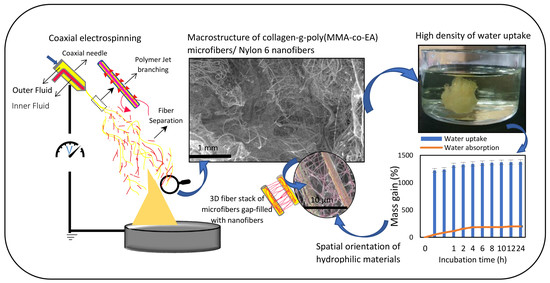

One-Step Fabrication of Three-Dimensional Fibrous Collagen-Based Macrostructure with High Water Uptake Capability by Coaxial Electrospinning

Abstract

:1. Introduction

2. Experimental Section

2.1. Material

2.2. Synthesis of ASC-g-poly(MMA-co-EA)

2.3. Preparation of Spinning Solutions and Coaxial Electrospinning

3. Results and Discussion

3.1. Synthesis of ASC-g-poly(MMA-co-EA)

3.2. Factors to Control CME/N6 3D Fiber Structure

3.3. The Growth Process and Morphology of the 3D Nanofibrous Structure

3.4. Self-Assembly Mechanism of 3D Fiber Stack

3.5. Wettability, Water Absorption and Degradation Properties of the 3D Fibrous Structure

4. Conclusions

Supplementary Materials

Supplementary File 1Author Contributions

Acknowledgments

Conflicts of Interest

References

- Soliman, S.; Pagliari, S.; Rinaldi, A.; Forte, G.; Fiaccavento, R.; Pagliari, F.; Franzese, O.; Minieri, M.; Di Nardo, P.; Licoccia, S.; et al. Multiscale three-dimensional scaffolds for soft tissue engineering via multimodal electrospinning. Acta Biomater. 2010, 6, 1227–1237. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bagherzadeh, R.; Latifi, M.; Kong, L.X. Three-dimensional pore structure analysis of polycaprolactone nano-microfibrous scaffolds using theoretical and experimental approaches. J. Biomed. Mater. Res. Part A 2014, 102, 903–910. [Google Scholar] [CrossRef] [PubMed]

- Ahirwal, D.; Hebraud, A.; Kadar, R.; Wilhelm, M.; Schlatter, G. From self-assembly of electrospun nanofibers to 3D cm thick hierarchical foams. Soft Matter 2013, 9, 3164–3172. [Google Scholar] [CrossRef]

- Chang, G.Q.; Zhu, X.F.; Li, A.K.; Kan, W.W.; Warren, R.; Zhao, R.G.; Wang, X.L.; Xue, G.; Shen, J.Y.; Lin, L.W. Formation and self-assembly of 3D nanofibrous networks based on oppositely charged jets. Mater. Design 2016, 97, 126–130. [Google Scholar] [CrossRef]

- Abbah, S.A.; Delgado, L.M.; Azeem, A.; Fuller, K.; Shologu, N.; Keeney, M.; Biggs, M.J.; Pandit, A.; Zeugolis, D.I. Harnessing hierarchical nano- and micro-fabrication technologies for musculoskeletal tissue engineering. Adv. Healthcare Mater. 2015, 4, 2488–2499. [Google Scholar] [CrossRef] [PubMed]

- Hejazi, F.; Mirzadeh, H.; Contessi, N.; Tanzi, M.C.; Faré, S. Novel class of collector in electrospinning device for the fabrication of 3D nanofibrous structure for large defect load-bearing tissue engineering application. J. Biomed. Mater. Res. Part A 2017, 105, 1535–1548. [Google Scholar] [CrossRef] [PubMed]

- Bazrafshan, Z.; Stylios, G.K. A novel approach to enhance the spinnability of collagen fibers by graft polymerization. Mater. Sci. Eng. C 2019, 94, 108–116. [Google Scholar] [CrossRef]

