Heat Dissipation in Flexible Nitride Nanowire Light-Emitting Diodes

Abstract

:1. Introduction

2. Materials and Methods

2.1. InGaN/GaN Nanowire Growth

2.2. Flexible InGaN/GaN Nanowire LED Fabrication

3. Results and Discussion

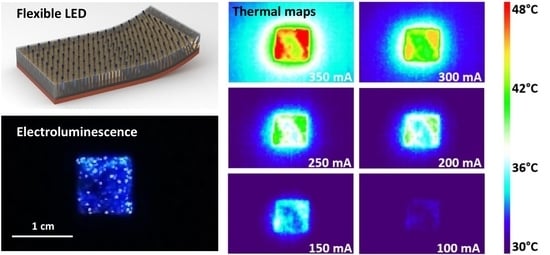

3.1. Flexible InGaN/GaN Nanowire LED Properties

3.2. Thermal Imaging of Flexible InGaN/GaN Nanowire LED under High Current

3.3. Modeling of Heat Dissipation in Flexible NW LEDs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Park, S.-I.; Xiong, Y.; Kim, R.-H.; Elvikis, P.; Meitl, M.; Kim, D.-H.; Wu, J.; Yoon, J.; Yu, C.-J.; Liu, Z.; et al. Printed Assemblies of Inorganic Light-Emitting Diodes for Deformable and Semitransparent Displays. Science 2009, 325, 977–981. [Google Scholar] [CrossRef] [Green Version]

- Chun, J.; Hwang, Y.; Choi, Y.-S.; Jeong, T.; Baek, J.H.; Ko, H.C.; Park, S.-J. Transfer of GaN LEDs From Sapphire to Flexible Substrates by Laser Lift-Off and Contact Printing. IEEE Photonics Technol. Lett. 2012, 24, 2115–2118. [Google Scholar] [CrossRef]

- Zhang, H.; Rogers, J.A. Recent Advances in Flexible Inorganic Light Emitting Diodes: From Materials Design to Integrated Optoelectronic Platforms. Adv. Opt. Mater. 2019, 7, 1800936. [Google Scholar] [CrossRef] [Green Version]

- Guan, N.; Dai, X.; Babichev, A.V.; Julien, F.H.; Tchernycheva, M. Flexible inorganic light emitting diodes based on semiconductor nanowires. Chem. Sci. 2017, 8, 7904–7911. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.-H.; Kim, Y.-J.; Hong, Y.J.; Jeon, S.-R.; Bae, S.; Hong, B.H.; Yi, G.-C. Flexible Inorganic Nanostructure Light-Emitting Diodes Fabricated on Graphene Films. Adv. Mater. 2011, 23, 4614–4619. [Google Scholar] [CrossRef]

- Chung, K.; Beak, H.; Tchoe, Y.; Oh, H.; Yoo, H.; Kim, M.; Yi, G.-C. Growth and characterizations of GaN micro-rods on graphene films for flexible light emitting diodes. APL Mater. 2014, 2, 092512. [Google Scholar] [CrossRef] [Green Version]

- May, B.J.; Sarwar, A.T.M.G.; Myers, R.C. Nanowire LEDs grown directly on flexible metal foil. Appl. Phys. Lett. 2016, 108, 141103. [Google Scholar] [CrossRef]

- Chung, K.; Yoo, H.; Hyun, J.K.; Oh, H.; Tchoe, Y.; Lee, K.; Baek, H.; Kim, M.; Yi, G.-C. Flexible GaN Light-Emitting Diodes Using GaN Microdisks Epitaxial Laterally Overgrown on Graphene Dots. Adv. Mater. 2016, 28, 7688–7694. [Google Scholar] [CrossRef]

- Li, X.; Li, X. Recent Advances on III-Nitride Nanowire Light Emitters on Foreign Substrates—Toward Flexible Photonics. Phys. Status Solidi 2018, 1800420. [Google Scholar] [CrossRef]

