Nanomechanical and Nanotribological Properties of Nanostructured Coatings of Tantalum and Its Compounds on Steel Substrates

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Elemental Analysis of Coatings

3.2. The Thickness of the Coatings and Fracture Microstructure

3.3. The Surface Microstructure of Coatings

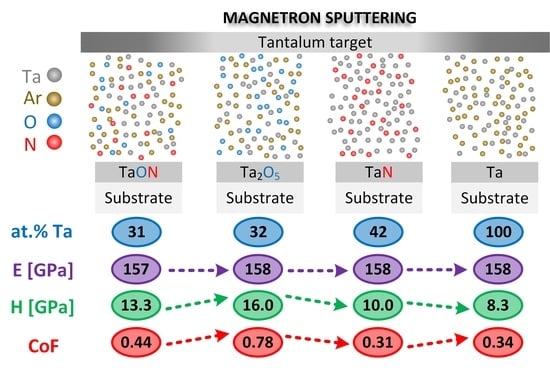

3.4. The Mechanical Properties of Coatings

3.5. The Tribological Characteristics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Mani, G.; Feldman, M.D.; Patel, D.; Agrawal, C.M. Coronary stents: A materials perspective. Biomaterials 2007, 28, 1689–1710. [Google Scholar] [CrossRef]

- Papirov, I.I. Materials of Medical Stents: Review; NSC KIPT: Kharkov, Ukraine, 2010. (In Russian) [Google Scholar]

- Rudnev, V.S.; Medkov, M.A.; Kilin, K.N.; Ustinov, A.Y.; Belobeletskaya, M.V.; Steblevskaya, N.I.; Mutylina, I.N.; Zherebtsov, T.O. Plasma-electrolytic formation of Ta-containing oxide coatings on titanium. Their composition and properties. Prot. Met. Phys. Chem. Surf. 2013, 49, 717–723. [Google Scholar] [CrossRef]

- Matsuno, H. Biocompatibility and osteogenesis of refractory metal implants, titanium, hafnium, niobium, tantalum and rhenium. Biomaterials 2001, 22, 1253–1262. [Google Scholar] [CrossRef]

- Leng, Y.; Chen, J.; Yang, P.; Sun, H.; Wang, J.; Huang, N. The biocompatibility of the tantalum and tantalum oxide films synthesized by pulse metal vacuum arc source deposition. Nucl. Instrum. Methods Phys. Res. Sect. B 2006, 242, 30–32. [Google Scholar] [CrossRef]

- Matsumoto, A.H.; Teitelbaum, G.P.; Barth, K.H.; Carvlin, M.J.; Savin, M.A.; Strecker, E.P. Tantalum vascular stents: In Vivo evaluation with MR imaging. Radiology 1989, 170, 753–755. [Google Scholar] [CrossRef]

- Wang, C.; Li, X.; Tong, C.; Cai, A.; Guo, H.; Yin, H. Preparation, In Vitro bioactivity and osteoblast cell response of Ca-Ta2O5 nanorods on tantalum. Surf. Coat. Technol. 2020, 391, 125701. [Google Scholar] [CrossRef]

- Cardonne, S.M.M.; Kumar, P.; Michaluk, C.A.A.; Schwartz, H.D.D. Tantalum and its alloys. Int. J. Refract. Met. Hard Mater. 1995, 13, 187–194. [Google Scholar] [CrossRef]

- Catania, P.; Doyle, J.P.; Cuomo, J.J. Low resistivity body-centered cubic tantalum thin films as diffusion barriers between copper and silicon. J. Vac. Sci. Technol. A 1992, 10, 3318–3321. [Google Scholar] [CrossRef]

- Kim, S.; Cha, B. Deposition of tantalum nitride thin films by D.C. magnetron sputtering. Thin Solid Films 2005, 475, 202–207. [Google Scholar] [CrossRef]

- Gladczuk, L.; Patel, A.; Paur, C.S.; Sosnowski, M. Tantalum films for protective coatings of steel. Thin Solid Films 2004, 467, 150–157. [Google Scholar] [CrossRef]

- Natishan, P.; McCafferty, E.; Puckett, P.; Michel, S. Ion beam assisted deposited tantalum oxide coatings on aluminum. Corros. Sci. 1996, 38, 1043–1049. [Google Scholar] [CrossRef]

