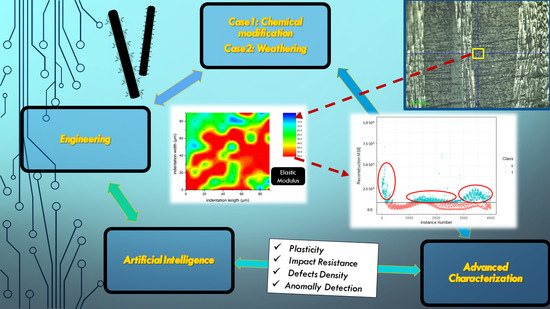

Carbon Fiber Reinforced Composites: Study of Modification Effect on Weathering-Induced Ageing via Nanoindentation and Deep Learning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Surface Functionalization of CFs

2.2. Composites Manufacturing

2.3. Weathering of CFRPs

2.4. Nanoindentation Testing

2.5. Artificial Intelligence

3. Results and Discussion

3.1. Effect of Modification and Weathering—Mapping of Nanomechanical Properties

3.2. Effect of Modification and Weathering on Defect Density of CFRPs via Weibull Analysis

3.3. Effect of Modification and Weathering on Impact Strength of CFRPs

3.4. Modelling of Composites Fingerprint for Condition Monitoring with Artificial Intelligence—Anomaly Detection

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Fan, W.; Li, J.-L. Rapid evaluation of thermal aging of a carbon fiber laminated epoxy composite. Polym. Compos. 2014, 35, 975–984. [Google Scholar] [CrossRef]

- Barbosa, A.P.C.; Fulco, A.P.P.; Guerra, E.S.S.; Arakaki, F.K.; Tosatto, M.; Costa, M.C.B.; Melo, J.D.D. Accelerated aging effects on carbon fiber/epoxy composites. Compos. Part B Eng. 2017, 110, 298–306. [Google Scholar] [CrossRef]

- Garcia-Moreno, I.; Caminero, M.A.; Rodriguez, G.P.; Lopez-Cela, J.J. Effect of Thermal Ageing on the Impact Damage Resistance and Tolerance of Carbon-Fibre-Reinforced Epoxy Laminates. Polymers 2019, 11, 80. [Google Scholar] [CrossRef] [Green Version]

- Buehler, F.U.; Seferis, J.C. Effect of reinforcement and solvent content on moisture absorption in epoxy composite materials. Compos. Part A Appl. Sci. Manuf. 2000, 31, 741–748. [Google Scholar] [CrossRef]

- Wang, Y.; Hahn, T.H. AFM characterization of the interfacial properties of carbon fiber reinforced polymer composites subjected to hygrothermal treatments. Compos. Sci. Technol. 2007, 67, 92–101. [Google Scholar] [CrossRef]

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. A review of key developments and pertinent issues in nanoindentation testing of fibre reinforced plastic microstructures. Compos. Struct. 2017, 180, 782–798. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, G.; Yang, F. Anisotropic Behavior of the Nanoindentation of Single Carbon Fibers. Nanosci. Nanotechnol. Lett. 2014, 6, 596–600. [Google Scholar] [CrossRef]

- Niu, Y.-F.; Yang, Y.; Wang, X.-R. Investigation of the interphase structures and properties of carbon fiber reinforced polymer composites exposed to hydrothermal treatments using peak force quantitative nanomechanics technique. Polym. Compos. 2018, 39, E791–E796. [Google Scholar] [CrossRef]

- Koumoulos, E.; Konstantopoulos, G.; Charitidis, C. Applying Machine Learning to Nanoindentation Data of (Nano-) Enhanced Composites. Fibers 2020, 8, 3. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Jia, X.; Yang, J.; Li, Y.; Song, H. Interfacial modification and tribological properties of carbon fiber grafted by TiO2 nanorods reinforced novel depolymerized thermosetting composites. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105860. [Google Scholar] [CrossRef]

- Claus, J.; Santos, R.A.M.; Gorbatikh, L.; Swolfs, Y. Effect of matrix and fibre type on the impact resistance of woven composites. Compos. Part B Eng. 2019, 183, 107736. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, L.; Li, L.; Wei, J. Effects of strain rate and high temperature environment on the mechanical performance of carbon fiber reinforced thermoplastic composites fabricated by hot press molding. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105905. [Google Scholar] [CrossRef]