- Asad, M.; Wang, R.; Ra, Y.-H.; Gavirneni, P.; Mi, Z.; Wong, W.S. Optically invariant InGaN nanowire light-emitting diodes on flexible substrates under mechanical manipulation. NPJ Flex. Electron. 2019, 3, 1–6. [Google Scholar] [CrossRef]

- Asad, M.; Li, Q.; Lee, C.-H.; Sachdev, M.; Wong, W.S. Integration of GaN light-emitting diodes with a-Si:H thin-film transistors for flexible displays. Nanotechnology 2019, 30, 324003. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Que, M.; Lee, H.E.; Bao, R.; Wang, X.; Lu, J.; Yuan, Z.; Li, X.; Tao, J.; Sun, J.; et al. Achieving high-resolution pressure mapping via flexible GaN/ZnO nanowire LEDs array by piezo-phototronic effect. Nano Energy 2019, 58, 633–640. [Google Scholar] [CrossRef]

- Asad, M.; Li, Q.; Sachdev, M.; Wong, W.S. Thermal and optical properties of high-density GaN micro-LED arrays on flexible substrates. Nano Energy 2020, 73, 104724. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Bernal, R.A.; Minary-Jolandan, M. A Review of Mechanical and Electromechanical Properties of Piezoelectric Nanowires. Adv. Mater. 2012, 24, 4656–4675. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Papadimitriou, I.; Castillo-Rodríguez, M.; Wang, C.; Esteban-Manzanares, G.; Yuan, X.; Tan, H.H.; Molina-Aldareguia, J.M.; Llorca, J. Mechanical Behavior of InP Twinning Superlattice Nanowires. Nano Lett. 2019, 19, 4490–4497. [Google Scholar] [CrossRef]

- Guan, N.; Amador-Mendez, N.; Wang, J.; Das, S.; Kapoor, A.; Julien, F.H.; Gogneau, N.; Foldyna, M.; Som, S.; Eymery, J.P.; et al. Colour optimization of phosphor-converted flexible nitride nanowire white light emitting diodes. J. Phys. Photonics 2019, 1, 035003. [Google Scholar] [CrossRef] [Green Version]

- Ra, Y.-H.; Lee, C.-R. Core–Shell Tunnel Junction Nanowire White-Light-Emitting Diode. Nano Lett. 2020, 20, 4162–4168. [Google Scholar] [CrossRef]

- Dai, X.; Messanvi, A.; Zhang, H.; Durand, C.; Eymery, J.; Bougerol, C.; Julien, F.H.; Tchernycheva, M. Flexible Light-Emitting Diodes Based on Vertical Nitride Nanowires. Nano Lett. 2015, 15, 6958–6964. [Google Scholar] [CrossRef] [Green Version]

- Guan, N.; Dai, X.; Messanvi, A.; Zhang, H.; Yan, J.; Gautier, E.; Bougerol, C.; Julien, F.H.; Durand, C.; Eymery, J.P.; et al. Flexible White Light Emitting Diodes Based on Nitride Nanowires and Nanophosphors. ACS Photonics 2016, 3, 597–603. [Google Scholar] [CrossRef] [Green Version]

- AlHamoud, A.A.; Alfaraj, N.; Priante, D.; Janjua, B.; Alatawi, A.A.; Albadri, A.M.; Alyamani, A.Y.; Ng, T.; Ooi, B.S. Functional integrity and stable high-temperature operation of planarized ultraviolet-A AlxGa1−xN/AlyGa1−yN multiple-quantum-disk nanowire LEDs with charge-conduction promoting interlayer. In Proceedings of the SPIE OPTO 2019, San Francisco, CA, USA, 2–7 February 2019. [Google Scholar] [CrossRef] [Green Version]

- Kapoor, A.; Grenier, V.; Robin, E.; Bougerol, C.; Jacopin, G.; Tchernycheva, M.; Eymery, J.; Durand, C. Dual-Color Emission from Core-Shell m-Plane InGaN/GaN Wires; unpublished.

