Compounds, and Microbial Stability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemical and Standards

2.2. Preparation of Fruit Material

2.3. 3D Printing of Snacks

2.4. Characterization of 3DP Products

2.4.1. Determination of pH and Water Activity (aw)

2.4.2. Determination of Bioactive Compounds and Antioxidant Capacity

- Determination of Total Phenolic Content (TPC)

- Determination of Total Monomeric Anthocyanins (ANT)

- Determination of Total Flavonoids (TF)

- Determination of Total Hydroxycinnamic Acids (HCA) and Total Flavonols (FL)

- Determination of Condensed Tannins (CT)

- Determination of Antioxidant Capacity (AOC)

- DPPH MethodThe antioxidant activity was determined using the spectrophotometric DPPH method described in the literature [28]. Briefly, 1.5 mL of the properly diluted extract and 3 mL of a 0.5 mM DPPH solution were pipetted into a glass test tube. As a control, 1.5 mL of 100% methanol and 3 mL of 0.5 mM DPPH solution were pipetted. Pure methanol was used as a blank. After setting up the reaction, the test tubes were kept in the dark for 20 min and then the absorbance was measured at 517 nm. Parallel measurements were performed for each sample. Antioxidant activity was calculated using a calibration curve generated with different concentrations of Trolox solution (10–150 µM) and the results were expressed as µM rolox equivalent (TE) per 100 g of the sample.

- FRAP (Ferric Reducing Antioxidant Power) MethodAnother method used to determine antioxidant activity was the spectrophotometric FRAP method described in the literature [29]. Briefly, 600 μL of the previously appropriately diluted extract and 4.5 mL of the FRAP reagent (prepared from acetate buffer (0.3 M), 2.5 mL of TPTZ reagent (2,4,6-tris-2-pyridyl-s-triazine; 10 mM), and 2.5 mL of iron (III) chloride (20 mM) in a ratio of 10:1:1) were pipetted into the glass tubes. Briefly, the reaction mixture was homogenized on a vortex shaker (Grant Instruments Ltd., Cambs, England) and thermostatted in a water bath at 37 °C for 10 min. For the blank sample, the determination procedure was identical except that the extraction solvent was used instead of the extract. After 10 min, the absorbance was read at 593 nm. Ferric reducing antioxidant power was calculated from a calibration curve obtained with different concentrations of Trolox solution (10–150 µM), and the results were expressed as mM Trolox equivalent (TE) per 100 g of the sample.

2.5. Determination of Color Parameters

2.6. Texture Analysis

2.6.1. Penetration Test

2.6.2. Forward Extrusion Test

2.7. Microscopic Analysis

2.8. Particle Size Distribution and Dimension Measurement of 3DP Samples

2.9. Shelf-Life Study

2.10. Statistical Analysis

3. Results and Discussion

3.1. The Influence of 3DP Technology on aw and pH

3.2. The Influence of 3DP Technology on the Stability of Bioactive Compounds and Antioxidant Capacity

3.3. The Influence of 3DP Technology on Color Parameters, Microscopic Analysis, and 3DP Dimension Measurement

3.4. The Influence of 3DP Technology on Texture Properties and Particle Size Distribution

3.5. Microbial Analyses of 3DP Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kerry Group. ProActive Health Division Global Survey. Available online: https://www.kerry.com/ (accessed on 29 November 2022).

- Bursać Kovačević, D.; Brdar, D.; Fabečić, P.; Barba, F.J.; Lorenzo, J.M.; Putnik, P. Strategies to achieve a healthy and balanced diet: Fruits and vegetables as a natural source of bioactive compounds. In Agri-Food Industry Strategies for Healthy Diets and Sustainability; Barba, F.J., Putnik, P., Bursać Kovačević, D., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 51–88. [Google Scholar]

- Giampieri, F.; Forbes-Hernandez, T.Y.; Gasparrini, M.; Alvarez-Suarez, J.M.; Afrin, S.; Bompadre, S.; Quiles, J.L.; Mezzetti, B.; Battino, M. Strawberry as a health promoter: An evidence based review. Food Funct. 2015, 6, 1386–1398. [Google Scholar] [CrossRef]

- WHO. Healthy Diet. Available online: https://www.who.int/news-room/fact-sheets/detail/healthy-diet (accessed on 29 November 2022).

- Ricci, I.; Derossi, A.; Severini, C. 3D printed food from fruits and vegetables. In Fundamentals of 3D Food Printing and Applications; Academic Press: Cambridge, MA, USA, 2019; pp. 117–149. [Google Scholar]

- Severini, C.; Derossi, A. Could the 3D printing technology be a useful strategy to obtain customized nutrition? J. Clin. Gastroenterol. 2016, 50, S175–S178. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Azzollini, D.; Severini, C. Application of 3D printing for customized food. A case on the development of a fruit-based snack for children. J. Food Eng. 2018, 220, 65–75. [Google Scholar] [CrossRef]

- Severini, C.; Derossi, A.; Ricci, I.; Caporizzi, R.; Fiore, A. Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. J. Food Eng. 2018, 220, 89–100. [Google Scholar] [CrossRef]

- Tran, J.L. Safety and labelling of 3D printed food. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandari, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 355–371. [Google Scholar]

- Cerrutti, P.; Alzamora, S.M.; Vidales, S.L. Vanillin as an antimicrobial for producing shelf-stable strawberry puree. J. Food Sci. 1997, 62, 608–610. [Google Scholar] [CrossRef]

- Ferrario, M.; Fenoglio, D.; Chantada, A.; Guerrero, S. Hurdle processing of turbid fruit juices involving encapsulated citral and vanillin addition and UV-C treatment. Int. J. Food Microbiol. 2020, 332, 108811. [Google Scholar] [CrossRef]

- Cassani, L.; Tomadoni, B.; Viacava, G.; Ponce, A.; Moreira, M.R. Enhancing quality attributes of fiber-enriched strawberry juice by application of vanillin or geraniol. LWT—Food Sci. Technol. 2016, 72, 90–98. [Google Scholar] [CrossRef]

- Tabanelli, G.; Montanari, C.; Arioli, S.; Magnani, M.; Patrignani, F.; Lanciotti, R.; Mora, D.; Gardini, F. Physiological response of Saccharomyces cerevisiae to citral combined with thermal treatment. LWT—Food Sci. Technol. 2019, 101, 827–834. [Google Scholar] [CrossRef]

- Patrignani, F.; Tabanelli, G.; Siroli, L.; Gardini, F.; Lanciotti, R. Combined effects of high pressure homogenization treatment and citral on microbiological quality of apricot juice. Int. J. Food Microbiol. 2013, 160, 273–281. [Google Scholar] [CrossRef]

- Char, C.D.; Guerrero, S.N.; Alzamora, S.M. Mild thermal process combined with vanillin plus citral to help shorten the inactivation time for Listeria innocua in orange juice. Food Bioprocess Technol. 2008, 3, 752–761. [Google Scholar] [CrossRef]

- Tomadoni, B.; Viacava, G.; Cassani, L.; Moreira, M.R.; Ponce, A. Novel biopreservatives to enhance the safety and quality of strawberry juice. J. Food Sci. Technol. 2015, 53, 281–292. [Google Scholar] [CrossRef]

- Yang, F.; Guo, C.; Zhang, M.; Bhandari, B.; Liu, Y. Improving 3D printing process of lemon juice gel based on fluid flow numerical simulation. LWT—Food Sci. Technol. 2019, 102, 89–99. [Google Scholar] [CrossRef]

- Azam, S.M.R.; Zhang, M.; Mujumdar, A.S.; Yang, C. Study on 3D printing of orange concentrate and material characteristics. J. Food Process Eng. 2018, 41, e12689. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef]

- Mu, J.; Wu, G.; Chen, Z.; Klosek, A.; Brennan, M.A.; Hui, X.; Brennan, C.S. The effects of blackcurrant and strawberry powder on the physicochemical and in vitro glycaemic response of starches derived from sweet potato (Ipomoea batatas) and potato (Solanum tuberosum). Int. J. Food Sci. Technol. 2021, 56, 6062–6072. [Google Scholar] [CrossRef]

