3.1. Nanoparticles in Solvent and Polymer: Dilute Conditions

The shape of the bare and grafted NPs has been studied by SAXS in suspension in ethanol, under high dilution. The corresponding form factor is shown in the

SI (Figure S2), and one can see that the superposition of the data is remarkable, across the entire q-range. This implies that although the grafting has taken place as proven by TGA, it has neither influence on the contrast in ethanol, that is, the grafted and solvated layer is invisible to X-rays, nor on the particle dispersion at this high dilution. The corresponding theoretical form factor is also superimposed on the data, and it corresponds to the log-normal size distribution of spheres reported in the methods section.

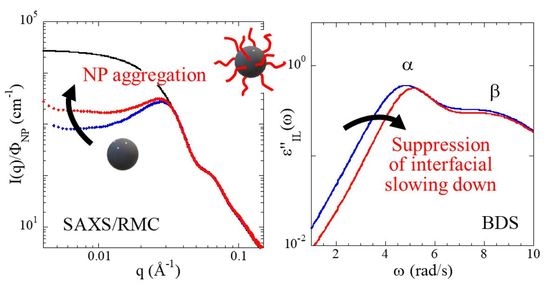

These particles have then been incorporated into a P2VP-matrix. A first series of samples at a nominal volume fraction of 2%v has been prepared and studied by SAXS. The resulting intensity curves are given in the

SI, and they show that some modification of the scattering length density around the particles is visible in the polymer matrix. Although the observed deviations are quite small and not visible at low grafting density, they present the first structural evidence of the impact of grafting. At low q, the samples with intermediate grafting show a slight decrease, indicating a change in NP interactions towards short-range repulsion. The highest grafting density has a clearly different shape with a dip in intensity called a correlation hole [

46], followed by a low-q increase, and it is a typical signature of aggregation in this nanocomposite.

The structure of PNCs at 2%v has also been studied by TEM. In

Figure 1, the series in grafting density up to 2.4 nm

−2 is shown, and compared to a series with 10 times higher silica content. These pictures illustrate that the NPs are rather well dispersed under all conditions, that is, there are no large structural heterogeneities.

At the higher volume fraction (ca. 20%v) in

Figure 1, the dispersion of the particles is seen to remain rather homogeneous. At the highest grafting densities, the occurrence of more whitish silica-free zones indicates the presence of spatial fluctuations in particle density. This is impossible to see in the left-hand figure, due to the high dilution and thus important average particle distance. Scattering, however, is capable of picking up such small fluctuations, as shown for the 2%v-samples in the

SI. At 20%v, the spatial averaging as performed by the SAXS experiments will indeed confirm these heterogeneities which develop upon grafting.

3.2. Dynamical Properties of the NP-Polymer Interface Probed by BDS

Broadband dielectric spectroscopy has been used to probe the segmental α-relaxation associated with the polymer glass transition. In the dielectric spectra, the α-process is surrounded at lower frequencies by ionic conductivity and MWS-processes related to the filler nanoparticles, and at higher frequencies by the secondary β-relaxation of P2VP. All processes have been included in our analysis, in order to extract the segmental dynamics in a trustworthy way. In

Figure 2, the dielectric loss spectra of the 30%v-PNC series are presented (15 and 20%v can be found in the

SI in Figure S3).

The dielectric loss of the PNCs illustrated in

Figure 2 is seen to decrease at low frequencies as expected due to MWS and conductivity, before reaching a minimum, followed by the maximum representative of the segmental relaxation of the polymer. This maximum is positioned at the right in the pure matrix. The α-relaxation is then slowed down as soon as the bare NPs are embedded in the polymer matrix (blue curve) before the peak moves back to the right with surface modification. This phenomenological observation is fundamental for this article, and confirms our previous findings with a longer graft (C

18 instead of C

8, see [

12]): the nanoparticle surface induces a slow-down of the neighboring polymer chains, whereas modification of the same surface with small silane molecules counteracts this slow-down. We will now analyze the modification of the α-relaxation in terms of the ILM, which describes the total dielectric response in terms of a bulk (with unmodified dynamics with respect to the neat polymer) and an interfacial contribution, as well as their interferences. As a result, the loss and storage permittivity responses are quantitatively and simultaneously described, and the fits describe well the data in

Figure 2 (as well as the other data shown in the

SI). Details of the fits are displayed in

Figure S4 in the SI, where the different contributions—MWS, α (including both IL and bulk contributions which are linked), β, and conductivity—to the dielectric loss are highlighted for two selected samples.

