Modification and Functionalization of Fibers Formed by Electrospinning: A Review

Abstract

:1. Introduction

2. The Electrospinning Process

2.1. Influence of Solution, Process and Environmental Parameters

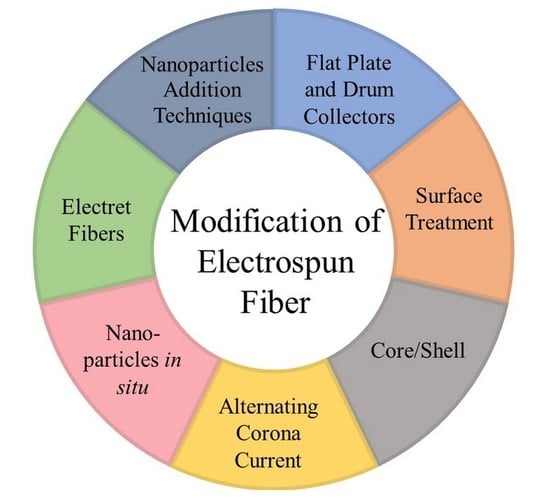

2.2. Fiber Modifications during the Electrospinning Process

2.2.1. Use of Flat Plate Collectors and Rotating Cylinders

2.2.2. Core/Shell Fibers

2.2.3. Electrospinning with Alternating Corona Current

2.2.4. Electret Fibers

2.2.5. Addition of Nanoparticles In Situ

2.3. Fiber Modifications after Electrospinning Process

2.3.1. Nanoparticles Addition Techniques

2.3.2. Reinforcing Composite Materials

2.3.3. Surface Treatment

3. Final Considerations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Quina, F.H. Nanotecnologia e o Meio Ambiente: Perspectivas e Riscos. Quim. Nova 2004, 27, 1028–1029. [Google Scholar] [CrossRef]

- Shao, J.; Xiao, X.; Fan, X.; Chen, L.; Zhu, H.; Yu, S.; Gong, Z.; Li, S.; Ge, H.; Wang, Q. A Low Temperature Mechanochemical Synthesis and Characterization of Amorphous Ni-B Ultrafine Nanoparticles. Mater. Lett. 2013, 109, 203–206. [Google Scholar] [CrossRef]

- Bamrungsap, S.; Zhao, Z.; Chen, T.; Wang, L.; Li, C.; Fu, T.; Tan, W. Nanotechnology in Therapeutics: A Focus on Nanoparticles as a Drug Delivery System. Nanomedicine 2012, 7, 1253–1271. [Google Scholar] [CrossRef] [PubMed]

- Langer, R.; Weissleder, R. Nanotechnology. J. Am. Med. Assoc. 2015, 313, 135–136. [Google Scholar] [CrossRef]

- Gyles, C. Nanotechnology. Can. Vet. J. La Rev. Vet. Can. 2012, 53, 819–822. [Google Scholar]

- Mu, L.; Sprando, R.L. Application of Nanotechnology in Cosmetics. Pharm. Res. 2010, 27, 1746–1749. [Google Scholar] [CrossRef]

- Liu, F.; Su, H.; Jin, L.; Zhang, H.; Chu, X.; Yang, W. Facile Synthesis of Ultrafine Cobalt Oxide Nanoparticles for High-Performance Supercapacitors. J. Colloid Interface Sci. 2017, 505, 796–804. [Google Scholar] [CrossRef]

- Yang, Q.; Liang, Q.; Liu, J.; Liang, S.; Tang, S.; Lu, P.; Lu, Y. Ultrafine MoO2 Nanoparticles Grown on Graphene Sheets as Anode Materials for Lithium-Ion Batteries. Mater. Lett. 2014, 127, 32–35. [Google Scholar] [CrossRef]

- Bannwarth, M.; Crespy, D. Combining the Best of Two Worlds: Nanoparticles and Nanofibers. Chem. Asian J. 2014, 9, 2030–2035. [Google Scholar] [CrossRef]

- Li, Y.; Yin, X.; Yu, J.; Ding, B. Electrospun Nanofibers for High-Performance Air Filtration. Compos. Commun. 2019, 15, 6–19. [Google Scholar] [CrossRef]

- Lou, L.; Osemwegie, O.; Ramkumar, S.S. Functional Nanofibers and Their Applications. Ind. Eng. Chem. Res. 2020, 59, 5439–5455. [Google Scholar] [CrossRef]

