Nanostructured BaCo0.4Fe0.4Zr0.1Y0.1O3-δ Cathodes with Different Microstructural Architectures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Synthesis

2.2. Materials Characterization

2.3. Fuel Cell Evaluation

3. Results and Discussion

3.1. Structural Analysis

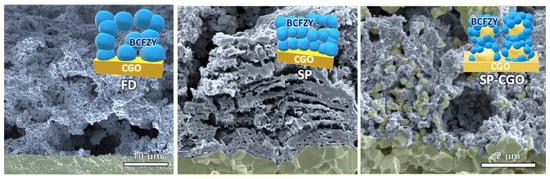

3.2. Morphology of the Electrodes

3.3. Electrochemical Properties

Contributions of the Electrode Polarization

3.4. Fuel Cell Performance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wachsman, E.D.; Lee, K.T. Lowering the temperature of solid oxide fuel cells. Science 2011, 334, 935–939. [Google Scholar] [CrossRef]

- Radhika, D.; Nesaraj, A.S. Materials and components for low temperature solid oxide fuel cells – an overview. Int. J. Renew. Energy Dev. 2013, 2, 87–95. [Google Scholar] [CrossRef]

- Gao, Z.; Mogni, L.V.; Miller, E.C.; Railsback, J.G.; Barnett, S.A. A perspective on low-temperature solid oxide fuel cells. Energy Environ. Sci. 2016, 9, 1602–1644. [Google Scholar] [CrossRef]

- Kan, W.H.; Samson, A.J.; Thangadurai, V. Trends in electrode development for next generation solid oxide fuel cells. J. Mater. Chem. A 2016, 4, 17913–17932. [Google Scholar] [CrossRef] [Green Version]

- Fleig, J. Solid oxide fuel cell cathodes: Polarization mechanisms and modeling of the electrochemical performance. Annu. Rev. Mater. Res. 2003, 33, 361–382. [Google Scholar] [CrossRef]

- Adler, S.B. Factors governing oxygen reduction in solid oxide fuel cell cathodes. Chem. Soc. Rev. 2004, 104, 4791–4844. [Google Scholar] [CrossRef]

- Jacobson, A.J. Materials for solid oxide fuel cells. Chem. Mater. 2010, 22, 660–674. [Google Scholar] [CrossRef]

- Azad, A.K.; Kim, J.H.; Irvine, J.T.S. Structure–property relationship in layered perovskite cathode LnBa0.5Sr0.5Co2O5+δ (Ln = Pr, Nd) for solid oxide fuel cells. J. Power Sources 2011, 196, 7333–7337. [Google Scholar] [CrossRef]

- Celikbilek, O.; Dessemond, L.; Djurado, E. State-of-the-Art La0.6Sr0.4Co0.2Fe0.8O3-δ cathode for SOFC: Microstructural and electrochemical properties. ECS Trans. 2017, 78, 747–758. [Google Scholar] [CrossRef]

- Muñoz-Gil, D.; Pérez-Coll, D.; Peña-Martínez, J.; Garcia-Martín, S. New insights into the GdBaCo2O5+δ material: Crystal structure, electrical and electrochemical properties. J. Power Sources 2014, 263, 90–97. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, X.; Yi, C.; Yan, D.; Su, W. Electrochemical performance of PrBaCo2O5+δ layered perovskite as an intermediate-temperature solid oxide fuel cell cathode. J. Power Sources 2008, 185, 193–196. [Google Scholar] [CrossRef]

- Egger, A.; Schrödl, N.; Gspan, C.; Sitte, W. La2NiO4+δ as electrode material for solid oxide fuel cells and electrolyzer cells. Solid State Ion. 2017, 299, 18–25. [Google Scholar] [CrossRef]

- Choi, S.; Yoo, S.; Kim, J.; Park, S.; Jun, A.; Sengodan, S.; Kim, J.; Shin, J.; Jeong, H.Y.; Choi, Y.M.; et al. Highly efficient and robust cathode materials for low-temperature solid oxide fuel cells: PrBa0.5Sr0.5Co2−xFexO5+δ. Sci. Rep. 2013, 3, 2426. [Google Scholar] [CrossRef] [Green Version]

- Efimov, K.; Xu, Q.; Feldhoff, A. Transmission electron microscopy study of Ba0.5Sr0.5Co0.8Fe0.2O3−δ perovskite decomposition at intermediate temperatures. Chem. Mater. 2010, 22, 5866–5875. [Google Scholar] [CrossRef]

- Saher, S.; Meffert, M.; Störmer, H.; Gerthsen, D.; Bouwmeester, H.J.M. Grain-size dependence of the deterioration of oxygen transport for pure and 3 mol% Zr-doped Ba0.5Sr0.5Co0.8Fe0.2O3−δ induced by thermal annealing. J. Mater. Chem. A 2017, 5, 4982–4990. [Google Scholar] [CrossRef]

