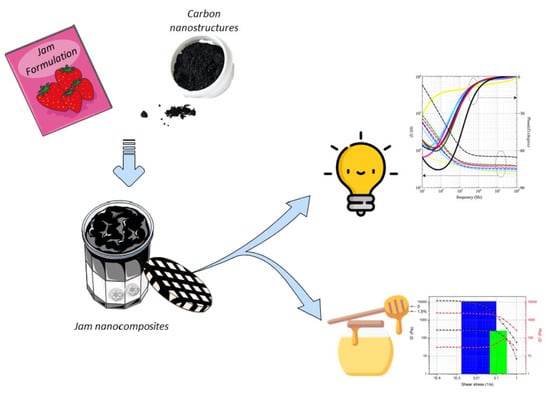

MacGyvered Multiproperty Materials Using Nanocarbon and Jam: A Spectroscopic, Electromagnetic, and Rheological Investigation

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Hydrogel Preparation

3. Characterization

4. Results and Discussion

4.1. Raman Spectroscopy

4.2. Impedance Measurement

4.3. Rheological Measurements

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kelly, J. How “MacGyver” Became a Verb. BBC News. 2015. Available online: https://www.bbc.com/news/magazine-34075407 (accessed on 18 November 2021).

- Awulachew, M.T. A Current Perspective to Jam Production. Adv. Nutr Food Sci. 2021, 6, 1–4. [Google Scholar]

- Huang, Y.; Kormakov, S.; He, X.; Gao, X.; Zheng, X.; Liu, Y.; Sun, J.; Wu, D. Conductive Polymer Composites from Renewable Resources: An Overview of Preparation, Properties, and Applications. Polymers 2019, 11, 187. [Google Scholar] [CrossRef] [Green Version]

- Sayyar, S.; Murray, E.; Thompson, B.; Chung, J.; Officer, D.; Gambhir, S.; Spinks, G.; Wallace, G. Processable Conducting Graphene/Chitosan Hydrogels for Tissue Engineering. J. Mater. Chem. B 2015, 3, 481–490. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Li, Y.; Li, L.; Guo, B.; Ma, P.X. Non-Cytotoxic Conductive Carboxymethyl-Chitosan/Aniline Pentamer Hydrogels. React. Funct. Polym. 2014, 82, 81–88. [Google Scholar] [CrossRef]

- Balint, R.; Cassidy, N.J.; Cartmell, S.H. Conductive Polymers: Towards a Smart Biomaterial for Tissue Engineering. Acta Biomater. 2014, 10, 2341–2353. [Google Scholar] [CrossRef]

- Ferrigno, B.; Bordett, R.; Duraisamy, N.; Moskow, J.; Arul, M.R.; Rudraiah, S.; Nukavarapu, S.P.; Vella, A.T.; Kumbar, S.G. Bioactive Polymeric Materials and Electrical Stimulation Strategies for Musculoskeletal Tissue Repair and Regeneration. Bioact. Mater. 2020, 5, 468–485. [Google Scholar] [CrossRef]

- Boni, R.; Ali, A.; Shavandi, A.; Clarkson, A.N. Current and Novel Polymeric Biomaterials for Neural Tissue Engineering. J. Biomed. Sci. 2018, 25, 90. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bakshi, P.S.; Selvakumar, D.; Kadirvelu, K.; Kumar, N.S. Chitosan as an Environment Friendly Biomaterial—A Review on Recent Modifications and Applications. Int. J. Biol. Macromol. 2020, 150, 1072–1083. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Ahmed, S. A Review on Chitosan and Its Nanocomposites in Drug Delivery. Int. J. Biol. Macromol. 2018, 109, 273–286. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Wan, Y.; Zheng, Y.; Lee, X.; Liu, T.; Yu, Z.; Huang, J.; Ok, Y.S.; Chen, J.; Gao, B. Alginate-Based Composites for Environmental Applications: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 318–356. [Google Scholar] [CrossRef] [PubMed]

- Hernández-González, A.C.; Téllez-Jurado, L.; Rodríguez-Lorenzo, L.M. Alginate Hydrogels for Bone Tissue Engineering, from Injectables to Bioprinting: A Review. Carbohydr. Polym. 2020, 229, 115514. [Google Scholar] [CrossRef] [PubMed]