- Bursać Kovačević, D.; Putnik, P.; Dragović-Uzelac, V.; Pedisić, S.; Režek Jambrak, A.; Herceg, Z. Effects of cold atmospheric gas phase plasma on anthocyanins and color in pomegranate juice. Food Chem. 2016, 190, 317–323. [Google Scholar] [CrossRef]

- Yuan, B.; Danao, M.-G.C.; Stratton, J.E.; Weier, S.A.; Weller, C.L.; Lu, M. High pressure processing (HPP) of aronia berry purée: Effects on physicochemical properties, microbial counts, bioactive compounds, and antioxidant capacities. Innov. Food Sci. Emerg. Technol. 2018, 47, 249–255. [Google Scholar] [CrossRef]

- Bebek Markovinović, A.; Putnik, P.; Stulić, V.; Batur, L.; Duralija, B.; Pavlić, B.; Vukušić Pavičić, T.; Herceg, Z.; Bursać Kovačević, D. The application and optimization of HIPEF technology in the processing of juice from strawberries harvested at two stages of ripeness. Foods 2022, 11, 1997. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis: Changes in Official Methods of Analysis Made at the Annual Meeting; AOAC International: Rockville, MD, USA, 1990. [Google Scholar]

- Chang, C.C.; Yang, M.H.; Wen, H.M.; Chern, J.C. Estimation of total flavonoid content in propolis by two complementary colorimetric methods. J. Food Drug Anal. 2002, 10, 178–182. [Google Scholar]

- Howard, L.R.; Clark, J.R.; Brownmiller, C. Antioxidant capacity and phenolic content in blueberries as affected by genotype and growing season. J. Sci. Food Agric. 2003, 83, 1238–1247. [Google Scholar] [CrossRef]

- Sun, B.; Ricardo-da-Silva, J.M.; Spranger, I. Critical factors of vanillin assay for catechins and proanthocyanidins. J. Agric. Food Chem. 1998, 46, 4267–4274. [Google Scholar] [CrossRef]

- Shortle, E.; O’Grady, M.N.; Gilroy, D.; Furey, A.; Quinn, N.; Kerry, J.P. Influence of extraction technique on the anti-oxidative potential of hawthorn (Crataegus monogyna) extracts in bovine muscle homogenates. Meat Sci. 2014, 98, 828–834. [Google Scholar] [CrossRef] [PubMed]

- Benzie, I.F.F. An automated, specific, spectrophotometric method for measuring ascorbic acid in plasma (EFTSA). Clin. Biochem. 1996, 29, 111–116. [Google Scholar] [CrossRef] [PubMed]

- Keerthana, K.; Anukiruthika, T.; Moses, J.A.; Anandharamakrishnan, C. Development of fiber-enriched 3D printed snacks from alternative foods: A study on button mushroom. J. Food Eng. 2020, 287, 110116. [Google Scholar] [CrossRef]

- Putnik, P.; Bursać Kovačević, D.; Herceg, K.; Levaj, B. Influence of antibrowning solutions, air exposure, and ultrasound on color changes in fresh-cut apples during storage. J. Food Process. Preserv. 2017, 41, e13288. [Google Scholar] [CrossRef]

- Orizano-Ponce, E.; Char, C.; Sepúlveda, F.; Ortiz-Viedma, J. Heat sensitization of Escherichia coli by the natural antimicrobials vanillin and emulsified citral in blended carrot-orange juice. Food Microbiol. 2022, 107, 104058. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Regulation (EC) No 2073/2005 of the European Parliament and of the Council of 29 April 2004 on Microbiological Criteria for Foodstuffs; 338/1; OJEU: Brussels, Belgium, 2005. [Google Scholar]

- Dogan, M.; Toker, O.S.; Goksel, M. Rheological behaviour of instant hot chocolate beverage: Part 1. Optimization of the effect of different starches and gums. Food Biophys. 2011, 6, 512–518. [Google Scholar] [CrossRef]

- Evans, I.D.; Haisman, D.R. The effect of solutes on the gelatinization temperature range of potato starch. Starch 1982, 34, 224–231. [Google Scholar] [CrossRef]