- Konstantopoulos, G.; Maroulas, P.; Dragatogiannis, D.A.; Koutsoumpis, S.; Kyritsis, A.; Charitidis, C.A. The effect of interfacial resistance and crystallinity on heat transfer mechanism in carbon nanotube reinforced polyethylene. Mater. Des. 2021, 199, 109420. [Google Scholar] [CrossRef]

- Semitekolos, D.; Kainourgios, P.; Jones, C.; Rana, A.; Koumoulos, E.P.; Charitidis, C.A. Advanced carbon fibre composites via poly methacrylic acid surface treatment; surface analysis and mechanical properties investigation. Compos. Part B Eng. 2018, 155, 237–243. [Google Scholar] [CrossRef]

- Ray, B.C.; Rathore, D. Durability and integrity studies of environmentally conditioned interfaces in fibrous polymeric composites: Critical concepts and comments. Adv. Colloid Interface Sci. 2014, 209, 68–83. [Google Scholar] [CrossRef]

- Niu, Y.-F.; Yang, Y.; Gao, S.; Yao, J.-W. Mechanical mapping of the interphase in carbon fiber reinforced poly(ether-ether-ketone) composites using peak force atomic force microscopy: Interphase shrinkage under coupled ultraviolet and hydro-thermal exposure. Polym. Test. 2016, 55, 257–260. [Google Scholar] [CrossRef]

- Cole, D.P.; Henry, T.C.; Gardea, F.; Haynes, R.A. Interphase mechanical behavior of carbon fiber reinforced polymer exposed to cyclic loading. Compos. Sci. Technol. 2017, 151, 202–210. [Google Scholar] [CrossRef]

- Lee, Y.M.; You, J.; Kim, M.; Kim, T.A.; Lee, S.-S.; Bang, J.; Park, J.H. Highly improved interfacial affinity in carbon fiber-reinforced polymer composites via oxygen and nitrogen plasma-assisted mechanochemistry. Compos. Part B Eng. 2019, 165, 725–732. [Google Scholar] [CrossRef]

- Mao, L.; Shen, H.; Han, W.; Chen, L.; Li, J.; Tang, Y. Hybrid polyurethane and silane sized carbon fibre/epoxy composites with enhanced impact resistance. Compos. Part A Appl. Sci. Manuf. 2019, 118, 49–56. [Google Scholar] [CrossRef]

- Broughton, W. Environmental induced failure in fibre-reinforced plastics. In Failure Mechanisms in Polymer Matrix Composites; Woodhead Publishing: Cambridge, UK, 2012; pp. 393–440. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, F.; Yao, Y.; Jin, Z.; Liu, X.; Huang, Y. High efficient and continuous surface modification of carbon fibers with improved tensile strength and interfacial adhesion. Appl. Surf. Sci. 2017, 412, 424–435. [Google Scholar] [CrossRef]

- Liang, Y.; Li, X.; Semitekolos, D.; Charitidis, C.A.; Dong, H. Enhanced properties of PAN-derived carbon fibres and resulting composites by active screen plasma surface functionalisation. Plasma Process. Polym. 2020, 17, 1900252. [Google Scholar] [CrossRef] [Green Version]

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. Fibrous composite matrix characterisation using nanoindentation: The effect of fibre constraint and the evolution from bulk to in-situ matrix properties. Compos. Part A Appl. Sci. Manuf. 2015, 68, 296–303. [Google Scholar] [CrossRef]

- Merino Perez, J.L.; Hodzic, A.; Ayvar, S. The influence of heat during short ageing periods on the mechanical properties of CFRP composites. In Proceedings of the ECCM16—16th European Conference on Composite Materials, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Genna, S.; Trovalusci, F.; Tagliaferri, V. Indentation test to study the moisture absorption effect on CFRP composite. Compos. Part B Eng. 2017, 124, 1–8. [Google Scholar] [CrossRef]

- Gu, Y.; Li, M.; Wang, J.; Zhang, Z. Characterization of the interphase in carbon fiber/polymer composites using a nanoscale dynamic mechanical imaging technique. Carbon 2010, 48, 3229–3235. [Google Scholar] [CrossRef]