- dos Santos-Gómez, L.; Porras-Vázquez, J.M.; Losilla, E.R.; Martín, F.; Ramos-Barrado, J.R.; Marrero-López, D. Stability and performance of La0.6Sr0.4Co0.2Fe0.8O3 nanostructured cathodes with Ce0.8Gd0.2O1.9 surface coating. J. Power Sources 2017, 347, 178–185. [Google Scholar] [CrossRef]

- Niania, M.; Podor, R.; Britton, T.B.; Li, C.; Cooper, S.J.; Svetkov, N.; Skinner, S.; Kilner, J. In situ study of strontium segregation in La0.6Sr0.4Co0.2Fe0.8O3−δ in ambient atmospheres using high-temperature environmental scanning electron microscopy. J. Mater. Chem. A 2018, 6, 14120–14135. [Google Scholar] [CrossRef]

- Le, M.V.; Tsai, D.S.; Nguyen, T.A. BSCF/GDC as a refined cathode to the single-chamber solid oxide fuel cell based on a LAMOX electrolyte. Ceram. Int. 2018, 44, 1726–1730. [Google Scholar] [CrossRef]

- Ren, R.; Wang, Z.; Xu, C.; Sun, W.; Qiao, J.; Rooney, D.W.; Sun, K. Tuning the defects of the triple conducting oxide BaCo0.4Fe0.4Zr0.1Y0.1O3−δ perovskite toward enhanced cathode activity of protonic ceramic fuel cells. J. Mater. Chem. A 2019, 7, 18365–18372. [Google Scholar] [CrossRef]

- Duan, C.; Tong, J.; Shang, M.; Nikodemski, S.; Sanders, M.; Ricote, S.; Almansoori, A.; O’Hayre, R. Readily processed protonic ceramic fuel cells with high performance at low temperatures. Science 2015, 349, 1321–1326. [Google Scholar] [CrossRef]

- Duan, C.; Hook, D.; Chen, Y.; Tong, J.; O’Hayre, R. Zr and Y co-doped perovskite as a stable, high performance cathode for solid oxide fuel cells operating below 500 °C. Energy Environ. Sci. 2017, 10, 176–182. [Google Scholar] [CrossRef]

- Kleitz, M.; Petitbon, F. Optimized SOFC electrode microstructure. Solid State Ion. 1996, 92, 65–74. [Google Scholar] [CrossRef]

- Connor, P.A.; Yue, X.; Savaniu, C.D.; Price, R.; Triantafyllou, G.; Cassidy, M.; Kerherve, G.; Payne, D.J.; Maher, R.C.; Cohen, L.F.; et al. Tailoring SOFC Electrode Microstructures for Improved Performance. Adv. Energy Mater. 2018, 8, 1800120. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, B.; Ding, D.; Liu, M.; Chen, F.; Xia, C. Fabrication and modification of solid oxide fuel cell anodes via wet impregnation/infiltration technique. J. Power Sources 2013, 237, 243–259. [Google Scholar] [CrossRef]

- Liu, Y.; Hashimoto, S.I.; Nishino, H.; Takei, K.; Mori, M.; Suzuki, T.; Funahashi, Y. Fabrication and characterization of micro-tubular cathode-supported SOFC for intermediate temperature operation. J. Power Sources 2007, 174, 95–102. [Google Scholar] [CrossRef]

- Park, J.Y.; Wachsman, E.D. Stable and high conductivity ceria/bismuth oxide bilayer electrolytes for lower temperature solid oxide fuel cells. Ionics 2006, 12, 15–20. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.; Kucharczyk, C.J.; Liang, Y.; Zhang, X.; Takeuchi, I.; Ji, H.I.; Haile, S.M. Exceptional power density and stability at intermediate temperatures in protonic ceramic fuel cells. Nat. Energy 2018, 3, 202–210. [Google Scholar] [CrossRef] [Green Version]

- Zapata-Ramírez, V.; dos Santos-Gómez, L.; Mather, G.C.; Marrero-López, D.; Pérez-Coll, D. Enhanced intermediate-temperature electrochemical performance of air electrodes for solid oxide cells with spray-pyrolyzed active layers. ACS Appl. Mater. Interfaces 2020, 12, 10571–10578. [Google Scholar] [CrossRef]

- dos Santos-Gómez, L.; Porras-Vázquez, J.M.; Losilla, E.R.; Marrero-López, D. Improving the efficiency of layered perovskite cathodes by microstructural optimization. J. Mater. Chem. A 2017, 5, 7896–7904. [Google Scholar] [CrossRef]

