Stretchable Transparent Light-Emitting Diodes Based on InGaN/GaN Quantum Well Microwires and Carbon Nanotube Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of InGaN/GaN Microwire Arrays

2.2. PDMS/MW Membrane Fabrication

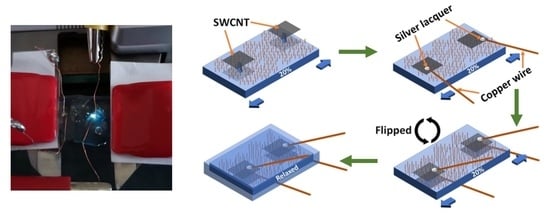

2.3. Synthesis and Application of SWCNT Contacts

2.4. Optical and Electrical Characterization

3. Results and Discussion

3.1. Device Transparency Measurements

3.2. Electrical Characterization

3.3. Electroluminescence Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Su, Y.; Ping, X.; Yu, K.J.; Lee, J.W.; Fan, J.A.; Wang, B.; Li, M.; Li, R.; Harburg, D.V.; Huang, Y.; et al. In-Plane Deformation Mechanics for Highly Stretchable Electronics. Adv. Mater. 2017, 29, 1604989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, C.-H.; Wang, C.; Keplinger, C.; Zuo, J.-L.; Jin, L.; Sun, Y.; Zheng, P.; Cao, Y.; Lissel, F.; Linder, C.; et al. A highly stretchable autonomous self-healing elastomer. Nat. Chem. 2016, 8, 618–624. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Ahmed, M.; Khan, Y.; Payne, M.E.; Zhu, J.; Lu, C.; Evans, J.W.; Arias, A.C. A potentiometric mechanotransduction mechanism for novel electronic skins. Sci. Adv. 2020, 6, eaba1062. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Xu, J.; Wang, W.; Wang, G.-J.N.; Rastak, R.; Molina-Lopez, F.; Chung, J.W.; Niu, S.; Feig, V.R.; Lopez, J.; et al. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nat. Cell Biol. 2018, 555, 83–88. [Google Scholar] [CrossRef]

- Wang, J.; Cai, G.; Li, S.; Gao, D.; Xiong, J.; Lee, P.S. Printable Superelastic Conductors with Extreme Stretchability and Robust Cycling Endurance Enabled by Liquid-Metal Particles. Adv. Mater. 2018, 30, e1706157. [Google Scholar] [CrossRef]

- Wang, J.-L.; Hassan, M.; Liu, J.-W.; Yu, S.-H. Nanowire Assemblies for Flexible Electronic Devices: Recent Advances and Perspectives. Adv. Mater. 2018, 30, e1803430. [Google Scholar] [CrossRef]

- Sekitani, T.; Nakajima, H.; Maeda, H.; Fukushima, T.; Aida, T.; Hata, K.; Someya, T. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat. Mater. 2009, 8, 494–499. [Google Scholar] [CrossRef]

- Larson, C.; Peele, B.; Li, S.; Robinson, S.; Totaro, M.; Beccai, L.; Mazzolai, B.; Shepherd, R. Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 2016, 351, 1071–1074. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.; Tong, K.; Pei, Q. A Water-Based Silver-Nanowire Screen-Print Ink for the Fabrication of Stretchable Conductors and Wearable Thin-Film Transistors. Adv. Mater. 2016, 28, 5986–5996. [Google Scholar] [CrossRef]

- Yang, C.H.; Chen, B.; Zhou, J.; Chen, Y.M.; Suo, Z. Electroluminescence of Giant Stretchability. Adv. Mater. 2016, 28, 4480–4484. [Google Scholar] [CrossRef]

- Wang, J.; Yan, C.; Cai, G.; Cui, M.; Eh, A.L.-S.; Lee, P.S. Extremely Stretchable Electroluminescent Devices with Ionic Conductors. Adv. Mater. 2016, 28, 4490–4496. [Google Scholar] [CrossRef]

