3. Results and Discussion

The first order of SP resonance occurring at the lowest energy, i.e., the longest wavelength region, produces the strongest interaction between the SPs and incident light and results in high transmittance [

13]. Therefore, the transmissive type of the plasmonic filters based on periodic domains use the first-order resonance as the pass-band. To use the imaging device, the color filter should possess a single selective pass-band in primary colors, (red, green, and blue).

Considering that the peak of resonance wavelengths appears in a short wavelength region, as expected in Equation (1), the effects of the multiple resonance orders have to be verified, except for the blue filter. Equation (1) provides less information, such as the effect of scattering, which could be affected by the size, shape of holes, and grating depth. However, it provides exact relative comparability between the λsp(m,n) corresponding multi-resonance orders. As expected from Equation (1), the second resonance order mode [λsp(1,1)] appears within the wavelength range times, compared with that in the first-order mode [λsp(1,0) or λsp(0,1)]. The red filters, for example, exhibit the main transmittance peak within the range of 600–700 nm, and the other transmittance peak originated from the second-order resonance roughly within the range of 424–495 nm. The additional transmission in the blue regent degrades the color purity, but the undesired transmission is inevitable.

To quantitatively analyze the enhancement of the color performance, the optical response of the plasmonic red filter (R-PF) for the reference and modified red filter (mR-PF) was numerically simulated.

Figure 1a illustrates the structure of R-PF. On a glass substrate, a 50 nm thick LiF layer, 150 nm thick Al layer, and a 150 nm thick LiF were sequentially stacked. The Al layer was perforated with 240 nm holes, which were separated with 370 nm of the period in the horizontal and vertical directions. The spectral characteristic of the R-PF is plotted in the graph, as shown in

Figure 1b, with a gray line. The transmission spectrum shows 51.4% of the maximum transmittance at 634 nm with 131 nm of the full width at half maximum (FWHM). The additional peak of the second-longest wavelength region [with the maximum value at

λsp(1,1)] results in 24.2% of the maximum value at 452 nm. The color of the light in this range is extremely far different from red. Additionally, the ratio of the average of the undesirable transmittance (420–512 nm) to the main peak transmittance (547–780 nm) is 36.3%.

We propose an optical design to suppress the transmittance peaks originating from the higher-order resonance modes by importing a photonic band gap (PBG). When two materials with different refractive indexes from each other are infinitely repeated, the structure [PhC] induced a PBG in the direction of the repetition [

17,

18]. For the lights in the PBG, photonic modes cannot be allowed in the structure. The light with the frequency at the edge of the PBG is strongly confined in the PhC, the lights within the PBG are reflected from the PhC, and the lights in the other range travel through the PhC. We suggest the introduction of a PBG effect to the reference using the 1D PhC, which comprised a finite number of layers as few as possible. The designed PBG exists around the

λsp(1,1) of the R-PF to suppress the undesired transmission. Additionally, the mR-PF does not exhibit degradation in the pass-band.

The top of the R-PF is modified with multilayers, as illustrated in

Figure 1a. The repetition of optical constants correlates to the top surface of the R-PF; therefore, the mR-PF exhibits the PBG effects through the transmission path. The additional layers comprise LiF and WO

3.

The imported PhC is not infinitely stacked; therefore, it reveals an imperfect band gap; 100% reflection or confinement is not expected. The strength of the PBG effect and bandwidth of the PBG is affected by the ratio of refractive indices between two materials. First, LiF was used as the continuum of the R-PF to reduce loss during the incidence of the PhC from the R-PF. In addition, the refractive index of LiF (~1.39) is small, similar to those of transparent dielectric materials. To form a PBG with as few layers as possible, a high contrast ratio of refractive indices is required. Materials that can be handled by thermal evaporation are advantageous, considering the in situ fabrication process. Therefore, WO3 with 2.0–2.2 of refractive index in the visible range was used.

