Polyethylene Glycol as Additive to Achieve N-Conductive Melt-Mixed Polymer/Carbon Nanotube Composites for Thermoelectric Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

3.1. Thermal Degradation of Polyethylene Glycol

3.2. Polymer Composites with SWCNTs

3.3. Effects of Polyethylene Glycol as Additive in Polymer Composites with SWCNTs

3.3.1. Polycarbonate-Based Composites

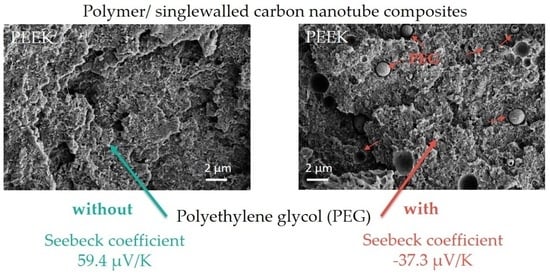

3.3.2. PEEK-Based Composites

3.3.3. PBT-Based Composites

4. Discussion

5. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Poehler, T.O.; Katz, H.E. Innovative thermoelectric materials. In Innovative Thermoelectric Materials; Imperial College Press: London, UK, 2016; pp. 1–37. [Google Scholar]

- Rowe, D.M. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Yazawa, K.; Bahk, J.-H.; Shakouri, A.T. Thermoelectric Energy Conversion Devices and Systems; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2021; p. 388. [Google Scholar]

- Goldsmid, H.J. Introduction to Thermoelectricity; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Hongmei, W.; Jun, Y.; Zhou, D. Review of recent developments in thermoelectric materials. In Proceedings of the 2016 International Conference on Robots & Intelligent System (ICRIS), ZhangJiaJie, China, 27–28 August 2016; pp. 394–397. [Google Scholar] [CrossRef]

- Gayner, C.; Kar, K.K. Recent advances in thermoelectric materials. Prog. Mater. Sci. 2016, 83, 330–382. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, X.-L.; Yang, Y.-L.; Chen, Z.-G. Flexible thermoelectric materials and devices: From materials to applications. Mater. Today 2021, 46, 62–108. [Google Scholar] [CrossRef]

- Nonoguchi, Y.; Ohashi, K.; Kanazawa, R.; Ashiba, K.; Hata, K.; Nakagawa, T.; Adachi, C.; Tanase, T.; Kawai, T. Systematic conversion of single walled carbon nanotubes into n-type thermoelectric materials by molecular dopants. Sci. Rep. 2013, 3, 3344. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Piao, M.; Alam, M.R.; Kim, G.; Dettlaff-Weglikowska, U.; Roth, S. Effect of chemical treatment on the thermoelectric properties of single walled carbon nanotube networks. Phys. Status Solidi 2012, 249, 2353–2356. [Google Scholar] [CrossRef]

- Xia, X.-G.; Zhang, Q.; Zhou, W.-B.; Xiao, Z.-J.; Xi, W.; Wang, Y.-C.; Zhou, W.-Y. Highly flexible and excellent performance continuous carbon nanotube fibrous thermoelectric modules for diversified applications. Chin. Phys. B 2021, 30, 078801. [Google Scholar] [CrossRef]

- Krause, B.; Barbier, C.; Levente, J.; Klaus, M.; Pötschke, P. Screening of different carbon nanotubes in melt-mixed polymer composites with different polymer matrices for their thermoelectric properties. J. Compos. Sci. 2019, 3, 106. [Google Scholar] [CrossRef] [Green Version]

- Ito, M.; Koizumi, T.; Kojima, H.; Saito, T.; Nakamura, M. From materials to device design of a thermoelectric fabric for wearable energy harvesters. J. Mater. Chem. A 2017, 5, 12068–12072. [Google Scholar] [CrossRef]

- Hewitt, C.A.; Montgomery, D.S.; Barbalace, R.L.; Carlson, R.D.; Carroll, D.L. Improved thermoelectric power output from multilayered polyethylenimine doped carbon nanotube based organic composites. J. Appl. Phys. 2014, 115, 184502. [Google Scholar] [CrossRef]

- Ding, T.; Chan, K.H.; Zhou, Y.; Wang, X.-Q.; Cheng, Y.; Li, T.; Ho, G.W. Scalable thermoelectric fibers for multifunctional textile-electronics. Nat. Commun. 2020, 11, 6006. [Google Scholar] [CrossRef]

- Voigt, O.; Krause, B.; Pötschke, P.; Müller, M.T.; Wießner, S. Thermoelectric performance of polypropylene/carbon nanotube/ionic liquid composites and its dependence on electron beam irradiation. J. Compos. Sci. 2022, 6, 25. [Google Scholar] [CrossRef]

- Luo, J.; Krause, B.; Pötschke, P. Polymer-carbon nanotube composites for thermoelectric applications. AIP Conf. Proc. 2017, 1914, 030001. [Google Scholar]

- Luo, J.; Cerretti, G.; Krause, B.; Zhang, L.; Otto, T.; Jenschke, W.; Ullrich, M.; Tremel, W.; Voit, B.; Pötschke, P. Polypropylene-based melt mixed composites with singlewalled carbon nanotubes for thermoelectric applications: Switching from p-type to n-type by the addition of polyethylene glycol. Polymer 2017, 108, 513–520. [Google Scholar] [CrossRef]

- Pötschke, P.; Krause, B.; Luo, J. Melt-mixed thermoplastic polymer/carbon nanotube composites for thermoelectric applications. TechConnect Briefs 2018, 1, 196–199. [Google Scholar]

- Pötschke, P.; Krause, B.; Luo, J. Melt mixed composites of polypropylene with single walled carbon nanotubes for thermoelectric applications: Switching from p- to n-type behavior by additive addition. AIP Conf. Proc. 2019, 2055, 090004. [Google Scholar]

- Chen, S.; Jiang, Y.; Wang, Z.; Zhang, X.; Dai, L.; Smet, M. Light-controlled single-walled carbon nanotube dispersions in aqueous solution. Langmuir 2008, 24, 9233–9236. [Google Scholar] [CrossRef]

- Lee, J.U.; Huh, J.; Kim, K.H.; Park, C.; Jo, W.H. Aqueous suspension of carbon nanotubes via non-covalent functionalization with oligothiophene-terminated poly(ethylene glycol). Carbon 2007, 45, 1051–1057. [Google Scholar] [CrossRef]

- Vaisman, L.; Marom, G.; Wagner, H.D. Dispersions of surface-modified carbon nanotubes in water-soluble and water-insoluble polymers. Adv. Funct. Mater. 2006, 16, 357–363. [Google Scholar] [CrossRef]

- Müller, M.T.; Krause, B.; Pötschke, P. A successful approach to disperse mwcnts in polyethylene by melt mixing using polyethylene glycol as additive. Polymer 2012, 53, 3079–3083. [Google Scholar] [CrossRef]

- Zou, S.; Na, B.; Lv, R.; Pan, H. The plasticizer-assisted formation of a percolating multiwalled carbon nanotube network in biodegradable poly(l-lactide). J. Appl. Polym. Sci. 2012, 123, 1843–1847. [Google Scholar] [CrossRef]

- Krause, B.; Pötschke, P.; Ilin, E.; Predtechenskiy, M. Melt mixed SWCNT-polypropylene composites with very low electrical percolation. Polymer 2016, 98, 45–50. [Google Scholar] [CrossRef]

- Predtechenskiy, M.R.; Khasin, A.A.; Bezrodny, A.E.; Bobrenok, O.F.; Dubov, D.Y.; Muradyan, V.E.; Saik, V.O.; Smirnov, S.N. New perspectives in SWCNT applications: Tuball SWCNTs. Part 1. Tuball by itself—All you need to know about it. Carbon Trends 2022, 8, 100175. [Google Scholar] [CrossRef]

- Konidakis, I.; Krause, B.; Park, G.-H.; Pulumati, N.; Reith, H.; Pötschke, P.; Stratakis, E. Probing the carrier dynamics of polymer composites with single and hybrid carbon nanotube fillers for improved thermoelectric performance. ACS Appl. Energy Mater. 2022, 5, 9770–9781. [Google Scholar] [CrossRef]

