Direct Laser Writing of Copper Micropatterns from Deep Eutectic Solvents Using Pulsed near-IR Radiation

Abstract

:1. Introduction

2. Methods and Materials

3. Results and Discussion

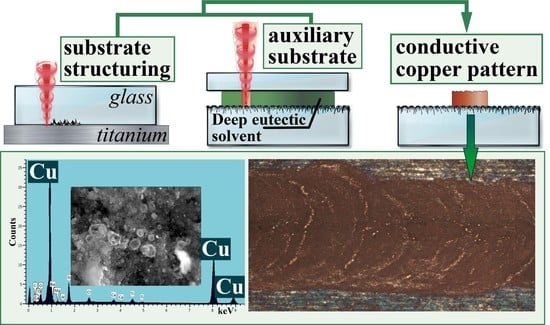

3.1. Acceptor Substrate Pre-Structuring

3.2. Auxiliary Substrate Usage

3.3. Laser Parameter’s Influence

3.4. LIPSSs Formation

4. Perspectives

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain Bhuiyan, M.E.; Moreno, S.; Wang, C.; Minary-Jolandan, M. Interconnect Fabrication by Electroless Plating on 3D-Printed Electroplated Patterns. ACS Appl. Mater. Interfaces 2021, 13, 19271–19281. [Google Scholar] [CrossRef] [PubMed]

- Kato, A.; Hasegawa, Y.; Taniguchi, K.; Shikida, M. Monolithic integration of MEMS thermal flow sensor and its driving circuit onto flexible Cu on polyimide film. Microsyst. Technol. 2020, 26, 2839–2846. [Google Scholar] [CrossRef]

- Li, P.; Qiaoyan, H.; Jidong, L.; Dianyu, Q.; Gan, H.; Zhu, J.; Liu, F.; Zijian, Z.; Wenjing, Z. Flexible Photodetectors Based on All-Solution-Processed Cu Electrodes and InSe Nanoflakes. Adv. Funct. Mater. 2021, 32, 2108261. [Google Scholar] [CrossRef]

- Bariya, M.; Shahpar, Z.; Park, H.; Sun, J.; Jung, Y.; Gao, W.; Nyein, H.Y.Y.; Liaw, T.S.; Tai, L.C.; Ngo, Q.P.; et al. Roll-to-Roll Gravure Printed Electrochemical Sensors for Wearable and Medical Devices. ACS Nano 2018, 12, 6978–6987. [Google Scholar] [CrossRef]

- Valverde, P.E.; Green, T.A.; Roy, S. Effect of water on the electrodeposition of copper from a deep eutectic solvent. J. Appl. Electrochem. 2020, 50, 699–712. [Google Scholar] [CrossRef]

- Vukmirovic, M.B.; Adzic, R.R.; Akolkar, R. Copper Electrodeposition from Deep Eutectic Solvents-Voltammetric Studies Providing Insights into the Role of Substrate: Platinum vs Glassy Carbon. J. Phys. Chem. B 2020, 124, 5465–5475. [Google Scholar] [CrossRef]

- Gates, B.D.; Xu, Q.; Stewart, M.; Ryan, D.; Willson, C.G.; Whitesides, G.M. New Approaches to Nanofabrication: Molding, Printing, and Other Techniques. Chem. Rev. 2005, 105, 1171–1196. [Google Scholar] [CrossRef]

- Piqué, A.; Kim, H.; Auyeung, R.C.Y.; Beniam, I.; Breckenfeld, E. Laser-induced forward transfer (LIFT) of congruent voxels. Appl. Surf. Sci. 2016, 374, 42–48. [Google Scholar] [CrossRef] [Green Version]

- Koritsoglou, O.; Theodorakos, I.; Zacharatos, F.; Makrygianni, M.; Kariyapperuma, D.; Price, R.; Cobb, B.; Melamed, S.; Kabla, A.; de la Vega, F.; et al. Copper micro-electrode fabrication using laser printing and laser sintering processes for on-chip antennas on flexible integrated circuits. Opt. Mater. Express 2019, 9, 3046. [Google Scholar] [CrossRef]

- Zhizhchenko, A.Y.; Tonkaev, P.; Gets, D.; Larin, A.; Zuev, D.; Starikov, S.; Pustovalov, E.V.; Zakharenko, A.M.; Kulinich, S.A.; Juodkazis, S.; et al. Light-Emitting Nanophotonic Designs Enabled by Ultrafast Laser Processing of Halide Perovskites. Small 2020, 16, 2000410. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Hayashi, T.; Narushima, J.; Ohishi, T. Femtosecond laser direct writing of Cu–Ni alloy patterns in ambient atmosphere using glyoxylic acid Cu/Ni mixed complexes. Opt. Laser Technol. 2021, 144, 107418. [Google Scholar] [CrossRef]