- Keysers, H. Unterschiede in der KristallisationsbestaÈndigkeit zwischen Invertzucker und High-Fructose-Glukosesirup sowie deren Weichhaltewirkung. Zucker U. SuÈûwarenwirtschaft 1982, 35, 147. [Google Scholar]

- Rababah, T.M.; Al-u’datt, M.H.; Al-Mahasneh, M.A.; Feng, H.; Alothman, A.M.; Almajwal, A.; Yang, W.; Kilani, I.; Alhamad, M.N.; Ereifej, K.; et al. Effect of storage on the physicochemical properties, total phenolic, anthocyanin, and antioxidant capacity of strawberry jam. J. Food Agric. Environ. 2011, 9, 101–105. [Google Scholar]

- Bravo-Núñez, Á.; Garzón, R.; Rosell, C.M.; Gómez, M. Evaluation of Starch–Protein Interactions as a Function of pH. Foods 2019, 8, 155. [Google Scholar] [CrossRef] [PubMed]

- Granato, D.; Barba, F.J.; Bursać Kovačević, D.; Lorenzo, J.M.; Cruz, A.G.; Putnik, P. Functional Foods: Product Development, Technological Trends, Efficacy Testing, and Safety. Annu. Rev. Food Sci. Technol. 2020, 11, 93–118. [Google Scholar] [CrossRef] [PubMed]

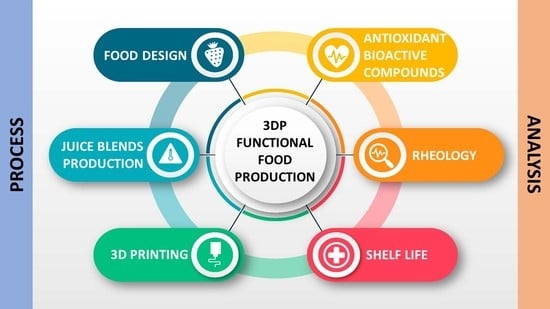

- Tomašević, I.; Putnik, P.; Valjak, F.; Pavlić, B.; Šojić, B.; Bebek Markovinović, A.; Bursać Kovačević, D. 3D printing as novel tool for fruit-based functional food production. Curr. Opin. Food Sci. 2021, 41, 138–145. [Google Scholar] [CrossRef]

- Chen, X.D. Food drying fundamentals. In Drying Technologies in Food Processing; Chen, X.D., Mujumdar, A.S., Eds.; Blackwell Publishing: Singapore, 2008; pp. 1–55. [Google Scholar]

- Liu, P.; Dang, X.; Woo, M.W.; Chattha, S.A.; An, J.; Shan, Z. Feasibility study of starch-based biomass incorporated 3D printed beef. Starch-Stärke 2022, 74, 2200030. [Google Scholar] [CrossRef]

- Zhang, F.; Fang, L.; Wang, C.; Shi, L.; Chang, T.; Yang, H.; Cui, M. Effects of starches on the textural, rheological, and color properties of surimi–beef gels with microbial tranglutaminase. Meat Sci. 2013, 93, 533–537. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Zhang, M.; Bhandari, B.; Liu, Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT—Food Sci. Technol. 2018, 87, 67–76. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, M.; Bhandari, B. Controlling the three-dimensional printing mechanical properties of Nostoc Sphaeroides system. Food Biophys. 2019, 15, 240–248. [Google Scholar] [CrossRef]

- Dong, X.; Huang, Y.; Pan, Y.; Wang, K.; Prakash, S.; Zhu, B. Investigation of sweet potato starch as a structural enhancer for three-dimensional printing of Scomberomorus niphonius surimi. J. Texture Stud. 2019, 50, 316–324. [Google Scholar] [CrossRef]

- Zheng, L.; Yu, Y.; Tong, Z.; Zou, Q.; Han, S.; Jiang, H. The characteristics of starch gels molded by 3D printing. J. Food Process. Preserv. 2019, 43, e13993. [Google Scholar] [CrossRef]

- Pereira, T.; Barroso, S.; Gil, M.M. Food texture design by 3D printing: A review. Foods 2021, 10, 320. [Google Scholar] [CrossRef]

