Repetitive Movements in Melon Cultivation Workers under Greenhouses

Abstract

:1. Introduction

- ▪

- Physical and biomechanical factors (load handling, forced postures, and repetitive movements);

- ▪

- Organizational and psychosocial factors;

- ▪

- Individual and personal factors.

2. Materials and Methods

2.1. Greenhouse, Cultivation, and Material

2.2. Participant Sample

2.3. Evaluation

2.3.1. Rapid Upper Limb Assessment Method

- ▪

- Posture adopted by different parts of the body (wrists, forearms, arms, neck, trunk, and legs);

- ▪

- Static muscle action or repetition;

- ▪

- Load.

2.3.2. Data Collection Techniques and Data Analyses

- ▪

- Observation of postures through video recordings of each of the cultivation tasks;

- ▪

- Selection of postures by task (agricultural work) that the worker performs more frequently or those which are more harmful;

- ▪

- The right and left parts of the body are individually evaluated. The one exposed to the greatest postural load (or both in case of doubt) is selected. In this evaluation, the most exposed body part was selected;

- ▪

- Measurements of angles in each posture (Appendix A). This was done on the images obtained from the observation;

- ▪

- The last steps of the method application were done using the Ergomet software [51]:

2.4. Melon Cultivation Tasks

3. Results

4. Discussion

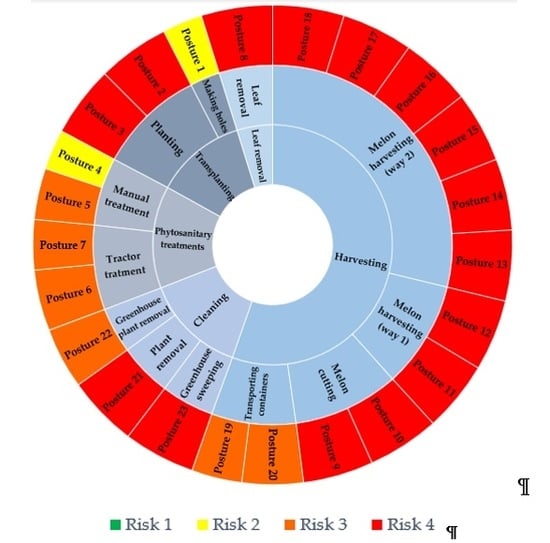

4.1. Risk Levels in Cultivation Tasks

4.2. Limitation and Advantages of the Study

4.3. Recommendations

- (a)

- In ‘melon harvesting (way 2)’, when the containers are stacked and have a high height, small stools could be used.

- (b)

- In the ‘making of holes’, ‘leaf removal’, ‘melon cutting’, or ‘sweeping’ task, it would be advisable to use tools with handles that can be adjusted according to the height of the worker.

- (c)

- For ‘melon harvesting (both ways)’, it would be recommended to use carts so as not to transport the boxes manually.

- (d)

- Use of carts to sit and be able to circulate in the workplace for subtasks such as ‘planting’, ‘cutting’ or ‘melon harvesting’.

- (e)

- Use of tractors more adapted to the Almeria-type greenhouses.

- (a)

- In subtasks such as ‘melon harvesting (both ways)’, lift loads by placing the legs with the balanced weight, using both hands and placing the load near the body.

- (b)

- In ‘melon harvesting (way 1)’, when heavier loads are lifted such as boxes full of melons, this subtask should be performed by two workers.

- (c)

- For subtasks that are practically carried out on the ground such as ‘planting’, ‘melon cutting’ and part of ‘melon harvesting’, knee bending is recommended.

- (d)

- For all cultivation tasks, change the posture after two minutes. Performing work shifts and tasks together are also recommended.

- (e)

- For tasks that may be possible, change arm and hand frequently, provided that the task does not involve much precision or force.

- (a)

- Taking ergonomic training courses for workers.