The main results of the dielectric analysis of these nanocomposites are the properties of the interfacial layer. An example of analysis of the interfacial layer is provided in

Figure 3a, and the fit parameters are reported for PNCs at all volume fractions in

Figure 3b,c. In

Figure 3a, the dielectric loss of a pure interfacial layer deduced from the fit of experimental data but without bulk contribution (Φ

bulk = 0), ε

IL″(ω), is represented for PNCs with 30%v of silica, and different grafting densities as given in the legend. It corresponds to the sum of two HN functions for the α- and β-processes as deduced from the ILM fit.

Two important parameters of the ILM analysis are the interfacial layer volume fraction, Φ

IL, given here with respect to the polymer part (Φ

IL + Φ

bulk = 1), and its characteristic time. The first is plotted in

Figure 3b. Two remarkable features can be seen: first, the volume fraction of the interphase is independent of the surface modification. Secondly, it increases with the silica volume fraction, that is, the available silica surface. Φ

IL can thus be used to determine the thickness of the interfacial layer. A simple cubic model calculation, which ignores silica interactions and thus real particle arrangement gives a thickness of 3.7 ± 0.1 nm for all PNCs. A more accurate model taking into account the particle positions from scattering and simulations and the overlapping volume is discussed below. Whatever the exact value, it is striking to see that the thickness of the interfacial layer is independent of experimental conditions, like silica content and grafting. Therefore, it seems to reflect an intrinsic property of the polymer-surface couple.

Figure 3c, finally, represents the characteristic time of the interfacial layer, expressed as a ratio to the value of the neat polymer. The selected temperature (423 K) corresponds to ca. T = 1.1 T

g, which is the closest temperature to T

g where the overall segmental dynamics of P2VP is well-visible in the BDS frequency window. The increase of the ratio τ

IL/τ

neat thus represents the slow-down of the polymer dynamics in the vicinity of the silica (i.e., within ca. 4 nm of the surface, as discussed in the preceding paragraph). It is interesting to see that the PNCs with bare particles possess an interfacial layer with virtually the same relaxation time for all silica contents. As surface modification is introduced, the dynamics accelerates, that is, the ratio decreases, and seems to level off at around one, which corresponds to unperturbed segmental dynamics. The effect of silane grafting on the slow-down can thus be followed, and above approximately 1.5 nm

−2, the pure P2VP dynamics is recovered. For comparison, we have superimposed the main result of a previous analysis with a similar but longer silane molecule, C

18 [

12]. The effect on τ

IL is considerably stronger, and with already 0.5 C

18 per nm

2, the pure P2VP relaxation is reached. Although the statistics of the two curves in

Figure 3c are insufficient for a precise determination of such a threshold value, it is clear from the decays that the relaxation time of the C

18-samples has already joined the pure P2VP value at 0.5 nm

−2, whereas the C

8-PNCs will do the same somewhere between 1.5 and 2 nm

−2. The ratio between the two thresholds is thus of the order of 3 or 4, which is considerably larger than the ratio of about two between the alkyl chain masses (18:8). As for a given surface grafting density, the total mass of alkyl chains surrounding a given NP is directly related to the molecular weight of the graft, it can be concluded that the effect on the dynamics is not simply related to the amount of CH

2 groups, but also to their spatial organization. In particular, one may speculate that the C

18 groups have a higher propensity to homogeneously cover the silica surface providing a more efficient screening effect from the polymer chains. The shorter C

8 might form locally dense regions due to a lower steric hindrance, leaving free silica zones, that is, covered by hydroxyl groups favoring polymer adsorption. Our findings are in qualitative agreement with recent results from atomistic molecular dynamics simulations of silica-filled polyisoprene, where planar silica substrates were covered with silane of different alkyl lengths (C

3 and C

8, i.e., with 3 or 8 carbon atoms in the alkyl part) and different grafting densities [

16]. It was found that the slow-down of the polymer dynamics due to polymer adsorption is weakened upon silane grafting with a stronger effect of the longest graft at high grafting density. This effect is concomitant with an increase of the diffusion coefficient of the adsorbed chains, which almost reaches the one of the bulk polymer chains.

