Hybrid Orthorhombic Carbon Flakes Intercalated with Bimetallic Au-Ag Nanoclusters: Influence of Synthesis Parameters on Optical Properties

Abstract

:1. Introduction

2. Experimental

2.1. Carbon Flakes Fabrication

2.2. Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Butler, S.Z.; Hollen, S.M.; Cao, L.; Cui, Y.; Gupta, J.A.; Gutiérrez, H.R.; Heinz, T.F.; Hong, S.S.; Huang, J.; Ismach, A.F.; et al. Progress, challenges, and opportunities in two-dimensional materials beyond graphene. ACS Nano 2013, 7, 2898–2926. [Google Scholar] [CrossRef] [PubMed]

- Baron, A.; Aradian, A.; Ponsinet, V.; Barois, P. Self-assembled optical metamaterials. Opt. Laser Technol. 2016, 82, 94–100. [Google Scholar] [CrossRef]

- Neshev, D.; Aharonovich, I. Optical metasurfaces: New generation building blocks for multi-functional optics. Light Sci. Appl. 2018, 7, 1–5. [Google Scholar] [CrossRef]

- Wang, Z.; Li, T.; Soman, A.; Mao, D.; Kananen, T.; Gu, T. On-chip wavefront shaping with dielectric metasurface. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Papaioannou, M.; Plum, E.; Valente, J.; Rogers, W.T.; Zheludev, N.I. Two-dimensional control of light with light on metasurfaces. Light Sci. Appl. 2016, 5, e16070. [Google Scholar] [CrossRef]

- de Leon, I.; Horton, M.J.; Schulz, S.A.; Upham, J.; Banzer, P.; Boyd, R.W. Strong, spectrally-tunable chirality in diffractive metasurfaces. Sci. Rep. 2015, 5, 13034. [Google Scholar] [CrossRef] [Green Version]

- Bashouti, M.Y.; Povolotckaia, A.V.; Povolotskiy, A.V.; Tunik, S.P.; Christ, S.H.; Leuchs, G.; Manshina, A.A. Spatially-controlled laser-induced decoration of 2D and 3D substrates with plasmonic nanoparticles. RSC Adv. 2016, 6, 75681–75685. [Google Scholar] [CrossRef]

- Yu, N.; Capasso, F. Flat optics with designer metasurfaces. Nat. Mater. 2014, 13, 139–150. [Google Scholar] [CrossRef]

- Capasso, F. The future and promise of flat optics: A personal perspective. Nanophotonics 2018, 7, 953–957. [Google Scholar] [CrossRef] [Green Version]

- Su, V.C.; Chu, C.H.; Sun, G.; Tsai, D.P. Advances in optical metasurfaces: Fabrication and applications. Opt. Express 2018, 26, 13148–13182. [Google Scholar] [CrossRef]

- Wang, J.; Du, J. Plasmonic and dielectric metasurfaces: Design, fabrication and applications. Appl. Sci. 2016, 6, 239. [Google Scholar] [CrossRef]

- Park, C.-S.; Shrestha, V.R.; Yue, W.; Gao, S.; Lee, S.S.; Kim, E.S.; Choi, D.Y. Structural color filters enabled by a dielectric metasurface incorporating hydrogenated amorphous silicon nanodisks. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Hong, W.; Bai, H.; Xu, Y.; Yao, Z.; Gu, Z.; Shi, G.J. Preparation of gold nanoparticle/graphene composites with controlled weight contents and their application in biosensors. Phys. Chem. C 2010, 114, 1822–1826. [Google Scholar] [CrossRef]

- Shen, J.; Shi, M.; Li, N.; Yan, B.; Ma, H.; Hu, Y.; Ye, M. Facile synthesis and application of Ag-chemically converted graphene nanocomposite. Nano Res. 2010, 3, 339–349. [Google Scholar] [CrossRef] [Green Version]

- Uslu, B.; Ozkan, S.A. Electroanalytical application of carbon based electrodes to the pharmaceuticals. Anal. Lett. 2007, 40, 817–853. [Google Scholar] [CrossRef]

- Cao, X.; Tan, C.; Sindoro, M.; Zhang, H. Hybrid micro-/nano-structures derived from metal–organic frameworks: Preparation and applications in energy storage and conversion. Chem. Soc. Rev. 2017, 46, 2660–2677. [Google Scholar] [CrossRef]

- Khalil, I.; Julkapli, N.; Yehye, W.; Basirun, W.; Bhargava, S. Graphene–gold nanoparticles hybrid—synthesis, functionalization, and application in a electrochemical and surface-enhanced Raman scattering biosensor. Materials 2016, 9, 406. [Google Scholar] [CrossRef] [Green Version]