- Greiner, A.; Wendorff, J.H. Electrospinning: A Fascinating Method for the Preparation of Ultrathin Fibers. Angew. Chem. Int. Ed. 2007, 46, 5670–5703. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A Review on Polymer Nanofibers by Electrospinning and Their Applications in Nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Anitha, S.; Brabu, B.; Thiruvadigal, D.J.; Gopalakrishnan, C.; Natarajan, T.S. Optical, Bactericidal and Water Repellent Properties of Electrospun Nano-Composite Membranes of Cellulose Acetate and ZnO. Carbohydr. Polym. 2012, 87, 1065–1072. [Google Scholar] [CrossRef]

- Reneker, D.H.; Chun, I. Nanometre Diameter Fibres of Polymer, Produced by Electrospinning. Nanotechnology 1996, 7, 216–223. [Google Scholar] [CrossRef]

- Pham, Q.P.; Sharma, U.; Mikos, A.G. Electrospinning of Polymeric Nanofibers for Tissue Engineering Applications: A Review. Tissue Eng. 2006, 5, 1197–1211. [Google Scholar] [CrossRef]

- Doshi, J.; Reneker, D.H. Electrospinning Process and Applications of Electrospun Fibers. J. Electrostat. 1995, 35, 151–160. [Google Scholar] [CrossRef]

- Costa, R.G.F.; de Oliveira, J.E.; de Paula, G.F.; de S. Picciani, P.H.; de Medeiros, E.S.; Ribeiro, C.; Mattoso, L.H.C. Eletrofiação de Polímeros Em Solução: Parte I: Fundamentação Teórica. Polímeros 2012, 22, 170–177. [Google Scholar] [CrossRef]

- Corradini, E.; Curti, P.S.; da Silva Gonzalez, R.; Pereira, A.G.B.; Dragunski, D.C.; Martins, A.F.; Muniz, E.C. Preparation of Polymeric Mats Through Electrospinning for Technological Uses. In Recent Advances in Complex Functional Materials; Longo, E., de Almeida La Porta, F., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; p. 83. [Google Scholar]

- Pillay, V.; Dott, C.; Choonara, Y.E.; Tyagi, C.; Tomar, L.; Kumar, P.; Toit, L.C.; Ndesendo, V.M.K. A Review of the Effect of Processing Variables on the Fabrication of Electrospun Nanofibers for Drug Delivery Applications. J. Nanomater. 2013, 2013, 789289. [Google Scholar] [CrossRef]

- Thenmozhi, S.; Dharmaraj, N.; Kadirvelu, K.; Kim, H.Y. Electrospun Nanofibers: New Generation Materials for Advanced Applications. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2017, 217, 36–48. [Google Scholar] [CrossRef]

- Yao, L.; Lee, C.; Kim, J. Fabrication of Electrospun Meta-Aramid Nanofibers in Different Solvent Systems. Fibers Polym. 2010, 11, 1032–1040. [Google Scholar] [CrossRef]

- Jarusuwannapoom, T.; Hongrojjanawiwat, W.; Jitjaicham, S.; Wannatong, L.; Nithitanakul, M.; Pattamaprom, C.; Koombhongse, P.; Rangkupan, R.; Supaphol, P. Effect of Solvents on Electro-Spinnability of Polystyrene Solutions and Morphological Appearance of Resulting Electrospun Polystyrene Fibers. Eur. Polym. J. 2005, 41, 409–421. [Google Scholar] [CrossRef]

- Thompson, C.J.; Chase, G.G.; Yarin, A.L.; Reneker, D.H. Effects of Parameters on Nanofiber Diameter Determined from Electrospinning Model. Polymer 2007, 48, 6913–6922. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Fujihara, K.; Teo, W.-E.; Lim, T.-C.; Ma, Z. An Introduction to Electrospinning and Nanofibers; World Scientific: Singapore, 2005; ISBN 978-981-256-415-3. [Google Scholar]

- Shenoy, S.L.; Bates, W.D.; Frisch, H.L.; Wnek, G.E. Role of Chain Entanglements on Fiber Formation during Electrospinning of Polymer Solutions: Good Solvent, Non-Specific Polymer-Polymer Interaction Limit. Polymer 2005, 46, 3372–3384. [Google Scholar] [CrossRef]