- Zhu, W.; O’Brien, C.; O’Brien, J.R.; Zhang, L.G. 3D nano/microfabrication techniques and nanobiomaterials for neural tissue regeneration. Nanomedicine 2014, 9, 859–875. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.H.; Bao, M.; Yuan, H.H.; Zhao, S.F.; Dong, W.; Zhang, Y.Z. Implication of stable jet length in electrospinning for collecting well-aligned ultrafine PLLA fibers. Polymer 2013, 54, 6867–6876. [Google Scholar] [CrossRef]

- Subbiah, T.; Bhat, G.S.; Tock, R.W.; Pararneswaran, S.; Ramkumar, S.S. Electrospinning of nanofibers. J. Appl. Polym. Sci. 2005, 96, 557–569. [Google Scholar] [CrossRef] [Green Version]

- Dong, H.; Nyame, V.; Macdiarmid, A.G.; Jones, W.E. Polyaniline/poly(methyl methacrylate) coaxial fibers: The fabrication and effects of the solution properties on the morphology of electrospun core fibers. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 3934–3942. [Google Scholar] [CrossRef]

- Sun, B.; Long, Y.Z.; Zhang, H.D.; Li, M.M.; Duvail, J.L.; Jiang, X.Y.; Yin, H.L. Advances in three-dimensional nanofibrous macrostructures via electrospinning. Prog. Polym. Sci. 2014, 39, 862–890. [Google Scholar] [CrossRef]

- Sun, B.; Long, Y.Z.; Yu, F.; Li, M.M.; Zhang, H.D.; Li, W.J.; Xu, T.X. Self-assembly of a three-dimensional fibrous polymer sponge by electrospinning. Nanoscale 2012, 4, 2134–2137. [Google Scholar] [CrossRef] [PubMed]

- Bonino, C.A.; Efimenko, K.; Jeong, S.I.; Krebs, M.D.; Alsberg, E.; Khan, S.A. Three-dimensional electrospun alginate nanofiber mats via tailored charge repulsions. Small 2012, 8, 1928–1936. [Google Scholar] [CrossRef] [PubMed]

- Ye, P.; Xu, Z.K.; Wu, J.; Innocent, C.; Seta, P. Nanofibrous poly(acrylonitrile-co-maleic acid) membranes functionalized with gelatin and chitosan for lipase immobilization. Biomaterials 2006, 27, 4169–4176. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.Y.; Su, Z.G.; Wang, P.; Ma, G.H.; Zhang, S.P. Integration of artificial photosynthesis system for enhanced electronic energy-transfer efficacy: A case study for solar-energy driven bioconversion of carbon dioxide to methanol. Small 2016, 12, 4753–4762. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.Z.; Yu, M.; Sun, B.; Gu, C.Z.; Fan, Z.Y. Recent advances in large-scale assembly of semiconducting inorganic nanowires and nanofibers for electronics, sensors and photovoltaics. Chem. Soc. Rev. 2012, 41, 4560–4580. [Google Scholar] [CrossRef] [PubMed]

- Edmondson, S.; Osborne, V.L.; Huck, W.T.S. Polymer brushes via surface-initiated polymerizations. Chem. Soc. Rev. 2004, 33, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Deitzel, J.M.; Kleinmeyer, J.; Harris, D.; Beck Tan, N.C. The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer 2001, 42, 261–272. [Google Scholar] [CrossRef]

- Son, W.K.; Youk, J.H.; Lee, T.S.; Park, W.H. The effects of solution properties and polyelectrolyte on electrospinning of ultrafine poly(ethylene oxide) fibers. Polymer 2004, 45, 2959–2966. [Google Scholar] [CrossRef]

- Qin, X.H.; Yang, E.L.; Li, N.; Wang, S.Y. Effect of different salts on electrospinning of polyacrylonitrile (PAN) polymer solution. J. Appl. Polym. Sci. 2007, 103, 3865–3870. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Singla, A.; Lee, Y. Biomedical applications of collagen. Int. J. Pharm. 2001, 221, 1–22. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Bazrafshan, Z.; Stylios, G.K. One-pot approach synthesizing and characterization of random copolymerization of ethyl acrylate-co-methyl methacrylate with broad range of glass transition temperature onto collagen. Polym. Eng. Sci. 2018, 58, 1261–1267. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Misra, B.N. Grafting: A versatile means to modify polymers—Techniques, factors and applications. Prog. Polym. Sci. 2004, 29, 767–814. [Google Scholar] [CrossRef]