- (b)

- In subtasks such as ‘melon harvesting (both ways)’, putting less load in the boxes, so that their weight is lower, or use smaller boxes, with less capacity for melons. Also, recommend using the way 1 of melon harvesting (ST7) instead of way 2 (ST8).

- (c)

- Taking breaks of 10 min after performing 50 min of repetitive tasks, so that the upper limbs do not suffer too much.

- (d)

- Rotate between different subtasks, for example, in harvesting, to alternate the collection with the transport of containers and within the collection, to alternate between the actions of taking up from the ground, passing the melons to another worker, and throwing them into the containers.

- (e)

- Reorganization of work [8].

- (f)

- Physical training of workers [8].

- (g)

- Perform, whenever possible, the harvesting task with more workers and less time. The cost of the work will be the same since the employer pays for hours worked.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- ISO. Quality Management Systems-Requirements; ISO 9001; International Organization for Standardization (ISO): Geneva, Switzerland, 2015. [Google Scholar]

- ISO. Environmental Management Systems-Requirements with Guidance for Use; ISO 14001; International Organization for Standardization (ISO): Geneva, Switzerland, 2015. [Google Scholar]

- ISO. Occupational Health and Safety Management Systems—Requirements with Guidance for Use; ISO 45001; International Organization for Standardization (ISO): Geneva, Switzerland, 2018. [Google Scholar]

- Zink, K.J. Designing sustainable work systems: The need for a system approach. Appl. Ergon. 2014, 45, 126–132. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Aragon, L.; Lopez-Liria, R.; Callejon-Ferre, A.J.; Gomez-Galan, M. Applications of the Standardized Nordic Questionnaire: A Review. Sustainability 2017, 9, 1514. [Google Scholar] [CrossRef]

- IEA (International Ergonomics Association). What Is Ergonomics? Available online: https://www.iea.cc/whats/index.html (accessed on 2 October 2018).

- Villar-Fernández, M.F. La Carga Física de Trabajo. Available online: https://www.insst.es/InshtWeb/Contenidos/Carga%20fisica%20tme.pdf (accessed on 3 October 2018).

- Lopez-Aragon, L.; Lopez-Liria, R.; Callejon-Ferre, A.J.; Perez-Alonso, J. Musculoskeletal disorders of agricultural workers in the greenhouses of Almería (Southeast Spain). Saf. Sci. 2018, 109, 219–235. [Google Scholar] [CrossRef]

- Kim, E.; Freivalds, A.; Takeda, F.; Li, C. Ergonomic Evaluation of Current Advancements in Blueberry Harvesting. Agronomy 2018, 8, 266. [Google Scholar] [CrossRef]

- Epstein, S.; Tran, B.N.; Capone, A.C.; Ruan, Q.Z.; Lee, B.T.; Singhal, D. Work-related musculoskeletal disorders among plastic surgeons: A systematic review. J. Reconstr. Microsurg. 2018, 34, 553–562. [Google Scholar] [CrossRef]

- Hulls, P.M.; Money, A.; Agius, R.M.; de Vocht, F. Work-related ill-health in radiographers. Occup. Med. Oxf. 2018, 68, 354–359. [Google Scholar] [CrossRef] [Green Version]

- Chao, C.J.; Chen, M.C.; Yau, Y.J. Prevention of work-related musculoskeletal disorders in a chemical plant in Taiwan and a comparison of three assessment tools. Hum. Factors Ergon. Manuf. 2018, 28, 238–249. [Google Scholar] [CrossRef]

- Aje, O.O.; Smith-Campbell, B.; Bett, C. Preventing musculoskeletal disorders in factory workers evaluating a new eight minute stretching program. Workplace Health Saf. 2018, 66, 343–347. [Google Scholar] [CrossRef]