- Juang, Z.Y.; Tseng, C.C.; Shi, Y.; Hsieh, W.P.; Ryuzaki, S.; Saito, N.; Hsiung, C.E.; Chang, W.H.; Hernandez, Y.; Han, Y.; et al. Graphene-Au nanoparticle based vertical heterostructures: A novel route towards high-ZT Thermoelectric devices. Nano Energy 2017, 38, 385–391. [Google Scholar] [CrossRef] [Green Version]

- Hajati, Y.; Zanbouri, Z.; Sabaeian, M. Low-loss and high-performance mid-infrared plasmon-phonon in graphene-hexagonal boron nitride waveguide. J. Opt. Soc. Am. B 2018, 35, 446–453. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Li, D.M.; Zhang, H.; Wang, W.; Zhu, Y.H.; Zhang, S.; Zhang, X.P.; Yi, J.M. Coexistence of two graphene-induced modulation effects on surface plasmons in hybrid graphene plasmonic nanostructures. Opt. Express 2019, 27, 13503–13515. [Google Scholar] [CrossRef]

- Bala, K.; Suriyaprakash, J.; Singh, P.; Chauhan, K.; Villa, A.; Gupta, N. Copper and cobalt nanoparticles embedded in naturally derived graphite electrodes for the sensing of the neurotransmitter epinephrine. New J. Chem. 2018, 42, 6604–6608. [Google Scholar] [CrossRef]

- Povolotckaia, A.; Pankin, D.; Petrov, Y.; Vasileva, A.; Kolesnikov, I.; Sarau, G.; Christiansen, S.; Leuchs, G.; Manshina, A. Plasmonic carbon nanohybrids from laser-induced deposition: Controlled synthesis and SERS properties. J. Mater. Sci. 2019, 54, 8177–8186. [Google Scholar] [CrossRef]

- Manshina, A.A.; Grachova, E.V.; Povolotskiy, A.V.; Povolotckaia, A.V.; Petrov, Y.V.; Koshevoy, I.O.; Makarova, A.A.; Vyalikh, D.V.; Tunik, S.P. Laser-induced transformation of supramolecular complexes: Approach to controlled formation of hybrid multi-yolk-shell Au-Ag@a-C:H nanostructures. Sci Rep. 2015, 5, 12027. [Google Scholar] [CrossRef] [Green Version]

- Manshina, A.; Povolotskaya, A.V.; Petrov, Y.V.; Willinger, E.; Willinger, M.-G.; Banzer, P.; Leuchs, G. Novel 2D carbon allotrope intercalated with Au-Ag nanoclusters: From laser design to functionality. OSA Adv. Photonics 2017. [Google Scholar] [CrossRef]

- Bashouti, M.; Manshina, A.; Povolotckaia, A.; Povolotskiy, A.; Kireev, A.; Petrov, Y.; Mačković, M.; Spiecker, E.; Koshevoy, I.; Tunik, S.; et al. Direct laser writing of μ-chips based on hybrid C–Au–Ag nanoparticles for express analysis of hazardous and biological substances. Lab Chip 2015, 15, 1742–1747. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Butt, A.; Neugebauer, M.; Lesina, A.C.; Ramunno, L.; Berini, P.; Vaccari, A.; Bauer, T.; Manshina, A.A.; Banzer, P.; Leuchs, G. Investigating the optical properties of a novel 3D self-assembled metamaterial made of carbon intercalated with bimetal nanoparticles. OSA Adv. Photonics 2018. [Google Scholar] [CrossRef]

- Butt, M.A.; Lesina, A.C.; Neugebauer, M.; Bauer, T.; Ramunno, L.; Vaccari, A.; Berini, P.; Petrov, Y.; Danilov, D.; Manshina, A.; et al. Investigating the optical properties of a laser induced 3D self-assembled carbon–metal hybrid structure. Small 2019, 15, 1900512. [Google Scholar] [CrossRef] [Green Version]

- Koshevoy, I.O.; Karttunen, A.J.; Tunik, S.P.; Haukka, M.; Selivanov, S.I.; Melnikov, A.S.; Serdobintsev, P.Y.; Pakkanen, T.A. Synthesis, characterization, photophysical, and theoretical studies of supramolecular gold(I)−silver(I) alkynyl-phosphine complexes. Organometallics 2009, 28, 1369–1376. [Google Scholar] [CrossRef]

- Arteaga, O.; Baldrís, M.; Antó, J.; Canillas, A.; Pascual, E.; Bertran, E. Mueller matrix microscope with a dual continuous rotating compensator setup and digital demodulation. Appl. Opt. 2014, 53, 2236–2245. [Google Scholar] [CrossRef] [Green Version]

