Incorporation of PVDF Nanofibre Multilayers into Functional Structure for Filtration Applications

Abstract

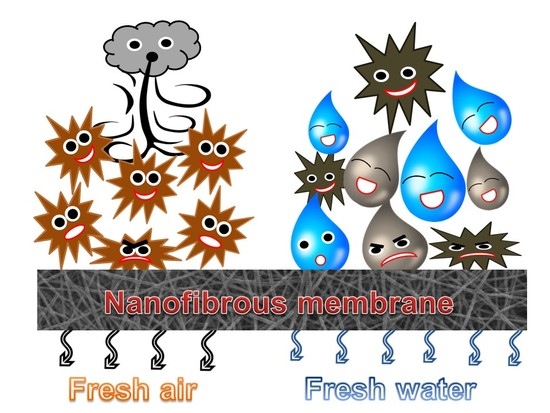

:1. Introduction

2. Materials and Methods

2.1. Preparation of Nanofibre Layers

2.2. Preparation of Nanofibrous Membranes

2.3. Mechanical Properties of the Membranes

2.4. Characterisation of Nanofibrous Multilayer Membranes

2.5. Filtration Test

3. Results and Discussion

3.1. Determination of Selective Membranes

3.2. Tensile Strength

3.3. Surface Characterisation

- (1)

- Membranes which were laminated under the same temperature and force of lamination but different lamination duration indicated that higher lamination duration decreased the pore size.

- (2)

- Membranes which were laminated under the same temperature and duration but different force of lamination showed that the pore size of the membrane did not change significantly.

- (3)

- Membranes which were laminated under the same force of lamination and duration but different temperature showed that the pore size of the membrane slightly decreased with increasing applied temperature.

- (4)

- All the membranes showed pore size below one µm.

3.4. Filtration Test

3.4.1. Air Filtration

3.4.2. Water Filtration

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Nanofibre | Temperature (°C) | Time (min) | Force of Lamination (kN) | Abbreviation |