- Someya, T.; Bao, Z.; Malliaras, G.G. The rise of plastic bioelectronics. Nature 2016, 540, 379–385. [Google Scholar] [CrossRef]

- Yokota, T.; Zalar, P.; Kaltenbrunner, M.; Jinno, H.; Matsuhisa, N.; Kitanosako, H.; Someya, T. Ultraflexible organic photonic skin. Sci. Adv. 2016, 2, e1501856. [Google Scholar] [CrossRef] [Green Version]

- Chortos, A.; Liu, J.; Bao, J.L.Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef]

- Chen, X.; Parida, K.; Wang, J.; Xiong, J.; Lin, M.-F.; Shao, J.; Lee, P.S. A Stretchable and Transparent Nanocomposite Nanogenerator for Self-Powered Physiological Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 42200–42209. [Google Scholar] [CrossRef]

- Zgierski-Johnston, C.; Ayub, S.; Fernández, M.; Rog-Zielinska, E.; Barz, F.; Paul, O.; Kohl, P.; Ruther, P. Cardiac pacing using transmural multi-LED probes in channelrhodopsin-expressing mouse hearts. Prog. Biophys. Mol. Biol. 2020, 154, 51–61. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Chen, K.; Li, X.; Zhang, S.; Wu, Y.; Zhou, Y.; Meng, K.; Sun, C.; He, Q.; Fan, W.; et al. Sign-to-speech translation using machine-learning-assisted stretchable sensor arrays. Nat. Electron. 2020, 3, 571–578. [Google Scholar] [CrossRef]

- Huang, H.; Han, L.; Li, J.; Fu, X.; Wang, Y.; Yang, Z.; Xu, M. Super-stretchable, elastic and recoverable ionic conductive hydrogel for wireless wearable, stretchable sensor. J. Mater. Chem. A 2020, 8, 10291–10300. [Google Scholar] [CrossRef]

- Hwang, B.-U.; Zabeeb, A.; Trung, T.Q.; Wen, L.; Lee, J.D.; Choi, Y.-I.; Lee, H.-B.; Kim, J.H.; Han, J.G.; Lee, N.-E. A transparent stretchable sensor for distinguishable detection of touch and pressure by capacitive and piezoresistive signal transduction. NPG Asia Mater. 2019, 11, 23. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Hsiang, E.-L.; Deng, M.-Y.; Wu, S.-T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light. Sci. Appl. 2020, 9, 1–16. [Google Scholar] [CrossRef]

- Joo, W.-J.; Kyoung, J.; Esfandyarpour, M.; Lee, S.-H.; Koo, H.; Song, S.; Kwon, Y.-N.; Song, S.H.; Bae, J.C.; Jo, A.; et al. Metasurface-driven OLED displays beyond 10,000 pixels per inch. Science 2020, 370, 459–463. [Google Scholar] [CrossRef]

- Garnett, E.; Mai, L.; Yang, P. Introduction: 1D Nanomaterials/Nanowires. Chem. Rev. 2019, 119, 8955–8957. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dai, X.; Messanvi, A.; Zhang, H.; Durand, C.; Eymery, J.; Bougerol, C.; Julien, F.; Tchernycheva, M. Flexible Light-Emitting Diodes Based on Vertical Nitride Nanowires. Nano Lett. 2015, 15, 6958–6964. [Google Scholar] [CrossRef] [Green Version]

- Guan, N.; Dai, X.; Messanvi, A.; Zhang, H.; Yan, J.; Gautier, E.; Bougerol, C.; Julien, F.; Durand, C.; Eymery, J.; et al. Flexible White Light Emitting Diodes Based on Nitride Nanowires and Nanophosphors. ACS Photon. 2016, 3, 597–603. [Google Scholar] [CrossRef] [Green Version]

- Nadarajah, A.; Word, R.C.; Meiss, J.; Könenkamp, R. Flexible Inorganic Nanowire Light-Emitting Diode. Nano Lett. 2008, 8, 534–537. [Google Scholar] [CrossRef] [PubMed]

