Hypophosphite/Graphitic Carbon Nitride Hybrids: Preparation and Flame-Retardant Application in Thermoplastic Polyurethane

Abstract

:1. Introduction

2. Experimental Section

2.1. Raw Materials

2.2. Synthesis of CAHPi

2.3. Preparation of TPU Nanocomposites

2.4. Instruments and Measurements

3. Results and Discussion

3.1. Structure and Morphology of CAHPi

3.2. Thermal Stability of TPU Nanocomposites

3.3. Flame Retardancy of TPU Nanocomposites and Mechanism Investigation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Finnigan, B.; Martin, D.; Halley, P.; Truss, R.; Campbell, K. Morphology and properties of thermoplastic polyurethane nanocomposites incorporating hydrophilic layered silicates. Polymer 2004, 45, 2249–2260. [Google Scholar] [CrossRef]

- Koerner, H.; Liu, W.; Alexander, M.; Mirau, P.; Dowty, H.; Vaia, R.A. Deformation–morphology correlations in electrically conductive carbon nanotube—Thermoplastic polyurethane nanocomposites. Polymer 2005, 46, 4405–4420. [Google Scholar] [CrossRef]

- Covaci, A.; Harrad, S.; Abdallah, M.A.E.; Ali, N.; Law, R.J.; Herzke, D.; De Wit, C.A. Novel brominated flame retardants: A review of their analysis, environmental fate and behaviour. Environ. Int. 2011, 37, 532–556. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Jiang, Y.; Jiao, C. Smoke suppression properties of ferrite yellow on flame retardant thermoplastic polyurethane based on ammonium polyphosphate. J. Hazard. Mater. 2014, 266, 114–121. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Jiang, Y.; Liu, J.; Jiao, C.; Qian, Y.; Li, S. Smoke suppression properties of fumed silica on flame-retardant thermoplastic polyurethane based on ammonium polyphosphate. J. Therm. Anal. Calorim. 2015, 120, 1493–1501. [Google Scholar] [CrossRef]

- Bourbigot, S.; Samyn, F.; Turf, T.; Duquesne, S. Nanomorphology and reaction to fire of polyurethane and polyamide nanocomposites containing flame retardants. Polym. Degrad. Stab. 2010, 95, 320–326. [Google Scholar] [CrossRef]

- Li, H.; Ning, N.; Zhang, L.; Wang, Y.; Liang, W.; Tian, M. Different flame retardancy effects and mechanisms of aluminium phosphinate in PPO, TPU and PP. Polym. Degrad. Stab. 2014, 105, 86–95. [Google Scholar] [CrossRef]

- Xiao, S.S.; Chen, M.J.; Dong, L.P.; Deng, C.; Chen, L.; Wang, Y.Z. Thermal degradation, flame retardance and mechanical properties of thermoplastic polyurethane composites based on aluminum hypophosphite. Chin. J. Polym. Sci. 2014, 32, 98–107. [Google Scholar] [CrossRef]

- Chen, X.; Ma, C.; Jiao, C. Synergistic effects between [Emim]PF6 and aluminum hypophosphite on flame retardant thermoplastic polyurethane. RSC Adv. 2016, 6, 67409–67417. [Google Scholar] [CrossRef]

- Lv, L.Y.; Pan, W.H.; Sun, L.M. Preparation and Characterization of Halogen Free Flame Retardant Thermoplastic Polyurethane. China Plast. Ind. 2013, 4, 013. [Google Scholar]

- Chen, X.; Song, W.; Liu, J.; Jiao, C.; Qian, Y. Synergistic flame-retardant effects between aluminum hypophosphite and expandable graphite in silicone rubber composites. J. Therm. Anal. Calorim. 2015, 120, 1819–1826. [Google Scholar] [CrossRef]

- Chen, X.; Ma, C.; Jiao, C. Enhancement of flame-retardant performance of thermoplastic polyurethane with the incorporation of aluminum hypophosphite and iron-graphene. Polym. Degrad. Stab. 2016, 129, 275–285. [Google Scholar] [CrossRef]

- Yang, W.; Song, L.; Hu, Y.; Lu, H.; Yuen, R.K.K. Enhancement of fire retardancy performance of glass-fibre reinforced poly(ethylene terephthalate) composites with the incorporation of aluminum hypophosphite and melamine cyanurate. Compos. Part B Eng. 2011, 42, 1057–1065. [Google Scholar] [CrossRef]