- Chen, C.T.; Gu, G.X. Generative Deep Neural Networks for Inverse Materials Design Using Backpropagation and Active Learning. Adv. Sci. 2020, 7, 1902607. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Larrañaga, P.; Atienza, D.; Diaz-Rozo, J.; Ogbechie, A.; Puerto-Santana, C.E.; Bielza, C. Industrial Applications of Machine Learning, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Cui, J.F.; Chae, H.S. Applying agglomerative hierarchical clustering algorithms to component identification for legacy systems. Inf. Softw. Technol. 2011, 53, 601–614. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Konstantopoulos, G.; Koumoulos, E.P.; Charitidis, C.A. Classification of mechanism of reinforcement in the fiber-matrix interface: Application of Machine Learning on nanoindentation data. Mater. Des. 2020, 192, 108705. [Google Scholar] [CrossRef]

- Konstantopoulos, G.; Koumoulos, E.P.; Charitidis, C.A. Testing Novel Portland Cement Formulations with Carbon Nanotubes and Intrinsic Properties Revelation: Nanoindentation Analysis with Machine Learning on Microstructure Identification. Nanomaterials 2020, 10, 645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giorcelli, M.; Guastella, S.; Mandracci, P.; Liang, Y.; Li, X.; Tagliaferro, A. Carbon fibre functionalization by plasma treatment for adhesion enhancement on polymers. AIP Conf. Proc. 2018, 1981, 020142. [Google Scholar] [CrossRef]

- Khan, A.; Jagdale, P.; Castellino, M.; Rovere, M.; Jehangir, Q.; Mandracci, P.; Rosso, C.; Tagliaferro, A. Innovative functionalized carbon fibers from waste: How to enhance polymer composites properties. Compos. Part B Eng. 2018, 139, 31–39. [Google Scholar] [CrossRef]

- Semitekolos, D.; Trompeta, A.F.; Husarova, I.; Man’ko, T.; Potapov, A.; Romenskaya, O.; Liang, Y.; Li, X.; Giorcelli, M.; Dong, H.; et al. Comparative Physical-Mechanical Properties Assessment of Tailored Surface-Treated Carbon Fibres. Materials 2020, 13, 3136. [Google Scholar] [CrossRef] [PubMed]

- ASTM G154-16, Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials; ASTM International: Washington, DC, USA, 2016.

- Koumoulos, E.; Charitidis, C. Integrity of Carbon-Fibre Epoxy Composites through a Nanomechanical Mapping Protocol towards Quality Assurance. Fibers 2018, 6, 78. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, A.; Natarajan, S. Applied Nanoindentation in Advanced Materials; John Wiley & Sons: Chichester, UK; Hoboken, NJ, USA, 2017. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Sundararajan, G.; Roy, M. Hardness Testing. In Reference Module in Materials Science and Materials Engineering, Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar] [CrossRef]

- Sammaknejad, N.; Zhao, Y.; Huang, B. A review of the Expectation Maximization algorithm in data-driven process identification. J. Process. Control 2019, 73, 123–136. [Google Scholar] [CrossRef]

- Merino-Pérez, J.L.; Hodzic, A.; Merson, E.; Ayvar-Soberanis, S. On the temperatures developed in CFRP drilling using uncoated WC-Co tools Part II: Nanomechanical study of thermally aged CFRP composites. Compos. Struct. 2015, 123, 30–34. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Xian, G.; Zhao, X.-L. Effects of hydrothermal aging on carbon fibre/epoxy composites with different interfacial bonding strength. Constr. Build. Mater. 2018, 161, 634–648. [Google Scholar] [CrossRef]

- Dey, A.; Mukhopadhyay, A. Nanoindentation of Brittle Solids; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Guo, S.; Liu, R.; Jiang, X.; Zhang, H.; Zhang, D.; Wang, J.; Pan, F. Statistical Analysis on the Mechanical Properties of Magnesium Alloys. Materials 2017, 10, 1271. [Google Scholar] [CrossRef] [Green Version]

- Kavouras, P.; Dragatogiannis, D.A.; Batsouli, D.I.; Charitidis, C.A. Effect of local microstructure on the indentation induced damage of a fiber reinforced composite. Polym. Test. 2017, 61, 197–204. [Google Scholar] [CrossRef]