- Hino, T. Effect of Droplets on Corrosion Resistance of Tantalum Oxide Films Fabricated by PLD. J. Laser Micro Nanoeng. 2011, 6, 10–14. [Google Scholar] [CrossRef]

- Khemasiri, N.; Jessadaluk, S.; Chananonnawathorn, C.; Vuttivong, S.; Lertvanithphol, T.; Horprathum, M.; Eiamchai, P.; Patthanasettakul, V.; Klamchuen, A.; Pankiew, A.; et al. Optical band engineering of metal-oxynitride based on tantalum oxide thin film fabricated via reactive gas-timing RF magnetron sputtering. Surf. Coat. Technol. 2016, 306, 346–350. [Google Scholar] [CrossRef]

- Bah, S.T.; Ba, C.O.; D’Auteuil, M.; Ashrit, P.; Sorelli, L.; Vallée, R.; Soreli, L. Fabrication of TaOxNy thin films by reactive ion beam-assisted ac double magnetron sputtering for optical applications. Thin Solid Films 2016, 615, 351–357. [Google Scholar] [CrossRef]

- Venkataraj, S.; Kittur, H.; Drese, R.; Wuttig, M. Multi-technique characterization of tantalum oxynitride films prepared by reactive direct current magnetron sputtering. Thin Solid Films 2006, 514, 1–9. [Google Scholar] [CrossRef]

- Jong, C.-A.; Chin, T.S. Optical characteristics of sputtered tantalum oxynitride Ta(N,O) films. Mater. Chem. Phys. 2002, 74, 201–209. [Google Scholar] [CrossRef]

- Navid, A.; Hodge, A. Nanostructured alpha and beta tantalum formation—Relationship between plasma parameters and microstructure. Mater. Sci. Eng. A 2012, 536, 49–56. [Google Scholar] [CrossRef]

- Shiri, S.; Zhang, C.; Odeshi, A.; Yang, Q. Growth and characterization of tantalum multilayer thin films on CoCrMo alloy for orthopedic implant applications. Thin Solid Films 2018, 645, 405–408. [Google Scholar] [CrossRef]

- Liu, L.L.; Xu, J.; Lu, X.; Munroe, P.; Xie, Z.-H. Electrochemical Corrosion Behavior of Nanocrystalline β-Ta Coating for Biomedical Applications. ACS Biomater. Sci. Eng. 2016, 2, 579–594. [Google Scholar] [CrossRef]

- Pham, V.-H.; Lee, S.-H.; Li, Y.; Kim, H.-E.; Shin, K.-H.; Koh, Y.-H. Utility of tantalum (Ta) coating to improve surface hardness In Vitro bioactivity and biocompatibility of Co–Cr. Thin Solid Films 2013, 536, 269–274. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Yu, X.; Feng, Y.; Wang, C.; Yang, K.; Su, D. Tantalum coating on porous Ti6Al4V scaffold using chemical vapor deposition and preliminary biological evaluation. Mater. Sci. Eng. C 2013, 33, 2987–2994. [Google Scholar] [CrossRef]

- Moreira, H.; Barbosa, A.A.C.; Marques, S.M.; Sampaio, P.; Carvalho, S. Evaluation of cell activation promoted by tantalum and tantalum oxide coatings deposited by reactive DC magnetron sputtering. Surf. Coat. Technol. 2017, 330, 260–269. [Google Scholar] [CrossRef]

- Hee, A.C.; Cao, H.; Zhao, Y.; Jamali, S.S.; Bendavid, A.; Martin, P.J. Cytocompatible tantalum films on Ti6Al4V substrate by filtered cathodic vacuum arc deposition. Bioelectrochemistry 2018, 122, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Gruen, T.A.; Poggie, R.A.; Lewallen, D.G.; Hanssen, A.D.; Lewis, R.J.; O’Keefe, T.J.; Stulberg, S.D.; Sutherland, C.J. Radiographic evaluation of a monoblock acetabular component: A multicenter study with 2-to 5-year results. J. Arthroplast. 2005, 20, 369–378. [Google Scholar] [CrossRef]

- Maccauro, G.; Iommetti, P.R.; Muratori, F.; Raffaelli, L.; Manicone, P.F.; Fabbrii, C. An overview about biomedical applications of micron and nano size tantalum. Recent Pat. Biotechnol. 2009, 3, 157–165. [Google Scholar] [CrossRef]