- dos Santos-Gómez, L.; Losilla, E.R.; Martín, F.; Ramos-Barrado, J.R.; Marrero-López, D. Novel microstructural strategies to enhance the electrochemical performance of La0.8Sr0.2MnO3-δ cathodes. ACS Appl. Mater. Interfaces 2015, 7, 7197–7205. [Google Scholar] [CrossRef] [Green Version]

- dos Santos-Gómez, L.; Porras-Vázquez, J.M.; Martín, F.; Ramos-Barrado, J.R.; Losilla, E.R.; Marrero-López, D. An easy and innovative method to obtain high efficiency cathodes for Solid Oxide Fuel Cells. J. Power Sources 2016, 319, 48–55. [Google Scholar] [CrossRef]

- Zhang, S.L.; Yu, H.X.; Li, C.X.; Lai, S.Y.; Li, C.J.; Yang, G.J.; Sun, H.B.; Wei, T.; Liu, M. Thermally sprayed high-performance porous metal-supported solid oxide fuel cells with nanostructured La0.6Sr0.4Co0.2Fe0.8O3−δ cathodes. J. Mater. Chem. A 2016, 4, 7461–7468. [Google Scholar] [CrossRef]

- Hong, T.; Lee, S.; Ohodnicki, P.R.; Brinkman, K. A highly scalable spray coating technique for electrode infiltration: Barium carbonate infiltrated La0.6Sr0.4Co0.2Fe0.8O3-δ perovskite structured electrocatalyst with demonstrated long term durability. Int. J. Hydrogen Energy 2017, 42, 24978–24988. [Google Scholar] [CrossRef]

- dos Santos-Gómez, L.; Compana, J.M.; Bruque, S.; Losilla, E.R.; Marrero-López, D. Symmetric electrodes for solid oxide fuel cells based on Zr-doped SrFeO3−δ. J. Power Sources 2015, 279, 419–427. [Google Scholar] [CrossRef]

- PANalytical X′Pert HighScore Plus; Malvern Panalytical: Almelo, The Netherlands, 2014.

- Larson, A.C.; von Dreele, R.B. General Structure Analysis System (GSAS); Los Alamos National Laboratory: Los Alamos, NM, USA, 1994.

- Escudero, M.J.; Aguadero, A.; Alonso, J.A.; Daza, L. A kinetic study of oxygen reduction reaction on La2NiO4 cathodes by means of impedance spectroscopy. J. Electroanal. Chem. 2007, 611, 107–116. [Google Scholar] [CrossRef]

- Chen, X.J.; Khor, K.A.; Chan, S.H. Identification of O2 reduction processes at yttria stabilized zirconia vertical bar doped lanthanum manganite interface. J. Power Sources 2003, 123, 17–25. [Google Scholar] [CrossRef]

- Johnson, D. ZView: A Software Program for IES Analysis; Version 2.9; Scribner Associates Inc.: Southern Pines, NC, USA, 2005. [Google Scholar]

- Koster, H.; Mertins, F.H.B. Powder diffraction of the cubic perovskite Ba0.5Sr0.5Co0.8Fe0.2O3−δ. Powder Diffr. 2003, 18, 56–59. [Google Scholar] [CrossRef]

- dos Santos-Gómez, L.; Porras-Vázquez, J.M.; Martín, F.; Ramos-Barrado, J.R.; Losilla, E.R.; Marrero-López, D. A novel multilaminated composite cathode for solid oxide fuel cells. Ceram. Int. 2019, 45, 18124–18127. [Google Scholar] [CrossRef]

- Fan, H.; Keane, M.; Li, N.; Tang, D.; Singh, P.; Han, M. Electrochemical stability of La0.6Sr0.4Co0.2Fe0.8O3-δ-infiltrated YSZ oxygen electrode for reversible solid oxide fuel cells. Int. J. Hydrogen Energy 2014, 39, 14071–14078. [Google Scholar] [CrossRef]

- Shao, Z.; Haile, S. A high-performance cathode for the next generation of solid-oxide fuel cells. Nature 2004, 431, 170–173. [Google Scholar] [CrossRef]

- Qi, H.; Zhao, Z.; Tu, B.; Cheng, M. Reaction tuned formation of hierarchical BaCo0.4Fe0.4Zr0.1Y0.1O3-δ cathode. J. Power Sources 2020, 455, 227971. [Google Scholar] [CrossRef]

- Yu, Y.; Yu, L.; Shao, K.; Li, Y.; Maliutina, K.; Yuan, W.; Wu, Q.; Fan, L. BaZr0.1Co0.4Fe0.4Y0.1O3-SDC composite as quasi-symmetrical electrode for proton conducting solid oxide fuel cells. Ceram. Int. 2020, 46, 11811–11818. [Google Scholar] [CrossRef]

- Wei, K.; Li, N.; Wu, Y.; Song, W.; Wang, X.; Guo, L.; Khan, M.; Wang, S.; Zhou, F.; Ling, Y. Characterization and optimization of highly active and Ba-deficient BaCo0.4Fe0.4Zr0.1Y0.1O3-δ-based cathode materials for protonic ceramics fuel cells. Ceram. Int. 2019, 45, 18583–18591. [Google Scholar] [CrossRef]

- Grimaud, A.; Mauvy, F.; Bassat, J.M.; Fourcade, S.; Marrony, M.; Grenier, J.C. Hydration and transport properties of the Pr2xSrxNiO4+δ compounds as H+-SOFC Cathodes. J. Mater. Chem. 2012, 22, 16017. [Google Scholar] [CrossRef]

- He, F.; Wu, T.; Peng, R.; Xia, C. Cathode reaction models and performance analysis of Sm0.5Sr0.5CoO3−δ–BaCe0.8Sm0.2O3−δ composite cathode for solid oxide fuel cells with proton conducting electrolyte. J. Power Sources 2009, 194, 263. [Google Scholar] [CrossRef]

- Peng, R.; Wu, T.; Liu, W.; Liu, X.; Meng, G. Cathode processes and materials for solid oxide fuel cells with proton conductors as electrolytes. J. Mater. Chem. 2010, 20, 6218–6225. [Google Scholar] [CrossRef]

- Wu, L.; Jiang, Z.; Wang, S.; Xia, C. (La,Sr)MnO3–(Y,Bi)2O3 composite cathodes for intermediate-temperature solid oxide fuel cells. Int. J. Hydrogen Energy 2013, 38, 2398–2406. [Google Scholar] [CrossRef]

| Compound | Electrolyte | ASR (Ω·cm2) | Ea (KJ·mol−1) | P (W·cm−2) (600 °C) | Reference | |

|---|---|---|---|---|---|---|

| 500 °C | 600 °C | |||||

| FD | CGO | 3.71 | 0.52 | 109 | - | This work |

| SP | CGO | 1.65 | 0.2 | 114 | - | This work |

| SP-CGO | CGO | 0.54 | 0.067 | 114 | 1.0 | This work |

| BCFZY | CGO20 | 1.1 (dry) | 0.25 (dry) | 79.2 (dry) | 0.97 (500 °C) | [21] |

| BCFZY | YSZ | - | 0.39 (650 °C) | - | 1.07 (650 °C) | [44] |

| BCFZY | BaZr0.1Ce0.7Y0.2O3-δ | 2 (dry) 0.5 (wet) | 0.2 (dry) 0.1 (wet) | 111.6 (dry) 80.8 (wet) | 0.67 | [19] |

| BCFZY | BaCe0.7Zr0.1Y0.1Yb0.1O3−δ | 2.0 (wet) | 0.6 (wet) | 88.8 (wet) | 0.65 | [20] |

| BCFZY | BaZr0.2Ce0.7Y0.1O3 | - | 0.81 | 105.2 | 0.07 | [45] |

| BCFZY | BaZr0.1Ce0.7Y0.2O3-δ | 1.45 (550 °C) | - | 100.2 | 0.25 | [46] |

| BSCF | CGO | 0.6 | 0.07 | 116 | 1.01 | [43] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos-Gómez, L.; Zamudio-García, J.; Porras-Vázquez, J.M.; Losilla, E.R.; Marrero-López, D. Nanostructured BaCo0.4Fe0.4Zr0.1Y0.1O3-δ Cathodes with Different Microstructural Architectures. Nanomaterials 2020, 10, 1055. https://doi.org/10.3390/nano10061055

dos Santos-Gómez L, Zamudio-García J, Porras-Vázquez JM, Losilla ER, Marrero-López D. Nanostructured BaCo0.4Fe0.4Zr0.1Y0.1O3-δ Cathodes with Different Microstructural Architectures. Nanomaterials. 2020; 10(6):1055. https://doi.org/10.3390/nano10061055

Chicago/Turabian Styledos Santos-Gómez, Lucía, Javier Zamudio-García, José M. Porras-Vázquez, Enrique R. Losilla, and David Marrero-López. 2020. "Nanostructured BaCo0.4Fe0.4Zr0.1Y0.1O3-δ Cathodes with Different Microstructural Architectures" Nanomaterials 10, no. 6: 1055. https://doi.org/10.3390/nano10061055

APA Styledos Santos-Gómez, L., Zamudio-García, J., Porras-Vázquez, J. M., Losilla, E. R., & Marrero-López, D. (2020). Nanostructured BaCo0.4Fe0.4Zr0.1Y0.1O3-δ Cathodes with Different Microstructural Architectures. Nanomaterials, 10(6), 1055. https://doi.org/10.3390/nano10061055