High-Energy Ball Milling for High Productivity of Nanobiochar from Oil Palm Biomass

Abstract

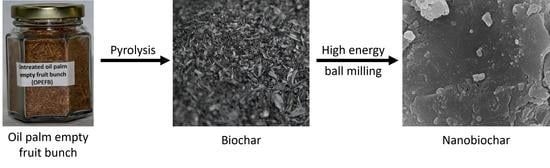

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Ball Milling

2.3. Morphology

2.4. Particle Size Distribution

2.5. Thermal Stability

2.6. Crystalline Properties

2.7. Fourier Tranform Infrared Spectroscopy (FTIR)

3. Results and Discussion

3.1. Morphology

3.2. Particle Size Distribution

3.3. Thermal Stability

3.4. Crystallinity

3.5. FTIR Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Malaysian Palm Oil Council. Malaysian Palm Oil Industry. Malays. Palm. Oil. Counc. 2020, 1. Available online: http://mpoc.org.my/malaysian-palm-oil-industry/ (accessed on 2 June 2022).

- Griffin, W.M.; Michalek, J.; Matthews, H.S.; Hassan, M.N.A.; Griffin, W.M. Availability of Biomass Residues for Co-Firing in Peninsular Malaysia: Implications for Cost and GHG Emissions in the Electricity Sector. Energies 2014, 7, 804–823. [Google Scholar] [CrossRef]

- Chang, S.H. An overview of empty fruit bunch from oil palm as feedstock for bio-oil production. Biomass Bioenergy 2014, 62, 174–181. [Google Scholar] [CrossRef]

- Abdullah, N.; Sulaiman, F. The Oil Palm Wastes in Malaysia. In Biomass Now-Sustainable Growth and Use; Intech Open: Rijeka, Croatia, 2013; Volume 1, pp. 75–93. [Google Scholar] [CrossRef]

- Megashah, L.N.; Ariffin, H.; Zakaria, M.R.; A Hassan, M. Properties of Cellulose Extract from Different Types of Oil Palm Biomass. IOP Conf. Series: Mater. Sci. Eng. 2018, 368, 012049. [Google Scholar] [CrossRef]

- Idris, J.; Shirai, Y.; Andou, Y.; Ali, A.A.M.; Othman, M.R.; Ibrahim, I.; Yamamoto, A.; Yasuda, N.; Hassan, M.A. Successful scaling-up of self-sustained pyrolysis of oil palm biomass under pool-type reactor. Waste Manag. Res. J. Sustain. Circ. Econ. 2016, 34, 176–180. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Idris, J.; Shirai, Y.; Ando, Y.; Ali, A.A.M.; Othman, M.R.; Ibrahim, I.; Hassan, M.A. Production of biochar with high mineral content from oil palm biomass. Malays. J. Anal. Sci. 2014, 18, 700–704. [Google Scholar]

- Jafri, N.; Wong, W.; Doshi, V.; Yoon, L.; Cheah, K. A review on production and characterization of biochars for application in direct carbon fuel cells. Process Saf. Environ. Prot. 2018, 118, 152–166. [Google Scholar] [CrossRef]

- Liu, X.; Liao, J.; Song, H.; Yang, Y.; Guan, C.; Zhang, Z. A Biochar-Based Route for Environmentally Friendly Controlled Release of Nitrogen: Urea-Loaded Biochar and Bentonite Composite. Sci. Rep. 2019, 9, 9548. [Google Scholar] [CrossRef]

- Ni, B.-J.; Huang, Q.-S.; Wang, C.; Ni, T.-Y.; Sun, J.; Wei, W. Competitive adsorption of heavy metals in aqueous solution onto biochar derived from anaerobically digested sludge. Chemosphere 2019, 219, 351–357. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2015, 50, 1161–1168. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from waste derived biochars: Mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.; Thomas, S.C. Biochar Particle Size and Post-Pyrolysis Mechanical Processing Affect Soil pH, Water Retention Capacity, and Plant Performance. Soil Syst. 2019, 3, 14. [Google Scholar] [CrossRef]

- Billah, M.M.; Ahmad, W.; Ali, M. Biochar particle size and Rhizobia strains effect on the uptake and efficiency of nitrogen in lentils. J. Plant Nutr. 2019, 42, 1709–1725. [Google Scholar] [CrossRef]

- Richard, S.; Rajadurai, J.S.; Manikandan, V. Influence of Particle Size and Particle Loading on Mechanical and Dielectric Properties of Biochar Particulate Reinforced Polymer Nanocomposites. Int. J. Polym. Anal. Charact. 2016, 21, 462–477. [Google Scholar] [CrossRef]