- Kaith, B.S.; Jindal, R.; Maiti, M. Induction of chemical and moisture resistance in Saccharum spontaneum L fiber through graft copolymerization with methyl methacrylate and study of morphological changes. J. Appl. Polym. Sci. 2009, 113, 1781–1791. [Google Scholar] [CrossRef]

- Keles, H.; Sacak, M. Graft copolymerization of methyl methacrylate onto gelatin using KMnO4-H2SO4 redox system. J. Appl. Polym. Sci. 2003, 89, 2836–2844. [Google Scholar] [CrossRef]

- Sun, Z.H.; Chen, F.S. Homogeneous grafting copolymerization of methylmethacrylate onto cellulose using ammonium persulfate. Cellul. Chem. Technol. 2014, 48, 217–223. [Google Scholar]

- Bazrafshan, Z.; Stylios, G. High performance of covalently grafting onto collagen in the presence of graphene oxide. Nanomaterials 2018, 8, 703. [Google Scholar] [CrossRef] [PubMed]

- Goldberg, M.; Langer, R.; Jia, X.Q. Nanostructured materials for applications in drug delivery and tissue engineering. J. Biomater. Sci.-Polym. Ed. 2007, 18, 241–268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, C.; Yan, K.W.; Lin, Y.D.; Hsieh, P.C.H. Biodegradable core/shell fibers by coaxial electrospinning: Processing, fiber characterization, and its application in sustained drug release. Macromolecules 2010, 43, 6389–6397. [Google Scholar] [CrossRef]

- Bazrafshan, Z.; Stylios, G.K. Custom-built electrostatics and supplementary bonding in the design of reinforced Collagen-g-P(methyl methacrylate-co-ethyl acrylate)/nylon 66 core-shell fibers. J. Mech. Behav. Biomed. Mater. 2018, 87, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.Q.; Hu, C.M.; Li, B.; Yang, H.L.; Cheng, Y.S.; Cui, W.G. A highly flexible paclitaxel-loaded poly(epsilon-caprolactone) electrospun fibrous-membrane-covered stent for benign cardia stricture. Acta Biomater. 2013, 9, 8328–8336. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.C.; Deitzel, J.M.; Knopf, J.; Chen, X.; Gillespie, J.W. The effect of solvent dielectric properties on the collection of oriented electrospun fibers. J. Appl. Polym. Sci. 2012, 125, 2585–2594. [Google Scholar] [CrossRef]

- Hohman, M.M.; Shin, M.; Rutledge, G.; Brenner, M.P. Electrospinning and electrically forced jets. I. Stability theory. Phys. Fluids 2001, 13, 2201–2220. [Google Scholar] [CrossRef]

- Shin, Y.; Hohman, M.; Brenner, M.; Rutledge, G. Experimental characterization of electrospinning: The electrically forced jet and instabilities. Polymer 2001, 42, 09955–09967. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, J.N.; Yu, G.Q.; Cardenas, R.; Wei, S.Y.; Wujcik, E.K.; Guo, Z.H. Coaxial electrospun fibers: Applications in drug delivery and tissue engineering. Wiley Interdiscipl. Rev.-Nanomed. Nanobiotechnol. 2016, 8, 654–677. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.H.; Fridrikh, S.V.; Rutledge, G.C. Production of submicrometer diameter fibers by two-fluid electrospinning. Adv. Mater. 2004, 16, 1562–1566. [Google Scholar] [CrossRef]

- Saville, D.A. Electrohydrodynamics: The taylor-melcher leaky dielectric model. Annu. Rev. Fluid Mech. 1997, 29, 27–64. [Google Scholar] [CrossRef]

- Gambhire, P.; Thaokar, R. Electrokinetic model for electric-field-induced interfacial instabilities. Phys. Rev. E 2014, 89, 032409. [Google Scholar] [CrossRef] [PubMed]