- Nam, V.B.; Shin, J.; Choi, A.; Choi, H.; Ko, S.H.; Lee, D. High-temperature, thin, flexible and transparent Ni-based heaters patterned by laser-induced reductive sintering on colorless polyimide. J. Mater. Chem. C 2021, 9, 5652–5661. [Google Scholar] [CrossRef]

- Tumkin, I.I.; Khairullina, E.M.; Panov, M.S.; Yoshidomi, K.; Mizoshiri, M. Copper and nickel microsensors produced by selective laser reductive sintering for non-enzymatic glucose detection. Materials 2021, 14, 2493. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Kumar, G.; Umar, A. Pulse laser deposited nanostructured zno thin films: A review. J. Nanosci. Nanotechnol. 2014, 14, 1911–1930. [Google Scholar] [CrossRef]

- Ratautas, K.; Andrulevičius, M.; Jagminienė, A.; Stankevičienė, I.; Norkus, E.; Račiukaitis, G. Laser-assisted selective copper deposition on commercial PA6 by catalytic electroless plating–Process and activation mechanism. Appl. Surf. Sci. 2019, 470, 405–410. [Google Scholar] [CrossRef]

- Liu, F.; Xie, D.; Jiao, C.; Bai, D.; Wu, H.; Shen, L.; Tian, Z.; Zhao, J. Selective metallization on additive manufactured polymer for fabrication of integrated device. J. Mater. Sci. 2022, 57, 1506–1515. [Google Scholar] [CrossRef]

- Kochemirovsky, V.A.; Menchikov, L.G.; Safonov, S.V.; Bal’makov, M.D.; Tumkin, I.I.; Tver’yanovich, Y.S. Laser-induced chemical liquid phase deposition of metals: Chemical reactions in solution and activation of dielectric surfaces. Russ. Chem. Rev. 2011, 80, 869–882. [Google Scholar] [CrossRef]

- Seo, J.M.; Kwon, K.K.; Song, K.Y.; Chu, C.N.; Ahn, S.H. Deposition of durable micro copper patterns into glass by combining laser-induced backside wet etching and laser-induced chemical liquid phase deposition methods. Materials 2020, 13, 2977. [Google Scholar] [CrossRef]

- Panov, M.S.; Grishankina, A.E.; Stupin, D.D.; Lihachev, A.I.; Mironov, V.N.; Strashkov, D.M.; Khairullina, E.M.; Tumkin, I.I.; Ryazantsev, M.N. In situ laser-induced fabrication of a ruthenium-based microelectrode for non-enzymatic dopamine sensing. Materials 2020, 13, 5385. [Google Scholar] [CrossRef]

- Smikhovskaia, A.V.; Andrianov, V.S.; Khairullina, E.M.; Lebedev, D.V.; Ryazantsev, M.N.; Panov, M.S.; Tumkin, I.I. In situ laser-induced synthesis of copper-silver microcomposite for enzyme-free D-glucose and L-alanine sensing. Appl. Surf. Sci. 2019, 488, 531–536. [Google Scholar] [CrossRef]

- Khairullina, E.M.; Tumkin, I.I.; Stupin, D.D.; Smikhovskaia, A.V.; Mereshchenko, A.S.; Lihachev, A.I.; Vasin, A.V.; Ryazantsev, M.N.; Panov, M.S. Laser-Assisted Surface Modification of Ni Microstructures with Au and Pt toward Cell Biocompatibility and High Enzyme-Free Glucose Sensing. ACS Omega 2021, 6, 18099–18109. [Google Scholar] [CrossRef] [PubMed]

- Vasileva, A.; Haschke, S.; Mikhailovskii, V.; Gitlina, A.; Bachmann, J.; Manshina, A. Direct laser-induced deposition of AgPt@C nanoparticles on 2D and 3D substrates for electrocatalytic glucose oxidation. Nano-Struct. Nano-Objects 2020, 24, 100547. [Google Scholar] [CrossRef]

- Kim, H.G.; Park, M.S. Circuit patterning using laser on transparent material. Surf. Coatings Technol. 2017, 315, 377–384. [Google Scholar] [CrossRef]