- Theagarajan, R.; Moses, J.A.; Anandharamakrishnan, C. 3D extrusion printability of rice starch and optimization of process variables. Food Bioprocess Technol. 2020, 13, 1048–1062. [Google Scholar] [CrossRef]

- Wilms, P.; Daffner, K.; Kern, C.; Gras, S.L.; Schutyser, M.A.I.; Kohlus, R. Formulation engineering of food systems for 3D-printing applications—A review. Food Res. Int. 2021, 148, 110585. [Google Scholar] [CrossRef] [PubMed]

| Sample | Starch Type | Starch Content | 3D Program |

|---|---|---|---|

| 1 | Control sample | - | - |

| 2 | Corn starch | 10% | Program 1 |

| 3 | Corn starch | 10% | Program 2 |

| 4 | Corn starch | 15% | Program 1 |

| 5 | Corn starch | 15% | Program 2 |

| 6 | Corn starch | 20% | Program 1 |

| 7 | Corn starch | 20% | Program 2 |

| 8 | Wheat starch | 10% | Program 1 |

| 9 | Wheat starch | 10% | Program 2 |

| 10 | Wheat starch | 15% | Program 1 |

| 11 | Wheat starch | 15% | Program 2 |

| 12 | Wheat starch | 20% | Program 1 |

| 13 | Wheat starch | 20% | Program 2 |

| Variable | n | aw | pH |

|---|---|---|---|

| Starch type | p ≤ 0.01 † | p ≤ 0.01 † | |

| Corn | 12 | 0.94 ± 0.0 b | 3.38 ± 0.0 b |

| Wheat | 12 | 0.95 ± 0.0 a | 3.50 ± 0.0 a |

| Starch content | p ≤ 0.01 † | p ≤ 0.01 † | |

| 10% | 8 | 0.94 ± 0.0 b | 3.25 ± 0.0 b |

| 15% | 8 | 0.96 ± 0.0 a | 3.53 ± 0.0 a |

| 20% | 8 | 0.95 ± 0.0 a | 3.53 ± 0.0 a |

| 3D Program | p = 0.12 ‡ | p ≤ 0.01 † | |

| Program 1 | 12 | 0.95 ± 0.0 a | 3.35 ± 0.0 b |

| Program 2 | 12 | 0.95 ± 0.0 a | 3.53 ± 0.0 a |

| Dataset average | 24 | 0.95 ± 0.0 | 3.53 ± 0.0 |

| Variable | n | TPC | HCA | FL | TF | ANT | CT | DPPH | FRAP |

|---|---|---|---|---|---|---|---|---|---|

| Starch type | p ≤ 0.01 † | p ≤ 0.01 † | p ≤ 0.01 † | p ≤ 0.01 † | p = 0.04 † | p = 0.01 † | p ≤ 0.01 † | p ≤ 0.01 † | |

| Corn | 12 | 74.47 ± 1.08 b | 19.44 ± 0.25 a | 6.90 ± 0.16 a | 5.30 ± 0.05 a | 7.50 ± 0.03 b | 43.90 ± 0.27 b | 487.83 ± 0.41 a | 1.19 ± 0.02 b |

| Wheat | 12 | 82.66 ± 1.08 a | 13.64 ± 0.25 b | 3.70 ± 0.16 b | 4.50 ± 0.05 b | 7.61 ± 0.03 a | 45.01 ± 0.27 a | 486.08 ± 0.41 b | 1.29 ± 0.02 a |

| Starch content | p = 0.54 ‡ | p = 0.09 ‡ | p ≤ 0.01 † | p = 0.04 † | p ≤ 0.01 † | p ≤ 0.01 † | p ≤ 0.01 † | p ≤ 0.01 † | |

| 10% | 8 | 77.4 ± 1.32 a | 16.00 ± 0.30 a | 4.47 ± 0.20 c | 4.86 ± 0.06 a,b | 7.82 ± 0.04 a | 45.02 ± 0.33 b | 515.76 ± 0.50 a | 1.24 ± 0.02 b |