- Kwon, O.E.; Shin, J.-W.; Oh, H.; Kang, C.-M.; Cho, H.; Kwon, B.-H.; Byun, C.-W.; Yang, J.-H.; Lee, K.M.; Han, J.-H.; et al. A prototype active-matrix OLED using graphene anode for flexible display application. J. Inf. Disp. 2019, 21, 49–56. [Google Scholar] [CrossRef]

- Yin, D.; Feng, J.; Jiang, N.-R.; Ma, R.; Liu, Y.-F.; Sun, H.-B. Two-Dimensional Stretchable Organic Light-Emitting Devices with High Efficiency. ACS Appl. Mater. Interfaces 2016, 8, 31166–31171. [Google Scholar] [CrossRef]

- Gilshteyn, E.P.; Romanov, S.A.; Kopylova, D.S.; Savostyanov, G.V.; Anisimov, A.S.; Glukhova, O.E.; Nasibulin, A.G. Mechanically Tunable Single-Walled Carbon Nanotube Films as a Universal Material for Transparent and Stretchable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 27327–27334. [Google Scholar] [CrossRef] [PubMed]

- Tuukkanen, S.; Hoikkanen, M.; Poikelispää, M.; Honkanen, M.; Vuorinen, T.; Kakkonen, M.; Vuorinen, J.; Lupo, D. Stretching of solution processed carbon nanotube and graphene nanocomposite films on rubber substrates. Synth. Met. 2014, 191, 28–35. [Google Scholar] [CrossRef]

- Koester, R.; Hwang, J.-S.; Salomon, D.; Chen, X.; Bougerol, C.; Barnes, J.-P.; Dang, D.L.S.; Rigutti, L.; Bugallo, A.D.L.; Jacopin, G.; et al. M-Plane Core–Shell InGaN/GaN Multiple-Quantum-Wells on GaN Wires for Electroluminescent Devices. Nano Lett. 2011, 11, 4839–4845. [Google Scholar] [CrossRef]

- Kapoor, A.; Guan, N.; Vallo, M.; Messanvi, A.; Mancini, L.; Gautier, E.; Bougerol, C.; Gayral, B.; Julien, F.H.; Vurpillot, F.; et al. Green Electroluminescence from Radial m-Plane InGaN Quantum Wells Grown on GaN Wire Sidewalls by Metal–Organic Vapor Phase Epitaxy. ACS Photon. 2018, 5, 4330–4337. [Google Scholar] [CrossRef]

- Koester, R.; Hwang, J.S.; Durand, C.; Dang, D.L.S.; Eymery, J. Self-assembled growth of catalyst-free GaN wires by metal–organic vapour phase epitaxy. Nanotechnology 2009, 21, 015602. [Google Scholar] [CrossRef] [PubMed]

- Tchoulfian, P.; Donatini, F.; Levy, F.; Amstatt, B.; Ferret, P.; Pernot, J. High conductivity in Si-doped GaN wires. Appl. Phys. Lett. 2013, 102, 122116. [Google Scholar] [CrossRef] [Green Version]

- Tchoulfian, P.; Donatini, F.; Levy, F.; Dussaigne, A.; Ferret, P.; Pernot, J. Direct Imaging of p–n Junction in Core–Shell GaN Wires. Nano Lett. 2014, 14, 3491–3498. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eymery, J.; Salomon, D.; Chen, X.; Durand, C. Method of Selective Growth without Catalyst on a Semiconducting Structure. World Intellectual Property Organization Patent WO2,012,136,665, 11 October 2012. [Google Scholar]

- Tessarek, C.; Heilmann, M.; Butzen, E.; Haab, A.; Hardtdegen, H.; Dieker, C.; Spiecker, E.; Christiansen, S. The Role of Si during the Growth of GaN Micro- and Nanorods. Cryst. Growth Des. 2014, 14, 1486–1492. [Google Scholar] [CrossRef]