- Pasquardini, L.; Lunelli, L.; Vanzetti, L.; Anderle, M.; Pederzolli, C. Immobilization of cationic rifampicin-loaded liposomes on polystyrene for drug-delivery applications. Colloids Surf. B Biointerfaces 2008, 62, 265–272. [Google Scholar] [CrossRef] [PubMed]

- Kezwon, A.; Goral, I.; Fraczyk, T.; Wojciechowski, K. Effect of surfactants on surface activity and rheological properties of type I collagen at air/water interface. Colloids Surf. B Biointerfaces 2016, 148, 238–248. [Google Scholar] [CrossRef] [PubMed]

- Schnitzer, O.; Yariv, E. The Taylor–melcher leaky dielectric model as a macroscale electrokinetic description. J. Fluid Mech. 2015, 773, 1–33. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L.; Fong, H.; Koombhongse, S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J. Appl. Phys. 2000, 87, 4531–4547. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Hohman, M.M.; Shin, M.; Rutledge, G.; Brenner, M.P. Electrospinning and electrically forced jets. II. applications. Phys. Fluids 2001, 13, 2221–2236. [Google Scholar] [CrossRef]

| Solutions | Viscosity (Pa·s) | Surface Tension (mN/m2) | Conductivity (ms/cm) |

|---|---|---|---|

| (CME, 10 wt/v% + Ydye, 0.1 wt% ) in FA | 5.87 | 33.3 | 1453 |

| (N6, 25 wt/v% + Rdye, 0.1 wt%) in FA | 5.97 | 37.8 | 4416 |

| Solution (a) | Distance (cm) | Voltage (kV) | Flow Rate (mL/h) | T (°C) | RH (%) | Observation | ||

| (CME, 10 wt/v% + Ydye, 0.1 wt%) in FA | 10 | 5–10 | 0.5 | 22 ± 2 | 35 ± 5 | One end of continuous electrospun fiber touches the collector. A bunch of aligned fibers was formed in yellow color. | ||

| 10 | 12–20 | 1.5 | 22 ± 2 | 35 ± 5 | ||||

| (N6, 25 wt/v% + Rdye, 0.1 wt%) in FA | 10 | 5–12 | 0.5–1 | 22 ± 2 | 35 ± 5 | Dropping; no Taylor cone angle, no electrospun fiber was observed. | ||

| 10 | 14–20 | 0.5–1 | 22 ± 2 | 35 ± 5 | 2D nano mat in a shade of light pink is achieved. | |||

| Core Solution (b) | Shell Solution | Distance (cm) | Voltage (kV) | Flow Rate (mL/h) | T (°C) | RH (%) | Comments (Coaxial CME/N6) | |

| Core | Shell | |||||||

| (N6, 25 wt/v% + Rdye, 0.1 wt%) in FA | (CME,10 wt/v% + Ydye, 0.1 wt%) in FA | 10 | 9.5–10 | 0.5 | 0.5 | 22 ± 2 | 35 ± 5 | Occasionally droplets of N6 were observed. |

| 10 | 17–17.5 | 0.5 | 0.5 | 22 ± 2 | 35 ± 5 | Chaotic CME polymer jet; whipping in the air. | ||

| 10 | 12–12.5 | 0.5 | 0.5 | 22 ± 2 | 35 ± 5 | No droplet was observed. | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bazrafshan, Z.; Stylios, G.K. One-Step Fabrication of Three-Dimensional Fibrous Collagen-Based Macrostructure with High Water Uptake Capability by Coaxial Electrospinning. Nanomaterials 2018, 8, 803. https://doi.org/10.3390/nano8100803

Bazrafshan Z, Stylios GK. One-Step Fabrication of Three-Dimensional Fibrous Collagen-Based Macrostructure with High Water Uptake Capability by Coaxial Electrospinning. Nanomaterials. 2018; 8(10):803. https://doi.org/10.3390/nano8100803

Chicago/Turabian StyleBazrafshan, Zahra, and George K. