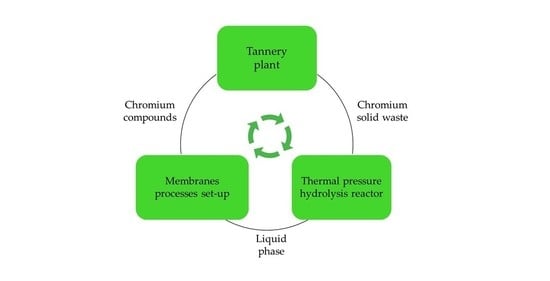

Application of an Integrated System of Thermal Pressure Hydrolysis/Membrane Techniques to Recover Chromium from Tannery Waste for Reuse in Hide Tanning Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Thermal Pressure Hydrolysis (TPH)

2.2. Membrane Filtration

2.3. Physical and Chemical Parameters of Waste, Hydrolysates, and Membrane Filtration Products

2.4. Model Tanning Tests

2.5. Microscope Tests

3. Results and Discussion

3.1. Hydrolysis of Tannery Waste Containing Chromium

3.2. Hydrolysate Treatment Using Micro- and Nanofiltration

3.3. Model Bovine Hide Tanning Test Using Chromium Recovered from Tannery Waste

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, J.; Wu, Q.; Tang, Y.; Zhou, J.; Guo, H. Tannery wastewater treatment: Conventional and promising processes, an updated 20-year review. J. Leather Sci. Eng. 2022, 4, 10. [Google Scholar] [CrossRef]

- Verma, S.K.; Sharma, P.C. Current trends in solid tannery waste management. Crit. Rev. Biotechnol. 2022, 20, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Chojnacka, K.; Skrzypczak, D.; Mikula, K.; Witek-Krowiak, A.; Izydorczyk, G.; Kuligowski, K.; Bandrów, P.; Kułażyński, M. Progress in sustainable technologies of leather wastes valorization as solutions for the circular economy. J. Clean. Prod. 2021, 313, 127902. [Google Scholar] [CrossRef]

- Saha, B.; Azam, F.A.B. Probable ways of tannery’s solid and liquid waste management in Bangladesh—An overview. Text. Leather rev. 2021, 4, 76–95. [Google Scholar] [CrossRef]

- Stefan, D.S.; Bosomoiu, M.; Constantinescu, R.R.; Ignat, M. Composite polymers from leather waste to produce smart fertilizers. Polymers 2021, 13, 4351. [Google Scholar] [CrossRef] [PubMed]

- Parisi, M.; Nanni, A.; Colonna, M. Recycling of chrome-tanned leather and its utilization as polymeric materials and in polymer-based composites: A review. Polymers 2021, 13, 429. [Google Scholar] [CrossRef] [PubMed]

- Lasek, W. Multi-directional recycling of chrome–leather offal together with chrome–polluted sewage sludge of any origin as a prerequisite for remediation of areas exploited by tannery and electroplating in Małopolska. Probl. Ekol. 2008, 12, 104–107. [Google Scholar]

- Famielec, S.; Wieczorek-Ciurowa, K. Incineration of tannery waste in a tunnel furnace system. Civ. Environ. Eng. Rep. 2013, 10, 63–72. [Google Scholar]

- Famielec, S. Chromium concentrate recovery from solid tannery waste in a thermal process. Materials 2020, 13, 1533. [Google Scholar] [CrossRef]

- Arcibar-Orozco, J.A.; Barajas-Elias, B.S.; Caballero-Briones, F.; Nielsen, L.; Rangel-Mendez, J.R. Hybrid carbon nanochromium composites prepared from chrome-tanned leather shavings for dye adsorption. Water Air Soil Pollut. 2019, 230, 142. [Google Scholar] [CrossRef]

- Banon, E.; Marcilla, A.; García, A.N.; Martínez, P.; Leon, M. Kinetic model of the thermal pyrolysis of chrome tanned leather treated with NaOH under different conditions using thermogravimetric analysis. Waste Manag. 2016, 48, 285–299. [Google Scholar] [CrossRef] [PubMed]

- Bizzi, C.A.; Zanatta, R.C.; Santos, D.; Giacobe, K.; Dallago, R.M.; Mello, P.A.; Flores, E.M.M. Ultrasound-assisted extraction of chromium from residual tanned leather: An innovation strategy for the reuse of waste in tanning industry. Ultrason. Sonochem. 2020, 64, 104682. [Google Scholar] [CrossRef] [PubMed]