- Costa, R.G.F.; de Oliveira, J.E.; de Paula, G.F.; de S. Picciani, P.H.; de Medeiros, E.S.; Ribeiro, C.; Mattoso, L.H.C. Eletrofiação de Polímeros Em Solução: Parte II: Aplicações e Perspectivas. Polímeros 2012, 22, 178–185. [Google Scholar] [CrossRef]

- Yan, X.; Gevelber, M. Electrospinning of Nanofibers: Characterization of Jet Dynamics and Humidity Effects. Part. Sci. Technol. 2017, 35, 139–149. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A Fascinating Fiber Fabrication Technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Electrospinning of Nanofibers: Reinventing the Wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Chen, C.H.; Li, D.L.; Chuang, A.D.C.; Dash, B.S.; Chen, J.P. Tension Stimulation of Tenocytes in Aligned Hyaluronic Acid/Platelet-Rich Plasma-Polycaprolactone Core-Sheath Nanofiber Membrane Scaffold for Tendon Tissue Engineering. Int. J. Mol. Sci. 2021, 22, 11215. [Google Scholar] [CrossRef]

- Merighi, S.; Mazzocchetti, L.; Benelli, T.; Maccaferri, E.; Zucchelli, A.; D’Amore, A.; Giorgini, L. A New Wood Surface Flame-Retardant Based on Poly-m-Aramid Electrospun Nanofibers. Polym. Eng. Sci. 2019, 59, 2541–2549. [Google Scholar] [CrossRef]

- Khajavi, R.; Abbasipour, M. Electrospinning as a Versatile Method for Fabricating Coreshell, Hollow and Porous Nanofibers. Sci. Iran. 2012, 19, 2029–2034. [Google Scholar] [CrossRef] [Green Version]

- Yarin, A.L. Coaxial Electrospinning and Emulsion Electrospinning of Core-Shell Fibers. Polym. Adv. Technol. 2011, 22, 310–317. [Google Scholar] [CrossRef]

- Aluigi, A.; Varesano, A.; Vineis, C.; Del Rio, A. Electrospinning of Immiscible Systems: The Wool Keratin/Polyamide-6 Case Study. Mater. Des. 2017, 127, 144–153. [Google Scholar] [CrossRef]

- Walsh, D.J. Polymer Blends. In Comprehensive Polymer Science and Supplements; Elsevier: Amsterdam, The Netherlands, 1989; Volume 74, pp. 135–154. [Google Scholar]

- Maccaferri, E.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. Rubbery-Modified Cfrps with Improved Mode i Fracture Toughness: Effect of Nanofibrous Mat Grammage and Positioning on Tanδ Behaviour. Polymers 2021, 13, 1918. [Google Scholar] [CrossRef] [PubMed]

- MacCaferri, E.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. Self-Assembled NBR/Nomex Nanofibers as Lightweight Rubbery Nonwovens for Hindering Delamination in Epoxy CFRPs. ACS Appl. Mater. Interfaces 2022, 14, 1885–1899. [Google Scholar] [CrossRef] [PubMed]

- Tipduangta, P.; Belton, P.; Fábián, L.; Wang, L.Y.; Tang, H.; Eddleston, M.; Qi, S. Electrospun Polymer Blend Nanofibers for Tunable Drug Delivery: The Role of Transformative Phase Separation on Controlling the Release Rate. Mol. Pharm. 2016, 13, 25–39. [Google Scholar] [CrossRef]

- Quan, Z.; Xu, Y.; Rong, H.; Yang, W.; Yang, Y.; Wei, G. Preparation of Oil-in-Water Core-Sheath Nanofibers through Emulsion Electrospinning for Phase Change Temperature Regulation. Polymer 2022, 256, 125252. [Google Scholar] [CrossRef]

- Park, S.; Son, C.W.; Lee, S.; Kim, D.Y.; Park, C.; Eom, K.S.; Fuller, T.F.; Joh, H.I.; Jo, S.M. Multicore-Shell Nanofiber Architecture of Polyimide/Polyvinylidene Fluoride Blend for Thermal and Long-Term Stability of Lithium Ion Battery Separator. Sci. Rep. 2016, 6, 1–8. [Google Scholar] [CrossRef]

- Agarwal, S.; Wendorff, J.H.; Greiner, A. Use of Electrospinning Technique for Biomedical Applications. Polymer 2008, 49, 5603–5621. [Google Scholar] [CrossRef]