- Park, J.-H.; Lee, J.-W.; Ma, Y.-W.; Kang, B.-S.; Hong, S.-M.; Shin, B.-S. Direct Laser Interference Ink Printing Using Copper Metal–Organic Decomposition Ink for Nanofabrication. Nanomaterials 2022, 12, 387. [Google Scholar] [CrossRef] [PubMed]

- Panov, M.S.; Khairullina, E.M.; Vshivtcev, F.S.; Ryazantsev, M.N. Laser-Induced Synthesis of Composite Materials Based on Iridium, Gold and Platinum for Non-Enzymatic Glucose Sensing. Materials 2020, 13, 3359. [Google Scholar] [CrossRef]

- Baranauskaite, V.E.; Novomlinskii, M.O.; Tumkin, I.I.; Khairullina, E.M.; Mereshchenko, A.S.; Balova, I.A.; Panov, M.S.; Kochemirovsky, V.A. In situ laser-induced synthesis of gas sensing microcomposites based on molybdenum and its oxides. Compos. Part B 2019, 157, 322–330. [Google Scholar] [CrossRef]

- Min, H.; Lee, B.; Jeong, S.; Lee, M. Laser-direct process of Cu nano-ink to coat highly conductive and adhesive metallization patterns on plastic substrate. Opt. Lasers Eng. 2016, 80, 12–16. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, J.; Jia, L.; Zhang, H.; Zhang, G.; Sun, S.; Zhou, T. Laser-Induced Selective Metallization on Polymer Substrates Using Organocopper for Portable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 13714–13723. [Google Scholar] [CrossRef]

- Rytlewski, P.; Jagodziński, B.; Malinowski, R.; Budner, B.; Moraczewski, K.; Wojciechowska, A.; Augustyn, P. Laser-induced surface activation and electroless metallization of polyurethane coating containing copper(II) L-tyrosine. Appl. Surf. Sci. 2020, 505, 144429. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Aoyama, K.; Uetsuki, A.; Ohishi, T. Direct writing of copper micropatterns using near-infrared femtosecond laser-pulse-induced reduction of glyoxylic acid copper complex. Micromachines 2019, 10, 401. [Google Scholar] [CrossRef] [Green Version]

- Kochemirovsky, V.A.; Fateev, S.A.; Logunov, L.S.; Tumkin, I.I.; Safonov, S.V. Laser-induced copper deposition with weak reducing agents. Int. J. Electrochem. Sci. 2014, 9, 644–658. [Google Scholar] [CrossRef] [Green Version]

- Bai, S.; Zhang, S.; Zhou, W.; Ma, D.; Ma, Y.; Joshi, P.; Hu, A. Laser-assisted reduction of highly conductive circuits based on copper nitrate for flexible printed sensors. Nano-Micro Lett. 2017, 9, 42. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shishov, A.; Bulatov, A.; Locatelli, M.; Carradori, S.; Andruch, V. Application of deep eutectic solvents in analytical chemistry. A review. Microchem. J. 2017, 135, 33–38. [Google Scholar] [CrossRef]

- Oseguera-Galindo, D.O.; Machorro-Mejia, R.; Bogdanchikova, N.; Mota-Morales, J.D. Silver nanoparticles synthesized by laser ablation confined in urea choline chloride deep-eutectic solvent. Colloids Interface Sci. Commun. 2016, 12, 1–4. [Google Scholar] [CrossRef]

- Krishnan, S.K.; Chipatecua Godoy, Y. Deep Eutectic Solvent-Assisted Synthesis of Au Nanostars Supported on Graphene Oxide as an Efficient Substrate for SERS-Based Molecular Sensing. ACS Omega 2020, 5, 1384–1393. [Google Scholar] [CrossRef]

- Tomé, L.I.N.; Baião, V.; Silva, W.; Brett, C.M.A. Deep eutectic solvents for the production and application of new materials. Appl. Mater. Today 2018, 10, 30–50. [Google Scholar] [CrossRef]

- Adhikari, L.; Larm, N.E.; Baker, G.A. Batch and Flow Nanomanufacturing of Large Quantities of Colloidal Silver and Gold Nanocrystals Using Deep Eutectic Solvents. ACS Sustain. Chem. Eng. 2020, 8, 14679–14689. [Google Scholar] [CrossRef]

- Shishov, A.; Gordeychuk, D.; Logunov, L.; Levshakova, A.; Andrusenko, E.; Chernyshov, I.; Danilova, E.; Panov, M.; Khairullina, E.; Tumkin, I. Laser-induced deposition of copper from deep eutectic solvents: Optimization of chemical and physical parameters. New J. Chem. 2021, 45, 21896–21904. [Google Scholar] [CrossRef]

