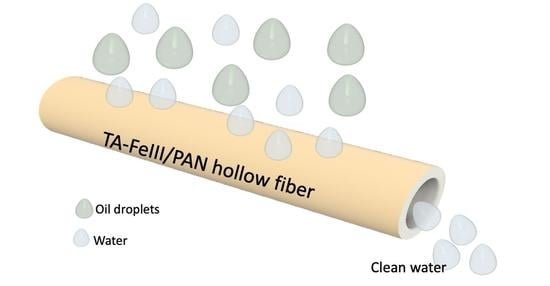

Using Tannic-Acid-Based Complex to Modify Polyacrylonitrile Hollow Fiber Membrane for Efficient Oil-In-Water Separation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization

2.3. Fabrication of Hollow Fiber Membranes

2.4. Surface Modification with TA-FeIII

2.5. Preparation of Oil–Water Emulsion

2.6. Crossflow Filtration and Antifouling Test

2.7. Determination of Molecular Weight Cutoff and Pore Size Distribution

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sutrisna, P.D.; Kurnia, K.A.; Siagian, U.W.R.; Ismadji, S.; Wenten, I.G. Membrane fouling and fouling mitigation in oil–water separation: A review. J. Environ. Chem. Eng. 2022, 10, 107532. [Google Scholar] [CrossRef]

- Zoubeik, M.; Ismail, M.; Salama, A.; Henni, A. New Developments in Membrane Technologies Used in the Treatment of Produced Water: A Review. Arab. J. Sci. Eng. 2017, 43, 2093–2118. [Google Scholar] [CrossRef]

- Wenten, I.G.; Khoiruddin, K.; Aryanti, P.T.P.; Victoria, A.V.; Tanukusuma, G. Membrane-based zero-sludge palm oil mill plant. Rev. Chem. Eng. 2020, 36, 237–263. [Google Scholar] [CrossRef]

- Mohammad, A.W.; Teow, Y.H.; Ang, W.L.; Chung, Y.T.; Oatley-Radcliffe, D.L.; Hilal, N. Nanofiltration membranes review: Recent advances and future prospects. Desalination 2015, 356, 226–254. [Google Scholar] [CrossRef]

- Hlavacek, M. Break-up of oil-in-water emulsions induced by permeation through a microfiltration membrane. J. Membr. Sci. 1995, 102, 1–7. [Google Scholar] [CrossRef]

- Gu, Y.; Zhang, B.; Fu, Z.; Li, J.; Yu, M.; Li, L.; Li, J. Poly (Vinyl alcohol) modification of poly (Vinylidene fluoride) microfiltration membranes for oil/water emulsion separation via an unconventional radiation method. J. Membr. Sci. 2021, 619, 118792. [Google Scholar] [CrossRef]

- Ahmad, T.; Guria, C.; Mandal, A. A review of oily wastewater treatment using ultrafiltration membrane: A parametric study to enhance the membrane performance. J. Water Process Eng. 2020, 36, 101289. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, X.; Wang, Y.; Qi, Y.; Zhang, Y.; Luo, J.; Cui, P.; Jiang, W. A review on oil/water emulsion separation membrane material. J. Environ. Chem. Eng. 2022, 10, 107257. [Google Scholar] [CrossRef]

- Dmitrenko, M.; Kuzminova, A.; Zolotarev, A.; Markelov, D.; Komolkin, A.; Loginova, E.; Plisko, T.; Burts, K.; Bildyukevich, A.; Penkova, A. Modification strategies of polyacrylonitrile ultrafiltration membrane using TiO2 for enhanced antifouling performance in water treatment. Sep. Purif. Technol. 2022, 286, 120500. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Devanadera, K.P.O.; Duena, A.N.R.; Luo, Z.Y.; Chiao, Y.H.; Millare, J.C.; Aquino, R.R.; Huang, S.H.; Lee, K.R. Modifying Cellulose Acetate Mixed-Matrix Membranes for Improved Oil-Water Separation: Comparison between Sodium and Organo-Montmorillonite as Particle Additives. Membranes 2021, 11, 80. [Google Scholar] [CrossRef]

- Lai, G.S.; Yusob, M.H.M.; Lau, W.J.; Gohari, R.J.; Emadzadeh, D.; Ismail, A.F.; Goh, P.S.; Isloor, A.M.; Arzhandi, M.R.-D. Novel mixed matrix membranes incorporated with dual-nanofillers for enhanced oil-water separation. Sep. Purif. Technol. 2017, 178, 113–121. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, M.; Wang, J.; Wang, H.; Men, X.; Zhang, Z. A rapid, facile and practical fabrication of robust PDMS@starch coatings for oil-water separation. J. Taiwan Inst. Chem. Eng. 2019, 99, 215–223. [Google Scholar] [CrossRef]

- Zeng, G.; Liu, Y.; Lin, Q.; Pu, S.; Zheng, S.; Ang, M.B.M.Y.; Chiao, Y.-H. Constructing composite membranes from functionalized metal organic frameworks integrated MXene intended for ultrafast oil/water emulsion separation. Sep. Purif. Technol. 2022, 293, 121052. [Google Scholar] [CrossRef]

- Xu, Z.; Li, L.; Liu, J.; Dai, C.; Sun, W.; Chen, J.; Zhu, Z.; Zhao, M.; Zeng, H. Mussel-inspired superhydrophilic membrane constructed on a hydrophilic polymer network for highly efficient oil/water separation. J. Colloid Interface Sci. 2022, 608, 702–710. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Luo, X.; Feng, S.; Wu, L. Preparation of a heparin-like functionalized tannic acid-coated polyethersulfone ultrafiltration membrane for hemodialysis by a simple surface modification method. Appl. Surf. Sci. 2022, 572, 151440. [Google Scholar] [CrossRef]

- Cho, E.-C.; Chang-Jian, C.-W.; Hsiao, Y.-S.; Lee, K.-C.; Huang, J.-H. Interfacial engineering of melamine sponges using hydrophobic TiO 2 nanoparticles for effective oil/water separation. J. Taiwan Inst. Chem. Eng. 2016, 67, 476–483. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Q.; Yang, Z.; Ye, Q.; An, Q.-F. Substrate-independent fabrication of superhydrophilic membrane based on dopamine methacrylamide and zwitterionic substance for effective oil-in-water emulsion separation. J. Taiwan Inst. Chem. Eng. 2022, 139, 104513. [Google Scholar] [CrossRef]

- Wang, X.; Chen, X.; Yoon, K.; Fang, D.; Hsiao, B.S.; Chu, B. High flux filtration medium based on nanofibrous substrate with hydrophilic nanocomposite coating. Environ. Sci. Technol. 2005, 39, 7684–7691. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Arena, J.T.; Manickam, S.S.; Jiang, X.; Willis, B.G.; McCutcheon, J.R. Improved mechanical properties and hydrophilicity of electrospun nanofiber membranes for filtration applications by dopamine modification. J. Membr. Sci. 2014, 460, 241–249. [Google Scholar] [CrossRef]

- Yu, S.; Yao, G.; Dong, B.; Zhu, H.; Peng, X.; Liu, J.; Liu, M.; Gao, C. Improving fouling resistance of thin-film composite polyamide reverse osmosis membrane by coating natural hydrophilic polymer sericin. Sep. Purif. Technol. 2013, 118, 285–293. [Google Scholar] [CrossRef]

- Yoo, S.M.; Ghosh, R. A method for coating of hollow fiber membranes with calcium alginate. J. Membr. Sci. 2018, 558, 45–51. [Google Scholar] [CrossRef]

- Fan, L.; Ma, Y.; Su, Y.; Zhang, R.; Liu, Y.; Zhang, Q.; Jiang, Z. Green coating by coordination of tannic acid and iron ions for antioxidant nanofiltration membranes. RSC Adv. 2015, 5, 107777–107784. [Google Scholar] [CrossRef]

- Xie, H.; Shen, L.; Xu, Y.; Hong, H.; Yang, L.; Li, R.; Lin, H. Tannic acid (TA)-based coating modified membrane enhanced by successive inkjet printing of Fe3+ and sodium periodate (SP) for efficient oil-water separation. J. Membr. Sci. 2022, 660, 120873. [Google Scholar] [CrossRef]

- Ren, J.; Kong, R.; Gao, Y.; Zhang, L.; Zhu, J. Bioinspired adhesive coatings from polyethylenimine and tannic acid complexes exhibiting antifogging, self-cleaning, and antibacterial capabilities. J. Colloid Interface Sci. 2021, 602, 406–414. [Google Scholar] [CrossRef] [PubMed]

- Chiao, Y.-H.; Mai, Z.; Hung, W.-S.; Matsuyama, H. Osmotically assisted solvent reverse osmosis membrane for dewatering of aqueous ethanol solution. J. Membr. Sci. 2023, 672, 121434. [Google Scholar] [CrossRef]

- Yan, W.; Shi, M.; Dong, C.; Liu, L.; Gao, C. Applications of tannic acid in membrane technologies: A review. Adv. Colloid Interface Sci. 2020, 284, 102267. [Google Scholar] [CrossRef]