- Nasrollahzadeh, M.; Sajjadi, M.; Iravani, S.; Varma, R.S. Starch, Cellulose, Pectin, Gum, Alginate, Chitin and Chitosan Derived (Nano) Materials for Sustainable Water Treatment: A Review. Carbohydr. Polym. 2020, 251, 116986. [Google Scholar] [CrossRef] [PubMed]

- Sorrentino, A.; Cataldo, A.; Curatolo, R.; Tagliatesta, P.; Mosca, L.; Bellucci, S. Novel Optimized Biopolymer-Based Nanoparticles for Nose-to-Brain Delivery in the Treatment of Depressive Diseases. RSC Adv. 2020, 10, 28941–28949. [Google Scholar] [CrossRef]

- Mauri, E.; Salvati, A.; Cataldo, A.; Mozetic, P.; Basoli, F.; Abbruzzese, F.; Trombetta, M.; Bellucci, S.; Rainer, A. Graphene-Laden Hydrogels: A Strategy for Thermally Triggered Drug Delivery. Mater. Sci. Eng. C 2021, 118, 111353. [Google Scholar] [CrossRef]

- Trapani, A.; Corbo, F.; Agrimi, G.; Ditaranto, N.; Cioffi, N.; Perna, F.; Quivelli, A.; Stefàno, E.; Lunetti, P.; Muscella, A.; et al. Oxidized Alginate Dopamine Conjugate: In Vitro Characterization for Nose-to-Brain Delivery Application. Materials 2021, 14, 3495. [Google Scholar] [CrossRef] [PubMed]

- Kim, S. Competitive Biological Activities of Chitosan and Its Derivatives: Antimicrobial, Antioxidant, Anticancer, and Anti-Inflammatory Activities. Int. J. Polym. Sci. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Banat, F.; Show, P.L.; Cocoletzi, H.H. Mango Leaf Extract Incorporated Chitosan Antioxidant Film for Active Food Packaging. Int. J. Biol. Macromol. 2019, 126, 1234–1243. [Google Scholar]

- Dou, L.; Li, B.; Zhang, K.; Chu, X.; Hou, H. Physical Properties and Antioxidant Activity of Gelatin-Sodium Alginate Edible Films with Tea Polyphenols. Int. J. Biol. Macromol. 2018, 118, 1377–1383. [Google Scholar] [CrossRef]

- Fabra, M.J.; Falcó, I.; Randazzo, W.; Sánchez, G.; López-Rubio, A. Antiviral and Antioxidant Properties of Active Alginate Edible Films Containing Phenolic Extracts. Food Hydrocoll. 2018, 81, 96–103. [Google Scholar] [CrossRef]

- Lara-Espinoza, C.; Carvajal-Millán, E.; Balandrán-Quintana, R.; López-Franco, Y.; Rascón-Chu, A. Pectin and Pectin-Based Composite Materials: Beyond Food Texture. Molecules 2018, 23, 942. [Google Scholar] [CrossRef] [Green Version]

- Gong, J.-L.; Wang, X.-Y.; Zeng, G.-M.; Chen, L.; Deng, J.-H.; Zhang, X.-R.; Niu, Q.-Y. Copper (II) Removal by Pectin–Iron Oxide Magnetic Nanocomposite Adsorbent. Chem. Eng. J. 2012, 185, 100–107. [Google Scholar] [CrossRef]

- Attallah, O.A.; Al-Ghobashy, M.A.; Nebsen, M.; Salem, M.Y. Removal of Cationic and Anionic Dyes from Aqueous Solution with Magnetite/Pectin and Magnetite/Silica/Pectin Hybrid Nanocomposites: Kinetic, Isotherm and Mechanism Analysis. RSC Adv. 2016, 6, 11461–11480. [Google Scholar] [CrossRef]

- Gupta, V.K.; Agarwal, S.; Pathania, D.; Kothiyal, N.C.; Sharma, G. Use of Pectin–Thorium (IV) Tungstomolybdate Nanocomposite for Photocatalytic Degradation of Methylene Blue. Carbohydr. Polym. 2013, 96, 277–283. [Google Scholar] [CrossRef]

- Cavallaro, G.; Lazzara, G.; Milioto, S. Sustainable Nanocomposites Based on Halloysite Nanotubes and Pectin/Polyethylene Glycol Blend. Polym. Degrad. Stab. 2013, 98, 2529–2536. [Google Scholar] [CrossRef] [Green Version]