- Levshakova, A.S.; Khairullina, E.M.; Logunov, L.S.; Panov, M.S.; Mereshchenko, A.S.; Sosnovsky, V.B.; Gordeychuk, D.I.; Yu, A.; Tumkin, I.I. Highly rapid direct laser fabrication of Ni micropatterns for enzyme-free sensing applications using deep eutectic solvent. Mater. Lett. 2022, 308, 131085. [Google Scholar] [CrossRef]

- Shishov, A.; Gordeychuk, D.; Logunov, L.; Tumkin, I. High rate laser deposition of conductive copper microstructures from deep eutectic solvents. Chem. Commun. 2019, 55, 9626–9628. [Google Scholar] [CrossRef] [PubMed]

- Lv, M.; Liu, J.; Zeng, X.; Du, Q.; Ai, J. High-adhesion Cu patterns fabricated by nanosecond laser modification and electroless copper plating. Appl. Surf. Sci. 2015, 353, 1150–1155. [Google Scholar] [CrossRef]

- Lv, M.; Liu, J.; Wang, S.; Ai, J.; Zeng, X. Higher-resolution selective metallization on alumina substrate by laser direct writing and electroless plating. Appl. Surf. Sci. 2016, 366, 227–232. [Google Scholar] [CrossRef]

- Tran, N.; Hoang, H.; Duong, T.; Kim, H. Using a nanosecond laser to pattern copper nanowire-based fl exible electrodes: From simulation to practical application. Appl. Surf. Sci. 2020, 520, 146216. [Google Scholar] [CrossRef]

- Qian, Y.; Huang, H.; Jiang, M.; Yan, J. Nanosecond pulsed laser-induced formation of nanopattern on Fe-based metallic glass surface. Appl. Surf. Sci. 2022, 577, 151976. [Google Scholar] [CrossRef]

- Rymkevich, V.S.; Sergeev, M.M.; Zakoldaev, R.A. Laser microplasma as a spot tool for glass processing: Focusing conditions. J. Mater. Process. Technol. 2021, 292, 117061. [Google Scholar] [CrossRef]

- Shkuratova, V.; Kostyuk, G.; Sergeev, M.; Zakoldaev, R.; Yakovlev, E.; Medvedev, O. Rapid fabrication of spiral phase plate on fused silica by laser-induced microplasma. Appl. Phys. B Lasers Opt. 2020, 126, 61. [Google Scholar] [CrossRef]

- Sinev, D.A.; Yuzhakova, D.S.; Moskvin, M.K.; Veiko, V.P. Formation of the submicron oxidative LIPSS on thin titanium films during nanosecond laser recording. Nanomaterials 2020, 10, 2161. [Google Scholar] [CrossRef]

- Rafailović, L.D.; Stupavska, M.; Prysiazhnyi, V.; Polt, G.; Rohr, O.; Nixon, S.; Rahel, J. Impact of atmospheric pressure plasma treatment on surface metallization of CFRP composites. Surf. Coatings Technol. 2021, 412, 127046. [Google Scholar] [CrossRef]

- Sang, J.; Yang, W.; Zhu, J.; Fu, L.; Li, D.; Zhou, L. Regulating interface adhesion and enhancing thermal conductivity of diamond/copper composites by ion beam bombardment and following surface metallization pretreatment. J. Alloys Compd. 2018, 740, 1060–1066. [Google Scholar] [CrossRef]

- Mamonova, D.V.; Vasileva, A.A.; Petrov, Y.V.; Danilov, D.V.; Kolesnikov, I.E.; Kalinichev, A.A.; Bachmann, J.; Manshina, A.A. Laser-Induced Deposition of Plasmonic Ag and Pt Nanoparticles, and Periodic Arrays. Materials 2021, 14, 10. [Google Scholar] [CrossRef] [PubMed]

- Mamonova, D.V.; Vasileva, A.A.; Petrov, Y.V.; Koroleva, A.V.; Danilov, D.V.; Kolesnikov, I.E.; Bikbaeva, G.I.; Bachmann, J.; Manshina, A.A. Single step laser-induced deposition of plasmonic au, ag, pt mono-, bi-and tri-metallic nanoparticles. Nanomaterials 2022, 12, 146. [Google Scholar] [CrossRef] [PubMed]

- Hansen, B.B.; Spittle, S.; Chen, B.; Poe, D.; Zhang, Y.; Klein, J.M.; Horton, A.; Adhikari, L.; Zelovich, T.; Doherty, B.W.; et al. Deep Eutectic Solvents: A Review of Fundamentals and Applications. Chem. Rev. 2021, 121, 1232–1285. [Google Scholar] [CrossRef] [PubMed]