- Reznik, S.N.; Yarin, A.L.; Zussman, E.; Bercovici, L. Evolution of a Compound Droplet Attached to a Core-Shell Nozzle under the Action of a Strong Electric Field. Phys. Fluids 2006, 18, 062101. [Google Scholar] [CrossRef]

- Weerasinghe, V.T.; Dissanayake, D.G.K.; Perera, W.P.T.D.; Tissera, N.D.; Wijesena, R.N.; Wanasekara, N.D. All-Organic, Conductive and Biodegradable Yarns from Core-Shell Nanofibers through Electrospinning. RSC Adv. 2020, 10, 32875–32884. [Google Scholar] [CrossRef] [PubMed]

- Ji, S.M.; Tiwari, A.P.; Kim, H.Y. Graphene Oxide Coated Zinc Oxide Core–Shell Nanofibers for Enhanced Photocatalytic Performance and Durability. Coatings 2020, 10, 1183. [Google Scholar] [CrossRef]

- Maleknia, L.; Dilamian, M.; Pilehrood, M.; Sadeghi-Aliabadi, H.; Hekmati, A. Preparation, Process Optimization and Characterization of Core-Shell Polyurethane/Chitosan Nanofibers as a Potential Platform for Bioactive Scaffolds. Res. Pharm. Sci. 2018, 13, 273. [Google Scholar] [CrossRef]

- Nie, J.; Wang, Z.L.; Li, J.F.; Gong, Y.; Sun, J.X.; Yang, S. guang Interface Hydrogen-Bonded Core-Shell Nanofibers by Coaxial Electrospinning. Chin. J. Polym. Sci. Engl. Ed. 2017, 35, 1001–1008. [Google Scholar] [CrossRef]

- Rahmani, S.; Arefazar, A.; Latifi, M. PMMA/PS Coaxial Electrospinning: Core-Shell Fiber Morphology as a Function of Material Parameters. Mater. Res. Express 2017, 4, 035304. [Google Scholar] [CrossRef]

- Forward, K.M.; Flores, A.; Rutledge, G.C. Production of Core/Shell Fibers by Electrospinning from a Free Surface. Chem. Eng. Sci. 2013, 104, 250–259. [Google Scholar] [CrossRef]

- Wu, X.F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning Core-Shell Nanofibers for Interfacial Toughening and Self-Healing of Carbon-Fiber/Epoxy Composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Paulett, K.; Brayer, W.A.; Hatch, K.; Kalous, T.; Sewell, J.; Liavitskaya, T.; Vyazovkin, S.; Liu, F.; Lukáš, D.; Stanishevsky, A. Effect of Nanocrystalline Cellulose Addition on Needleless Alternating Current Electrospinning and Properties of Nanofibrous Polyacrylonitrile Meshes. J. Appl. Polym. Sci. 2018, 135, 1–10. [Google Scholar] [CrossRef]

- Balogh, A.; Cselkó, R.; Démuth, B.; Verreck, G.; Mensch, J.; Marosi, G.; Nagy, Z.K. Alternating Current Electrospinning for Preparation of Fibrous Drug Delivery Systems. Int. J. Pharm. 2015, 495, 75–80. [Google Scholar] [CrossRef]

- Nagy, Z.K.; Balogh, A.; Drávavölgyi, G.; Ferguson, J.; Pataki, H.; Vajna, B.; Marosi, G. Solvent-Free Melt Electrospinning for Preparation of Fast Dissolving Drug Delivery System and Comparison with Solvent-Based Electrospun and Melt Extruded Systems. J. Pharm. Sci. 2013, 102, 508–517. [Google Scholar] [CrossRef]

- Theron, S.A.; Yarin, A.L.; Zussman, E.; Kroll, E. Multiple Jets in Electrospinning: Experiment and Modeling. Polymer 2005, 46, 2889–2899. [Google Scholar] [CrossRef]

- Yu, D.G.; Li, X.Y.; Wang, X.; Yang, J.H.; Bligh, S.W.A.; Williams, G.R. Nanofibers Fabricated Using Triaxial Electrospinning as Zero Order Drug Delivery Systems. ACS Appl. Mater. Interfaces 2015, 7, 18891–18897. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.-G.; White, K.; Chatterton, N.; Li, Y.; Li, L.; Wang, X. Structural Lipid Nanoparticles Self-Assembled from Electrospun Core–Shell Polymeric Nanocomposites. RSC Adv. 2015, 5, 9462–9466. [Google Scholar] [CrossRef]