- Wang, X.; Maeda, K.; Thomas, A.; Takanabe, K.; Xin, G.; Carlsson, J.M.; Domen, K.; Antonietti, M. A metal-free polymeric photocatalyst for hydrogen production from water under visible light. Nat. Mater. 2009, 8, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, X.; Antonietti, M. Polymeric graphitic carbon nitride as a heterogeneous organocatalyst: From photochemistry to multipurpose catalysis to sustainable chemistry. Angew. Chem. Int. Ed. 2012, 51, 68–89. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Shen, S.; Guo, P.; Wang, M.; Wu, P.; Wang, X.; Guo, L. In-situ reduction synthesis of nano-sized Cu2O particles modifying g-C3N4 for enhanced photocatalytic hydrogen production. Appl. Catal. B Environ. 2014, 152–153, 335–341. [Google Scholar] [CrossRef]

- Fang, Y.; Lv, Y.; Che, R.; Wu, H.; Zhang, X.; Gu, D.; Zheng, G.; Zhao, D. Two-Dimensional Mesoporous Carbon Nanosheets and Their Derived Graphene Nanosheets: Synthesis and Efficient Lithium Ion Storage. J. Am. Chem. Soc. 2013, 135, 1524–1530. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xie, X.; Wang, H.; Zhang, J.; Pan, B.; Xie, Y. Enhanced Photoresponsive Ultrathin Graphitic-Phase C3N4 Nanosheets for Bioimaging. J. Am. Chem. Soc. 2013, 135, 18–21. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Mori, T.; Niu, L.; Ye, J. Non-covalent doping of graphitic carbon nitride polymer with graphene: Controlled electronic structure and enhanced optoelectronic conversion. Energy Environ. Sci. 2011, 4, 4517–4521. [Google Scholar] [CrossRef]

- Sadhukhan, M.; Barman, S. Bottom-up fabrication of two-dimensional carbon nitride and highly sensitive electrochemical sensors for mercuric ions. J. Mater. Chem. A 2013, 1, 2752–2756. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, T.; Wang, Z.; Dawson, G.; Chen, W. Simple pyrolysis of urea into graphitic carbon nitride with recyclable adsorption and photocatalytic activity. J. Mater. Chem. 2011, 21, 14398–14401. [Google Scholar] [CrossRef]

- Zou, X.X.; Li, G.D.; Wang, Y.N.; Zhao, J.; Yan, C.; Guo, M.Y.; Li, L.; Chen, J.S. Direct conversion of urea into graphitic carbon nitride over mesoporous TiO2 spheres under mild condition. Chem. Commun. 2011, 47, 1066–1068. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Hu, Y.; Song, L.; Wu, J.; Fang, S. Influence of Fe-MMT on the fire retarding behavior and mechanical property of (ethylene-vinyl acetate copolymer/magnesium hydroxide) composite. Polym. Adv. Technol. 2008, 19, 960–966. [Google Scholar] [CrossRef]

- Gu, J.; Liang, C.; Zhao, X.; Gan, B.; Qiu, H.; Guo, Y.; Yang, X.; Zhang, Q.; Wang, D. Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities. Compos. Sci. Technol. 2017, 139, 83–89. [Google Scholar] [CrossRef]

- Kalali, E.N.; Wang, X.; Wang, D.Y. Functionalized layered double hydroxide-based epoxy nanocomposites with improved flame retardancy and mechanical properties. J. Mater. Chem. A 2015, 3, 6819–6826. [Google Scholar] [CrossRef]

- Gu, J.; Meng, X.; Tang, Y.; Li, Y.; Zhuang, Q.; Kong, J. Hexagonal boron nitride/polymethyl-vinyl siloxane rubber dielectric thermally conductive composites with ideal thermal stabilities. Compos. Part A Appl. Sci. Manuf. 2017, 92, 27–32. [Google Scholar] [CrossRef]

- Yang, M.; Chen, X.; Wang, Y.; Yuan, B.; Niu, Y.; Zhang, Y.; Liao, R.; Zhang, Z. Comparative evaluation of thermal decomposition behavior and thermal stability of powdered ammonium nitrate under different atmosphere conditions. J. Hazard. Mater. 2017, 337, 10–19. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Jiang, S.; Zhou, K.; Bao, C.; Yu, B.; Qian, X.; Wang, B.; Hong, N.; Wen, P.; Gui, Z.; et al. Influence of g-C3N4 nanosheets on thermal stability and mechanical properties of biopolymer electrolyte nanocomposite films: A novel investigation. ACS Appl. Mater. Interfaces 2013, 6, 429–437. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Gui, Z.; Yu, B.; Yuen, R.K.; Wang, B.; Hu, Y. Graphite-like carbon nitride and functionalized layered double hydroxide filled polypropylene-grafted maleic anhydride nanocomposites: Comparison in flame retardancy, and thermal, mechanical and UV-shielding properties. Compos. Part B Eng. 2015, 79, 277–284. [Google Scholar] [CrossRef]