- Zheng, Q.; Li, C.; Rai, A.; Leach, J.H.; Broido, D.A.; Cahill, D.G. Thermal conductivity of GaN, 71GaN, and SiC from 150 K to 850 K. Phys. Rev. Mater. 2019, 3, 014601. [Google Scholar] [CrossRef]

- Nishizawa, H.; Nishiguchi, M.; Miki, A.; Fujihira, M. Method of Measuring Junction Temperature. U.S. Patent No. US5401099A, 28 March 1995. [Google Scholar]

- Park, J.; Shin, M.; Lee, C.C. Measurement of temperature profiles on visible light-emitting diodes by use of a nematic liquid crystal and an infrared laser. Opt. Lett. 2004, 29, 2656–2658. [Google Scholar] [CrossRef]

- Schwegler, V.; Schad, S.S.; Kirchner, C.; Seyboth, M.; Kamp, M.; Ebeling, K.J.; Kudryashov, V.E.; Turkin, A.N.; Yunovich, A.E.; Stempfle, U.; et al. Ohmic Heating of InGaN LEDs during Operation: Determination of the Junction Temperature and Its Influence on Device Performance. Phys. Stat. Sol. A 1999, 176, 78. [Google Scholar] [CrossRef]

- Hsu, C.-N.; Huang, C.-C.; Wu, Y.-H. Effect of heat convection on the thermal and structure stress of high-power InGaN light-emitting diode. J. Therm. Anal. Calorim. 2014, 119, 1245–1257. [Google Scholar] [CrossRef]

- Su, Z.; Huang, L.; Liu, F.; Freedman, J.P.; Porter, L.M.; Davis, R.; Malen, J.A. Layer-by-layer thermal conductivities of the Group III nitride films in blue/green light emitting diodes. Appl. Phys. Lett. 2012, 100, 201106. [Google Scholar] [CrossRef] [Green Version]

- Priante, D.; Elafandy, R.T.; Prabaswara, A.; Janjua, B.; Zhao, C.; Alias, M.S.; Tangi, M.; Alaskar, Y.; Albadri, A.M.; Alyamani, A.Y.; et al. Diode junction temperature in ultraviolet AlGaN quantum-disks-in-nanowires. J. Appl. Phys. 2018, 124, 015702. [Google Scholar] [CrossRef]

- Zhang, S.; Connie, A.T.; Laleyan, D.A.; Nguyen, H.P.T.; Wang, Q.; Song, J.; Shih, I.; Mi, Z. On the Carrier Injection Efficiency and Thermal Property of InGaN/GaN Axial Nanowire Light Emitting Diodes. IEEE J. Quantum Electron. 2014, 50, 483–490. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes, 3rd ed.; Cambridge University Press: Cambridge, UK, 2018. [Google Scholar]

- EIA/JEDEC Standard JESD51-1, Integrated Circuits Thermal Measurement Method-Electrical Test Method (Single Semiconductor Device). December 1995. Available online: http://www.jedec.org/sites/default/files/docs/jesd51-1.pdf (accessed on 14 October 2020).

- Xi, Y.; Xi, J.-Q.; Gessmann, T.; Shah, J.M.; Kim, J.K.; Schubert, E.F.; Fischer, A.J.; Crawford, M.H.; Bogart, K.H.A.; Allerman, A.A. Junction and carrier temperature measurements in deep-ultraviolet light-emitting diodes using three different methods. Appl. Phys. Lett. 2005, 86, 031907. [Google Scholar] [CrossRef]

- Chen, Q.; Luo, X.; Zhou, S.; Liu, S. Dynamic junction temperature measurement for high power light emitting diodes. Rev. Sci. Instrum. 2011, 82, 084904. [Google Scholar] [CrossRef]

- Zhuang, R.R.; Cai, P.; Huang, J.L. Study the Effect of Junction Temperature on the Peak Wavelength in GaN-Based High-Power Green Light Emitting Diodes. Adv. Mater. Res. 2011, 399, 1034–1038. [Google Scholar] [CrossRef]

