Bimodal-Structured 0.9KNbO3-0.1BaTiO3 Solid Solutions with Highly Enhanced Electrocaloric Effect at Room Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the Filler and Matrix Powders

2.2. Preparation of Bimodal Structured KN-BT(9/1) Ceramics

2.3. Characterization

2.3.1. Microstructure and Morphology

2.3.2. Measurement of Specific Heat Capacity

2.3.3. Characterization of Dielectric and Ferroelectric Properties

2.3.4. Measurement of Electrocaloric Effect

3. Results and Discussion

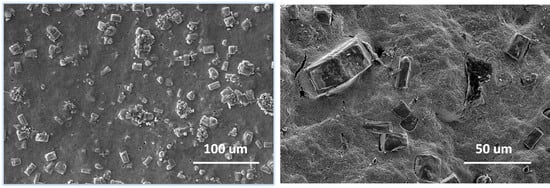

3.1. Phase Composition and Microstructure of the Bimodal Structured Ceramics

3.2. Dielectric and Ferroelectric Properties

3.3. Electrocaloric Effect

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Neese, B.; Chu, B.; Lu, S.G.; Wang, Y.; Furman, E.; Zhang, Q.M. Large electrocaloric effect in ferroelectric polymers near room temperature. Science 2008, 321, 821–823. [Google Scholar] [CrossRef]

- Mischenko, A.S.; Zhang, Q.; Scott, J.F.; Whatmore, R.W.; Mathur, N.D. Giant electrocaloric effect in thin-film PbZr0.95Ti0.05O3. Science 2006, 311, 1270–1271. [Google Scholar] [CrossRef] [Green Version]

- Qian, X.S.; Han, D.L.; Zheng, L.R.; Chen, J.; Tyagi, M.; Li, Q.; Du, F.H.; Zheng, S.Y.; Huang, X.Y.; Zhang, S.H.; et al. High-entropy polymer produces a giant electrocaloric effect at low fields. Nature 2021, 600, 664–669. [Google Scholar] [CrossRef]

- Shi, J.; Han, D.; Li, Z.; Yang, L.; Lu, S.-G.; Zhong, Z.; Chen, J.; Zhang, Q.M.; Qian, X. Electrocaloric cooling materials and devices for zero-global-warming-potential, high-efficiency refrigeration. Joule 2019, 3, 1200–1225. [Google Scholar] [CrossRef]

- Barman, A.; Kar-Narayan, S.; Mukherjee, D. Caloric effects in perovskite oxides. Adv. Mater. Interfaces 2019, 6, 1900291. [Google Scholar] [CrossRef] [Green Version]

- Gu, H.; Qian, X.; Li, X.; Craven, B.; Zhu, W.; Cheng, A.; Yao, S.C.; Zhang, Q.M. A chip scale electrocaloric effect based cooling device. Appl. Phys. Lett. 2013, 102, 122904. [Google Scholar] [CrossRef]

- Tuttle, B.A.; Payne, D.A. The effects of microstructure on the electrocaloric properties of Pb(Zr,Sn,Ti)O3 ceramics. Ferroelectrics 1981, 37, 603–606. [Google Scholar] [CrossRef]

- Luo, L.; Chen, H.; Zhu, Y.; Li, W.; Luo, H.; Zhang, Y. Pyroelectric and electrocaloric effect of <111>-oriented 0.9PMN–0.1PT single crystal. J. Alloys Compd. 2011, 509, 8149–8152. [Google Scholar] [CrossRef]

- Li, G.H.; Shi, C.; Zhu, K.; Ge, G.L.; Yan, F.; Lin, J.F.; Shi, Y.J.; Shen, B.; Zhai, J.W. Achieving synergistic electromechanical and electrocaloric responses by local structural evolution in lead-free BNT-based relaxor ferroelectrics. Chem. Eng. J. 2022, 431, 133386. [Google Scholar] [CrossRef]

- Lines, M.E.; Glass, A.M. Principles and Applications of Ferroelectrics and Related Materials; Oxford University Press: New York, NY, USA, 1977; Volume 66. [Google Scholar]

- Bratton, R.J.; Tien, T.Y. Phase transitions in the system BaTiO3-KNbO3. J. Am. Ceram. Soc. 1967, 50, 90–93. [Google Scholar] [CrossRef]

- Birks, E.; Dunce, M.; Sternberg, A. High electrocaloric effect in ferroelectrics. Ferroelectrics 2010, 400, 336–343. [Google Scholar] [CrossRef]

- Pribosic, I.; Makovec, D.; Drofenik, M. Chemical synthesis of KNbO3 and KNbO3–BaTiO3 ceramics. J. Eur. Ceram. Soc. 2005, 25, 2713–2717. [Google Scholar] [CrossRef]

- Zhang, H.F.; Chen, X.; Gao, J.; Lam, K.H.; Liang, S.D.; Fei, L.F.; Mak, C.L.; Chen, J.F. The fabrication and electrocaloric effect of bimodal-grain structure (Ba0.60Sr0.40)TiO3 using the induced abnormal grain growth method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 678, 012138. [Google Scholar] [CrossRef] [Green Version]

- Hreniak, D.; Strek, W.; Amami, J.; Guyot, Y.; Boulon, G.; Goutaudier, C.; Pazik, R. The size-effect on luminescence properties of BaTiO3:Eu3+ nanocrystallites prepared by the sol–gel method. J. Alloys Compd. 2004, 380, 348–351. [Google Scholar] [CrossRef]

- Kakimoto, K.; Masuda, I.; Ohsato, H. Ferroelectricity and solid-solution structure of KNbO3 ceramics doped with La and Fe. Key Eng. Mater. 2004, 269, 7–10. [Google Scholar] [CrossRef]

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to Ceramics; John Wiley & Sons: Hoboken, NJ, USA, 1976; Volume 17. [Google Scholar]

- Kang, S.L.; Ko, S.Y.; Moon, S.Y. Mixed control of boundary migration and the principle of microstructural evolution. J. Ceram. Soc. Jpn. 2016, 124, 259–267. [Google Scholar] [CrossRef] [Green Version]

- Ravez, J.; Simon, A. Relaxor ferroelectricity in ceramics with composition Ba1−xKx(Ti1−xNbx)O3. Mater. Lett. 1998, 36, 81–84. [Google Scholar] [CrossRef]

- Uchino, K.; Nomura, S. Critical exponents of the dielectric constants in diffused-phase-transition crystals. Ferroelectr. Lett. 1982, 44, 55–61. [Google Scholar] [CrossRef]

- Zheng, S.; Odendo, E.; Liu, L.; Shi, D.; Huang, Y.; Fan, L.; Chen, J.; Fang, L.; Elouadi, B. Electrostrictive and Relaxor Ferroelectric Behavior in BiAlO3-Modified BaTiO3 Lead-Free Ceramics. J. Appl. Phys. 2013, 113, 094102. [Google Scholar] [CrossRef]

- Liu, L.; Knapp, M.; Ehrenberg, H.; Fang, L.; Fan, H.; Schmitt, L.A.; Fuess, H.; Hoelzel, M.; Dammak, H.; Thi, M.P.; et al. Average vs. Local Structure and Composition-Property Phase Diagram of K0.5Na0.5NbO3-Bi½Na½TiO3 System. J. Eur. Ceram. Soc. 2017, 37, 1387–1399. [Google Scholar] [CrossRef]

- Lu, S.G.; Liu, H.L.; Han, Y.; Zhang, L.Y.; Yao, X. Phase-transition of nanophase ferroelectric PbTiO3 ultrafine powders. Ferroelectr. Lett. 1994, 18, 115–120. [Google Scholar] [CrossRef]

- Nagasawa, M.; Kawaji, H.; Tojo, T.; Atake, T. Absence of the heat capacity anomaly in the Pb-free relaxor BaTi0.65Zr0.35O3. Phys. Rev. B 2006, 74, 132101. [Google Scholar] [CrossRef]

- Vrabelj, M.; Ursic, H.; Kutnjak, Z.; Rozic, B.; Drnovsek, S.; Bencan, A.; Bobnar, V.; Fulanovic, L.; Malic, B. Large electrocaloric effect in grain-size-engineered 0.9Pb(Mg1/3Nb2/3)O3-0.1PbTiO3. J. Eur. Ceram. Soc. 2016, 36, 75–80. [Google Scholar] [CrossRef]

- Qian, X.S.; Ye, H.J.; Zhang, Y.T.; Gu, H.M.; Li, X.Y.; Randall, C.A.; Zhang, Q.M. Giant electrocaloric response over a broad temperature range in modified BaTiO3 ceramics. Adv. Funct. Mater. 2014, 24, 1300–1305. [Google Scholar] [CrossRef]

- Bai, Y.; Han, X.; Ding, K.; Qiao, L.J. Combined effects of diffuse phase transition and microstructure on the electrocaloric effect in Ba1−xSrxTiO3 ceramics. Appl. Phys. Lett. 2013, 103, 162902. [Google Scholar]