|---|---|---|---|---|

| PVDF | 110 | 2 | 30 | PVDF_110_2_30 |

| 110 | 2 | 40 | PVDF_110_2_40 | |

| 110 | 2 | 50 | PVDF_110_2_50 | |

| 110 | 2 | 100 | PVDF_110_2_100 | |

| 110 | 3 | 30 | PVDF_110_3_30 | |

| 110 | 3 | 40 | PVDF_110_3_40 | |

| 110 | 3 | 50 | PVDF_110_3_50 | |

| 110 | 3 | 100 | PVDF_110_3_100 | |

| 110 | 5 | 30 | PVDF_110_5_30 | |

| 110 | 5 | 40 | PVDF_110_5_40 | |

| 110 | 5 | 50 | PVDF_110_5_50 | |

| 110 | 5 | 100 | PVDF_110_5_100 | |

| 120 | 2 | 30 | PVDF_120_2_30 | |

| 120 | 2 | 40 | PVDF_120_2_40 | |

| 120 | 2 | 50 | PVDF_120_2_50 | |

| 120 | 2 | 100 | PVDF_120_2_100 | |

| 120 | 3 | 30 | PVDF_120_3_30 | |

| 120 | 3 | 40 | PVDF_120_3_40 | |

| 120 | 3 | 50 | PVDF_120_3_50 | |

| 120 | 3 | 100 | PVDF_120_3_100 | |

| 120 | 5 | 30 | PVDF_120_5_30 | |

| 120 | 5 | 40 | PVDF_120_5_40 | |

| 120 | 5 | 50 | PVDF_120_5_50 | |

| 120 | 5 | 100 | PVDF_120_5_100 | |

| 125 | 2 | 30 | PVDF_125_2_30 | |

| 125 | 2 | 40 | PVDF_125_2_40 | |

| 125 | 2 | 50 | PVDF_125_2_50 | |

| 125 | 2 | 100 | PVDF_125_2_100 | |

| 125 | 3 | 30 | PVDF_125_3_30 | |

| 125 | 3 | 40 | PVDF_125_3_40 | |

| 125 | 3 | 50 | PVDF_125_3_50 | |

| 125 | 3 | 100 | PVDF_125_3_100 | |

| 125 | 5 | 30 | PVDF_125_5_30 | |

| 125 | 5 | 40 | PVDF_125_5_40 | |

| 125 | 5 | 50 | PVDF_125_5_50 | |

| 125 | 5 | 100 | PVDF_125_5_100 | |

| 130 | 2 | 30 | PVDF_130_2_30 | |

| 130 | 2 | 40 | PVDF_130_2_40 | |

| 130 | 2 | 50 | PVDF_130_2_50 | |

| 130 | 2 | 100 | PVDF_130_2_100 | |

| 130 | 3 | 30 | PVDF_130_3_30 | |

| 130 | 3 | 40 | PVDF_130_3_40 | |

| 130 | 3 | 50 | PVDF_130_3_50 | |

| 130 | 3 | 100 | PVDF_130_3_100 | |

| 130 | 5 | 30 | PVDF_130_5_30 | |

| 130 | 5 | 40 | PVDF_130_5_40 | |

| 130 | 5 | 50 | PVDF_130_5_50 | |

| 130 | 5 | 100 | PVDF_130_5_100 |

| Abbreviation | Air Permeability (Lm−2s−1) | Max. Burst Pressure (kPa) |

|---|---|---|

| PVDF_110_2_30 | 15.33 ± 2.04 | 138.00 ± 6.16 |

| PVDF_110_2_40 | 15.10 ± 1.84 | 154.00 ± 14.17 |

| * PVDF_110_2_50 | 12.49 ± 2.74 | 276.00 ± 15.78 |

| PVDF_110_2_100 | 3.59 ± 0.63 | 213.00 ± 7.12 |

| PVDF_110_3_30 | 14.40 ± 1.34 | 149.66 ± 8.81 |

| PVDF_110_3_40 | 12.50 ± 1.71 | 162.66 ± 4.19 |

| PVDF_110_3_50 | 11.73 ± 2.10 | 151.00 ± 20.61 |

| PVDF_110_3_100 | 3.91 ± 1.29 | 184.00 ± 34.71 |

| PVDF_110_5_30 | 9.92 ± 0.94 | 146.66 ± 15.17 |

| *PVDF_110_5_40 | 9.52 ± 1.75 | 194.66 ± 13.37 |

| *PVDF_110_5_50 | 8.74 ± 1.82 | 203.00 ± 16.19 |

| PVDF_110_5_100 | 3.96 ± 0.55 | 345.33 ± 26.41 |

| PVDF_120_2_30 | 10.51 ± 2.01 | 90.33 ± 10.34 |

| PVDF_120_2_40 | 9.71 ± 2.04 | 117.66 ± 34.12 |

| PVDF_120_2_50 | 7.64 ± 1.26 | 146.33 ± 7.93 |

| PVDF_120_2_100 | 3.73 ± 0.38 | 201.66 ± 13.60 |

| PVDF_120_3_30 | 9.74 ± 1.64 | 100.33 ± 31.33 |

| * PVDF_120_3_40 | 9.15 ± 1.08 | 237.00 ± 10.61 |

| PVDF_120_3_50 | 7.64 ± 0.97 | 116.00 ± 24.85 |

| PVDF_120_3_100 | 4.16 ± 0.14 | 176.00 ± 15.25 |

| PVDF_120_5_30 | 8.42 ± 0.66 | 84.00 ± 19.50 |

| PVDF_120_5_40 | 8.70 ± 0.19 | 104.33 ± 57.56 |

| PVDF_120_5_50 | 6.14 ± 0.97 | 116.00 ± 31.90 |

| PVDF_120_5_100 | 3.57 ± 0.52 | 237.00 ± 34.92 |

| PVDF_125_2_30 | 9.79 ± 1.16 | 93.00 ± 23.10 |

| PVDF_125_2_40 | 6.98 ± 2.22 | 103.33 ± 17.80 |

| PVDF_125_2_50 | 7.41 ± 2.53 | 114.66 ± 33.73 |

| PVDF_125_2_100 | 5.61 ± 0.77 | 174.66 ± 6.02 |

| PVDF_125_3_30 | 9.68 ± 1.23 | 103.00 ± 28.16 |

| PVDF_125_3_40 | 8.38 ± 2.58 | 116.33 ± 15.76 |

| *PVDF_125_3_50 | 8.48 ± 1.75 | 183.33 ± 14.29 |

| PVDF_125_3_100 | 3.78 ± 0.38 | 178.33 ± 25.63 |

| PVDF_125_5_30 | 8.12 ± 1.22 | 126.33 ± 33.21 |

| PVDF_125_5_40 | 7.20 ± 1.28 | 135.33 ± 8.29 |

| PVDF_125_5_50 | 5.76 ± 0.45 | 121.66 ± 9.03 |

| PVDF_125_5_100 | 2.09 ± 0.14 | 225.33 ± 30.94 |

| PVDF_130_2_30 | 10.65 ± 1.88 | 137.00 ± 15.63 |

| * PVDF_130_2_40 | 9.25 ± 1.19 | 294.33 ± 16.05 |

| PVDF_130_2_50 | 9.19 ± 0.71 | 108.33 ± 19.94 |

| PVDF_130_2_100 | 4.53 ± 0.19 | 182.33 ± 26.66 |

| PVDF_130_3_30 | 7.47 ± 0.92 | 141.66 ± 13.96 |

| PVDF_130_3_40 | 6.95 ± 1.95 | 132.33 ± 12.73 |

| * PVDF_130_3_50 | 7.16 ±0.89 | 197.00 ± 15.00 |

| PVDF_130_3_100 | 3.34 ± 0.24 | 161.66 ± 29.49 |

| PVDF_130_5_30 | 7.6 ± 0.70 | 104.00 ± 21.85 |

| PVDF_130_5_40 | 4.13 ± 0.09 | 157.00 ± 20.08 |

| PVDF_130_5_50 | 4.30 ± 0.62 | 203.66 ± 17.48 |

| PVDF_130_5_100 | 3.81 ± 0.68 | 123.33 ± 23.54 |

References

- Fang, M.; Chan, C.K.; Yao, X. Managing air quality in a rapidly developing nation: China. Atmos. Environ. 2009, 43, 79–86. [Google Scholar] [CrossRef]

- Fenger, J. Air pollution in the last 50 years-From local to global. Atmos. Environ. 2009, 43, 13–22. [Google Scholar] [CrossRef]

- Han, L.; Gao, B.; Hao, H.; Zhou, H.; Lu, J.; Sun, K. Lead contamination in sediments in the past 20 years: A challenge for China. Sci. Total Environ. 2018, 640–641, 746–756. [Google Scholar] [CrossRef] [PubMed]

- Da Souza, I.C.; Arrivabene, H.P.; Craig, C.-A.; Midwood, A.J.; Thornton, B.; Matsumoto, S.T.; Elliott, M.; Wunderlin, D.A.; Monferrán, M.V.; Fernandes, M.N. Interrogating pollution sources in a mangrove food web using multiple stable isotopes. Sci. Total Environ. 2018, 640–641, 501–511. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.; Wang, R.; Tian, M.; Qiu, C.; Fane, A.G. Fabrication of polyvinylidene fluoride (PVDF) nanofiber membranes by electro-spinning for direct contact membrane distillation. J. Membr. Sci. 2013, 425–426, 30–39. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Siekierka, A.; Bryjak, M. Surface modification of electrospun nanofibrous membranes for oily wastewater separation. RSC Adv. 2017, 7, 56704–56712. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Kang, W.; Zhao, H.; Hu, M.; Wei, N.; Qiu, J.; Cheng, B. A Novel Polyvinylidene Fluoride Tree-Like Nanofiber Membrane for Microfiltration. Nanomaterials 2016, 6, 152. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.H.; Kang, H.W. Advanced electrospinning using circle electrodes for freestanding PVDF nanofiber film fabrication. Appl. Surf. Sci. 2018, 455, 251–257. [Google Scholar] [CrossRef]

- Wu, C.-M.; Chou, M.-H.; Zeng, W.-Y. Piezoelectric Response of Aligned Electrospun Polyvinylidene Fluoride/Carbon Nanotube Nanofibrous Membranes. Nanomaterials 2018, 8, 420. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zheng, S.; Zou, H.; Zheng, X.; Liu, Z.; Yang, W.; Yang, M. Two-step positive temperature coefficient effect with favorable reproducibility achieved by specific “island-bridge” electrical conductive networks in HDPE/PVDF/CNF composite. Compos. Part A Appl. Sci. Manuf. 2017, 94, 21–31. [Google Scholar] [CrossRef]

- Choi, S.-S.; Lee, Y.S.; Joo, C.W.; Lee, S.G.; Park, J.K.; Han, K.-S. Electrospun PVDF nanofiber web as polymer electrolyte or separator. Electrochim. Acta 2004, 50, 339–343. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Elbahri, M. Nanocomposite Electrospun Nanofiber Membranes for Environmental Remediation. Materials (Basel) 2014, 7, 1017–1045. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yalcinkaya, F.; Siekierka, A.; Bryjak, M. Preparation of fouling-resistant nanofibrous composite membranes for separation of oily wastewater. Polymers (Basel) 2017, 9, 679. [Google Scholar] [CrossRef]

- Grimmelsmann, N.; Homburg, S.V.; Ehrmann, A. Electrospinning chitosan blends for nonwovens with morphologies between nanofiber mat and membrane. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Guangzhou, China, 2017; IOP Publishing Ltd.: Bristol, UK, 2017; Volume 213, p. 012007. [Google Scholar]

- Banner, J.; Dautzenberg, M.; Feldhans, T.; Hofmann, J.; Plümer, P.; Ehrmann, A. Water resistance and morphology of electrospun gelatine blended with citric acid and coconut oil. Tekstilec 2018, 61, 129–135. [Google Scholar] [CrossRef]

- Yalcinkaya, F. Preparation of various nanofiber layers using wire electrospinning system. Arab. J. Chem. 2016. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, P.; Long, Z.; Jiang, Y.; Xu, F.; Di, W. The ionic conductivity and mechanical property of electrospun P(VdF-HFP)/PMMA membranes for lithium ion batteries. J. Membr. Sci. 2009, 329, 56–59. [Google Scholar] [CrossRef]

- Jahanbaani, A.R.; Behzad, T.; Borhani, S.; Darvanjooghi, M.H.K. Electrospinning of cellulose nanofibers mat for laminated epoxy composite production. Fibers Polym. 2016, 17, 1438–1448. [Google Scholar] [CrossRef]

- Viter, R.; Iatsunskyi, I.; Fedorenko, V.; Tumenas, S.; Balevicius, Z.; Ramanavicius, A.; Balme, S.; Kempiński, M.; Nowaczyk, G.; Jurga, S.; et al. Enhancement of Electronic and Optical Properties of ZnO/Al2O3 Nanolaminate Coated Electrospun Nanofibers. J. Phys. Chem. C 2016, 120, 5124–5132. [Google Scholar] [CrossRef]

- Turky, A.O.; Barhoum, A.; MohamedRashad, M.; Bechlany, M. Enhanced the structure and optical properties for ZnO/PVP nanofibers fabricated via electrospinning technique. J. Mater. Sci. Mater. Electron. 2017, 28, 17526–17532. [Google Scholar] [CrossRef]

- Charles, L.E.; Kramer, E.R.; Shaw, M.T.; Olson, J.R.; Wei, M. Self-reinforced composites of hydroxyapatite-coated PLLA fibers: Fabrication and mechanical characterization. J. Mech. Behav. Biomed. Mater. 2012, 17, 269–277. [Google Scholar] [CrossRef] [PubMed]