- Liu, G.; Zheng, H.; Jiang, Z.; Zhao, J.; Wang, Z.; Pan, B.; Xing, B. Formation and Physicochemical Characteristics of Nano Biochar: Insight into Chemical and Colloidal Stability. Environ. Sci. Technol. 2018, 52, 10369–10379. [Google Scholar] [CrossRef]

- Naghdi, M.; Taheran, M.; Pulicharla, R.; Rouissi, T.; Brar, S.K.; Verma, M.; Surampalli, R. Pine-wood derived nanobiochar for removal of carbamazepine from aqueous media: Adsorption behavior and influential parameters. Arab. J. Chem. 2019, 12, 5292–5301. [Google Scholar] [CrossRef]

- Li, L.; Zhang, K.; Chen, L.; Huang, Z.; Liu, G.; Li, M.; Wen, Y. Mass preparation of micro/nano-powders of biochar with water-dispersibility and their potential application. New J. Chem. 2017, 41, 9649–9657. [Google Scholar] [CrossRef]

- Zolriasatein, A.; Shokuhfar, A.; Safari, F.; Abdi, N. Comparative study of SPEX and planetary milling methods for the fabrication of complex metallic alloy nanoparticles. Micro Nano Lett. 2018, 13, 448–451. [Google Scholar] [CrossRef]

- Aguilar, C.; Ordóñez, S.; Marín, J.; Castro, F.; Martínez, V. Study and methods of analysis of mechanically alloyed Cu–Mo powders. Mater. Sci. Eng. A 2007, 464, 288–294. [Google Scholar] [CrossRef]

- Wallace, C.A.; Saha, G.C.; Afzal, M.T.; Lloyd, A. Experimental and computational modeling of effective flexural/tensile properties of microwave pyrolysis biochar reinforced GFRP biocomposites. Compos. Part B Eng. 2019, 175, 107180. [Google Scholar] [CrossRef]

- Lawal, A.A.; Hassan, M.A.; Farid, M.A.A.; Yasim-Anuar, T.A.T.; Samsudin, M.H.; Yusoff, M.Z.M.; Zakaria, M.R.; Mokhtar, M.N.; Shirai, Y. Adsorption mechanism and effectiveness of phenol and tannic acid removal by biochar produced from oil palm frond using steam pyrolysis. Environ. Pollut. 2020, 269, 116197. [Google Scholar] [CrossRef] [PubMed]

- Naghdi, M.; Taheran, M.; Brar, S.K.; Rouissi, T.; Verma, M.; Surampalli, R.Y.; Valero, J.R. A green method for production of nanobiochar by ball milling- optimization and characterization. J. Clean. Prod. 2017, 164, 1394–1405. [Google Scholar] [CrossRef]

- De Castro, C.L.; Mitchell, B.M. Nanoparticles from Mechanical Attrition. In Synthesis, Functionalization, and Surface Treatment of Nanoparticles; American Scientific Publishers: New Orleans, LA, USA, 2003; pp. 2–3. [Google Scholar]

- Li, X.; Shen, Q.; Zhang, D.; Mei, X.; Ran, W.; Xu, Y.; Yu, G. Functional Groups Determine Biochar Properties (pH and EC) as Studied by Two-Dimensional 13C NMR Correlation Spectroscopy. PLoS ONE 2013, 8, e65949. [Google Scholar] [CrossRef]

- Bakhtiar, M.H.A.M.; Sari, N.A.; Yaacob, A.; Yunus, M.F.B.M.; Ismail, K.B. Characterization of oil palm Empty Fruit Bunch (EFB) biochar activated with potassium hydroxide under different pyrolysis temperature. J. Eng. Sci. Technol. 2019, 14, 2792–2807. [Google Scholar]

- O Bird, J.; Chivers, P.J. Linear momentum and impulse. In Newnes Engineering and Physical Science Pocket Book; Elsevier: Amsterdam, The Netherlands, 1993; Volume 1, pp. 228–229. [Google Scholar] [CrossRef]

- Wei, Y.; Shen, C.; Xie, J.; Bu, Q. Study on reaction mechanism of superior bamboo biochar catalyst production by molten alkali carbonates pyrolysis and its application for cellulose hydrolysis. Sci. Total Environ. 2020, 712, 136435. [Google Scholar] [CrossRef]

- Shariff, A.; Aziz, N.S.M.; Abdullah, N. Slow Pyrolysis of Oil Palm Empty Fruit Bunches for Biochar Production and Characterisation. J. Phys. Sci. 2014, 25, 97–112. [Google Scholar]