- Tsapenko, A.P.; Goldt, A.E.; Shulga, E.; Popov, Z.I.; Maslakov, K.I.; Anisimov, A.S.; Sorokin, P.B.; Nasibulin, A.G. Highly conductive and transparent films of HAuCl4-doped single-walled carbon nanotubes forflexible applications. Carbon 2018, 130, 448–457. [Google Scholar] [CrossRef]

- Jacopin, G.; Bugallo, A.D.L.; Lavenus, P.; Rigutti, L.; Julien, F.H.; Zagonel, L.F.; Kociak, M.; Durand, C.; Salomon, D.; Chen, X.J.; et al. Single-Wire Light-Emitting Diodes Based on GaN Wires Containing Both Polar and Nonpolar InGaN/GaN Quantum Wells. Appl. Phys. Express 2011, 5, 014101. [Google Scholar] [CrossRef]

- Neplokh, V.; Messanvi, A.; Zhang, H.; Julien, F.; Babichev, A.; Eymery, J.; Durand, C.; Tchernycheva, M. Substrate-Free InGaN/GaN Nanowire Light-Emitting Diodes. Nanoscale Res. Lett. 2015, 10, 1–6. [Google Scholar] [CrossRef]

- Messanvi, A.; Zhang, H.; Neplokh, V.; Julien, F.H.; Bayle, F.; Foldyna, M.; Tchernycheva, M. Investigation of photovoltaic properties of single core–shell InGaN/GaN wires. ACS Appl. Mater. Interfaces 2015, 7, 21898–21906. [Google Scholar] [CrossRef]

- Neplokh, V.; Kochetkov, F.M.; Deriabin, K.V.; Fedorov, V.V.; Bolshakov, A.D.; Eliseev, I.E.; Islamova, R.M. Modified silicone rubber for fabrication and contacting of flexible suspended membranes of n-/p-GaP nanowires with a single-walled carbon nanotube transparent contact. J. Mater. Chem. C 2020, 8, 3764–3772. [Google Scholar] [CrossRef] [Green Version]

- Kochetkov, F.M.; Neplokh, V.V.; Deriabin, K.V.; Fedorov, V.V.; Bolshakov, A.D.; Eliseev, I.E.; Mikhailovskii, V.Y.; Ilatovskii, D.A.; Krasnikov, D.V.; Tchernycheva, M.; et al. Fabrication and electrical study of large area free-standing membrane with embedded GaP NWs for flexible devices. Nanotechnology 2020, 31, 46LT01. [Google Scholar] [CrossRef] [PubMed]

- Nasibulin, A.G.; Ollikainen, A.; Anisimov, A.S.; Brown, D.P.; Pikhitsa, P.V.; Holopainen, S.; Penttilä, J.S.; Helistö, P.; Ruokolainen, J.; Choi, M.; et al. Integration of single-walled carbon nanotubes into polymer films by thermo-compression. Chem. Eng. J. 2008, 136, 409–413. [Google Scholar] [CrossRef]

- Khabushev, E.M.; Krasnikov, D.V.; Zaremba, O.T.; Tsapenko, A.P.; Goldt, A.E.; Nasibulin, A.G. Machine Learning for Tailoring Optoelectronic Properties of Single-Walled Carbon Nanotube Films. J. Phys. Chem. Lett. 2019, 10, 6962–6966. [Google Scholar] [CrossRef]

- Goldt, A.E.; Zaremba, O.T.; Bulavskiy, M.O.; Fedorov, F.S.; Larionov, K.V.; Tsapenko, A.P.; Popov, Z.I.; Sorokin, P.; Anisimov, A.S.; Inani, H.; et al. Highly efficient bilateral doping of single-walled carbon nanotubes. J. Mater. Chem. C 2021, 9, 4514–4521. [Google Scholar] [CrossRef]

- Kolaric, B.; Vandeparre, H.; Desprez, S.; Vallée, R.A.L.; Damman, P. In situ tuning the optical properties of a cavity by wrinkling. Appl. Phys. Lett. 2010, 96, 043119. [Google Scholar] [CrossRef] [Green Version]

- Bai, J.; Cai, Y.; Feng, P.; Fletcher, P.; Zhao, X.; Zhu, C.; Wang, T. A Direct Epitaxial Approach to Achieving Ultrasmall and Ultrabright InGaN Micro Light-Emitting Diodes (μLEDs). ACS Photon. 2020, 7, 411–415. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Konoplev, S.S.; Bulashevich, K.A.; Karpov, S.Y. From large-size to micro-LEDs: Scaling trends revealed by modeling. Phys. Status Solidi A 2018, 215, 1700508. [Google Scholar] [CrossRef]

- Tchernycheva, M.; Messanvi, A.; Bugallo, A.D.L.; Jacopin, G.; Lavenus, P.; Rigutti, L.; Zhang, H.; Halioua, Y.; Julien, F.; Eymery, J.; et al. Integrated Photonic Platform Based on InGaN/GaN Nanowire Emitters and Detectors. Nano Lett. 2014, 14, 3515–3520. [Google Scholar] [CrossRef]

- Sizov, V.S.; Neploh, V.V.; Tsatsulnikov, A.F.; Sakharov, A.V.; Lundin, W.V.; Zavarin, E.E.; Nikolaev, A.E.; Mintairov, A.M.; Merz, J.L. Study of tunneling transport of carriers in structures with an InGaN/GaN active region. Semiconductors 2010, 44, 1567–1575. [Google Scholar] [CrossRef]

- Hong, Y.J.; Lee, C.H.; Yoon, A.; Kim, M.; Seong, H.K.; Chung, H.J.; Sone, C.; Park, Y.J.; Yi, G.C. Visible-Color-Tunable Light-Emitting Diodes. Adv. Mater. 2011, 23, 3224. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kochetkov, F.M.; Neplokh, V.; Mastalieva, V.A.; Mukhangali, S.; Vorob’ev, A.A.; Uvarov, A.V.; Komissarenko, F.E.; Mitin, D.M.; Kapoor, A.; Eymery, J.; et al. Stretchable Transparent Light-Emitting Diodes Based on InGaN/GaN Quantum Well Microwires and Carbon Nanotube Films. Nanomaterials 2021, 11, 1503. https://doi.org/10.3390/nano11061503

Kochetkov FM, Neplokh V, Mastalieva VA, Mukhangali S, Vorob’ev AA, Uvarov AV, Komissarenko FE, Mitin DM, Kapoor A, Eymery J, et al. Stretchable Transparent Light-Emitting Diodes Based on InGaN/GaN Quantum Well Microwires and Carbon Nanotube Films. Nanomaterials. 2021; 11(6):1503. https://doi.org/10.3390/nano11061503

Chicago/Turabian StyleKochetkov, Fedor M., Vladimir Neplokh, Viktoria A. Mastalieva, Sungat Mukhangali, Aleksandr A. Vorob’ev, Aleksandr V. Uvarov, Filipp E. Komissarenko, Dmitry M. Mitin, Akanksha Kapoor, Joel Eymery, and et al. 2021. "Stretchable Transparent Light-Emitting Diodes Based on InGaN/GaN Quantum Well Microwires and Carbon Nanotube Films" Nanomaterials 11, no. 6: 1503. https://doi.org/10.3390/nano11061503

APA StyleKochetkov, F. M., Neplokh, V., Mastalieva, V. A., Mukhangali, S., Vorob’ev, A. A., Uvarov, A. V., Komissarenko, F. E., Mitin, D. M., Kapoor, A., Eymery, J., Amador-Mendez, N., Durand, C., Krasnikov, D., Nasibulin, A. G., Tchernycheva, M., & Mukhin, I. S. (2021). Stretchable Transparent Light-Emitting Diodes Based on InGaN/GaN Quantum Well Microwires and Carbon Nanotube Films. Nanomaterials, 11(6), 1503. https://doi.org/10.3390/nano11061503