- Goossens, L.; Vercruysse, S.; Cardon, G.; Haerens, L.; Witvrouw, E.; De Clercq, D. Musculoskeletal injuries in physical education versus non-physical education teachers: A prospective study. J. Sport Sci. 2016, 34, 1107–1115. [Google Scholar] [CrossRef]

- Karakaya, I.C.; Karayaka, M.G.; Tunc, E.; Kihtir, M. Musculoskeletal problems and quality of life of elementary school teachers. Int. J. Occup. Saf. Ergo. 2015, 21, 344–350. [Google Scholar] [CrossRef]

- European Agency for Safety and Health at Work (EU-OSHA). Preventing Work-Related Musculoskeletal Disorders. FACTS 4. Available online: https://osha.europa.eu/en/tools-and-publications/publications/factsheets/4/view (accessed on 3 October 2018).

- European Agency for Safety and Health at Work (EU-OSHA). Introduction to Work-Related Musculoskeletal Disorders. FACTS 71. Available online: https://osha.europa.eu/en/tools-and-publications/publications/factsheets/71/view (accessed on 3 October 2018).

- Oficina Internacional del Trabajo (OIT). Seguridad y Salud en la Agricultura. Repertorio de Recomendaciones Prácticas. Available online: http://www.ilo.org/wcmsp5/groups/public/---ed_protect/---protrav/---safework/documents/normativeinstrument/wcms_161137.pdf (accessed on 6 October 2018).

- Cividino, S.R.S.; Pergher, G.; Gubiani, R.; Moreschi, C.; Da Broi, U.; Vello, M.; Rinaldi, F. Definition of a methodology for gradual and sustainable safety improvements on farms and its preliminary applications. Agriculture 2018, 8, 7. [Google Scholar] [CrossRef]

- Cutini, M.; Forte, G.; Maietta, M.; Mazzenga, M.; Mastrangelo, S.; Bisaglia, C. Safety-critical manuals for agricultural tractor drivers: A method to improve their usability. Agriculture 2017, 7, 67. [Google Scholar] [CrossRef]

- Gomez-Galan, M.; Perez-Alonso, J.; Callejon-Ferre, A.J.; Sanchez-Hermosilla-Lopez, J. Assessment of postural load during melon cultivation in Mediterranean greenhouses. Sustainability 2018, 10, 2729. [Google Scholar] [CrossRef]

- Gomez-Galan, M.; Gonzalez-Parra, J.M.; Perez-Alonso, J.; Golasi, I.; Callejon-Ferre, A.J. Forced Postures in Courgette Greenhouse Workers. Agronomy 2019, 9, 253. [Google Scholar] [CrossRef]

- Vazquez-Cabrera, F.J. Ergonomic evaluation, with the RULA method, of greenhouse tasks of trellising crops. Work 2016, 54, 517–531. [Google Scholar] [CrossRef]

- European Agency for Safety and Health at Work (EU-OSHA). Protección de la Salud y la Seguridad de los Trabajadores en la Agricultura, la Ganadería, la Horticultura y la Silvicultura. Available online: https://osha.europa.eu/es/tools-and-publications/publications/protecting-health-and-safety-workers-agriculture-livestock/view (accessed on 5 July 2019).

- Nuraydin, A.; Bilek, O.; Kenziman, A.K.; Korkusuz, M.A.; Atagun, A.I.; Cakar, N.O.; Ozer, N.; Deniz, S.; Basarali, M.K.; Ozlu, A.; et al. The mersin greenhouse workers study. Surveillance of work-related skin, respiratory, and musculoskeletal diseases. Ann. Glob. Health 2018, 84, 504–511. [Google Scholar] [CrossRef]

- Yao, H.Y.; Liu, J.J.; Zheng, W.J. Musculoskeletal disorders and its correlates among farmers working on vegetable greenhouse. Inj. Prev. 2016, 22, 274–275. [Google Scholar] [CrossRef]