- Levine, B.R.; Sporer, S.; Poggie, R.A.; Della Valle, C.J.; Jacobs, J.J. Experimental and clinical performance of porous tantalum in orthopedic surgery. Biomaterials 2006, 27, 4671–4681. [Google Scholar] [CrossRef]

- Khan, F.A.; Rose, P.S.; Yanagisawa, M.; Lewallen, D.G.; Sim, F.H. Surgical Technique: Porous Tantalum Reconstruction for Destructive Nonprimary Periacetabular Tumors. Clin. Orthop. Relat. Res. 2012, 470, 594–601. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, C.; Li, J.; Zhu, C.; Zhang, Q.; Yu, J.; Wang, J.; Wang, Q.; Tang, J.; Zhou, H.; Shen, H. Advanced antibacterial activity of biocompatible tantalum nanofilm via enhanced local innate immunity. Acta Biomater. 2019, 89, 403–418. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.A.; Walls, M.; Rondot, B.; Belo, M.D.C.; Guidoin, R. Electrochemical and microstructural studies of tantalum and its oxide films for biomedical applications in endovascular surgery. J. Mater. Sci. Mater. Electron. 2002, 13, 495–500. [Google Scholar] [CrossRef]

- Papirov, I.I.; Tikhonovsky, M.A.; Shokurov, V.S.; Pikalov, A.I.; Sivtsov, V.S.; Storozhilov, G.E.; Emljaninova, T.G.; Mazin, A.I.; Shkuropatenko, V.A. Reception of fine-grained tantalum. Bull. Kharkov Univ. 2005, 664, 99–102. [Google Scholar]

- Liu, L.; Xu, J.; Jiang, S. Nanocrystalline β-Ta Coating Enhances the Longevity and Bioactivity of Medical Titanium Alloys. Metals 2016, 6, 221. [Google Scholar] [CrossRef] [Green Version]

- Ding, M.; Wang, B.; Li, L.; Zheng, Y. Preparation and characterization of TaCxN1−x coatings on biomedical 316L stainless steel. Surf. Coat. Technol. 2010, 204, 2519–2526. [Google Scholar] [CrossRef]

- Rodionov, I.V.; Proskuryakov, V.I.; Koshuro, V.A. Morphology of oxide films on the tantal after thermal air treatment. Mod. Mater. Technol. Technol. 2018, 17, 58–65. [Google Scholar]

- Dai, W.; Shi, Y. Effect of Bias Voltage on Microstructure and Properties of Tantalum Nitride Coatings Deposited by RF Magnetron Sputtering. Coatings 2021, 11, 911. [Google Scholar] [CrossRef]

- Zaman, A.; Shen, Y.; Meletis, E.I. Microstructure and Mechanical Property Investigation of TaSiN Thin Films Deposited by Reactive Magnetron Sputtering. Coatings 2019, 9, 338. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Kumari, N.; Kumar, V.P.; Karar, V.; Sharma, A.L. Determination of optical constants of tantalum oxide thin film deposited by electron beam evaporation. Mater. Today Proc. 2018, 5, 3764–3769. [Google Scholar] [CrossRef]

- Cheviot, M.; Gouné, M.; Poulon-Quintin, A. Monitoring tantalum nitride thin film structure by reactive RF magnetron sputtering: Influence of processing parameters. Surf. Coat. Technol. 2015, 284, 192–197. [Google Scholar] [CrossRef]

- Riekkinen, T.; Molarius, J.; Laurila, T.; Nurmela, A.; Suni, I.; Kivilahti, J. Reactive sputter deposition and properties of TaxN thin films. Microelectron. Eng. 2002, 64, 289–297. [Google Scholar] [CrossRef]

- Petrovskaya, A.S.; Lapitskaya, V.; Melnikova, G.; Kuznetsova, T.A.; Chizhik, S.A.; Zykova, A.V.; Safonov, V.I. Hydrophilic properties of surface of nanostructured tantalum films and its oxynitride compounds. J. Phys. Conf. Ser. 2019, 1281, 012061. [Google Scholar] [CrossRef] [Green Version]

- Yakovin, S.; Dudin, S.; Zykov, A.; Farenik, V. Integral cluster set-up for complex compound composites synthesis. Probl. At. Sci. Technol. Ser. Plasma Phys. 2011, 1, 152–154. [Google Scholar]