- Jenschke, W.; Ullrich, M.; Krause, B.; Pötschke, P. Messanlage zur Untersuchung des Seebeck-Effektes in Polymermaterialien–Measuring apparatus for study of seebeck-effect in polymer materials. Tech. Mess. 2020, 87, 495–503. [Google Scholar] [CrossRef]

- Luo, J.; Krause, B.; Pötschke, P. Melt-mixed thermoplastic composites containing carbon nanotubes for thermoelectric applications. AIMS Mater. Sci. 2016, 3, 1107–1116. [Google Scholar] [CrossRef]

- Paleo, A.J.; Krause, B.; Soares, D.; Melle-Franco, M.; Muñoz, E.; Pötschke, P.; Rocha, A.M. Thermoelectric properties of n-type poly(ether ether ketone) carbon nanofiber melt-processed composites. Polymers 2022, 14, 4803. [Google Scholar] [CrossRef]

- Krause, B.; Barbier, C.; Kunz, K.; Pötschke, P. Comparative study of singlewalled, multiwalled, and branched carbon nanotubes melt mixed in different thermoplastic matrices. Polymer 2018, 159, 75–85. [Google Scholar] [CrossRef]

- Kunz, K.; Krause, B.; Kretzschmar, B.; Juhasz, L.; Kobsch, O.; Jenschke, W.; Ullrich, M.; Pötschke, P. Direction dependent electrical conductivity of polymer/carbon filler composites. Polymers 2019, 11, 591. [Google Scholar] [CrossRef] [Green Version]

- Krause, B.; Liguoro, A.; Pötschke, P. Blend structure and n-type thermoelectric performance of PA6/SAN and PA6/PMMA blends filled with singlewalled carbon nanotubes. Nanomaterials 2021, 11, 1146. [Google Scholar] [CrossRef]

- Krause, B.; Konidakis, I.; Arjmand, M.; Sundararaj, U.; Fuge, R.; Liebscher, M.; Hampel, S.; Klaus, M.; Serpetzoglou, E.; Stratakis, E.; et al. Nitrogen-doped carbon nanotube/polypropylene composites with negative seebeck coefficient. J. Compos. Sci. 2020, 4, 14. [Google Scholar] [CrossRef]

| Polymer | Temperature (°C) | Rotation Speed (rpm) | Mixing Time (min) | Pressing Time (min) |

|---|---|---|---|---|

| PBT | 265 | 200 | 5 | 1 |

| PC | 280 | 250 | 5 | 1 |

| PEEK | 360 | 250 | 5 | 1 |

| Composite | El. vol. Conductivity σ (S/m) | Seebeck Coeff. S (µV/K) | Power Factor PF (µW/(m·K2)) |

|---|---|---|---|

| PC/0.75 wt% Tuball [27] | 0.9 | 39.5 ± 0.8 | 1.4 × 10−3 |

| PC/0.75 wt% Tuball + 1.5 wt% PEG | 0.57 ± 0.1 | −13.9 ± 0.4 | 1.1 × 10−4 |

| PC/1 wt% Tuball [27] | 1.0 | 36.7 ± 2.0 | 1.3 × 10−3 |

| PC/1 wt% Tuball + 2 wt% PEG | 1.77 ± 0.3 | −18.3 ± 2.7 | 6.0 × 10−4 |

| PC/2 wt% Tuball [27] | 1.0 | 37.8 ± 0.3 | 1.2 × 10−3 |

| PC/2 wt% Tuball + 2 wt% PEG | 1.32 ± 0.3 | −13.0 ± 0.1 | 2.2 × 10−4 |

| PC/2 wt% Tuball + 3 wt% PEG | 7.18 ± 0.4 | −28.9 ± 1.0 | 6.0 × 10−3 |

| PC/2 wt% Tuball + 4 wt% PEG | 4.65 ± 0.3 | −26.4 ± 1.9 | 3.4 × 10−3 |

| PC/2 wt% Tuball + 5 wt% PEG | 8.58 ± 1.4 | −30.1 ± 0.7 | 7.8 × 10−3 |

| PC/2 wt% Tuball + 8 wt% PEG | 9.33 ± 1.9 | −27.2 ± 0.8 | 6.9 × 10−3 |

| Composite | El. Vol. Conductivity σ (S/m) | Seebeck Coeff. S (µV/K) | Power Factor PF (µW/(m·K2)) |