| 15% | 8 | 79.48 ± 1.32 a | 17.04 ± 0.30 a | 6.06 ± 0.20 a | 5.04 ± 0.06 a | 7.94 ± 0.04 a | 47.14 ± 0.33 a | 489.15 ± 0.50 b | 1.32 ± 0.02 a |

| 20% | 8 | 78.83 ± 1.32 a | 16.58 ± 0.30 a | 5.37 ± 0.20 b | 4.80 ± 0.06 b | 6.91 ± 0.04 b | 41.20 ± 0.33 c | 455.97 ± 0.50 c | 1.16 ± 0.02 c |

| 3D Program | p = 0.03 † | p = 0.08 ‡ | p = 0.09 ‡ | p ≤ 0.01 † | p ≤ 0.01 † | p = 0.02 † | p ≤ 0.01 † | p = 0.08 ‡ | |

| Program 1 | 12 | 76.62 ± 1.08 b | 16.21 ± 0.25 a | 5.32 ± 0.16 a | 4.79 ± 0.05 b | 7.43 ± 0.03 b | 43.96 ± 0.27 b | 485.26 ± 0.41 b | 1.22 ± 0.02 a |

| Program 2 | 12 | 80.51 ± 1.08 a | 16.87 ± 0.25 a | 5.28 ± 0.16 a | 5.01 ± 0.05 a | 7.69 ± 0.03 a | 44.95 ± 0.27 a | 488.66 ± 0.41 a | 1.27 ± 0.02 a |

| Dataset average | 24 | 78.57 ± 1.08 | 16.54 ± 0.18 | 5.30 ± 0.12 | 4.90 ± 0.04 | 7.56 ± 0.02 | 44.46 ± 0.19 | 486.96 ± 0.29 | 1.24 ± 0.01 |

| 3DP Program | Type of Starch | Starch Content (%) | L* | a* | b* | C* | h (°) | ΔE* |

|---|---|---|---|---|---|---|---|---|

| Control sample | / | / | 24.84 | 30.42 | 20.88 | 36.90 | 34.46 | / |

| Program 1 | corn | 10 | 34.16 | 22.64 | 7.50 | 23.85 | 18.33 | 18.07 |

| corn | 15 | 35.90 | 24.12 | 10.82 | 26.44 | 24.16 | 16.22 | |

| corn | 20 | 44.10 | 27.32 | 12.22 | 29.93 | 24.09 | 21.34 | |

| wheat | 10 | 38.64 | 27.52 | 11.76 | 29.93 | 23.14 | 16.79 | |

| wheat | 15 | 34.44 | 22.64 | 9.50 | 24.55 | 22.76 | 16.78 | |

| wheat | 20 | 39.54 | 24.46 | 9.74 | 26.33 | 21.71 | 19.38 | |

| Program 2 | corn | 10 | 34.20 | 23.10 | 8.86 | 24.74 | 20.98 | 16.91 |

| corn | 15 | 33.52 | 22.54 | 10.04 | 24.67 | 24.01 | 15.97 | |

| corn | 20 | 43.94 | 26.68 | 12.98 | 29.67 | 25.94 | 21.01 | |

| wheat | 10 | 34.90 | 27.52 | 11.76 | 29.93 | 23.14 | 13.88 | |

| wheat | 15 | 33.40 | 22.8 | 11.10 | 25.36 | 25.96 | 15.07 | |

| wheat | 20 | 39.24 | 23.22 | 10.14 | 25.34 | 23.59 | 19.35 |

| Parameter | 3DP Program | Type of Starch | Starch Content |

|---|---|---|---|

| L* | 0.34 | 0.47 | ≤0.01 * |

| a* | 0.72 | 0.82 | 0.29 |

| b* | 0.60 | 0.80 | 0.59 |

| C* | 0.89 | 0.82 | 0.42 |

| h | 0.17 | 0.66 | 0.11 |

| Fp | 0.07 | 0.03 * | 0.04 * |

| Wp | 0.11 | 0.26 | 0.02 * |

| F | 1.00 | ≤0.01 * | 0.02 * |

| W | 0.99 | ≤0.01 * | 0.02 * |

| D (3.2) | 0.95 | 0.05 * | ≤0.01 * |

| D (4.3) | 0.95 | 0.05 * | ≤0.01 * |

| d (0.1) | 0.82 | ≤0.01 * | ≤0.01 * |

| d (0.5) | 0.85 | 0.85 | ≤0.01 * |

| d (0.9) | 0.25 | 0.20 | ≤0.01 * |

| Length | 0.51 | 0.06 | 0.23 |

| Width | 0.52 | 0.54 | 0.40 |

| Height | 0.76 | 0.78 | 0.16 |

| 3DP Program | Type of Starch | Starch Content (%) | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|