- Ławińska, K.; Obraniak, A.; Modrzewski, R. Granulation process of waste tanning shavings. Fibres Text. East. Eur. 2019, 2, 107–110. [Google Scholar] [CrossRef]

- Oruko, R.O.; Selvarajan, R.; Ogola, H.J.O.; Edokpayi, J.N.; Odiyo, J.O. Contemporary and future direction of chromium tanning andmanagement in sub Saharan Africa tanneries. Process Saf. Environ. Prot. 2020, 133, 369–386. [Google Scholar] [CrossRef]

- Sivaram, N.M.; Barik, D. Toxic waste from leather industries. In Energy from Toxic Organic Waste for Heat and Power Generation; Barik, D., Ed.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2018; pp. 55–67. [Google Scholar]

- Kokkinos, E.; Zouboulis, A.I. The chromium recovery and reuse from tanneries: A case study according to the principles of circular economy. In Leather and Footwear Sustainability. Textile Science and Clothing Technology; Muthu, S., Ed.; Springer: Singapore, 2020; pp. 123–157. [Google Scholar]

- Scopel, B.S.; Baldasso, C.; Dettmer, A.; Santana, R.M.C. Hydrolysis of chromium tanned leather waste: Turning waste into valuable materials—A review. JALCA 2018, 113, 122–129. [Google Scholar]

- Mia, M.; Sayid, A.; Ahmad, F.; Rahman, M. An overview of chromium removal techniques from tannery effluent. Appl. Water Sci. 2020, 10, 205. [Google Scholar]

- Cassano, A.; Pietra, L.D.; Drioli, E. Integrated membrane process for the recovery of chromium salts from tannery effluents. Ind. Eng. Chem. Res. 2007, 46, 6825–6830. [Google Scholar] [CrossRef]

- Kowalik-Klimczak, A.; Zalewski, M.; Gierycz, P. Removal of Cr(III) ions from salt solution by nanofiltration: Experimental and modelling analysis. Pol. J. Chem. Technol. 2016, 18, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Fabiani, C.; Ruscio, F.; Spadoni, M.; Pizzichini, M. Chromium(III) salts recovery process from tannery wastewaters. Desalination 1996, 108, 183–191. [Google Scholar] [CrossRef]

- Mahammed, K.; Sahu, O. Recovery of chromium from tannery industry waste water by membrane separation technology: Health and engineering aspects. Sci. Afr. 2019, 4, 00096. [Google Scholar] [CrossRef]

- Kowalik-Klimczak, A. Influence of NF membrane properties on water recovery from the dairy industry wastewater. J. Membr. Sci. Res. 2022, 8, 530129. [Google Scholar]

- Kowalik-Klimczak, A.; Stanisławek, E. Reclamation of water from dairy wastewater using polymeric nanofiltration membranes. Desalin. Water Treat. 2018, 128, 364–371. [Google Scholar]

- Agustini, C.B.; da Costa, M.; Gutterres, M. Tannery wastewater as nutrient supply in production of biogas from solid tannery wastes mixed through anaerobic co-digestion. Process Saf. Environ. Prot. 2020, 135, 38–45. [Google Scholar] [CrossRef]

- Mia, M.A.S.; Nur-e-Alam, M.; Huque, S.; Rahman, M.M.; Ratnaweera, H. Biogas production through anaerobic digestion of tannery solid waste. IJEE 2017, 8, 210–215. [Google Scholar]

- Fernández-Rodríguez, J.; Lorea, B.; González-Gaitano, G. Biological solubilisation of leather industry waste in anaerobic conditions: Effect of chromium(III) presence, pre-treatments and temperature strategies. Int. J. Mol. Sci. 2022, 23, 13647. [Google Scholar]

- Ławińska, K.; Serweta, W.; Jaruga, I.; Popovych, N. Examination of selected upper shoe materials based on bamboo fabrics. Fibres Text. East. Eur. 2019, 27, 85–90. [Google Scholar] [CrossRef]

- Qiao, D.; Yao, J.; Song, L.; Yan, J. Migration of leather tannins and chromium in soils under the effect of simulated rain. Chemosphere 2021, 284, 131413. [Google Scholar] [CrossRef] [PubMed]

| Type of Membrane | MF JX | NF TS40 | NF DL |

|---|---|---|---|

| Manufacturer | SUEZ(GE) | TriSEP | SUEZ(GE) |

| Material | PVDF | PPZ | PA |

| Pore size [µm] | 0.3 | - | - |

| Cut-off [Da] | - | ~200 | ~150–300 |

| pH range | 1–11 | 2–11 | 2–10 |

| Max. temperature [°C] | 45 | 45 | 45 |

| Parameter | Shavings | Cuttings | Dust |

|---|---|---|---|

| Dry matter content [%] | 79.8–80.7 | 83.6–87.3 | 90.9–91.6 |

| Organic dry matter content [% dm] | 83.9–87.7 | 82.2–93.5 | 86.1–86.5 |

| Total nitrogen bound [% dm] | 13.0–15.1 | 13.0–14.5 | 7.7–8.0 |

| Total chromium [% dm] | 2.74–3.30 | 2.88–3.86 | 2.25–23.38 |

| Tanning Waste Type | Recovery [% of feed] | ||

|---|---|---|---|

| Dry Matter | Organic Dry Matter | Total Chromium | |

| Cuttings | 89 | 99 | 85 |

| Shavings | 95 | 101 | 81 |

| Dust | 33 | 34 | 9 |

| Parameter | Value |

|---|---|

| pH | 2.515 ± 0.004 |

| Conductivity [mS/cm] | 26.89 ± 0.02 |

| Total chromium [g/dm3] | 3.00 ± 0.01 |

| Chromium (VI) [mg/dm3] | 24.20 ± 0.35 |

| Chemical oxygen demand [g O2/dm3] | 115.4 ± 5.7 |

| Total organic carbon [g/dm3] | 29.11 ± 0.27 |

| Total nitrogen bound [g/dm3] | 19.31 ± 0.23 |

| Chlorides [g/dm3] | 4.79 ± 0.16 |

| Sulphates [g/dm3] | 7.447 ± 0.042 |

| Dry matter content [%] | 10.15 ± 0.01 |

| Organic dry matter content [% dry matter] | 85.71 ± 0.21 |

| Parameter | Sample 1 | Sample 2 |

|---|---|---|

| Thickness [mm] | 1.42 | 1.37 |

| Tensile strength [N/mm2] | 17.80 | 17.22 |

| Elongation [%] | 44 | 45 |

| Tear strength [N] | 90.00 | 93.83 |

| Brusting factor (lastometer) | 8.5 | 8.5 |

| Adhesion of finish [N/cm] | 1.9 | 1.8 |

| Chromium(III) content converted to Cr2O3 [%]. | 3.99 | 4.06 |

| Sample 1—Hide tanned using a commercial tanning agent | ||

| Sample 2—Hide tanned using chromium recovered from waste subject to acid hydrolysis | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalik-Klimczak, A.; Życki, M.; Łożyńska, M.; Schadewell, C.; Fiehn, T.; Woźniak, B.; Flisek, M. Application of an Integrated System of Thermal Pressure Hydrolysis/Membrane Techniques to Recover Chromium from Tannery Waste for Reuse in Hide Tanning Processes. Membranes 2023, 13, 18. https://doi.org/10.3390/membranes13010018

Kowalik-Klimczak A, Życki M, Łożyńska M, Schadewell C, Fiehn T, Woźniak B, Flisek M. Application of an Integrated System of Thermal Pressure Hydrolysis/Membrane Techniques to Recover Chromium from Tannery Waste for Reuse in Hide Tanning Processes. Membranes. 2023; 13(1):18. https://doi.org/10.3390/membranes13010018

Chicago/Turabian StyleKowalik-Klimczak, Anna, Maciej Życki, Monika Łożyńska, Christian Schadewell, Thomas Fiehn, Bogusław Woźniak, and Monika Flisek. 2023. "Application of an Integrated System of Thermal Pressure Hydrolysis/Membrane Techniques to Recover Chromium from Tannery Waste for Reuse in Hide Tanning Processes" Membranes 13, no. 1: 18. https://doi.org/10.3390/membranes13010018

APA StyleKowalik-Klimczak, A., Życki, M., Łożyńska, M., Schadewell, C., Fiehn, T., Woźniak, B., & Flisek, M. (2023). Application of an Integrated System of Thermal Pressure Hydrolysis/Membrane Techniques to Recover Chromium from Tannery Waste for Reuse in Hide Tanning Processes. Membranes, 13(1), 18. https://doi.org/10.3390/membranes13010018