|---|---|---|---|

| PEEK/0.5 wt% Tuball [27] | 2.2 | 59.4 ± 1.2 | 7.6 × 10−2 |

| PEEK/0.5 wt% Tuball + 1 wt% PEG | 2.70 ± 0.1 | 13.9 ± 0.5 | 5.2 × 10−4 |

| PEEK/0.5 wt% Tuball + 2 wt% PEG | 1.28 ± 0.5 | −22.6 ± 0.6 | 6.6 × 10−4 |

| PEEK/0.5 wt% Tuball + 3 wt% PEG | 12.27 ± 2.0 | −37.3 ± 0.3 | 1.7 × 10−2 |

| PEEK/0.75 wt% Tuball [27] | 1.8 | 61.3 ± 0.2 | 1.2 × 10−2 |

| PEEK/0.75 wt% Tuball + 1.5 wt% PEG | 4.88 ± 0.0 | −22.4 ± 1:6 | 2.5 × 10−3 |

| PEEK/0.75 wt% Tuball + 2 wt% PEG | 4.73 ± 0.2 | −44.1 ± 3.8 | 9.2 × 10−3 |

| PEEK/0.75 wt% Tuball + 3 wt% PEG | 0.45 ± 0.2 | −36.7 ± 1.0 | 6.1 × 10−4 |

| PEEK/1 wt% Tuball [27] | 6.2 | 48.0 ± 1.3 | 7.2 × 10−3 |

| PEEK/1 wt% Tuball + 1 wt% PEG | 14.32± 3.2 | −24.0 ± 4.2 | 8.3 × 10−3 |

| PEEK/1 wt% Tuball + 2 wt% PEG | 28.44 ± 19.9 | −35.0 ± 5.1 | 3.5 × 10−2 |

| PEEK/1 wt% Tuball + 3 wt% PEG | 15.91 ± 3.9 | −33.7 ± 2.1 | 1.8 × 10−2 |

| Composite | El. Vol. Conductivity σ (S/m) | Seebeck Coeff. S (µV/K) | Power Factor PF (µW/(m·K2)) |

|---|---|---|---|

| PBT/2 wt% Tuball [11] | 2.2 | 59.4 ± 1.2 | 1.0 × 10−2 |

| PBT/2 wt% Tuball + 3 wt% PEG | 12.42 ± 4.2 | −14.0 ± 1.1 | 2.4 × 10−3 |

| PBT/2 wt% Tuball + 5 wt% PEG | 24.01 ± 4.8 | −14.5 ± 0.1 | 5.1 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krause, B.; Pötschke, P. Polyethylene Glycol as Additive to Achieve N-Conductive Melt-Mixed Polymer/Carbon Nanotube Composites for Thermoelectric Application. Nanomaterials 2022, 12, 3812. https://doi.org/10.3390/nano12213812

Krause B, Pötschke P. Polyethylene Glycol as Additive to Achieve N-Conductive Melt-Mixed Polymer/Carbon Nanotube Composites for Thermoelectric Application. Nanomaterials. 2022; 12(21):3812. https://doi.org/10.3390/nano12213812

Chicago/Turabian StyleKrause, Beate, and Petra Pötschke. 2022. "Polyethylene Glycol as Additive to Achieve N-Conductive Melt-Mixed Polymer/Carbon Nanotube Composites for Thermoelectric Application" Nanomaterials 12, no. 21: 3812. https://doi.org/10.3390/nano12213812

APA StyleKrause, B., & Pötschke, P. (2022). Polyethylene Glycol as Additive to Achieve N-Conductive Melt-Mixed Polymer/Carbon Nanotube Composites for Thermoelectric Application. Nanomaterials, 12(21), 3812. https://doi.org/10.3390/nano12213812