- Arteaga, O.; Nichols, S.M.; Antó, J. Back-focal plane Mueller matrix microscopy: Mueller conoscopy and Mueller diffractrometry. Appl. Surf. Sci. 2017, 421, 702–706. [Google Scholar] [CrossRef]

- Bueno, J.M. Liquid-crystal variable retarders for aerospace polarimetry applications. J. Opt. A Pure Appl. Opt. 2000, 46, 689–698. [Google Scholar] [CrossRef]

- Stokes, G.G. On the composition and resolution of streams of polarized light from different sources. Trans. Cambridge Philos. Soc. 1852, 9, 399. [Google Scholar] [CrossRef]

- Wu, S.T.; Efron, U.; Hess, L.D. Birefringence measurements of liquid crystals. Appl. Opt. 1984, 23, 3911–3915. [Google Scholar] [CrossRef] [PubMed]

- Bass, M.; DeCusatis, C.; Enoch, J.; Lakshminarayanan, V.; Li, G.; Macdonald, C.; Mahajan, V.; Stryland, E.V. Polarimetry. In Handbook of Optics Volume II: Design, Fabrication and Testing, Sources and Detectors, Radiometry and Photometry; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Azzam, R.M.A. Stokes-vector and Mueller-matrix polarimetry. Opt. Soc. Am. 2016, 33, 1396–1408. [Google Scholar] [CrossRef] [PubMed]

- Arteaga, O.; Canillas, A. Analytic inversion of the Mueller–Jones polarization matrices for homogeneous media. Opt. Lett. 2010, 35, 559–561. [Google Scholar] [CrossRef]

| Sample | Laser Irradiation Time (min) | SMC Concentration (g/L) | Electric Field (V/m) | Resulting Thickness of Carbon Flakes (nm) |

|---|---|---|---|---|

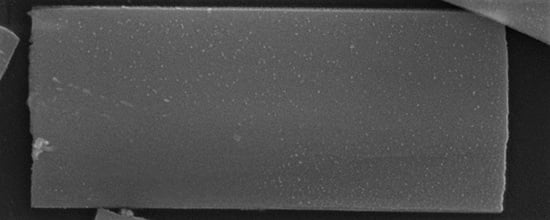

| C1 [27] | 15 | 4 * | Off | 150–500 |

| C2 | 40 | 2 | Off | 250–750 |

| C3 | 40 | 2 | On | 250–750 |

| C4 | 80 | 2 | Off | 1200–1700 |

| C5 | 40 | 6 | Off | 150–750 |

| Varied Fabrication Parameter | Effect on Optical Properties of Carbon Flakes | Effect on Geometrical Properties of Carbon Flakes |

|---|---|---|

| Electric field on or off | Optical properties remain unchanged | Lateral elongation of flakes (with field switched on) |

| Laser irradiation time | Optical properties remain unchanged | Increase in thickness with increasing irradiation time |

| SMC concentration | Increase in attenuation with the increasing SMC concentration | No observed effect on structural parameters |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, M.A.; Mamonova, D.; Petrov, Y.; Proklova, A.; Kritchenkov, I.; Manshina, A.; Banzer, P.; Leuchs, G. Hybrid Orthorhombic Carbon Flakes Intercalated with Bimetallic Au-Ag Nanoclusters: Influence of Synthesis Parameters on Optical Properties. Nanomaterials 2020, 10, 1376. https://doi.org/10.3390/nano10071376

Butt MA, Mamonova D, Petrov Y, Proklova A, Kritchenkov I, Manshina A, Banzer P, Leuchs G. Hybrid Orthorhombic Carbon Flakes Intercalated with Bimetallic Au-Ag Nanoclusters: Influence of Synthesis Parameters on Optical Properties. Nanomaterials. 2020; 10(7):1376. https://doi.org/10.3390/nano10071376

Chicago/Turabian StyleButt, Muhammad Abdullah, Daria Mamonova, Yuri Petrov, Alexandra Proklova, Ilya Kritchenkov, Alina Manshina, Peter Banzer, and Gerd Leuchs. 2020. "Hybrid Orthorhombic Carbon Flakes Intercalated with Bimetallic Au-Ag Nanoclusters: Influence of Synthesis Parameters on Optical Properties" Nanomaterials 10, no. 7: 1376. https://doi.org/10.3390/nano10071376

APA StyleButt, M. A., Mamonova, D., Petrov, Y., Proklova, A., Kritchenkov, I., Manshina, A., Banzer, P., & Leuchs, G. (2020). Hybrid Orthorhombic Carbon Flakes Intercalated with Bimetallic Au-Ag Nanoclusters: Influence of Synthesis Parameters on Optical Properties. Nanomaterials, 10(7), 1376. https://doi.org/10.3390/nano10071376