- Mangiacapra, P.; Gorrasi, G.; Sorrentino, A.; Vittoria, V. Biodegradable Nanocomposites Obtained by Ball Milling of Pectin and Montmorillonites. Carbohydr. Polym. 2006, 64, 516–523. [Google Scholar] [CrossRef]

- Farahnaky, A.; Sharifi, S.; Imani, B.; Dorodmand, M.M.; Majzoobi, M. Physicochemical and Mechanical Properties of Pectin-Carbon Nanotubes Films Produced by Chemical Bonding. Food Packag. Shelf Life 2018, 16, 8–14. [Google Scholar] [CrossRef]

- Pandele, A.M.; Andronescu, C.; Vasile, E.; Radu, I.C.; Stanescu, P.; Iovu, H. Non-Covalent Functionalization of GO for Improved Mechanical Performances of Pectin Composite Films. Compos. Part. A Appl. Sci. Manuf. 2017, 103, 188–195. [Google Scholar] [CrossRef]

- Gong, X.; Wu, J.; Meng, Y.; Zhang, Y.; Ye, L.-W.; Zhu, C. Ligand-Free Palladium Catalyzed Ullmann Biaryl Synthesis: “Household” Reagents and Mild Reaction Conditions. Green Chem. 2019, 21, 995–999. [Google Scholar] [CrossRef]

- Rojanarata, T.; Plianwong, S.; Opanasopit, P.; Ngawhirunpat, T. Enrichment of Gamma-Aminobutyric Acid in Bean Sprouts: Exploring Biosynthesis of Plant Metabolite Using Common Household Reagents. Biochem. Mol. Biol. Educ. 2018, 46, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Peper, S.M.; McNamara, B.K.; O’Hara, M.J.; Douglas, M. A Green Approach to Snf Reprocessing: Are Common Household Reagents the Answer? In Proceedings of the 8th International Conference on Facility Operations: Safeguards Interface, Portland, OR, USA, 30 March–4 April 2008; Volume 1, pp. 308–314. [Google Scholar]

- Weng, B.; Shepherd, R.L.; Crowley, K.; Killard, A.J.; Wallace, G.G. Printing Conducting Polymers. Analyst 2010, 135, 2779–2789. [Google Scholar] [CrossRef]

- Rosati, G.; Ravarotto, M.; Sanavia, M.; Scaramuzza, M.; De Toni, A.; Paccagnella, A. Inkjet Sensors Produced by Consumer Printers with Smartphone Impedance Readout. Sens. Bio-Sens. Res. 2019, 26, 100308. [Google Scholar] [CrossRef]

- Ismail, Z.; Idris, W.F.W.; Abdullah, A.H. From Shear Exfoliation of Graphite in Coca-Cola® to Few-Layer Graphene for Smart Ink. Ceram. Int. 2021, 47, 23309–23317. [Google Scholar] [CrossRef]

- Ismail, Z.; Kassim, N.F.A.; Abdullah, A.H.; Abidin, A.S.Z.; Ismail, F.S.; Yusoh, K. Black Tea Assisted Exfoliation Using a Kitchen Mixer Allowing One-Step Production of Graphene. Mater. Res. Express 2017, 4, 075607. [Google Scholar] [CrossRef]

- Nyanor, P.; El-Kady, O.; Yehia, H.M.; Hamada, A.S.; Nakamura, K.; Hassan, M.A. Effect of Carbon Nanotube (CNT) Content on the Hardness, Wear Resistance and Thermal Expansion of in-Situ Reduced Graphene Oxide (RGO)-Reinforced Aluminum Matrix Composites. Met. Mater. Int. 2021, 27, 1315–1326. [Google Scholar] [CrossRef]

- Salahuddin, B.; Faisal, S.N.; Baigh, T.A.; Alghamdi, M.N.; Islam, M.S.; Song, B.; Zhang, X.; Gao, S.; Aziz, S. Carbonaceous Materials Coated Carbon Fibre Reinforced Polymer Matrix Composites. Polymers 2021, 13, 2771. [Google Scholar] [CrossRef]

- Li, S.; Liao, X.; Xiao, W.; Jiang, Q.; Li, G. The Improved Foaming Behavior of PLA Caused by the Enhanced Rheology Properties and Crystallization Behavior via Synergistic Effect of Carbon Nanotubes and Graphene. J. Appl. Polym. Sci. 2021, 139, 51874. [Google Scholar] [CrossRef]

- Bianco, A.; Kostarelos, K.; Prato, M. Applications of Carbon Nanotubes in Drug Delivery. Curr. Opin. Chem. Biol. 2005, 9, 674–679. [Google Scholar] [CrossRef]