- Persano, L.; Camposeo, A.; Tekmen, C.; Pisignano, D. Industrial Upscaling of Electrospinning and Applications of Polymer Nanofibers: A Review. Macromol. Mater. Eng. 2013, 298, 504–520. [Google Scholar] [CrossRef]

- Farkas, B.; Balogh, A.; Cselkó, R.; Molnár, K.; Farkas, A.; Borbás, E.; Marosi, G.; Nagy, Z.K. Corona Alternating Current Electrospinning: A Combined Approach for Increasing the Productivity of Electrospinning. Int. J. Pharm. 2019, 561, 219–227. [Google Scholar] [CrossRef]

- Kessick, R.; Fenn, J.; Tepper, G. The Use of AC Potentials in Electrospraying and Electrospinning Processes. Polymer 2004, 45, 2981–2984. [Google Scholar] [CrossRef]

- Maheshwari, S.; Chang, H.C. Assembly of Multi-Stranded Nanofiber Threads through AC Electrospinning. Adv. Mater. 2009, 21, 349–354. [Google Scholar] [CrossRef]

- Sarkar, S.; Deevi, S.; Tepper, G. Biased AC Electrospinning of Aligned Polymer Nanofibers. Macromol. Rapid Commun. 2007, 28, 1034–1039. [Google Scholar] [CrossRef]

- Agarwal, S.; Greiner, A.; Wendorff, J.H. Functional Materials by Electrospinning of Polymers. Prog. Polym. Sci. 2013, 38, 963–991. [Google Scholar] [CrossRef]

- He, J.-H.; Liu, Y.; Xu, L. Apparatus for Preparing Electrospun Nanofibres: A Comparative Review. Mater. Sci. Technol. 2010, 26, 1275–1287. [Google Scholar] [CrossRef]

- Balogh, A.; Farkas, B.; Faragó, K.; Farkas, A.; Wagner, I.; Van Assche, I.; Verreck, G.; Nagy, Z.K.; Marosi, G. Melt-Blown and Electrospun Drug-Loaded Polymer Fiber Mats for Dissolution Enhancement: A Comparative Study. J. Pharm. Sci. 2015, 104, 1767–1776. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pokorny, P.; Kostakova, E.; Sanetrnik, F.; Mikes, P.; Chvojka, J.; Kalous, T.; Bilek, M.; Pejchar, K.; Valtera, J.; Lukas, D. Effective AC Needleless and Collectorless Electrospinning for Yarn Production. Phys. Chem. Chem. Phys. 2014, 16, 26816–26822. [Google Scholar] [CrossRef]

- Hinds, W.C. Aerosol Technology: Properties, Behaviour, and Measurement of Airborne Particles, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA; New York, NY, USA, 1999; ISBN 0-471-19410-7. [Google Scholar]

- Li, Y.; Yin, X.; Si, Y.; Yu, J.; Ding, B. All-Polymer Hybrid Electret Fibers for High-Efficiency and Low-Resistance Filter Media. Chem. Eng. J. 2020, 398, 125626. [Google Scholar] [CrossRef]

- Thakur, R.; Das, D.; Das, A. Electret Air Filters. Sep. Purif. Rev. 2013, 42, 87–129. [Google Scholar] [CrossRef]

- Ensor, D.S.; Walls, H.J.; Andrady, A.L.; Walker, T.A. Particle Filter System Incorporating Nanofibers. U.S. Patent 20100031617A1, 11 February 2010. [Google Scholar]

- Lolla, D.; Lolla, M.; Abutaleb, A.; Shin, H.U.; Reneker, D.H.; Chase, G.G. Fabrication, Polarization of Electrospun Polyvinylidene Fluoride Electret Fibers and Effect on Capturing Nanoscale Solid Aerosols. Materials 2016, 9, 671. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Electret Polyvinylidene Fluoride Nanofibers Hybridized by Polytetrafluoroethylene Nanoparticles for High-Efficiency Air Filtration. ACS Appl. Mater. Interfaces 2016, 8, 23985–23994. [Google Scholar] [CrossRef] [PubMed]