- Hong, Y.J.; Lee, C.-H.; Yoon, A.; Kim, M.; Seong, H.-K.; Chung, H.J.; Sone, C.; Park, Y.J.; Yi, G.-C. Inorganic Optoelectronics: Visible-Color-Tunable Light-Emitting Diodes (Adv. Mater. 29/2011). Adv. Mater. 2011, 23, 3224. [Google Scholar] [CrossRef]

- Zhang, H.; Jacopin, G.; Neplokh, V.; Largeau, L.; Julien, F.H.; Kryliouk, O.; Tchernycheva, M. Color control of nanowire InGaN/GaN light emitting diodes by post-growth treatment. Nanotechnology 2015, 26, 465203. [Google Scholar] [CrossRef] [PubMed]

- Chang, K.S.; Yang, S.C.; Kim, J.-Y.; Kook, M.H.; Ryu, S.Y.; Choi, H.Y.; Kim, G.-H. Precise Temperature Mapping of GaN-Based LEDs by Quantitative Infrared Micro-Thermography. Sensors 2012, 12, 4648–4660. [Google Scholar] [CrossRef] [PubMed]

- Narendran, N.; Gu, Y.; Hosseinzadeh, R. Estimating junction temperature of high-flux white LEDs. In Proceedings of the Integrated Optoelectronic Devices 2004, San Jose, CA, USA, 26–29 January 2004; pp. 158–160. [Google Scholar] [CrossRef]

- Sannicolo, T.; Muñoz-Rojas, D.; Nguyen, N.D.; Moreau, S.; Celle, C.; Simonato, J.-P.; Bréchet, Y.; Bellet, D. Direct Imaging of the Onset of Electrical Conduction in Silver Nanowire Networks by Infrared Thermography: Evidence of Geometrical Quantized Percolation. Nano Lett. 2016, 16, 7046–7053. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.U.; Park, K.S.; Jeong, C.B.; Kim, G.H.; Chang, K.S. Quantitative temperature measurement of multi-layered semiconductor devices using spectroscopic thermoreflectance microscopy. Opt. Express 2016, 24, 13906–13916. [Google Scholar] [CrossRef]

- Koester, R.; Hwang, J.S.; Durand, C.; Dang, D.L.S.; Eymery, J. Self-assembled growth of catalyst-free GaN wires by metal–organic vapour phase epitaxy. Nanotechnology 2009, 21, 015602. [Google Scholar] [CrossRef]

- Koester, R.; Hwang, J.-S.; Salomon, D.; Chen, X.; Bougerol, C.; Barnes, J.-P.; Dang, D.L.S.; Rigutti, L.; Bugallo, A.D.L.; Jacopin, G.; et al. M-Plane Core–Shell InGaN/GaN Multiple-Quantum-Wells on GaN Wires for Electroluminescent Devices. Nano Lett. 2011, 11, 4839–4845. [Google Scholar] [CrossRef]

- Eymery, J.; Salomon, D.; Chen, X.J.; Durand, C. Process for Catalyst-Free Selective Growth on a Semiconductor Structure. Patent WO/2012/136665, 3 April 2012. [Google Scholar]

- Tessarek, C.; Heilmann, M.; Butzen, E.; Haab, A.; Hardtdegen, H.; Dieker, C.; Spiecker, E.; Christiansen, S. The Role of Si during the Growth of GaN Micro- and Nanorods. Cryst. Growth Des. 2014, 14, 1486–1492. [Google Scholar] [CrossRef]

- Bugallo, A.D.L.; Rigutti, L.; Jacopin, G.; Julien, F.H.; Durand, C.; Chen, X.J.; Salomon, D.; Eymery, J.P.; Tchernycheva, M. Single-wire photodetectors based on InGaN/GaN radial quantum wells in GaN wires grown by catalyst-free metal-organic vapor phase epitaxy. Appl. Phys. Lett. 2011, 98, 233107. [Google Scholar] [CrossRef]

- Tchernycheva, M.; Neplokh, V.; Zhang, H.; Lavenus, P.; Rigutti, L.; Bayle, F.; Julien, F.H.; Babichev, A.; Jacopin, G.; Largeau, L.; et al. Core–shell InGaN/GaN nanowire light emitting diodes analyzed by electron beam induced current microscopy and cathodoluminescence mapping. Nanoscale 2015, 7, 11692–11701. [Google Scholar] [CrossRef] [Green Version]