The results shown in

Figure 3c demonstrate that it is possible to tune the interfacial dynamics using grafts with longer or shorter alkyl chains, at different concentrations. The remaining question to be answered is how such a surface modification affects the structure of the nanocomposites, and TEM (

Figure 1), and in particular, SAXS are the most suited methods, to be discussed in the next section.

3.3. Structure of PNCs Studied by SAXS

The microstructure of all nanocomposites has been investigated by SAXS. Results for the 15 and 20%v-series are reported in the

SI. They are conceptually very similar to the 30%v-series shown in

Figure 4. In

Figure 4a, the scattered intensities are plotted for different grafting densities. The intensities are compared to the form factor measured at high dilution as discussed before. At high q, where the intensity is sensitive to the surface and the shape of the particle, a good superposition is observed. Around 3.3 × 10

−2 Å

−1, the PNC intensities at these high concentrations begin to deviate. For bare NPs, or low grafting density up to 1.3 nm

−2, the curves present a well-defined peak around 2.8 × 10

−2 Å

−1. At the highest grafting of 2.9 nm

−2, the curve shows a completely different spatial organization. As already visible at 2%v (see

SI and discussion above), there is a deep correlation hole, and the intensity deviates from the form factor at higher q-vectors. At low q, a strong upturn is found. This low-q increase translates the attractive interactions between nanoparticles, inducing aggregation. They are triggered by the suppression of attractive polymer–silica interactions caused by surface modification, and thus of the steric protection against aggregation. Depletion interactions induced by the polymer chains (which are about a factor of two smaller than the particles) may also participate in generating interparticle attraction. All these features correspond to aggregation and large-scale spatial fluctuations induced by the high grafting density and they correspond to those reported for nanocomposite melts by Hall et al. [

47] These authors experimentally varied the interfacial attraction via the polymer. They studied poly(ethylene oxide) and polytetrahydrofuran (PTHF)-systems, the latter being less attractive because of less hydrogen bonding with the silica. A decrease of the interfacial attraction in PTHF reduces local order and thus leads to a low-q increase, and a structure factor peak shifted towards higher q. PRISM integral equations describe these features, and provide a satisfactory description of polymer-mediated NP concentration fluctuations. The latter ultimately induces depletion aggregation and microphase separation. In our case, increasing coating coverage decreases the polymer–NP effective attraction [

12] with a qualitatively similar behavior as predicted by PRISM in terms of peak shift and low-q upturn.

By comparing the families of curves at 15 and 20%v of silica (see

Figure S5 in SI) to the 30%-curves in

Figure 4, the series at higher volume fractions are found to bundle at lower intensities at low q. This is the natural consequence of the increase in silica content, increasingly highlighting the hard-core repulsion between particles. This repulsion induces a decrease in the apparent compressibility. As the surface modification is added, some intermediate upturns at 2.4 nm

−2 can be seen at 15 and 20%v of silica, showing that grafting affects NP interactions in a progressive (and thus tunable) way. One can also follow the peak positions as a function of volume fraction for bare NPs and intermediate grafting (while it disappears at the highest grafting): at 15%v, the peaks correspond to center-to-center distances of 27–31 nm, which are larger than two particle radii, and indicates that NPs still have quite some space to re-organize. At 20%v, the upturn is more prominent at low q, but the peaks remain well-defined leading to distances of ca. 24 to 26 nm. At 30%v, finally, the peak position corresponds to a center-to-center particle distance of ca. 22.5 nm. This distance expresses the fact that particles interact repulsively due to their hard cores, and they do not have much space to reorganize at this concentration. There does not seem to be any systematic dependence with the amount of surface modification. Indeed, we found that the peak positions follow a Φ

−1/3-law for the three series (see

SI, Figures S6 and S7) and the slight variations observed upon grafting are compatible with the variation in volume fraction between samples (

Table 1).