- Wang, J.; Yang, T.; Chen, S.; Li, G.; Yao, X. Characteristics and dielectric properties of (Pb0.97−xLa0.02Bax)(Zr0.72Sn0.22Ti0.06)O3 ceramics. J. Alloys Compd. 2012, 539, 280–283. [Google Scholar]

- Wang, J.F.; Yang, T.Q.; Wei, K.; Yao, X. Temperature-electric field hysteresis loop of electrocaloric effect in ferroelectricity-direct measurement and analysis of electrocaloric effect. Appl. Phys. Lett. 2013, 102, 152907. [Google Scholar] [CrossRef]

- Bai, Y.; Han, X.; Qiao, L.J. Optimized electrocaloric refrigeration capacity in lead-free (1−x)BaZr0.2Ti0.8O3−xBa0.7Ca0.3TiO3 ceramics. Appl. Phys. Lett. 2013, 102, 252904. [Google Scholar]

- Bai, Y.; Ding, K.; Zheng, G.P.; Shi, S.Q.; Cao, J.L.; Qiao, L.J. The electrocaloric effect around the orthorhombic-tetragonal first-order phase transition in BaTiO3. AIP Adv. 2012, 2, 022162. [Google Scholar]

| Material | Form | T (°C) | (K) | E (MV m−1) | (10−6 Km V−1) | (10−6 Jm kg−1 K−1 V−1) | Method | Reference |

|---|---|---|---|---|---|---|---|---|

| KN-BT(9/1) | Ceramic | 23 | 1.5 | 1 | 1.50 | 2.48 | Direct | This work |

| Ba(ZrxTi1–x)O3 | Ceramic | 38 | 1.1 | 2.1 | 0.52 | 0.93 | Direct | [26] |

| Bi0.5Na0.5TiO3-based | Ceramic | 23 | 0.45 | 3 | - | - | Direct | [9] |

| Ba0.65Sr0.35TiO3 | Ceramic | 23 | 0.4 | 2 | 0.21 | - | Indirect | [27] |

| (Pb, La, Ba)(Zr, Sn, Ti)O3 | Ceramic | 30 | 0.25 | 2.2 | 0.11 | - | Direct | [28] |

| PZT-5 | Ceramic | 30 | 0.15 | 2.8 | 0.05 | - | Direct | [29] |

| (Ba, Ca)(Zr, Ti)O3 | Ceramic | 60 | 0.3 | 2.0 | 0.15 | - | Indirect | [30] |

| 0.9PMN-0.1PT | Ceramic | 25 | 0.63 | 2.8 | 0.23 | - | Direct | [25] |

| BaTiO3 | Single crystal | 10 | 1.4 | 1 | 1.4 | - | Direct | [31] |

| 0.9PMN-0.1PT | Single crystal | 50 | 1.0 | 4.00 | 0.25 | - | Indirect | [8] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Liu, L.; Gao, J.; Kwok, K.W.; Lu, S.-G.; Kong, L.-B.; Peng, B.; Hou, F. Bimodal-Structured 0.9KNbO3-0.1BaTiO3 Solid Solutions with Highly Enhanced Electrocaloric Effect at Room Temperature. Nanomaterials 2022, 12, 2674. https://doi.org/10.3390/nano12152674

Zhang H, Liu L, Gao J, Kwok KW, Lu S-G, Kong L-B, Peng B, Hou F. Bimodal-Structured 0.9KNbO3-0.1BaTiO3 Solid Solutions with Highly Enhanced Electrocaloric Effect at Room Temperature. Nanomaterials. 2022; 12(15):2674. https://doi.org/10.3390/nano12152674

Chicago/Turabian StyleZhang, Hongfang, Liqiang Liu, Ju Gao, K. W. Kwok, Sheng-Guo Lu, Ling-Bing Kong, Biaolin Peng, and Fang Hou. 2022. "Bimodal-Structured 0.9KNbO3-0.1BaTiO3 Solid Solutions with Highly Enhanced Electrocaloric Effect at Room Temperature" Nanomaterials 12, no. 15: 2674. https://doi.org/10.3390/nano12152674

APA StyleZhang, H., Liu, L., Gao, J., Kwok, K. W., Lu, S. -G., Kong, L. -B., Peng, B., & Hou, F. (2022). Bimodal-Structured 0.9KNbO3-0.1BaTiO3 Solid Solutions with Highly Enhanced Electrocaloric Effect at Room Temperature. Nanomaterials, 12(15), 2674. https://doi.org/10.3390/nano12152674