- Zaccaria, M.; Fabiani, D.; Zucchelli, A.; Belcari, J.; Bocchi, O.; Cramer, T.; Fraboni, B. Electret Behavior of Electrospun PVdF-Based Polymers. Annu. Rep. Conf. Electr. Insul. Dielectr. Phenom. CEIDP 2016, 137–140. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, C.; Zhong, J.; Lin, S.; Xiao, Y.; Zhong, Q.; Jiang, H.; Wu, N.; Li, W.; Chen, S.; et al. Electrospun Polyetherimide Electret Nonwoven for Bi-Functional Smart Face Mask. Nano Energy 2017, 34, 562–569. [Google Scholar] [CrossRef]

- Gao, H.; Yang, Y.; Akampumuza, O.; Hou, J.; Zhang, H.; Qin, X. A Low Filtration Resistance Three-Dimensional Composite Membrane Fabricated via Free Surface Electrospinning for Effective PM2.5 Capture. Environ. Sci. Nano 2017, 4, 864–875. [Google Scholar] [CrossRef]

- Yeom, B.Y.; Shim, E.; Pourdeyhimi, B. Boehmite Nanoparticles Incorporated Electrospun Nylon-6 Nanofiber Web for New Electret Filter Media. Macromol. Res. 2010, 18, 884–890. [Google Scholar] [CrossRef]

- Oh, Y.W.; Jeon, K.J.; Jung, A.I.; Jung, Y.W. A Simulation Study on the Collection of Submicron Particles in a Unipolar Charged Fiber. Aerosol Sci. Technol. 2002, 36, 573–582. [Google Scholar] [CrossRef]

- Huang, Z.X.; Liu, X.; Zhang, X.; Wong, S.C.; Chase, G.G.; Qu, J.P.; Baji, A. Electrospun Polyvinylidene Fluoride Containing Nanoscale Graphite Platelets as Electret Membrane and Its Application in Air Filtration under Extreme Environment. Polymer 2017, 131, 143–150. [Google Scholar] [CrossRef]

- Song, X.; Cheng, G.; Cheng, B.; Xing, J. Electrospun Polyacrylonitrile/Magnetic Fe3O4-Polyhedral Oligomeric Silsesquioxanes Nanocomposite Fibers with Enhanced Filter Performance for Electrets Filter Media. J. Mater. Res. 2016, 31, 2662–2671. [Google Scholar] [CrossRef]

- Ignatova, M.; Yovcheva, T.; Viraneva, A.; Mekishev, G.; Manolova, N.; Rashkov, I. Study of Charge Storage in the Nanofibrous Poly(Ethylene Terephthalate) Electrets Prepared by Electrospinning or by Corona Discharge Method. Eur. Polym. J. 2008, 44, 1962–1967. [Google Scholar] [CrossRef]

- Li, N.; Georas, S.; Alexis, N.; Fritz, P.; Xia, T.; Williams, M.A.; Horner, E.; Nel, A. A Work Group Report on Ultrafine Particles (American Academy of Allergy, Asthma & Immunology): Why Ambient Ultrafine and Engineered Nanoparticles Should Receive Special Attention for Possible Adverse Health Outcomes in Human Subjects. J. Allergy Clin. Immunol. 2016, 138, 386–396. [Google Scholar] [CrossRef] [PubMed]

- Nel, A. Toxic Potential of Materials at the Nanolevel. Science 2006, 311, 622–627. [Google Scholar] [CrossRef]

- Stone, V.; Johnston, H.; Clift, M.J.D.D. Air Pollution, Ultrafine and Nanoparticle Toxicology: Cellular and Molecular Interactions. IEEE Trans. Nanobiosci. 2007, 6, 331–340. [Google Scholar] [CrossRef]

- Vance, M.E.; Kuiken, T.; Vejerano, E.P.; McGinnis, S.P.; Hochella, M.F.; Hull, D.R. Nanotechnology in the Real World: Redeveloping the Nanomaterial Consumer Products Inventory. Beilstein J. Nanotechnol. 2015, 6, 1769–1780. [Google Scholar] [CrossRef]

- Park, G.; Kim, S.; Chae, S.; Han, H.; Le, T.H.; Yang, K.S.; Chang, M.; Kim, H.; Yoon, H. Combining SWNT and Graphene in Polymer Nanofibers: A Route to Unique Carbon Precursors for Electrochemical Capacitor Electrodes. Langmuir 2019, 35, 3077–3086. [Google Scholar] [CrossRef]