In

Figure 4b, the apparent structure factors obtained by division of the experimental intensities by the average form factor of the nanoparticles as measured in dilute suspension are presented. The apparent structure factor is a generalization of the structure factor of monodisperse spheres, where it is given by the Fourier transform of the pair-correlation function. Here, all pair correlations are weighted by the different particle volumes, and the apparent structure factor roughly coincides with the true one for low enough polydispersities. In any event, in all model calculations below, the polydispersity is taken into account. The apparent structure factors provide the same information as the intensities, but they focus on the interactions. For instance, the absence of interactions, as in ideal gases, would result in a constant, 1. In this log-lin representation, one observes the close vicinity of all curves at the highest grafting. In particular at low q, the highly repulsive character is visible, the low-q limit for monodisperse spheres would give exactly the compressibility relative to an ideal gas. At intermediate q, a peak is reached, with higher order peaks decreasing towards 1. Once again, the notable exception is the PNC at the highest grafting, where the structure factor has a completely different shape: the low-q upturn and the correlation hole are clearly visible, and at high q, a strong peak is reached at a position at the right-hand-side of the other samples. This peak position corresponds to a shorter typical center-to-center distance of 14 nm, to be compared to 2R

NP = 17 nm. The same is observed for the lower volume fractions, 15 and 20%v. Our interpretation of this result is that the system has developed into a highly aggregated one, where the internal structure is probably optimized towards higher density by peculiar correlations between larger and smaller beads.

The apparent structure factors measured for all PNCs at all silica contents have been fitted by a reverse Monte Carlo algorithm [

33,

34,

35], as described in the Methods section. The result is a sequence of particle configurations, the scattering of which is compatible with the measured structure factor. In

Figure 4b, the corresponding fit functions have been superimposed on the data. The fit quality is seen to be quite good for all samples except the highest grafting densities, where the strong correlation hole is difficult to reproduce. The origin of this mismatch is unclear at the current stage, but it might be due to deviations of the real silica NPs from ideal spheres, which may affect local interactions in close contact. Once the sequence of configurations is available, a statistical analysis of the particle positions can be performed. As we are interested in the action of the grafts and possibly adsorbed polymer on the correlations between particles, the interparticle spacing (IPS) distribution function has been deduced from the particle positions. This function is a generalization of the pair-correlation function for polydisperse spheres, with a focus on the interparticle spacing: it expresses the number of times a certain surface-to-surface distance is encountered in the simulation box representing the configuration. The results are plotted for all samples in

Figure 5 in terms of the normed IPS, that is, the number of times a given surface-to-surface distance is found, normed to the same number for a hard-sphere gas of same characteristics. For an analysis of uncertainties in IPS and a comparison with g(r) determined from the particle centers, see

SI (Figures S8 and S9).

The low-distance limit of the normed IPS function in

Figure 5 expresses the probability of contact with respect to the hard-sphere gas. Whereas this number is low for the bare NPs (presumably due to the steric buffer action of the adsorbed polymer chains), the increase in contact probability is seen to be highest for the lowest volume fraction, and for the highest grafting densities. Moreover, there is a notable preference for particles to be close, within typical distances of ca. 1 nm. Around distances corresponding to about one or two particle radii, that is, above 10 nm, there is some structure visible, which is due to the second layer of neighbors. At high distances, finally, the normed IPS tends to 1, implying that there is no difference at large distances between PNC samples and hard-sphere gases.

When comparing the normed IPS functions for the different volume fraction series, it appears that the family of curves gets closer with increasing silica content. Simultaneously, the increase of probability of contact becomes smaller, that is, it approaches the hard-sphere gas. This means that the impact of grafting on structure at high volume fraction is smaller, presumably due to the higher crowding which leaves less space for reorganization, as discussed directly with the structure factors in

Figure 4.