- Hasnain, M.S.; Nayak, A.K. Carbon Nanotubes for Targeted Drug Delivery; Springer: Berlin/Heildeberg, Germany, 2019. [Google Scholar]

- Liu, J.; Cui, L.; Losic, D. Graphene and Graphene Oxide as New Nanocarriers for Drug Delivery Applications. Acta Biomater. 2013, 9, 9243–9257. [Google Scholar] [CrossRef]

- Harrison, B.S.; Atala, A. Carbon Nanotube Applications for Tissue Engineering. Biomaterials 2007, 28, 344–353. [Google Scholar] [CrossRef]

- Sahithi, K.; Swetha, M.; Ramasamy, K.; Srinivasan, N.; Selvamurugan, N. Polymeric Composites Containing Carbon Nanotubes for Bone Tissue Engineering. Int. J. Biol. Macromol. 2010, 46, 281–283. [Google Scholar] [CrossRef]

- Shin, S.R.; Li, Y.-C.; Jang, H.L.; Khoshakhlagh, P.; Akbari, M.; Nasajpour, A.; Zhang, Y.S.; Tamayol, A.; Khademhosseini, A. Graphene-Based Materials for Tissue Engineering. Adv. Drug Deliv. Rev. 2016, 105, 255–274. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cellot, G.; Cilia, E.; Cipollone, S.; Rancic, V.; Sucapane, A.; Giordani, S.; Gambazzi, L.; Markram, H.; Grandolfo, M.; Scaini, D. Carbon Nanotubes Might Improve Neuronal Performance by Favouring Electrical Shortcuts. Nat. Nanotechnol. 2009, 4, 126. [Google Scholar] [CrossRef] [PubMed]

- Bellucci, S.; Bozzi, M.; Cataldo, A.; Moro, R.; Mencarelli, D.; Pierantoni, L. Graphene as a Tunable Resistor. In Proceedings of the 2014 International Semiconductor Conference (CAS), Sinaia, Romania, 13–15 October 2014; pp. 17–20. [Google Scholar]

- Dabrowska, A.; Bellucci, S.; Cataldo, A.; Micciulla, F.; Huczko, A. Nanocomposites of Epoxy Resin with Graphene Nanoplates and Exfoliated Graphite: Synthesis and Electrical Properties. Phys. Status Solidi B 2014, 251, 2599–2602. [Google Scholar] [CrossRef]

- Maffucci, A.; Micciulla, F.; Cataldo, A.; Miano, G.; Bellucci, S. Bottom-up Realization and Electrical Characterization of a Graphene-Based Device. Nanotechnology 2016, 27, 095204. [Google Scholar] [CrossRef]

- Thakur, B.R.; Singh, R.K.; Handa, A.K.; Rao, M.A. Chemistry and Uses of Pectin—A Review. Crit. Rev. Food Sci. Nutr. 1997, 37, 47–73. [Google Scholar] [CrossRef]

- Sundar Raj, A.A.; Rubila, S.; Jayabalan, R.; Ranganathan, T.V. A Review on Pectin: Chemistry Due to General Properties of Pectin and Its Pharmaceutical Uses. Open Access Sci. Rep. 2012, 1. [Google Scholar] [CrossRef]

- Sammer, M.; Laarhoven, B.; Mejias, E.; Yntema, D.; Fuchs, E.C.; Holler, G.; Brasseur, G.; Lankmayr, E. Biomass Measurement of Living Lumbriculus Variegatus with Impedance Spectroscopy. J. Electr. Bioimpedance 2014, 5, 92–98. [Google Scholar] [CrossRef] [Green Version]

- Miranda, A.R.; Vannucci, A.; Pontuschka, W.M. Impedance Spectroscopy of Water in Comparison with High Dilutions of Lithium Chloride. Mater. Res. Innov. 2011, 15, 302–309. [Google Scholar] [CrossRef]

- Sekine, Y.; Ikeda-Fukazawa, T. Structural Changes of Water in a Hydrogel during Dehydration. J. Chem. Phys. 2009, 130, 034501. [Google Scholar] [CrossRef]

- Mezger, T. The Rheology Handbook; Vincentz Network: Hannover, Germany, 2020. [Google Scholar]