- Sagitha, P.; Reshmi, C.R.; Sundaran, S.P.; Sujith, A. Recent Advances in Post-Modification Strategies of Polymeric Electrospun Membranes. Eur. Polym. J. 2018, 105, 227–249. [Google Scholar] [CrossRef]

- Khalili, S.; Chenari, H.M. Successful Electrospinning Fabrication of ZrO2 Nanofibers: A Detailed Physical-Chemical Characterization Study. J. Alloys Compd. 2020, 828, 154414. [Google Scholar] [CrossRef]

- Sundarrajan, S.; Venkatesan, A.; Agarwal, S.R.; Shaik Anwar Ahamed, N.N.; Ramakrishna, S. Fabrication of NiO/Zirconium Oxide Nanofibers by Electrospinning. Mater. Sci. Eng. C 2014, 45, 369–373. [Google Scholar] [CrossRef] [PubMed]

- Annur, D.; Wang, Z.-K.; Liao, J.-D.; Kuo, C. Plasma-Synthesized Silver Nanoparticles on Electrospun Chitosan Nanofiber Surfaces for Antibacterial Applications. Biomacromolecules 2015, 16, 3248–3255. [Google Scholar] [CrossRef] [PubMed]

- Bortolassi, A.C.C.; Nagarajan, S.; de Araújo Lima, B.; Guerra, V.G.; Aguiar, M.L.; Huon, V.; Soussan, L.; Cornu, D.; Miele, P.; Bechelany, M. Efficient Nanoparticles Removal and Bactericidal Action of Electrospun Nanofibers Membranes for Air Filtration. Mater. Sci. Eng. C 2019, 102, 718–729. [Google Scholar] [CrossRef]

- Lu, P.; Murray, S.; Zhu, M. Electrospun Nanofibers for Catalysts. In Electrospinning: Nanofabrication and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 695–717. ISBN 9780323512701. [Google Scholar]

- Homaeigohar, S.; Elbahri, M. Nanocomposite Electrospun Nanofiber Membranes for Environmental Remediation. Materials 2014, 7, 1017–1045. [Google Scholar] [CrossRef]

- Salavagione, H.J.; Gómez-Fatou, M.A.; Shuttleworth, P.S.; Ellis, G.J. New Perspectives on Graphene/Polymer Fibers and Fabrics for Smart Textiles: The Relevance of the Polymer/Graphene Interphase. Front. Mater. 2018, 5, 1–6. [Google Scholar] [CrossRef]

- Leonés, A.; Lieblich, M.; Benavente, R.; Gonzalez, J.L.; Peponi, L. Potential Applications of Magnesium-Based Polymeric Nanocomposites Obtained by Electrospinning Technique. Nanomaterials 2020, 10, 1524. [Google Scholar] [CrossRef]

- Schneider, R.; Facure, M.H.M.; Chagas, P.A.M.; Andre, R.S.; dos Santos, D.M.; Correa, D.S. Tailoring the Surface Properties of Micro/Nanofibers Using 0D, 1D, 2D, and 3D Nanostructures: A Review on Post-Modification Methods. Adv. Mater. Interfaces 2021, 8, 2100430. [Google Scholar] [CrossRef]

- Naeimirad, M.; Zadhoush, A.; Kotek, R.; Esmaeely Neisiany, R.; Nouri Khorasani, S.; Ramakrishna, S. Recent Advances in Core/Shell Bicomponent Fibers and Nanofibers: A Review. J. Appl. Polym. Sci. 2018, 135, 28–30. [Google Scholar] [CrossRef]

- Povolo, M.; Maccaferri, E.; Cocchi, D.; Brugo, T.M.; Mazzocchetti, L.; Giorgini, L.; Zucchelli, A. Damping and Mechanical Behaviour of Composite Laminates Interleaved with Rubbery Nanofibers. Compos. Struct. 2021, 272, 114228. [Google Scholar] [CrossRef]

- Daelemans, L.; Kizildag, N.; Van Paepegem, W.; D’hooge, D.R.; De Clerck, K. Interdiffusing Core-Shell Nanofiber Interleaved Composites for Excellent Mode I and Mode II Delamination Resistance. Compos. Sci. Technol. 2019, 175, 143–150. [Google Scholar] [CrossRef]