| Program 1 | corn | 10 | 53.36 ± 0.53 | 51.22 ± 0.49 | 12.24 ± 0.29 |

| corn | 15 | 52.11 ± 0.56 | 51.45 ± 0.25 | 12.41 ± 0.23 | |

| corn | 20 | 52.12 ± 0.66 | 51.76 ± 0.31 | 12.49 ± 0.38 | |

| wheat | 10 | 52.25 ± 0.31 | 51.33 ± 0.51 | 11.72 ± 0.76 | |

| wheat | 15 | 52.26 ± 0.41 | 51.36 ± 0.14 | 12.25 ± 0.38 | |

| wheat | 20 | 51.76 ± 0.38 | 50.98 ± 0.91 | 12.36 ± 0.88 | |

| Program 2 | corn | 10 | 52.12 ± 0.89 | 51.11 ± 0.75 | 11.87 ± 0.48 |

| corn | 15 | 53.28 ± 0.39 | 51.25 ± 0.57 | 11.81 ± 0.71 | |

| corn | 20 | 52.23 ± 0.62 | 51.34 ± 0.67 | 12.66 ± 0.43 | |

| wheat | 10 | 52.25 ± 0.54 | 51.25 ± 0.55 | 12.41 ± 0.27 | |

| wheat | 15 | 51.56 ± 0.37 | 51.46 ± 0.77 | 12.49 ± 0.57 | |

| wheat | 20 | 51.22 ± 0.67 | 52.91 ± 0.39 | 12.55 ± 0.64 |

| 3DP Program | Type of Starch | Starch Content (%) | F (N) | W (Nmm) | Fp (N) | Wp (Nmm) |

|---|---|---|---|---|---|---|

| Program 1 | corn | 10 | 53.538 | 535.200 | 0.143 | 0.115 |

| corn | 15 | 50.437 | 504.279 | 0.278 | 0.116 | |

| corn | 20 | 95.881 | 958.52 | 0.18 | 0.129 | |

| wheat | 10 | 98.543 | 985.129 | 0.073 | 0.074 | |

| wheat | 15 | 177.914 | 1778.729 | 0.147 | 0.149 | |

| wheat | 20 | 162.755 | 1627.201 | 0.139 | 0.145 | |

| Program 2 | corn | 10 | 39.367 | 393.599 | 0.084 | 0.077 |

| corn | 15 | 37.723 | 377.149 | 0.14 | 0.092 | |

| corn | 20 | 92.904 | 917.987 | 0.173 | 0.106 | |

| wheat | 10 | 99.029 | 990.085 | 0.085 | 0.081 | |

| wheat | 15 | 182.785 | 1827.473 | 0.126 | 0.118 | |

| wheat | 20 | 187.259 | 1872.168 | 0.108 | 0.143 |

| 3DP Program | Type of Starch | Starch Content (%) | D (3.2) (µm) | D (4.3) (µm) | d (0.1) (µm) | d (0.5) (µm) | d (0.9) (µm) |