- Gyemi, D.L.; van Wyk, P.M.; Statham, M.; Casey, J.; Andrews, D.M. 3D peak and cumulative low back and shoulder loads and postures during greenhouse pepper harvesting using a video-based approach. Work 2016, 55, 817–829. [Google Scholar] [CrossRef]

- Son, H.M.; Seonwoo, H.; Lim, K.T.; Chung, J.H. Continuous measurement of worker’s physiological and biomechanical information in the greenhouse. In Proceedings of the 6th World Congress of Biomechanics (WCB), Singapore, 1–6 August 2010; Lim, C.T., Goh, J.C.H., Eds.; pp. 103–106. [Google Scholar]

- Riemer, R.; Bechar, A. Investigation of productivity enhancement and biomechanical risks in greenhouse crops. Biosyst. Eng. 2016, 147, 39–50. [Google Scholar] [CrossRef]

- Okano, K.; Nakano, Y.; Watanabe, S. Single-truss tomato system-A labor-saving management system for tomato production. JARQ Jpn. Agric. Res. Q. 2001, 35, 177–184. [Google Scholar] [CrossRef]

- Cajamar-Caja Rural, 2018. AnáLisis de la Campana Hortofrutícola de Almería. Campaña 2017/2018. Available online: https://almeria2030.es/wp-content/uploads/2018/12/analisis-de-la-campana-hortofruticola-18.pdf (accessed on 7 July 2019).

- Callejon-Ferre, A.J.; Perez-Alonso, J.; Sanchez-Hermosilla, J.; Carreño-Ortega, A. Ergonomics and psycho-sociological quality indeces in greenhouses, Almería. Span. J. Agric. Res. 2009, 7, 50–58. [Google Scholar] [CrossRef]

- Gomez-Galan, M.; Perez-Alonso, J.; Callejon-Ferre, A.J.; Lopez-Martínez, J. Musculoskeletal disorders: OWAS review. Ind. Health 2017, 55, 314–337. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karhu, O.; Kansi, P.; Kuorinka, I. Correcting working postures in industry: A practical method for analysis. Appl. Ergon. 1977, 8, 199–201. [Google Scholar] [CrossRef]

- Kilbom, A.; Persson, J.; Jonsson, B. Risk Factors for Work-Related Disorders of the Neck and Shoulder—With Special Emphasis on Working Postures and Movements. In the Ergonomics of Working Postures; Corlett, E.N., Wilson, J., Manenica, I., Eds.; Taylor & Francis: London, UK, 1986; pp. 44–53. [Google Scholar]

- Buchholz, B.; Paquet, V.; Punnett, L.; Lee, D.; Moir, S. PATH: A work sampling-based approach to ergonomic job analysis for construction and other non-repetitive work. Appl. Ergon. 1996, 27, 177–187. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Corlett, E.; Madeley, S.; Manenica, I. Posture targeting: A technique for recording working postures. Ergonomics 1979, 22, 357–633. [Google Scholar] [CrossRef]

- Monnington, S.; Quarrie, C.; Pinder, A.; Morris, L. Development of Manual Handling Assessment Charts (MAC) for health and safety inspectors. In Contemporary Ergonomics; Taylor & Francis: London, UK, 2003. [Google Scholar]

- Snook, S.H.; Ciriello, V.M. The design of manual handling tasks: Revised tables of maximum acceptable weights and forces. Ergonomics 1991, 34, 1197–1213. [Google Scholar] [CrossRef]

- Jürgens, W.W.; Mohr, D.; Pangert, R.; Pernack, E.; Schultz, K.; Steinberg, U. Handlungsanleitung zur Beurteilung der Arbeitsbedingungen beim Heben und Tragen von Lasten. LASI Veröffentlichung 2001, 9. [Google Scholar]

- Instituto Nacional de Seguridad y Salud en el Trabajo (INSST). Guía Técnica para la Evaluación y Prevención de los Riesgos Relativos a la Manipulación Manual de Cargas. Guías Técnicas; INSST: Madrid, Spain, 1998. [Google Scholar]

- Liberty-Mutual. Manual Materials Handling Tables. Available online: https://libertymmhtables.libertymutual.com/CM_LMTablesWeb/taskSelection.do?action=initTaskSelection (accessed on 9 October 2018).