- Penu, C.; Hu, G.-H.; Fernandez, A.; Marchal, P.; Choplin, L. Rheological and Electrical Percolation Thresholds of Carbon Nanotube/Polymer Nanocomposites. Polym. Eng. Sci. 2012, 52, 2173–2181. [Google Scholar] [CrossRef]

- Ferrigno, L.; Cataldo, A.; Sibilia, S.; Maffucci, A.; Bellucci, S. A Monitorable and Renewable Pollution Filter Based on Graphene Nanoplatelets. Nanotechnology 2019, 31, 075701. [Google Scholar] [CrossRef] [PubMed]

- Miele, G.; Bellucci, S.; Cataldo, A.; Di Tinno, A.; Ferrigno, L.; Maffucci, A.; Micheli, L.; Sibilia, S. Electrical Impedance Spectroscopy for Real-Time Monitoring of the Life Cycle of Graphene Nanoplatelets Filters for Some Organic Industrial Pollutants. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Ferrigno, L.; Maffucci, A.; Miele, G.; Sibilia, S.; Bellucci, S.; Cataldo, A. Multi-Frequency Signal for Saturation Detection of a Pollution Filter Based on Graphene Nanoplatelets. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020; pp. 1–6. [Google Scholar]

- Masotti, A.; Miller, M.R.; Celluzzi, A.; Rose, L.; Micciulla, F.; Hadoke, P.W.; Bellucci, S.; Caporali, A. Regulation of Angiogenesis through the Efficient Delivery of MicroRNAs into Endothelial Cells Using Polyamine-Coated Carbon Nanotubes. Nanomed. Nanotechnol. Biol. Med. 2016, 12, 1511–1522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sample | Peak Frequency (Hz) | Simulated Peak Frequency (Hz) |

|---|---|---|

| Jam | 69.0 | 71.5 |

| CNT 0.05% | 40.7 | 38.5 |

| CNT 0.25% | 53.0 | 46.9 |

| CNT 0.5% | 31.3 | 32.4 |

| CNT 0.75% | 22.0 | 24.1 |

| CNT 1% | - | 9.1 |

| CNT 1.5% | - | 6.3 |

| Sample | 1st Peak Frequency (Hz) | 2nd Peak Frequency (Hz) | 1st Simulated Peak Frequency (Hz) | 2nd Simulated Peak Frequency (Hz) |

|---|---|---|---|---|

| Jam | 69.0 | - | 75.6 | - |

| GNP 0.05% | 53.0 | - | 47.2 | - |

| GNP 0.25% | 31.3 | 88,194.4 | 36.4 | 52,266.1 |

| GNP 0.5% | 27.4 | 56,864.3 | 36.3 | 40,128.8 |

| GNP 0.75% | 37.3 | 80,783.1 | 45.4 | 49,621.7 |

| GNP 1% | 24.1 | 56,864.3 | 21.5 | 38,453.2 |

| GNP 1.5% | - | 96,285.5 | 7.8 | 59,672.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cataldo, A.; La Pietra, M.; Zappelli, L.; Mencarelli, D.; Pierantoni, L.; Bellucci, S. MacGyvered Multiproperty Materials Using Nanocarbon and Jam: A Spectroscopic, Electromagnetic, and Rheological Investigation. J. Funct. Biomater. 2022, 13, 5. https://doi.org/10.3390/jfb13010005

Cataldo A, La Pietra M, Zappelli L, Mencarelli D, Pierantoni L, Bellucci S. MacGyvered Multiproperty Materials Using Nanocarbon and Jam: A Spectroscopic, Electromagnetic, and Rheological Investigation. Journal of Functional Biomaterials. 2022; 13(1):5. https://doi.org/10.3390/jfb13010005

Chicago/Turabian StyleCataldo, Antonino, Matteo La Pietra, Leonardo Zappelli, Davide Mencarelli, Luca Pierantoni, and Stefano Bellucci. 2022. "MacGyvered Multiproperty Materials Using Nanocarbon and Jam: A Spectroscopic, Electromagnetic, and Rheological Investigation" Journal of Functional Biomaterials 13, no. 1: 5. https://doi.org/10.3390/jfb13010005

APA StyleCataldo, A., La Pietra, M., Zappelli, L., Mencarelli, D., Pierantoni, L., & Bellucci, S. (2022). MacGyvered Multiproperty Materials Using Nanocarbon and Jam: A Spectroscopic, Electromagnetic, and Rheological Investigation. Journal of Functional Biomaterials, 13(1), 5. https://doi.org/10.3390/jfb13010005