Optimization of Air Backwash Frequency during the Ultrafiltration of Seawater

Abstract

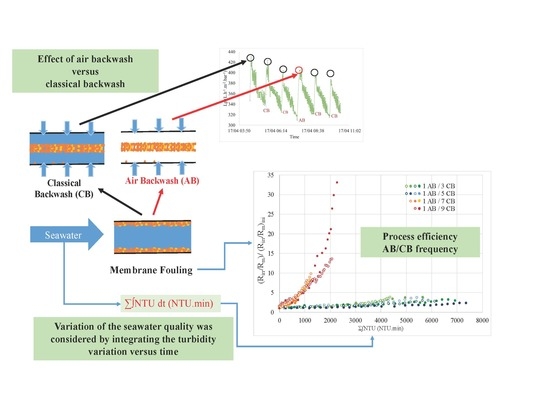

:- New air backwash in two steps

- New method based on turbidity integration to check the air backwash/backwash efficiency.

1. Introduction

2. Permeability and Resistance

3. Material and Methods

4. Results and Discussion

4.1. Air Backwash and Classical Backwash

4.2. Effect of Air Backwash Frequency

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fadzil, A.F.A.; Alwi, S.R.W.; Manan, Z.; Klemeš, J.J. Industrial site water minimisation via one-way centralised water reuse header. J. Clean. Prod. 2018, 200, 174–187. [Google Scholar] [CrossRef]

- Cherchi, C.; Kesaano, M.; Badruzzaman, M.; Schwab, K.; Jacangelo, J.G. Municipal reclaimed water for multi-purpose applications in the power sector: A review. J. Environ. Manag. 2019, 236, 561–570. [Google Scholar] [CrossRef] [PubMed]

- Deviller, G.; Lundy, L.; Fatta-Kassinos, D. Recommendations to derive quality standards for chemical pollutants in reclaimed water intended for reuse in agricultural irrigation. Chemosphere 2020, 240. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Liang, H.; Qu, F.; Liu, B.; Yu, H.; Du, X.; Li, G.; Snyder, S.A. Hydraulic backwashing for low-pressure membranes in drinking water treatment: A review. J. Memb. Sci. 2017, 540, 362–380. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E. Advantages and disadvantages of techniques used for wastewater treatment. Environ. Chem. Lett. 2019, 17, 145–155. [Google Scholar] [CrossRef]

- Li, X.; Jiang, L.; Li, H. Application of ultrafiltration technology in water treatment. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 186. [Google Scholar] [CrossRef]

- Cordier, C.; Charpin, L.; Stavrakakis, C.; Papin, M.; Guyomard, K.; Sauvade, P.; Coelho, F.; Moulin, P. Ultrafiltration: A solution to recycle the breeding waters in shellfish production. Aquaculture 2019, 504, 30–38. [Google Scholar] [CrossRef] [Green Version]

- Foglia, A.; Akyol, Ç.; Frison, N.; Katsou, E.; Eusebi, A.L.; Fatone, F. Long-term operation of a pilot-scale anaerobic membrane bioreactor (AnMBR) treating high salinity low loaded municipal wastewater in real environment. Sep. Purif. Technol. 2020, 236, 116279. [Google Scholar] [CrossRef]

- Chew, C.M.; Aroua, M.K.; Hussain, M.A.; Ismail, W.M.Z.W. Evaluation of ultrafiltration and conventional water treatment systems for sustainable development: An industrial scale case study. J. Clean. Prod. 2016, 112, 3152–3163. [Google Scholar] [CrossRef]

- Bai, L.; Qu, F.; Liang, H.; Ma, J.; Chang, H.; Wang, M.; Li, G. Membrane fouling during ultrafiltration (UF) of surface water: Effects of sludge discharge interval (SDI). Desalination 2013, 319, 18–24. [Google Scholar] [CrossRef]