- NIOSH (National Institute for Occupational Safety and Health). Work Practices Guide for Manual Lifting; NIOSH Technical Report; NIOSH: Cincinnaty, OH, USA, 1981; pp. 81–122. [Google Scholar]

- Colombini, D. An observational method for classifying exposure to repetitive movements of the upper limbs. Ergonomics 1998, 41, 1261–1289. [Google Scholar] [CrossRef]

- Kemmlert, K. A method assigned for the identification of ergonomic hazards—PLIBEL. Appl. Ergon. 1995, 26, 199–211. [Google Scholar] [CrossRef]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- García, C.; Chirivela, C.; Page del Pozo, A.; Moraga, R.; Jorquera, J. Método Ergo IBV. Evaluación de Riesgos Laborales Asociados a la Carga Física; Instituto de Biomecánica de Valencia (IBV): Valencia, Spain, 1997. [Google Scholar]

- James, C.P.A.; Harburn, K.L.; Kramer, J.F. Cumulative trauma disorders in the upper extremities: Reliability of the Postural and Repetitive Risk-Factors Index. Arch. Phys. Med. Rehab. 1997, 78, 860–866. [Google Scholar] [CrossRef]

- Moore, J.S.; Garg, A. The Strain Index: A proposed method to analyze jobs for risk of distal upper extremity disorders. Am. Ind. Hyg. Assoc. J. 1995, 56, 443–458. [Google Scholar] [CrossRef]

- Instituto de Ergonomía (INERMAP). Ergomet 3.0. Available online: http://www.inermap.com/software/ergomet.html (accessed on 12 November 2018).

- Kim, K.; Kim, K.; Kim, H.; Lee, K. Risk assessment and symptoms of musculoskeletal disorders in melon farm workers. J. Korean Soc. Occup. Environ. Hyg. 2006, 16, 385–397. [Google Scholar]

- Callejon-Ferre, A.J.; Perez-Alonso, J.; Carreno-Ortega, A.; Velazquez-Marti, B. Indices of ergonomic-psycholsociological workplace quality in the greenhouses of Almeria (Spain): Crops of cucumbers, peppers, aubergines and melons. Saf. Sci. 2011, 49, 746–750. [Google Scholar] [CrossRef]

- Mohd Nasir, N.S.; Mohd Tamrin, S.B.; Subramanian, K.; Shukoor, N.S.; Zolkifli, N.; Ng, G.S.; Muhamad Akir, N.F.; Ananta, G.P. Association of Workplace Stressor with Salivary Alpha-Amylase Activity Levels among Fresh Fruit Bunch Cutters in Selangor. Iran. J. Public Health 2016, 45, 68–76. [Google Scholar]

- Jain, R.; Meena, M.L.; Dangayach, G.S.; Bhardwaj, A.K. Risk factors for musculoskeletal disorders in manual harvesting farmers of Rajasthan. Ind. Health 2018, 56, 241–248. [Google Scholar] [CrossRef] [Green Version]

- Fathallah, F.A. Musculoskeletal disorders in labor-intensive agriculture. Appl. Ergon. 2010, 41, 738–743. [Google Scholar] [CrossRef]

- Castilla, N. Invernaderos de plástico. Tecnología y manejo; Mundi-Prensa: Madrid, Spain, 2005. [Google Scholar]

- Almodóvar-Molina, A.; Galiana-Blanco, M.L.; Hervás-Rivero, P.; Pinilla-García, F.J. VII Encuesta Nacional de Condiciones de Trabajo 2011. Available online: http://www.insht.es/InshtWeb/Contenidos/Documentacion/FICHAS%20DE%20PUBLICACIONES/EN%20CATALOGO/OBSERVATORIO/Informe%20(VII%20ENCT).pdf (accessed on 10 July 2019).