There are different ways to analyze the IPS, or to express it in terms of properties of real space configurations. In

Figure 6a, the normed contact probability is plotted for all PNC samples. It is seen to increase with grafting, and to decrease with silica volume fraction. The latter effect indicates that, at higher silica contents, the particle structures are closer to that of a hard-sphere gas, and less subjected to changes induced by surface modification. As the first neighboring particle is usually in close contact, and as the distance to any particle is expressed by the IPS, one can integrate the raw IPS function to determine the distance where a second particle is encountered. In

Figure 6b, this distance is shown, for all silica contents, as a function of grafting density. The distance is seen to be rather large (around 4–5 nm) at 15%v, implying a rather loose assembly of particles at low grafting, before it decreases at high grafting, meaning that, on average, a second particle is “pulled in” into close contact. This effect is seen to decrease for higher volume fractions, where particle assemblies are denser anyhow. Nonetheless, a critical threshold value of about 1.5 nm

−2 seems to persist. In

Figure 6b, there appears to be an artefact at 15%v, where an increase in the second-particle distance is seen at 1.3 nm

−2. We have attempted to understand the origin of this increase and we have checked if it can be traced back to slight uncertainties in the absolute intensity. We have, therefore, repeated the same Monte Carlo analysis for three sample data sets at 1.3 nm

−2, shifting two of them by ±2% which corresponds to the uncertainty in positioning the sample intensity with respect to the particle form factor (see

SI, Figure S8). The resulting indicators in

Figure 6, including the “two particle distances”, have been converted into an error bar. The increased value at 1.3 nm

−2 and 15%v of silica in

Figure 6b is seen to persist within the error bar. We conclude that, while we do not have any physical explanation for such an effect, its origin does not lie in a wrong positioning of the scattering curve in absolute intensity. In the last plot,

Figure 6c, a different analysis is proposed. Here a fixed distance, corresponding to the length of two C

8 molecules (2L = 2.5 nm) has been used as upper bound for the integral over the raw IPS. The result is the number of neighbors typically encountered up to this distance. This number obviously increases with the volume fraction, but also with the grafting density, and the latter effect is again stronger for the lowest silica fraction. Finally, one may note that

Figure 6b,c are two sides of the same coin, expressed by different parameters.

The different ways of exploring the IPS proposed in

Figure 6 illustrate how the NP dispersion in the nanocomposite changes with volume fraction and grafting density. The volume fraction effect has been discussed several times, and is thought to be mainly a crowding effect which approaches the particle configuration to a hard-sphere configuration. The surface modification effect is more subtle, and it seems to imply the existence of a threshold of ca. 1.5 nm

−2. Below this threshold, particle dispersions are only slightly affected by the grafting, whereas above it, a complete reorganization, with strong aggregation, is observed.

It is instructive, finally, to compare the structural indicators obtained with C

8 with the corresponding indicators for C

18. For this purpose, we have superimposed the evolution of the three indicators with the grafting density of C

18 at 15%v of silica in

Figure 6, that is, when the signature of aggregation with respect to hard spheres is most developed. The contact values are higher for C

18 than for C

8 in

Figure 6a, indicating denser assemblies. In parallel, both the strong decrease of the distance between two NPs and the increase of the number of neighbors within a shell corresponding to the size of two silanes are clearly shifted towards lower grafting densities, in

Figure 6b,c, respectively. As observed for the dynamical features in

Section 3.2, the influence of the longer alkyl-chain length of C

18 is stronger than C

8 to favor NP aggregation by reducing the buffer effect of the polymer segments at the silica surface. As with the dynamics, by again comparing the threshold values in

Figure 6, it appears that the C

18 effect is stronger than the mass effect of (18:8) expected from the ratio between the alkyl chain masses.

3.4. Determination of the True Interfacial Thickness by Combining BDS, SAXS, and RMC

A key result of the ILM analysis of segmental dynamics of the interfacial layer discussed above is the volume fraction of the polymer layer slowed-down by the presence of the silica. Based on an idealized cubic model, this volume fraction has been converted into an estimation of the interfacial thickness of a few nanometers. Having measured the particle dispersion by SAXS, and having sets of particle dispersions compatible with this experimental intensity at hand, it is possible to refine this value by taking overlap between particle layers of the obtained configuration explicitly into account. It is thus important to study the relationship between dispersion and interfacial layers more in detail.