- Shi, Y.; Yu, B.; Zhou, K.; Yuen, R.K.; Gui, Z.; Hu, Y.; Jiang, S. Novel CuCo2O4/graphitic carbon nitride nanohybrids: Highly effective catalysts for reducing CO generation and fire hazards of thermoplastic polyurethane nanocomposites. J. Hazard. Mater. 2015, 293, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Jiang, S.; Zhou, K.; Wang, B.; Wang, B.; Gui, Z.; Hu, Y.; Yuen, R.K. Facile preparation of ZnS/g-C3N4 nanohybrids for enhanced optical properties. RSC Adv. 2013, 4, 2609. [Google Scholar] [CrossRef]

- Wang, X.; Maeda, K.; Chen, X.; Takanabe, K.; Domen, K.; Hou, Y.; Fu, X.; Antonietti, M. Polymer Semiconductors for Artificial Photosynthesis: Hydrogen Evolution by Mesoporous Graphitic Carbon Nitride with Visible Light. J. Am. Chem. Soc. 2009, 131, 1680–1681. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.C.; Li, Z.S.; Zou, Z.G. Photodegradation performance of g-C3N4 fabricated by directly heating melamine. Langmuir 2009, 25, 10397–10401. [Google Scholar] [CrossRef] [PubMed]

- Tang, G.; Wang, X.; Zhang, R.; Wang, B.; Hong, N.; Hu, Y.; Song, L.; Gong, X. Effect of Rare Earth Hypophosphite Salts on the Fire Performance of Biobased Polylactide Composites. Ind. Eng. Chem. Res. 2013, 52, 7362–7372. [Google Scholar] [CrossRef]

- Yang, W.; Tang, G.; Song, L.; Hu, Y.; Yuen, R.K. Effect of rare earth hypophosphite and melamine cyanurate on fire performance of glass-fiber reinforced poly(1,4-butylene terephthalate) composites. Thermochim. Acta 2011, 526, 185–191. [Google Scholar] [CrossRef]

- Lin, M.; Li, B.; Li, Q.; Li, S.; Zhang, S. Synergistic effect of metal oxides on the flame retardancy and thermal degradation of novel intumescent flame-retardant thermoplastic polyurethanes. J. Appl. Polym. Sci. 2011, 121, 1951–1960. [Google Scholar] [CrossRef]

- Almeras, X.; Le Bras, M.; Hornsby, P.; Bourbigot, S.; Marosi, G.; Keszei, S.; Poutch, F. Effect of fillers on the fire retardancy of intumescent polypropylene compounds. Polym. Degrad. Stab. 2003, 82, 325–331. [Google Scholar] [CrossRef]

- Wang, B.; Tang, Q.; Hong, N.; Song, L.; Wang, L.; Shi, Y.; Hu, Y. Effect of Cellulose Acetate Butyrate Microencapsulated Ammonium Polyphosphate on the Flame Retardancy, Mechanical, Electrical, and Thermal Properties of Intumescent Flame-Retardant Ethylene–Vinyl Acetate Copolymer/Microencapsulated Ammonium Polyphosphate/Polyamide-6 Blends. ACS Appl. Mater. Interfaces 2011, 3, 3754–3761. [Google Scholar] [PubMed]

- Zhao, B.; Chen, L.; Long, J.W.; Chen, H.B.; Wang, Y.Z. Aluminum Hypophosphite versus Alkyl-Substituted Phosphinate in Polyamide 6: Flame Retardance, Thermal Degradation, and Pyrolysis Behavior. Ind. Eng. Chem. Res. 2013, 52, 2875–2886. [Google Scholar] [CrossRef]