- Wang, Z.; Han, M.; Zhang, J.; He, F.; Peng, S.; Li, Y. Investigating and significantly improving the stability of tannic acid (TA)-aminopropyltriethoxysilane (APTES) coating for enhanced oil-water separation. J. Membr. Sci. 2020, 593, 117383. [Google Scholar] [CrossRef]

- Liu, J.; Yu, X.; Yang, E.; Li, T.; Yu, H.; Wang, Z.; Dong, B.; Fane, A.G. A combined tannic acid-copper-iron coating of ultrafiltration membrane for enhanced anti-bacterial and algal-inhibition performance. J. Water Process Eng. 2022, 50, 103250. [Google Scholar] [CrossRef]

- Marquez, J.A.D.; Ang, M.B.M.Y.; Doma, B.T.; Huang, S.-H.; Tsai, H.-A.; Lee, K.-R.; Lai, J.-Y. Application of cosolvent-assisted interfacial polymerization technique to fabricate thin-film composite polyamide pervaporation membranes with PVDF hollow fiber as support. J. Membr. Sci. 2018, 564, 722–731. [Google Scholar] [CrossRef]

- Hanafi, Y.; Szymczyk, A.; Rabiller-Baudry, M.; Baddari, K. Degradation of poly(ether sulfone)/polyvinylpyrrolidone membranes by sodium hypochlorite: Insight from advanced electrokinetic characterizations. Environ. Sci. Technol. 2014, 48, 13419–13426. [Google Scholar] [CrossRef]

- Yang, Q.; Chung, T.-S.; Santoso, Y.E. Tailoring pore size and pore size distribution of kidney dialysis hollow fiber membranes via dual-bath coagulation approach. J. Membr. Sci. 2007, 290, 153–163. [Google Scholar] [CrossRef]

| Spinning Condition | Setting |

|---|---|

| Bore liquid composition | 80/20 H2O/NMP |

| External coagulant | Water |

| Coagulation temperature | 25 °C |

| Air gap | 60 cm |

| Bore liquid flow rate | 1 mL/min |

| Dope extrusion pressure | 10 bar |

| Spinneret diameter | OD/ID, 2.0/0.9 (mm) |

| Humidity/temperature | 70%/25 °C |

| Reaction Time (min) | C | N | O | Fe | O/C |

|---|---|---|---|---|---|

| 0 | 71.36 | 19.75 | 8.89 | 0.12 | |

| 1 | 70.70 | 17.19 | 11.99 | 0.25 | 0.16 |

| 2 | 68.53 | 13.22 | 17.80 | 0.46 | 0.26 |

| 3 | 61.17 | 5.42 | 32.68 | 0.75 | 0.53 |

| Membrane Condition | MWCO (kDa) | Geometric Mean Pore Diameter (nm), μp = μs | Geometric Pore Standard Deviation, σp = σg |

|---|---|---|---|

| PAN | 4.38 | 5.25 | |

| TA-FeIII | 870.26 | 1.55 | 7.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ang, M.B.M.Y.; Hsu, W.-L.; Wang, Y.-S.; Kuo, H.-Y.; Tsai, H.-A.; Lee, K.-R. Using Tannic-Acid-Based Complex to Modify Polyacrylonitrile Hollow Fiber Membrane for Efficient Oil-In-Water Separation. Membranes 2023, 13, 351. https://doi.org/10.3390/membranes13030351

Ang MBMY, Hsu W-L, Wang Y-S, Kuo H-Y, Tsai H-A, Lee K-R. Using Tannic-Acid-Based Complex to Modify Polyacrylonitrile Hollow Fiber Membrane for Efficient Oil-In-Water Separation. Membranes. 2023; 13(3):351. https://doi.org/10.3390/membranes13030351

Chicago/Turabian StyleAng, Micah Belle Marie Yap, Wei-Lin Hsu, You-Syuan Wang, Hsin-Yu Kuo, Hui-An Tsai, and Kueir-Rarn Lee. 2023. "Using Tannic-Acid-Based Complex to Modify Polyacrylonitrile Hollow Fiber Membrane for Efficient Oil-In-Water Separation" Membranes 13, no. 3: 351. https://doi.org/10.3390/membranes13030351

APA StyleAng, M. B. M. Y., Hsu, W. -L., Wang, Y. -S., Kuo, H. -Y., Tsai, H. -A., & Lee, K. -R. (2023). Using Tannic-Acid-Based Complex to Modify Polyacrylonitrile Hollow Fiber Membrane for Efficient Oil-In-Water Separation. Membranes, 13(3), 351. https://doi.org/10.3390/membranes13030351