- Jacopin, G.; Bugallo, A.D.L.; Lavenus, P.; Rigutti, L.; Julien, F.H.; Zagonel, L.F.; Kociak, M.; Durand, C.; Salomon, D.; Chen, X.J.; et al. Single-Wire Light-Emitting Diodes Based on GaN Wires Containing Both Polar and Nonpolar InGaN/GaN Quantum Wells. Appl. Phys. Express 2011, 5, 014101. [Google Scholar] [CrossRef]

- Messanvi, A.; Zhang, H.; Neplokh, V.; Julien, F.H.; Bayle, F.; Foldyna, M.; Bougerol, C.; Gautier, E.; Babichev, A.V.; Durand, C.; et al. Investigation of Photovoltaic Properties of Single Core–Shell GaN/InGaN Wires. ACS Appl. Mater. Interfaces 2015, 7, 21898–21906. [Google Scholar] [CrossRef] [PubMed]

- Dühn, J.; Tessarek, C.; Schowalter, M.; Coenen, T.; Gerken, B.; Müller-Caspari, K.; Mehrtens, T.; Heilmann, M.; Christiansen, S.; Rosenauer, A.; et al. Spatially resolved luminescence properties of non- and semi-polar InGaN quantum wells on GaN microrods. J. Phys. D Appl. Phys. 2018, 51, 355102. [Google Scholar] [CrossRef]

- Comsol Multiphysics. Available online: https://www.comsol.com/ (accessed on 14 October 2020).

- Davoody, A.H.; Ramayya, E.; Maurer, L.N.; Knezevic, I. Ultrathin GaN nanowires: Electronic, thermal, and thermoelectric properties. Phys. Rev. B 2014, 89, 115313. [Google Scholar] [CrossRef] [Green Version]

- Guthy, C.; Nam, C.-Y.; Fischer, J.E. Unusually low thermal conductivity of gallium nitride nanowires. J. Appl. Phys. 2008, 103, 64319. [Google Scholar] [CrossRef] [Green Version]

- Danilchenko, B.A.; Paszkiewicz, T.; Wolski, S.; Jeżowski, A.; Plackowski, T. Heat capacity and phonon mean free path of wurtzite GaN. Appl. Phys. Lett. 2006, 89, 61901. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, N.; Amador-Mendez, N.; Kunti, A.; Babichev, A.; Das, S.; Kapoor, A.; Gogneau, N.; Eymery, J.; Julien, F.H.; Durand, C.; et al. Heat Dissipation in Flexible Nitride Nanowire Light-Emitting Diodes. Nanomaterials 2020, 10, 2271. https://doi.org/10.3390/nano10112271

Guan N, Amador-Mendez N, Kunti A, Babichev A, Das S, Kapoor A, Gogneau N, Eymery J, Julien FH, Durand C, et al. Heat Dissipation in Flexible Nitride Nanowire Light-Emitting Diodes. Nanomaterials. 2020; 10(11):2271. https://doi.org/10.3390/nano10112271

Chicago/Turabian StyleGuan, Nan, Nuño Amador-Mendez, Arup Kunti, Andrey Babichev, Subrata Das, Akanksha Kapoor, Noëlle Gogneau, Joël Eymery, François Henri Julien, Christophe Durand, and et al. 2020. "Heat Dissipation in Flexible Nitride Nanowire Light-Emitting Diodes" Nanomaterials 10, no. 11: 2271. https://doi.org/10.3390/nano10112271

APA StyleGuan, N., Amador-Mendez, N., Kunti, A., Babichev, A., Das, S., Kapoor, A., Gogneau, N., Eymery, J., Julien, F. H., Durand, C., & Tchernycheva, M. (2020). Heat Dissipation in Flexible Nitride Nanowire Light-Emitting Diodes. Nanomaterials, 10(11), 2271. https://doi.org/10.3390/nano10112271