The center wavelength of PBG (

is related to the optical length affected by the refractive index (

n) and thickness of each layer (

d) as follows [

19]:

Because of the imperfect PBG, the transmission spectrum of the PhC has a deep valley around

and additional shallow ripples, which originated from the interference between the reflected light modes from the LiF and WO

3 interfaces, as shown in the

Appendix A and

supplementary information (Figure S1). To enhance the color purity of the R-PF, the multilayer stack was designed to form a deep and wide valley range near 450 nm corresponding to the

λsp(1,1) of R-PF. In addition, only one peak is required between 600 and 700 nm to maintain the maximum transmittance in the main pass-band region [around

λsp(1,0)]. Using Equation (2), the thicknesses of LiF and WO

3 were set to 80 and 53 nm, respectively. Three pairs of WO

3 and LiF were used. This is because when the PhCs were three pairs, their transmittance spectra exhibit low transmission at the

λsp(1,1) while maintaining high transmission at the

λsp(1,0) of R-PF (

Figure S1).

The modified transmission characteristics of the mR-PF produced by introducing three pairs of LiF and WO

3 are examined, as shown in

Figure 1b, with the black line. Compared with the reference, the transmittance spectrum of the mR-PF exhibits several differences, such as a long-wavelength shift, suppressed undesired peak, and inflection points. The mR-PF exhibits distortion under the dominant trends, which is expected as the effect of the multilayer. The main peak shape is distorted with 10 nm of the peak shift to the right side and 10 nm of a wide FWHM. The maximum transmittance value was reduced by 6.7%p. The intensity of the undesired peak (second-order peak) decreased significantly by 17.5%p. In addition, the ratio of the average undesirable transmittance (420–512 nm) to the main peak transmittance (547–780 nm) was reduced by 27.7%p from 36.3% (R-PF) to 8.6% (mR-PF). The suppressed undesired peak improves the filtering properties. However, the shape of the transmittance is distorted due to the creation of a valley around 600 nm. This will be covered in greater detail later.

The redshift of the main peak can be understood using the dielectric media change at the upper interface. To apply the modification in the upper dielectric structure (in addition to the 1D PhC pairs and finite thickness of LiF), the dielectric constant of Equation (1) was modified from the bulk medium values to the effective refractive index,

, obtained from a previous study [

20,

21,

22].

Equation (3) indicates the effective refractive index of two stacked structures;

and

are the bulk refractive indices, respectively;

x is the volume occupied by

in the stacked structure.

Equation (4) is an equation for the effective refractive index in the plasmonic structure;

and

are the refractive indices of the surrounding media (air in this case) and the thin deposited layer on the metal surface, respectively; t is the thickness of the deposited layer; and

is the decay length of the SP in a continuous dielectric film. To calculate the final effective refractive index of the mR-PF at the upper interface, the results obtained from Equation (3) were used in Equation (4).

Figure 2 shows the bulk refractive index and effective refractive indices calculated using the aforementioned equations. The imaginary part of all refractive indices is close to zero in the visible range. For the real part, the effective refractive index of a finite thick LiF (150 nm),

, is approximately 1.25–1.26, and that of the bottom side (LiF/Glass) is approximately 1.47, respectively.

is a refractive index of a structure with three pairs of (LiF/WO

3) PhC atop the LiF (150 nm), calculated using Equations (3) and (4).

For the mR-PCF, the calculated resulted in the real part of 1.59–1.69, which is 0.34–0.43 higher than the The mR-PF has a higher effective refractive index of the upper dielectric of the filter than that of the R-PF; therefore, it can be expected that the peak wavelength (λsp) had shifted a long-wavelength through Equation (1). However, this is not proportional to the peak wavelength exactly to the ratio of the refractive index of the filters to the upper dielectric. This is because Equation (1) does not consider the diffraction/interference effect on the size of the hole. Therefore, it may be used to determine only the peak wavelength shift.

To understand the mechanism of the mR-PF, we analyze the optical characteristics of the PCF and 1D PhC separately.

Figure 3 shows the calculated and simulated spectra for mR-PF. In determining the spectral properties of the PCF with mR-PF, the optical effects of the PCF and 1D PhC are predominant. To validate the optical effects of PCF and 1D PhC, we confirm the transmissive spectra of the optical structures inserted in

Figure 3a,b using the FDTD simulation. The total transmittance (

Ttotal) of the mR-RF can be simply modeled as the product of the transmittances of the PCF (

TPCF) and 1D PhC (

TPhCs) [

23].

where

,

, and

are the refractive indices of the glass, LiF, and air, respectively, and

and

are the transmission coefficients of light transmitted through the PCF and 1D PhC structures.

Figure 3a shows the calculated transmission spectrum of the PCF structure. The

TPCF is a quantitative value of the light transmitted from the glass substrate through to the LiF layer via the PCF structure. This spectrum exhibited a major peak at a wavelength of 638 nm and an undesirable passband in the range of 398–531 nm. The main peak was 53.4%, and the average value of a passband from 398–531 nm was calculated to be 27%.

Figure 3b shows the calculated spectrum of a structure, which is light transmitted from the LiF layer to the air layer via the 1D PhC. Through the PBG effect of 1D PhC, the transmission spectrum had a deep valley near

(445 nm).

Figure 3c shows the calculated and simulated spectra of the mR-PF. Using Equation (5), we calculate the

TTotal using the

TPCF and

T1D PhC. In the calculated transmission spectrum, the value of the main peak at 638 nm was 48.8%, and the average value of an undesired passband from 398–531 nm was 6.8%. Owing to the PBG effect of 1D PhC, the average of the unnecessary passband decreased by approximately 41.4%, compared with the R-PF. In addition, the main peak shifted to a longer wavelength by approximately 4 nm. Although the simulated and calculated spectra of the mR-PF are similar, there are differences at specific wavelengths. It indicates that additional optical effects are required to accurately predict the transmission spectrum of the mR-PF.

To estimate the valley from the simulation results, we use the FDTD simulation to confirm the electric field profile images at inflection points in the transmission spectrum of the mR-PF.

Figure 4 shows the spectral response and electric field profile images of the R-PF and mR-PF.

Figure 4a shows the inflection points in the transmission spectra of the R-PF and mR-PF, as shown in

Figure 1b. The inflection points appear in the wavelength range of

(644 nm) to

(469 nm). To verify the variation in the SP modes of the PCFs by the 1D PhC, we analyze profile images of the electric field at the inflection points.

Figure 4b,c illustrate the profile images of the electric field for the R-PF and mR-PF at the inflection points. There are two distinct modes in the PCF structure: those originating from the top metal–dielectric interface (SP

top) and those originating from the bottom metal–dielectric interface (SP

bottom).

The profile images of the electric field for the R-PF are shown in

Figure 4b. As the wavelength decreased, the SP

top and SP

bottom sequentially increased into first-, second-, and third-order resonant modes (m = 1, 2, and 3) for the R-PF. When the SP

top and SP

bottom were in first- and third-order resonant modes simultaneously, the light incident on the glass substrate was transmitted into the air through the PCF at the following inflection points:

(644 nm),

(600 nm),

(492 nm), and

(469 nm). The electric field was simultaneously excited around the rims of the nanohole at the SP

top and SP

bottom, resulting in resonance within the nanohole when the polarization direction of the electric field of the incident light was the same as that of the excited electric field at the nanohole. This contributes to the transmissive energy of the R-PF. At an inflection point of

(644 nm), high transmittance can be achieved in the matching modes of SP

top and SP

bottom. When the second-order resonant mode (m = 2) was generated around SP

top and SP

bottom, the transmittance was low at the following inflection wavelengths:

(553 nm) and

(521 nm). The electric field was concentrated on the upper or lower Al and LiF interfaces in the second-order resonant mode. This electric field decreases in the z-axis direction by the SP penetration depth and does not contribute to the transmissive energy.