- Charles, L.F.; Shaw, M.T.; Olson, J.R.; Wei, M. Fabrication and mechanical properties of PLLA/PCL/HA composites via a biomimetic, dip coating, and hot compression procedure. J. Mater. Sci. Mater. Med. 2010, 21, 1845–1854. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zhang, X.; Wang, X.; Wang, X.; Li, X.; Shen, C.; Li, Q. Simultaneous enhancements in the strength, modulus and toughness of electrospun polymeric membranes. RSC Adv. 2017, 7. [Google Scholar] [CrossRef]

- Yalcinkaya, B.; Yalcinkaya, F.; Chaloupek, J. Thin Film Nanofibrous Composite Membrane for Dead-End Seawater Desalination. J. Nanomater. 2016, 2016, 2694373. [Google Scholar] [CrossRef]

- Yalcinkaya, B.; Yalcinkaya, F.; Chaloupek, J. Optimisation of thin film composite nanofiltration membranes based on laminated nanofibrous and nonwoven supporting material. Desalin. Water Treat. 2017, 59, 19–30. [Google Scholar] [CrossRef]

- Vijayan, P.P.; Puglia, D.; Dąbrowska, A.; Vijayan, P.P.; Huczko, A.; Kenny, J.M.; Thomas, S. Mechanical and thermal properties of epoxy/silicon carbide nanofiber composites. Polym. Adv. Technol. 2015, 26, 142–146. [Google Scholar] [CrossRef]

- Park, C.H.; Kim, C.H.; Tijing, L.D.; Lee, D.H.; Yu, M.H.; Pant, H.R.; Kim, Y.; Kim, C.S. Preparation and characterization of (polyurethane/nylon-6) nanofiber/(silicone) film composites via electrospinning and dip-coating. Fibers Polym. 2012, 13, 339–345. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, Y.; Wang, Z.; Lei, Y.; Wang, B.; Wu, N.; Han, C.; Xie, S.; Gou, Y. Three-dimensional (3D) interconnected networks fabricated via in-situ growth of N-doped graphene/carbon nanotubes on Co-containing carbon nanofibers for enhanced oxygen reduction. Nano Res. 2016, 9, 317–328. [Google Scholar] [CrossRef]

- Wang, M.S.; Song, W.L.; Fan, L.Z. Three-Dimensional Interconnected Network of Graphene-Wrapped Silicon/Carbon Nanofiber Hybrids for Binder-Free Anodes in Lithium-Ion Batteries. ChemElectroChem 2015, 2, 1699–1706. [Google Scholar] [CrossRef] [Green Version]

- Yalcinkaya, F.; Hruza, J. Effect of Laminating Pressure on Polymeric Nanofibre Composite Membranes for Liquid Filtration. Nanomaterials 2018, 8, 272. [Google Scholar] [CrossRef] [PubMed]

- Hernández, A.; Calvo, J.I.; Prádanos, P.; Tejerina, F. Pore size distributions in microporous membranes. A critical analysis of the bubble point extended method. J. Membr. Sci. 1996, 112, 1–12. [Google Scholar] [CrossRef]

- Szczerbińska, J.; Kujawski, W.; Arszyńska, J.M.; Kujawa, J. Assessment of air-gap membrane distillation with hydrophobic porous membranes utilized for damaged paintings humidification. J. Membr. Sci. 2017, 538, 1–8. [Google Scholar] [CrossRef]

- Kujawski, W.; Adamczak, P.; Narebska, A. A Fully Automated System for the Determination of Pore Size Distribution in Microfiltration and Ultrafiltration Membranes. Sep. Sci. Technol. 1989, 24, 495–506. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Yalcinkaya, B.; Hruza, J.; Hrabak, P. Effect of Nanofibrous Membrane Structures on the Treatment of Wastewater Microfiltration. Sci. Adv. Mater. 2016, 9, 747–757. [Google Scholar] [CrossRef]