- Yakovin, S.D.; Dudin, S.V.; Zykov, A.V.; Farenik, V.I.; Karazin, V.N. Synthesis of thin-film Ta2O5 coatings by reactive magnetron sputtering. Probl. At. Sci. Technol. Ser. Plasma Phys. 2016, 6, 248. [Google Scholar]

- Dudin, S.; Yakovin, S.; Zykov, A.; Yefymenko, N. Optical and mass spectra from reactive plasma at magnetron deposition of tantalum oxynitride. Probl. At. Sci. Technol. Ser. Plasma Phys. 2021, 1, 122. [Google Scholar]

- Chizhik, S.A.; Rymuza, Z.; Chikunov, V.V.; Kuznetsova, T.A.; Jarzabek, D. Micro-and nanoscale testing of tribomechanical properties of surfaces. In Recent Advances in Mechatronics, Proceedings of the 7th International Conference Mechatronics 2007, Warsaw University of Technology, Warsaw, Poland, 19–21 September 2007; Jablonski, R., Turkowski, M., Szewczyk, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 541–545. [Google Scholar]

- Hertzian Contact Stress Calculator. 2013. Available online: http://www.amesweb.info/HertzianContact/HertzianContact.aspx/ (accessed on 9 October 2018).

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 10th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Kuznetsova, T.; Lapitskaya, V.; Chizhik, S.; Kuprin, A.; Tolmachova, G.; Ovcharenko, V.; Gilewicz, A.; Lupicka, O.; Warcholinski, B. Friction and Wear of Cr-O-N Coatings Characterized by Atomic Force Microscopy. Tribol. Ind. 2019, 41, 274–285. [Google Scholar] [CrossRef]

- Zykova, A.; Safonov, V.; Yakovin, S.; Dudin, S.; Melnikova, G.; Petrovskaya, A.; Tolstaya, T.; Kuznetsova, T.; Chizhik, S.A.; Donkov, N. Comparative analysis of platelets adhesion to the surface of Ta-based ceramic coatings deposited by magnetron sputtering. J. Phys. Conf. Ser. 2020, 1492. [Google Scholar] [CrossRef]

- Donkov, N.; Walkowicz, J.; Zavaleyev, V.; Zykova, A.; Safonov, V.; Dudin, S.; Yakovin, S. Mechanical properties of tantalum-based ceramic coatings for biomedical applications. J. Phys. Conf. Ser. 2018, 992, 012034. [Google Scholar] [CrossRef]

- Chun, W.-J.; Ishikawa, A.; Fujisawa, H.; Takata, T.; Kondo, J.N.; Hara, M.; Kawai, M.; Matsumoto, Y.; Domen, K. Conduction and Valence Band Positions of Ta2O5, TaON, and Ta3N5 by UPS and Electrochemical Methods. ChemInform 2003, 688, 137403. [Google Scholar] [CrossRef]

- Matizamhuka, W.; Sigalas, I.; Herrmann, M. Synthesis, sintering and characterisation of TaON materials. Ceram. Int. 2008, 34, 1481–1486. [Google Scholar] [CrossRef]

- Abadias, G.; Colin, J.; Tingaud, D.; Djemia, P.; Belliard, L.; Tromas, C. Elastic properties of α- and β-tantalum thin films. Thin Solid Films 2019, 688, 137403. [Google Scholar] [CrossRef]

- Kim, I.-S.; Cho, M.-Y.; Lee, D.-W.; Ko, P.-J.; Shin, W.H.; Park, C.; Oh, J.-M. Degradation behaviors and failure of magnetron sputter deposited tantalum nitride. Thin Solid Films 2020, 697, 137821. [Google Scholar] [CrossRef]

- Alishahi, M.; Mahboubi, F.; Khoie, S.M.M.; Aparicio, M.; Lopez-Elvira, E.; Méndez, J.; Gago, R. Structural properties and corrosion resistance of tantalum nitride coatings produced by reactive DC magnetron sputtering. RSC Adv. 2016, 6, 89061–89072. [Google Scholar] [CrossRef]

- Kommel, L.; Shahreza, B.O.; Mikli, V. Microstructure and physical-mechanical properties evolution of pure tantalum processed with hard cyclic viscoplastic deformation. Int. J. Refract. Met. Hard Mater. 2019, 83, 104983. [Google Scholar] [CrossRef]

- Hirpara, J.; Chawla, V.; Chandra, R. Investigation of tantalum oxynitride for hard and anti-corrosive coating application in diluted hydrochloric acid solutions. Mater. Today Commun. 2020, 23, 101113. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, I.-K.; Zhang, X. Mechanical properties of sputtered silicon oxynitride films by nanoindentation. Mater. Sci. Eng. A 2008, 489, 294–301. [Google Scholar] [CrossRef]

- Marinelli, G.; Martina, F.; Ganguly, S.; Williams, S. Microstructure, hardness and mechanical properties of two different unalloyed tantalum wires deposited via wire + arc additive manufacture. Int. J. Refract. Met. Hard Mater. 2019, 83, 104974. [Google Scholar] [CrossRef] [Green Version]

- Kaliaraj, G.S.; Kumar, N. Oxynitrides decorated 316L SS for potential bioimplant application. Mater. Res. Express 2018, 5, 036403. [Google Scholar] [CrossRef]

- Lapitskaya, V.; Kuznetsova, T.; Chizhik, S.A.; Sudzilouskaya, K.A.; Kotov, D.A.; Nikitiuk, S.A.; Zaparozhchanka, Y.V. Lateral force microscopy as a method of surface control after low-temperature plasma treatment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 443, 012019. [Google Scholar] [CrossRef] [Green Version]

- Grzywacz, H.; Milczarek, M.; Jenczyk, P.; Dera, W.; Michałowski, M.; Jarząbek, D.M. Quantitative measurement of nanofriction between PMMA thin films and various AFM probes. Measurement 2021, 168, 108267. [Google Scholar] [CrossRef]

| Type of Coating | Gas Pressure P [Pa] | Magnetron Voltage Um [V] | Magnetron Current Im [A] | Time of Deposition [min] | Gas Mass Flow Rate Q [cm3/min] |

|---|---|---|---|---|---|

| Ta | 1 × 10−1 (Ar) | 495 | 6.6 | 30 | - |

| Ta2O5 | 1.3 × 10−1 (general) | 500 | 6.4 | 20 | 25 (O2) |

| TaN | 1.2 × 10−1 (N2) | 800 | 3.4 | 60 | 95 (N2) |

| TaON | 1.5 × 10−1 (general) | 620 | 4.0 | 30 | 10 (O2) 45 (N2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melnikova, G.; Kuznetsova, T.; Lapitskaya, V.; Petrovskaya, A.; Chizhik, S.; Zykova, A.; Safonov, V.; Aizikovich, S.; Sadyrin, E.; Sun, W.; et al. Nanomechanical and Nanotribological Properties of Nanostructured Coatings of Tantalum and Its Compounds on Steel Substrates. Nanomaterials 2021, 11, 2407. https://doi.org/10.3390/nano11092407

Melnikova G, Kuznetsova T, Lapitskaya V, Petrovskaya A, Chizhik S, Zykova A, Safonov V, Aizikovich S, Sadyrin E, Sun W, et al. Nanomechanical and Nanotribological Properties of Nanostructured Coatings of Tantalum and Its Compounds on Steel Substrates. Nanomaterials. 2021; 11(9):2407. https://doi.org/10.3390/nano11092407

Chicago/Turabian StyleMelnikova, Galina, Tatyana Kuznetsova, Vasilina Lapitskaya, Agata Petrovskaya, Sergei Chizhik, Anna Zykova, Vladimir Safonov, Sergei Aizikovich, Evgeniy Sadyrin, Weifu Sun, and et al. 2021. "Nanomechanical and Nanotribological Properties of Nanostructured Coatings of Tantalum and Its Compounds on Steel Substrates" Nanomaterials 11, no. 9: 2407. https://doi.org/10.3390/nano11092407

APA StyleMelnikova, G., Kuznetsova, T., Lapitskaya, V., Petrovskaya, A., Chizhik, S., Zykova, A., Safonov, V., Aizikovich, S., Sadyrin, E., Sun, W., & Yakovin, S. (2021). Nanomechanical and Nanotribological Properties of Nanostructured Coatings of Tantalum and Its Compounds on Steel Substrates. Nanomaterials, 11(9), 2407. https://doi.org/10.3390/nano11092407