- Zhang, H.; Bilotti, E.; Peijs, T. The Structural Integrity of Carbon Fiber Composites. In Fifty Years of Progress and Achievement of the Science, Development, and Applications; Beaumont, P.W.R., Soutis, C., Eds.; Springer Nature: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Tsikourkitoudi, V.P.; Koumoulos, E.P.; Papadopoulos, N.; Charitidis, C.A. Growth, Structural and Mechanical Characterization and Reliability of Chemical Vapor Deposited Co and Co3O4 Thin Films as Candidate Materials for Sensing Applications. Key Eng. Mater. 2011, 495, 108–111. [Google Scholar] [CrossRef]

- Charitidis, C.A. Local mechanical properties and nanoscale deformation of aluminium and magnesium lightweight alloys. Int. J. Surf. Sci. Eng. 2011, 5, 20. [Google Scholar] [CrossRef]

- Jebur, H.H.; Ngadi, A.; Omar, S. Machine Learning Techniques for Anomaly Detection: An Overview. Int. J. Comput. Appl. 2013, 79, 33–41. [Google Scholar] [CrossRef]

- Konstantopoulos, G. Anomally-Detection-in-R, Athens, Greece. 2020. Available online: https://github.com/konstanto21/anomally-detection-in-R (accessed on 27 September 2021).

- Kainourgios, P.; Kartsonakis, I.A.; Dragatogiannis, D.A.; Koumoulos, E.P.; Goulis, P.; Charitidis, C.A. Electrochemical surface functionalization of carbon fibers for chemical affinity improvement with epoxy resins. Appl. Surf. Sci. 2017, 416, 593–604. [Google Scholar] [CrossRef]

| Matrix | Interface | CFs | ||||

|---|---|---|---|---|---|---|

| m | Er,ch (GPa) | m | Er,ch (GPa) | m | Er,ch (GPa) | |

| Pristine | 2.31 | 14.71 | 5.91 | 36.75 | 15.20 | 49.47 |

| PMAA | 1.88 | 11.01 | 5.56 | 42.14 | 14.30 | 51.27 |

| APP | 1.80 | 19.21 | 7.67 | 37.02 | 13.50 | 50.33 |

| Weathered pristine | 3.30 | 9.91 | 4.94 | 26.56 | 18.90 | 44.18 |

| Weathered PMAA | 2.00 | 13.26 | 7.69 | 25.15 | 6.89 | 51.07 |

| Weathered APP | 3.28 | 22.42 | 9.65 | 42.58 | 17.10 | 54.92 |

| Model & Weathered Specimen | Pristine-on-Pristine Model | PMAA-on-Pristine Model | APP-on-Pristine Model | PMAA-on-PMAA Model | APP-on-APP Model |

|---|---|---|---|---|---|

| Anomalies | 1783 | 117 | 1020 | 70 | 958 |

| Percentage | 44.6% | 2.9% | 25.5% | 1.8% | 24.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konstantopoulos, G.; Semitekolos, D.; Koumoulos, E.P.; Charitidis, C. Carbon Fiber Reinforced Composites: Study of Modification Effect on Weathering-Induced Ageing via Nanoindentation and Deep Learning. Nanomaterials 2021, 11, 2631. https://doi.org/10.3390/nano11102631

Konstantopoulos G, Semitekolos D, Koumoulos EP, Charitidis C. Carbon Fiber Reinforced Composites: Study of Modification Effect on Weathering-Induced Ageing via Nanoindentation and Deep Learning. Nanomaterials. 2021; 11(10):2631. https://doi.org/10.3390/nano11102631

Chicago/Turabian StyleKonstantopoulos, Georgios, Dionisis Semitekolos, Elias P. Koumoulos, and Costas Charitidis. 2021. "Carbon Fiber Reinforced Composites: Study of Modification Effect on Weathering-Induced Ageing via Nanoindentation and Deep Learning" Nanomaterials 11, no. 10: 2631. https://doi.org/10.3390/nano11102631

APA StyleKonstantopoulos, G., Semitekolos, D., Koumoulos, E. P., & Charitidis, C. (2021). Carbon Fiber Reinforced Composites: Study of Modification Effect on Weathering-Induced Ageing via Nanoindentation and Deep Learning. Nanomaterials, 11(10), 2631. https://doi.org/10.3390/nano11102631