- Zheng, N.; Liu, H.Y.; Gao, J.; Mai, Y.W. Synergetic Improvement of Interlaminar Fracture Energy in Carbon Fiber/Epoxy Composites with Nylon Nanofiber/Polycaprolactone Blend Interleaves. Compos. Part B Eng. 2019, 171, 320–328. [Google Scholar] [CrossRef]

- Selatile, M.K.; Ojijo, V.; Sadiku, R.; Ray, S.S. Development of Bacterial-Resistant Electrospun Polylactide Membrane for Air Filtration Application: Effects of Reduction Methods and Their Loadings. Polym. Degrad. Stab. 2020, 178, 109205. [Google Scholar] [CrossRef]

- Tajer, M.; Anbia, M.; Salehi, S. Fabrication of Polyacrylonitrile Hybrid Nanofiber Scaffold Containing Activated Carbon by Electrospinning Process as Nanofilter Media for SO2, CO2, and CH4 Adsorption. Environ. Prog. Sustain. Energy 2020, 40, e13498. [Google Scholar] [CrossRef]

- Razzaz, A.; Ghorban, S.; Hosayni, L.; Irani, M.; Aliabadi, M. Chitosan Nanofibers Functionalized by TiO2 Nanoparticles for the Removal of Heavy Metal Ions. J. Taiwan Inst. Chem. Eng. 2016, 58, 333–343. [Google Scholar] [CrossRef]

- Al-Dhahebi, A.M.; Gopinath, S.C.B.; Saheed, M.S.M. Graphene Impregnated Electrospun Nanofiber Sensing Materials: A Comprehensive Overview on Bridging Laboratory Set-up to Industry. Nano Converg. 2020, 7, 27. [Google Scholar] [CrossRef]

- Francavilla, P.; Ferreira, D.P.; Araújo, J.C.; Fangueiro, R. Smart Fibrous Structures Produced by Electrospinning Using the Combined Effect of Pcl/Graphene Nanoplatelets. Appl. Sci. 2021, 11, 1124. [Google Scholar] [CrossRef]

- Laurano, R.; Boffito, M.; Torchio, A.; Cassino, C.; Chiono, V.; Ciardelli, G. Plasma Treatment of Polymer Powder as an Eective Tool to Functionalize Polymers: Case Study Application on an Amphiphilic Polyurethane. Polymers 2019, 11, 2109. [Google Scholar] [CrossRef]

- Shaulsky, E.; Nejati, S.; Boo, C.; Perreault, F.; Osuji, C.O.; Elimelech, M. Post-Fabrication Modification of Electrospun Nanofiber Mats with Polymer Coating for Membrane Distillation Applications. J. Memb. Sci. 2017, 530, 158–165. [Google Scholar] [CrossRef]

- Hou, J.; Park, C.; Jang, W.; Byun, H. Facile Fabrication and Characterization of Aliphatic Polyketone (PK) Micro/Nano Fiber Membranes via Electrospinning and a Post Treatment Process. RSC Adv. 2020, 11, 678–683. [Google Scholar] [CrossRef]

- Nauman, S.; Lubineau, G.; Alharbi, H.F. Post Processing Strategies for the Enhancement of Mechanical Properties of Enms (Electrospun Nanofibrous Membranes): A Review. Membranes 2021, 11, 39. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medeiros, G.B.; Lima, F.d.A.; de Almeida, D.S.; Guerra, V.G.; Aguiar, M.L. Modification and Functionalization of Fibers Formed by Electrospinning: A Review. Membranes 2022, 12, 861. https://doi.org/10.3390/membranes12090861

Medeiros GB, Lima FdA, de Almeida DS, Guerra VG, Aguiar ML. Modification and Functionalization of Fibers Formed by Electrospinning: A Review. Membranes. 2022; 12(9):861. https://doi.org/10.3390/membranes12090861

Chicago/Turabian StyleMedeiros, Gabriela B., Felipe de A. Lima, Daniela S. de Almeida, Vádila G. Guerra, and Mônica L. Aguiar. 2022. "Modification and Functionalization of Fibers Formed by Electrospinning: A Review" Membranes 12, no. 9: 861. https://doi.org/10.3390/membranes12090861

APA StyleMedeiros, G. B., Lima, F. d. A., de Almeida, D. S., Guerra, V. G., & Aguiar, M. L. (2022). Modification and Functionalization of Fibers Formed by Electrospinning: A Review. Membranes, 12(9), 861. https://doi.org/10.3390/membranes12090861