|---|---|---|---|---|---|---|---|

| Program 1 | corn | 10 | 49.56 | 23.563 | 21.391 | 122.724 | 598.039 |

| corn | 15 | 25.763 | 116.602 | 12.901 | 35.68 | 357.256 | |

| corn | 20 | 22.458 | 76.682 | 11.468 | 31.748 | 234.055 | |

| wheat | 10 | 44.827 | 176.767 | 22.855 | 74.155 | 489.584 | |

| wheat | 15 | 30.226 | 90.956 | 15.759 | 46.31 | 168.747 | |

| wheat | 20 | 27.99 | 94.021 | 14 | 43.511 | 287.481 | |

| Program 2 | corn | 10 | 44.133 | 221.151 | 19.313 | 95.741 | 591.564 |

| corn | 15 | 25.945 | 119.374 | 12.852 | 36.627 | 364.902 | |

| corn | 20 | 21.959 | 84.936 | 10.757 | 31.725 | 262.309 | |

| wheat | 10 | 48.053 | 201.603 | 24.092 | 84.512 | 541.467 | |

| wheat | 15 | 33.328 | 126.287 | 16.924 | 51.738 | 362.298 | |

| wheat | 20 | 28.011 | 92.548 | 13.804 | 43.546 | 270.289 |

| Microorganism Type | Sample | Days of Storage | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 7 | 10 | ||

| Aerobic mesophilic bacteria | control | 1.5 × 102 | 9 × 102 | 1.8 × 103 | n.d. | n.d. |

| vanillin 1 g L−1 | n.d. | 9 × 102 | 9 × 102 | 3.8 × 104 * | 9 × 104 * | |

| vanillin 2 g L−1 | n.d. | n.d. | 9 × 104 * | n.d. | 9 × 102 | |

| citral 75 mg L−1 | 1.8 × 103 | n.d. | n.d. | n.d. | n.d. | |

| citral 150 mg L−1 | 1.5 × 102 | 9 × 102 | 3,6 × 103 | n.d. | n.d. | |

| Enterobacteriaceae | control | n.d. | n.d. | n.d. | n.d. | n.d. |

| vanillin 1 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| vanillin 2 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 75 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 150 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| Salmonella sp. | control | n.d. | n.d. | n.d. | n.d. | n.d. |

| vanillin 1 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| vanillin 2 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 75 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 150 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| Escherichia coli | control | n.d. | n.d. | n.d. | n.d. | n.d. |

| vanillin 1 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| vanillin 2 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 75 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 150 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| Yeasts and molds | control | n.d. | n.d. | n.d. | n.d. | n.d. |

| vanillin 1 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| vanillin 2 g L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 75 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

| citral 150 mg L−1 | n.d. | n.d. | n.d. | n.d. | n.d. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bebek Markovinović, A.; Putnik, P.; Bosiljkov, T.; Kostelac, D.; Frece, J.; Markov, K.; Žigolić, A.; Kaurinović, J.; Pavlić, B.; Duralija, B.; et al. 3D Printing of Functional Strawberry Snacks: Food Design, Texture, Antioxidant Bioactive Compounds, and Microbial Stability. Antioxidants 2023, 12, 436. https://doi.org/10.3390/antiox12020436

Bebek Markovinović A, Putnik P, Bosiljkov T, Kostelac D, Frece J, Markov K, Žigolić A, Kaurinović J, Pavlić B, Duralija B, et al. 3D Printing of Functional Strawberry Snacks: Food Design, Texture, Antioxidant Bioactive Compounds, and Microbial Stability. Antioxidants. 2023; 12(2):436. https://doi.org/10.3390/antiox12020436

Chicago/Turabian StyleBebek Markovinović, Anica, Predrag Putnik, Tomislav Bosiljkov, Deni Kostelac, Jadranka Frece, Ksenija Markov, Adrijana Žigolić, Jelena Kaurinović, Branimir Pavlić, Boris Duralija, and et al. 2023. "3D Printing of Functional Strawberry Snacks: Food Design, Texture, Antioxidant Bioactive Compounds, and Microbial Stability" Antioxidants 12, no. 2: 436. https://doi.org/10.3390/antiox12020436

APA StyleBebek Markovinović, A., Putnik, P., Bosiljkov, T., Kostelac, D., Frece, J., Markov, K., Žigolić, A., Kaurinović, J., Pavlić, B., Duralija, B., Zavadlav, S., & Bursać Kovačević, D. (2023). 3D Printing of Functional Strawberry Snacks: Food Design, Texture, Antioxidant Bioactive Compounds, and Microbial Stability. Antioxidants, 12(2), 436. https://doi.org/10.3390/antiox12020436