- Porcelli, N.; Judd, S. Chemical cleaning of potable water membranes: A review. Sep. Purif. Technol. 2010, 71, 137–143. [Google Scholar] [CrossRef] [Green Version]

- Cornelissen, E.R.; Vrouwenvelder, J.S.; Heijman, S.G.J.; Viallefont, X.D.; van der Kooij, D.; Wessels, L.P. Periodic air/water cleaning for control of biofouling in spiral wound membrane elements. J. Memb. Sci. 2007, 287, 94–101. [Google Scholar] [CrossRef]

- American Water Works Association. Microfiltration and Ultrafiltration Membranes for Drinking Water; American Water Works Association: Denver, CO, USA, 2005. [Google Scholar]

- Cabassud, C.; Laborie, S.; Durand-Bourlier, L.; Lainé, J.M. Air sparging in ultrafiltration hollow fibers: Relationship between flux enhancement, cake characteristics and hydrodynamic parameters. J. Memb. Sci. 2001, 181, 57–69. [Google Scholar] [CrossRef]

- Cordier, C.; Stavrakakis, C.; Sauvade, P.; Coelho, F.; Moulin, P. Air backwash efficiency on organic fouling of UF membranes applied to shellfish hatchery effluents. Membranes (Basel) 2018, 8, 48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cordier, C.; Stavrakakis, C.; Dupuy, B.; Papin, M.; Sauvade, P.; Coelho, F.; Moulin, P. Ultrafiltration for environment safety in shellfish production: Removal of oyster gametes in hatchery effluents. Aquac. Eng. 2019, 84, 80–90. [Google Scholar] [CrossRef] [Green Version]

- Chellam, S.; Jacangelo, J.G.; Bonacquisti, T.P. Modeling and experimental verification of pilot-scale hollow fiber, direct flow microfiltration with periodic backwashing. Environ. Sci. Technol. 1998, 32, 75–81. [Google Scholar] [CrossRef]

- Waterman, D. Bench-Scale Analysis of Ultra Filtration Membranes for Investigating Fouling by Natural Organic Matter in Surface Water. Ph.D. Thesis, University of Ottawa, Ottawa, ON, Canada, 2008. [Google Scholar]

- Lipp, P.; Baldauf, G. Application of out—In MF/UF-systems for drinking water treatment with air supported backwash—Three case studies. Desalination 2002, 147, 63–68. [Google Scholar] [CrossRef]

- Ye, Y.; Chen, V.; Le-Clech, P. Evolution of fouling deposition and removal on hollow fibre membrane during filtration with periodical backwash. Desalination, Special issue in honour of Professor Tony Fane on his 70th Birthday. Desalination 2011, 283, 198–205. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cordier, C.; Eljaddi, T.; Ibouroihim, N.; Stavrakakis, C.; Sauvade, P.; Coelho, F.; Moulin, P. Optimization of Air Backwash Frequency during the Ultrafiltration of Seawater. Membranes 2020, 10, 78. https://doi.org/10.3390/membranes10040078

Cordier C, Eljaddi T, Ibouroihim N, Stavrakakis C, Sauvade P, Coelho F, Moulin P. Optimization of Air Backwash Frequency during the Ultrafiltration of Seawater. Membranes. 2020; 10(4):78. https://doi.org/10.3390/membranes10040078

Chicago/Turabian StyleCordier, Clemence, Tarik Eljaddi, Nadjim Ibouroihim, Christophe Stavrakakis, Patrick Sauvade, Franz Coelho, and Philippe Moulin. 2020. "Optimization of Air Backwash Frequency during the Ultrafiltration of Seawater" Membranes 10, no. 4: 78. https://doi.org/10.3390/membranes10040078

APA StyleCordier, C., Eljaddi, T., Ibouroihim, N., Stavrakakis, C., Sauvade, P., Coelho, F., & Moulin, P. (2020). Optimization of Air Backwash Frequency during the Ultrafiltration of Seawater. Membranes, 10(4), 78. https://doi.org/10.3390/membranes10040078