- Mirza, N.R.; Nicholas, N.J.; Wu, Y.; Kentish, S.; Stevens, G.W. Estimation of Normal Boiling Temperatures, Critical Properties, and Acentric Factors of Deep Eutectic Solvents. J. Chem. Eng. Data 2015, 60, 1844–1854. [Google Scholar] [CrossRef]

- Gygli, G.; Xu, X.; Pleiss, J. Meta-analysis of viscosity of aqueous deep eutectic solvents and their components. Sci. Rep. 2020, 10, 21395. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Zeng, X.; Liu, J. Laser direct writing of conductive silver film on polyimide surface from decomposition of organometallic ink. J. Electron. Mater. 2011, 40, 301–305. [Google Scholar] [CrossRef]

- Chang, C.L.; Cheng, C.W.; Chen, J.K. Femtosecond laser-induced periodic surface structures of copper: Experimental and modeling comparison. Appl. Surf. Sci. 2019, 469, 904–910. [Google Scholar] [CrossRef]

- Maragkaki, S.; Derrien, T.J.Y.; Levy, Y.; Bulgakova, N.M.; Ostendorf, A.; Gurevich, E.L. Wavelength dependence of picosecond laser-induced periodic surface structures on copper. Appl. Surf. Sci. 2017, 417, 88–92. [Google Scholar] [CrossRef] [Green Version]

- Bonse, J.; Gräf, S. Ten open questions about laser-induced periodic surface structures. Nanomaterials 2021, 11, 3326. [Google Scholar] [CrossRef]

- Rung, S.; Hellmann, R. Laser-induced period surface structures to improve solderability of electrical solder pads. Appl. Sci. 2022, 12, 80. [Google Scholar] [CrossRef]

- Mokhtarpour, M.; Shekaari, H. Application of Prigogine–Flory–Patterson theory to correlate the thermodynamic properties of aqueous mixtures of some three-component deep eutectic solvents based on choline chloride and carboxylic acids at T = (288.15 to 318.15) K. J. Mol. Liq. 2020, 320, 114224. [Google Scholar] [CrossRef]

- Leron, R.B.; Li, M.H. Molar heat capacities of choline chloride-based deep eutectic solvents and their binary mixtures with water. Thermochim. Acta 2012, 530, 52–57. [Google Scholar] [CrossRef]

- Gautam, R.K.; Seth, D. Thermal conductivity of deep eutectic solvents. J. Therm. Anal. Calorim. 2020, 140, 2633–2640. [Google Scholar] [CrossRef]

- Khairullina, E.M.; Panov, M.S.; Andriianov, V.S.; Ratautas, K.; Tumkin, I.I. High rate fabrication of copper and copper–gold electrodes by laser-induced selective electroless plating for enzyme-free glucose sensing. RSC Adv. 2021, 11, 19521–19530. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avilova, E.A.; Khairullina, E.M.; Shishov, A.Y.; Eltysheva, E.A.; Mikhailovskii, V.; Sinev, D.A.; Tumkin, I.I. Direct Laser Writing of Copper Micropatterns from Deep Eutectic Solvents Using Pulsed near-IR Radiation. Nanomaterials 2022, 12, 1127. https://doi.org/10.3390/nano12071127

Avilova EA, Khairullina EM, Shishov AY, Eltysheva EA, Mikhailovskii V, Sinev DA, Tumkin II. Direct Laser Writing of Copper Micropatterns from Deep Eutectic Solvents Using Pulsed near-IR Radiation. Nanomaterials. 2022; 12(7):1127. https://doi.org/10.3390/nano12071127

Chicago/Turabian StyleAvilova, Ekaterina A., Evgeniia M. Khairullina, Andrey Yu. Shishov, Elizaveta A. Eltysheva, Vladimir Mikhailovskii, Dmitry A. Sinev, and Ilya I. Tumkin. 2022. "Direct Laser Writing of Copper Micropatterns from Deep Eutectic Solvents Using Pulsed near-IR Radiation" Nanomaterials 12, no. 7: 1127. https://doi.org/10.3390/nano12071127

APA StyleAvilova, E. A., Khairullina, E. M., Shishov, A. Y., Eltysheva, E. A., Mikhailovskii, V., Sinev, D. A., & Tumkin, I. I. (2022). Direct Laser Writing of Copper Micropatterns from Deep Eutectic Solvents Using Pulsed near-IR Radiation. Nanomaterials, 12(7), 1127. https://doi.org/10.3390/nano12071127