- Villar-Fernández, M.F. Posturas de Trabajo: Evaluación del Riesgo. Available online: https://www.insst.es/documents/94886/96076/Posturas+de+trabajo.pdf/3ff0eb49-d59e-4210-92f8-31ef1b017e66 (accessed on 30 November 2018).

- Instituto Nacional de Seguridad y Salud en el Trabajo (INSST). Buenas Prácticas Mediante la Modificación o Adquisición de Herramientas y Equipos. Trastornos Musculoesqueléticos. Available online: http://www.insht.es/MusculoEsqueleticos/Contenidos/Buenas%20practicas/ficheros/55.BP_Modificación_adquisición_herramientas_equipos.pdf (accessed on 20 November 2018).

- Instituto Nacional de Seguridad y Salud en el Trabajo (INSST). Buenas Prácticas Mediante Técnicas de Ejecución del Trabajo. Trastornos Musculoesqueléticos. Available online: http://www.insht.es/MusculoEsqueleticos/Contenidos/Buenas%20practicas/ficheros/56.BP_Tecnicas.pdf (accessed on 20 November 2018).

- Instituto Nacional de Seguridad y Salud en el Trabajo (INSST). Buenas Prácticas Mediante la Organización del Trabajo. Trastornos Musculoesqueléticos. Available online: http://www.insht.es/MusculoEsqueleticos/Contenidos/Buenas%20practicas/ficheros/54.BP_Organización%20del%20trabajo.pdf (accessed on 20 November 2018).

| OCRA [45] | RULA [47] | Job Strain Index [50] | |

|---|---|---|---|

| Consider a large number of risks | 5 | 3 | 4 |

| Consider more body parts in addition to upper limbs | 0 | 4 | 0 |

| Long observation period | 5 | 4 | 4 |

| Low complexity in its application | 1 | 3 | 3 |

| Total | 11 | 14 | 11 |

| Action Level | Score | Corrections |

|---|---|---|

| 1 | 1–2 | It is not necessary to take actions. Acceptable risk. |

| 2 | 3–4 | It may be necessary to adopt some modifications, but not in a short period. |

| 3 | 5–6 | Corrections must be implemented in the task performance in a short period. |

| 4 | 7 | Corrections must be implemented in the task performance immediately. |

| Tasks | Subtasks (See Appendix A) | Posture | Angles (°) | ||||

|---|---|---|---|---|---|---|---|

| Arm | Forearm | Wrist | Neck | Trunk | |||

| Transplanting | Making holes (ST1) | 1 | 24 | 94 | 26 | 33 | 20 |

| Planting (ST2) | 2 | 63 | 18 | 20 | 12 | 63 | |

| 3 | 85 | 29 | 43 | 15 | 102 | ||

| Phytosanitary treatments | Manual treatment (ST3) | 4 | 33 | 62 | 12 | 13 | 3 |

| 5 | 19 | 80 | 0 | 26 | 4 | ||

| Tractor treatment (ST4) | 6 | 39 | 49 | 24 | 21 | 22 | |

| 7 | 23 | 71 | 0 | 9 | 10 | ||

| Leaf removal | Leaf removal (ST5) | 8 | 60 | 62 | 0 | 34 | 15 |

| Harvesting | Melon cutting (ST6) | 9 | 91 | 38 | 22 | 43 | 112 |

| 10 | 76 | 45 | 28 | 33 | 95 | ||

| Melon harvesting (way 1) (ST7) | 11 | 34 | 82 | 0 | 16 | 84 | |

| 12 | 14 | 65 | 10 | 14 | 0 | ||

| Melon harvesting (way 2) (ST8) | 13 | 91 | 59 | 0 | 61 | 105 | |

| 14 | 88 | 24 | 13 | 37 | 58 | ||

| 15 | 14 | 54 | 16 | 13 | 26 | ||

| 16 | 57 | 70 | 0 | 20 | 20 | ||

| 17 | 31 | 75 | 17 | 17 | 26 | ||

| 18 | 119 | 38 | 0 | 0 | 17 | ||

| Transporting containers (ST9) | 19 | 55 | 13 | 24 | 24 | 17 | |

| 20 | 37 | 51 | 8 | 20 | 22 | ||

| Cleaning | Plant removal (ST10) | 21 | 44 | 80 | 30 | 0 | 79 |

| Greenhouse plant removal (ST11) | 22 | 27 | 24 | 70 | 0 | 17 | |

| Greenhouse sweeping (ST12) | 23 | 30 | 73 | 0 | 13 | 36 | |

| Tasks | Subtasks (See Appendix A) | Posture | Score C | Score D | Total Score (See Table 2) |

|---|---|---|---|---|---|

| Transplanting | Making holes (ST1) | 1 | 4 | 4 | 4 |

| Planting (ST2) | 2 | 5 | 6 | 7 | |

| 3 | 6 | 6 | 7 | ||

| Phytosanitary treatments | Manual treatment (ST3) | 4 | 5 | 3 | 4 |

| 5 | 4 | 5 | 5 | ||

| Tractor treatment (ST4) | 6 | 4 | 6 | 6 | |

| 7 | 4 | 5 | 5 | ||

| Leaf removal | Leaf removal (ST5) | 8 | 6 | 7 | 7 |

| Harvesting | Melon cutting (ST6) | 9 | 5 | 6 | 7 |

| 10 | 5 | 7 | 7 | ||

| Melon harvesting (way 1) (ST7) | 11 | 5 | 8 | 7 | |

| 12 | 6 | 9 | 7 | ||

| Melon harvesting (way2) (ST8) | 13 | 5 | 6 | 7 | |

| 14 | 5 | 6 | 7 | ||

| 15 | 6 | 7 | 7 | ||

| 16 | 6 | 6 | 7 | ||

| 17 | 6 | 8 | 7 | ||

| 18 | 7 | 6 | 7 | ||

| Transporting containers (ST9) | 19 | 5 | 4 | 5 | |

| 20 | 4 | 6 | 6 | ||

| Cleaning | Plant removal (ST10) | 21 | 6 | 8 | 7 |

| Greenhouse plant removal (ST11) | 22 | 5 | 5 | 6 | |

| Greenhouse sweeping (ST12) | 23 | 5 | 7 | 7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-Galán, M.; Callejón-Ferre, Á.-J.; Pérez-Alonso, J.; Díaz-Pérez, M.; Golasi, I. Repetitive Movements in Melon Cultivation Workers under Greenhouses. Agriculture 2019, 9, 236. https://doi.org/10.3390/agriculture9110236

Gómez-Galán M, Callejón-Ferre Á-J, Pérez-Alonso J, Díaz-Pérez M, Golasi I. Repetitive Movements in Melon Cultivation Workers under Greenhouses. Agriculture. 2019; 9(11):236. https://doi.org/10.3390/agriculture9110236

Chicago/Turabian StyleGómez-Galán, Marta, Ángel-Jesús Callejón-Ferre, José Pérez-Alonso, Manuel Díaz-Pérez, and Iacopo Golasi. 2019. "Repetitive Movements in Melon Cultivation Workers under Greenhouses" Agriculture 9, no. 11: 236. https://doi.org/10.3390/agriculture9110236

APA StyleGómez-Galán, M., Callejón-Ferre, Á. -J., Pérez-Alonso, J., Díaz-Pérez, M., & Golasi, I. (2019). Repetitive Movements in Melon Cultivation Workers under Greenhouses. Agriculture, 9(11), 236. https://doi.org/10.3390/agriculture9110236