Figure 4c illustrates the electric field profile images for the mR-PF. Dissimilar to the R-PF, the SP

top of the mR-PF exhibited discontinuity with the first-, third-, second-, third-, and second-order resonant modes because of the effect of the 1D PhC as the wavelength decreased. When the inflection points were

(553 nm),

(521 nm) and

(469 nm), the resonant modes of the SP

top were the second-order mode. As previously mentioned, transmittance was low at certain inflection points, including the second-order resonant mode of the SP

top or SP

bottom. Compared with the R-PF, the valley at

(469 nm) was caused by the second-order resonant mode of the SP

top. Additionally, the valley at

(600 nm) occurred because of trapped light within the 1D PhC. It indicates that the 1D PhC in the mR-RF can reduce the transmittance at undesirable wavelength bands as well as the variation of the SP

top resonant mode. Therefore, the 1D PhC can suppress unwanted peaks of the PCF and create inflection points by changing the SP mode of the PCF.

Finally, each filter was fabricated, and the optical characteristics are examined as shown in

Figure 5. After evaporating LiF and Al in turn, periodic holes were created by laser interference lithography.

Figure 5b shows the holes on the photoresist layer after developing. Thereafter, the Al layer was etched by reactive ion etching and evaporated several LiF and WO

3 layers, as designed. Details of the process are described elsewhere [

13].

Figure 5c shows the transmittance properties of each fabricated structure. The position of the main peak shifted a long-wavelength from 643 (R-PF) to 678 nm (mR-PF). The intensity of the peak decreased by 0.73%p from 29.96 (R-PF) to 29.23% (mR-PF). The spectra were redshifted by the addition of the 1D PhC structure. Furthermore, it indicates that undesired additional peaks in the short wavelength region of the R-PF significantly decrease. As shown in

Figure 5a, the reason for the difference from the simulation results is that the surface morphology is not flat. The optical properties of the PhC are most affected by the periodicity of each thick layer. If the surface morphology is not flat, the thickness of the layers varies, resulting in mismatched periodicity and faults.

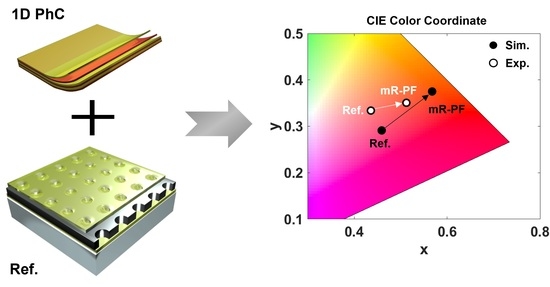

Figure 6 shows the optical characteristics of the fabricated and simulated filters. For quantitative analysis, the transmittance spectrum of each filter is mapped to the CIE 1931 color coordinate, as shown in

Figure 6c. The coordinates in the CIE 1931 color coordinate are (0.4358, 0.3339) (Exp_R-PF), (0.5122, 0.3507) (Exp_mR-PF), (0.4591, 0.2911) (Sim_R-PF), and (0.5676, 0.375) (Sim_mR-PF). The proposed structures confirm that by adding the 1D PhC structure, the color purity is enhanced by moving the color coordinate to the outside point (0.078) (Exp.) and (0.137) (Sim.).

As a result of adding the PhC to the PCF, undesired transmission in the low wavelength region decreased, resulting in better color purity. As shown in

Figure 3, the PCF and PhC in mR-PF can be analyzed separately. To minimize new or lost optical modes between PCF and PhC, the LiF was used as the first layer of PhC. It can also eliminate one step of the PhC deposition process. It can be used for multilayer structures of organic light-emitting diodes made by thermal evaporation or plasma-enhanced chemical vapor deposition, such as thin-film encapsulation or distributed Bragg reflectors comprising materials with a high refractive index ratio.