- Li, Q.; Li, B.; Zhang, S.; Lin, M. Investigation on effects of aluminum and magnesium hypophosphites on flame retardancy and thermal degradation of polyamide 6. J. Appl. Polym. Sci. 2012, 125, 1782–1789. [Google Scholar] [CrossRef]

| Sample No. | TPU | TPU/CAHPi5 | TPU/CAHPi10 | TPU/CAHPi20 | TPU/AHPi | |

|---|---|---|---|---|---|---|

| N2 | T-10 (°C) | 322.7 | 301.7 | 302.0 | 305.2 | 304.6 |

| Tmax1 (°C) | 331.0 | 326.5 | 324.4 | 333.2 | 324.4 | |

| Tmax2 (°C) | 426.0 | 386.2 | 384.1 | 390.7 | 399.4 | |

| Tmax3 (°C) | – | – | – | – | – | |

| Residues at 800 °C (wt %) | 2.5 | 9.7 | 10.4 | 8.3 | 10.2 | |

| Air | T-10 (°C) | 329.0 | 301.5 | 298.0 | 299.2 | 296.2 |

| Tmax1 (°C) | 342.0 | 322.2 | 317.7 | 315.4 | 315.4 | |

| Tmax2 (°C) | 408.3 | 397.4 | 395.2 | 397.4 | 397.4 | |

| Tmax3 (°C) | 580.7 | 576.5 | 571.9 | 558.7 | 549.9 | |

| Residues at 800 °C (wt %) | 0.7 | 7.6 | 7.0 | 5.3 | 7.8 | |

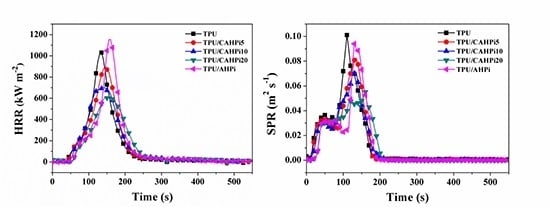

| Sample No. | TTI 1 (s) | HRR (kW·m−2) | THR (MJ·m−2) | SPR (m2·s−1) | TSP (m2·m−2) | FPI 2 (m2·s−1·kW−1) | FGI 3 (kW·m−2·s−1) |

|---|---|---|---|---|---|---|---|

| TPU | 51 | 1031 | 78.2 | 0.10 | 849.7 | 0.049 | 7.637 |

| TPU/CAHPi5 | 53 | 896 | 79.1 | 0.08 | 781.3 | 0.059 | 6.179 |

| TPU/CAHPi10 | 59 | 698 | 78.2 | 0.07 | 730.4 | 0.084 | 4.986 |

| TPU/CAHPi20 | 65 | 622 | 73.0 | 0.05 | 696.9 | 0.104 | 4.013 |

| TPU/AHPi | 64 | 1153 | 81.9 | 0.09 | 728.2 | 0.056 | 7.206 |

| Sample No. | Additives Content (wt %) | pHRR Reduction (%) | TSP Reduction (%) | Ref. |

|---|---|---|---|---|

| TPU/AHPi | 25 wt % AHPi | 31% | - | [8] |

| TPU/AHPi | 30 wt % AHPi | 27% | −146% | [7] |

| TPU/AHPi/[Emim]PF6 | 19.94 wt % AHPi + 0.06 wt % [Emim]PF6 | 92% | 54% | [9] |

| This work | 10 wt % CAHPi20 | 40% | 50% | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Fu, L.; Chen, X.; Guo, J.; Yang, F.; Wang, J.; Zheng, Y.; Hu, Y. Hypophosphite/Graphitic Carbon Nitride Hybrids: Preparation and Flame-Retardant Application in Thermoplastic Polyurethane. Nanomaterials 2017, 7, 259. https://doi.org/10.3390/nano7090259

Shi Y, Fu L, Chen X, Guo J, Yang F, Wang J, Zheng Y, Hu Y. Hypophosphite/Graphitic Carbon Nitride Hybrids: Preparation and Flame-Retardant Application in Thermoplastic Polyurethane. Nanomaterials. 2017; 7(9):259. https://doi.org/10.3390/nano7090259

Chicago/Turabian StyleShi, Yongqian, Libi Fu, Xilei Chen, Jin Guo, Fuqiang Yang, Jingui Wang, Yuying Zheng, and Yuan Hu. 2017. "Hypophosphite/Graphitic Carbon Nitride Hybrids: Preparation and Flame-Retardant Application in Thermoplastic Polyurethane" Nanomaterials 7, no. 9: 259. https://doi.org/10.3390/nano7090259

APA StyleShi, Y., Fu, L., Chen, X., Guo, J., Yang, F., Wang, J., Zheng, Y., & Hu, Y. (2017). Hypophosphite/Graphitic Carbon Nitride Hybrids: Preparation and Flame-Retardant Application in Thermoplastic Polyurethane. Nanomaterials, 7(9), 259. https://doi.org/10.3390/nano7090259