- Ruz, P.; Banerjee, S.; Pandey, M.; Sudarsan, V.; Sastry, P.; Kshirsagar, R. Structural evolution of turbostratic carbon: Implications in H2 storage. Solid State Sci. 2016, 62, 105–111. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.G.; Kleber, M. Dynamic Molecular Structure of Plant Biomass-Derived Black Carbon (Biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef]

- E Mahmoud, A.; Wasly, H.S.; A Doheim, M. Studies of crystallite size and lattice strain in al-al2o3 powders produced by high-energy mechanical milling. JES. J. Eng. Sci. 2014, 42, 1430–1439. [Google Scholar] [CrossRef]

- Rojas-Hernandez, R.E.; Rubio-Marcos, F.; Enríquez, E.; De La Rubia, M.A.; Fernandez, J.F. A low-energy milling approach to reduce particle size maintains the luminescence of strontium aluminates. RSC Adv. 2015, 5, 42559–42567. [Google Scholar] [CrossRef]

- Belassel, M. Residual Stress Measurement using X-Ray Diffraction Techniques, Guidelines and Normative Standards. SAE Int. J. Mater. Manuf. 2012, 5, 352–356. [Google Scholar] [CrossRef]

| Grinding Media | Sample Code | Milling Duration (min) |

|---|---|---|

| Various sizes (2.5 mm–11 mm) | BC | 0 |

| 30NBC | 30 | |

| 60NBC | 60 | |

| 90NBC | 90 | |

| 150NBC | 150 | |

| 180NBC | 180 | |

| 360NBC | 360 | |

| Uniform size (2.5 mm) | 60NBC-S | 60 |

| Uniform size (11 mm) | 60NBC-L | 60 |

| Sample | Peaks | Size (d.nm) |

|---|---|---|

| BC | Peak 1 | 331 |

| 30NBC | Peak 1 | 98 |

| 60NBC | Peak 1 | 77 |

| 90NBC | Peak 1 | 35 |

| 150NBC | Peak 1 | 28 |

| 180NBC | Peak 1 | 71 |

| 360NBC | Peak 1 | 83 |

| Peak 2 | 687 | |

| 60NBC-S | Peak 1 | 232 |

| 60NBC-L | Peak 1 | 72 |

| Peak 2 | 350 |

| Samples | 2θ, ° (002) | 2θ, ° (100) | FWHM (100) | Average Crystallite Diameter, La (nm) | Stacking Height, Lc (nm) (002) | D-Spacing, (Å) (002) |

|---|---|---|---|---|---|---|

| Raw | 23.10 | 40.53 | 5.37 | 1.02 | 0.94 | 3.85 |

| 30NBC | 23.29 | 41.12 | 6.94 | 0.84 | 0.93 | 3.82 |

| 60NBC | 23.06 | 41.41 | 7.49 | 0.79 | 0.93 | 3.85 |

| 90NBC | 23.42 | 41.78 | 7.82 | 0.78 | 0.95 | 3.79 |

| 150NBC | 23.47 | 41.84 | 7.86 | 0.78 | 0.98 | 3.79 |

| 180NBC | 23.77 | 43.74 | 7.28 | 0.83 | 0.98 | 3.74 |

| 360NBC | 23.63 | 43.88 | 7.13 | 0.83 | 0.96 | 3.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ng, L.Y.F.; Ariffin, H.; Yasim-Anuar, T.A.T.; Farid, M.A.A.; Hassan, M.A. High-Energy Ball Milling for High Productivity of Nanobiochar from Oil Palm Biomass. Nanomaterials 2022, 12, 3251. https://doi.org/10.3390/nano12183251

Ng LYF, Ariffin H, Yasim-Anuar TAT, Farid MAA, Hassan MA. High-Energy Ball Milling for High Productivity of Nanobiochar from Oil Palm Biomass. Nanomaterials. 2022; 12(18):3251. https://doi.org/10.3390/nano12183251

Chicago/Turabian StyleNg, Lawrence Yee Foong, Hidayah Ariffin, Tengku Arisyah Tengku Yasim-Anuar, Mohammed Abdillah Ahmad Farid, and Mohd Ali Hassan. 2022. "High-Energy Ball Milling for High Productivity of Nanobiochar from Oil Palm Biomass" Nanomaterials 12, no. 18: 3251. https://doi.org/10.3390/nano12183251

APA StyleNg, L. Y. F., Ariffin, H., Yasim-Anuar, T. A. T., Farid, M. A. A., & Hassan, M. A. (2022). High-Energy Ball Milling for High Productivity of Nanobiochar from Oil Palm Biomass. Nanomaterials, 12(18), 3251. https://doi.org/10.3390/nano12183251