- Yao, M.; Woo, Y.C.; Tijing, L.D.; Shim, W.-G.; Choi, J.-S.; Kim, S.-H.; Shon, H.K. Effect of heat-press conditions on electrospun membranes for desalination by direct contact membrane distillation. Desalination 2016, 378, 80–91. [Google Scholar] [CrossRef]

- Kim, K.; Lee, C.; Kim, I.W.; Kim, J. Performance modification of a melt-blown filter medium via an additional nano-web layer prepared by electrospinning. Fibers Polym. 2009, 10, 60–64. [Google Scholar] [CrossRef]

- Hung, C.-H.; Leung, W.W.-F. Filtration of nano-aerosol using nanofiber filter under low Peclet number and transitional flow regime. Sep. Purif. Technol. 2011, 79, 34–42. [Google Scholar] [CrossRef]

- Leung, W.W.-F.; Hung, C.-H.; Yuen, P.-T. Effect of face velocity, nanofiber packing density and thickness on filtration performance of filters with nanofibers coated on a substrate. Sep. Purif. Technol. 2010, 71, 30–37. [Google Scholar] [CrossRef]

- Podgórski, A.; Bałazy, A.; Gradoń, L. Application of nanofibers to improve the filtration efficiency of the most penetrating aerosol particles in fibrous filters. Chem. Eng. Sci. 2006, 61, 6804–6815. [Google Scholar] [CrossRef]

- Balgis, R.; Kartikowati, C.W.; Ogi, T.; Gradon, L.; Bao, L.; Seki, K.; Okuyama, K. Synthesis and evaluation of straight and bead-free nanofibers for improved aerosol filtration. Chem. Eng. Sci. 2015, 137, 947–954. [Google Scholar] [CrossRef]

- Maze, B.; Vahedi Tafreshi, H.; Wang, Q.; Pourdeyhimi, B. A simulation of unsteady-state filtration via nanofiber media at reduced operating pressures. J. Aerosol Sci. 2007, 38, 550–571. [Google Scholar] [CrossRef]

- Marega, C.; Marigo, A. Influence of annealing and chain defects on the melting behaviour of poly(vinylidene fluoride). Eur. Polym. J. 2003, 39, 1713–1720. [Google Scholar] [CrossRef]

- Na, H.; Zhao, Y.; Zhao, C.; Zhao, C.; Yuan, X. Effect of hot-press on electrospun poly(vinylidene fluoride) membranes. Polym. Eng. Sci. 2008, 48, 934–940. [Google Scholar] [CrossRef]

- Parker, A.; Ueda, A.; Marvinney, C.E.; Hargrove, S.K.; Williams, F.; Mu, R. Structural and Thermal Treatment Evaluation of Electrospun PVDF Nanofibers for Sensors. J. Polym. Sci. Appl. 2018, 2, 5–8. [Google Scholar]

| Sample | Tensile Strength (N/25 mm) | Elongation at Break (%) | ||

|---|---|---|---|---|

| MD | CD | MD | CD | |

| PVDF_130_2_40 | 94.45 | 89.143 | 49.86 | 70.37 |

| PVDF_130_3_50 | 94.32 | 87.37 | 52.52 | 68.38 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roche, R.; Yalcinkaya, F. Incorporation of PVDF Nanofibre Multilayers into Functional Structure for Filtration Applications. Nanomaterials 2018, 8, 771. https://doi.org/10.3390/nano8100771

Roche R, Yalcinkaya F. Incorporation of PVDF Nanofibre Multilayers into Functional Structure for Filtration Applications. Nanomaterials. 2018; 8(10):771. https://doi.org/10.3390/nano8100771

Chicago/Turabian StyleRoche, Remi, and Fatma Yalcinkaya. 2018. "Incorporation of PVDF Nanofibre Multilayers into Functional Structure for Filtration Applications" Nanomaterials 8, no. 10: 771. https://doi.org/10.3390/nano8100771

APA StyleRoche, R., & Yalcinkaya, F. (2018). Incorporation of PVDF Nanofibre Multilayers into Functional Structure for Filtration Applications. Nanomaterials, 8(10), 771. https://doi.org/10.3390/nano8100771