The idea is to use the concept of interfacial thickness to characterize the type of particle dispersion. For a given 3D particle arrangement, there should be a specific relationship between the thickness and the volume fraction of the interface, due to overlap. Perfectly ordered and well-dispersed particles, like in a cubic crystal, for example, have an interfacial volume proportional to the particle surface, as long as the interfacial thickness is small enough to avoid overlap. In the presence of overlap, the interfacial volume fraction increases less strongly with thickness than in the ideal case. For the ideal cubic case, simple geometric expressions are available, including overlap [

17]. As soon as particles tend to agglomerate, they are, however, of limited use.

In

Figure 7a, the evolution of the interfacial volume fraction Φ

ILPNC with a (hypothetical) interfacial layer thickness is plotted exemplarily for different types of dispersion, corresponding to PNC samples with 15%v silica content, with either bare particles or high silane grafting (2.9 nm

−2). The silica content is also represented and is seen to meet the experimental volume fraction with high accuracy. Note that the silica and the layer volume fractions are determined by the same algorithm based on the positions of N particles in the simulation box, thereby providing a cross-check of the algorithm. Another verification lies in the fact that Φ

ILPNC-curves saturate at values approaching 1 − Φ

NP, which is why we have left the silica in the definition of Φ

ILPNC (Φ

ILPNC + Φ

NP + Φ

bulk = 1) as opposed to the pure polymer part discussed in

Figure 3b.

The two Φ

ILPNC-curves in

Figure 7a follow different laws despite their close silica contents. For very small thicknesses, PNC with bare NPs display a steeper slope, meaning that the dispersion is better, and more interfacial volume is created with every Angstrom of thickness around the more individually dispersed particles. On the contrary, in the highly aggregated case, there is immediate overlap of interfacial layers, leading to a reduction of volume of the latter. For bare NPs, the maximum available polymer volume is thus reached with ca. 15 nm thickness, while 25 nm are needed to cover all the particle-free regions of the sample in the aggregated case. The evolution of the interfacial volume fraction with thickness shown in

Figure 7a for different grafting densities thus characterizes the quality of the dispersion. In

Figure 7a, the determination of the real thickness corresponding to the total interfacial layer volume fraction is exemplarily shown, and a thickness of 4.6 nm is found for the bare system, based on an interfacial layer volume fraction determined by BDS of Φ

ILPNC = 0.31.

In

Figure 7b, the total interfacial layer volume fraction has been reported for the 30%v-PNC made with bare NPs. Results for the highest grafting density are given in the

SI (Figure S10). It is found again that the grafting has only limited impact on the dispersion at such high silica content, and thus the Φ

ILPNC-curves are quite similar. It is instructive, however, to superimpose the prediction of the cubic model (including possible overlap between neighboring layers) used in the literature to the RMC-analysis of experimental data in

Figure 7b. Clearly, the large interparticle distance between all spheres in the cubic model leads to a much stronger increase of the Φ

ILPNC–function with thickness. It is concluded that it is by no means suitable for dense and possibly aggregated structures as studied here.

The procedure of comparing Φ

ILPNC to the experimental value of the interfacial volume fraction determined by BDS can be generalized to all samples, and the corresponding thickness can be read off following the downward arrow. The interfacial layer thicknesses reported in

Figure 8 for all nanocomposite samples, as a function of grafting density, represent a key result of the present study, together with

Figure 3c where the time scale of the interfacial dynamics is plotted. It needs to be emphasized that the true thickness could only be obtained by a combination of static structural (SAXS) and dynamic methods (BDS), with the help of RMC simulations. As a result, the interfacial layer thickness is found to be remarkably constant with both the grafting density and the silica fraction in PNC. An average value of 4.9 ± 0.2 nm is found, where the error bar has been determined from the standard deviation and the number of points. Moreover, it is found to be compatible with the value obtained with C

18-surface modification (5.0 ± 0.5 nm) with a lower error bar due to a lesser dispersion of the points [

12]. In the presence or absence of surface modification of any type (C

8 or C

18), the range of interactions between the polymer segments and the silica surface is thus constant, intrinsic to the polymer–surface couple, or possibly intrinsic to the transmission of cage constraints [

13] from one polymer layer to the next. Depending on the grafting, however, the strength of the interaction varies, inducing a stronger (in the case of bare) or weaker (for grafted, longer molecules having a higher impact) slow-down of the segmental dynamics.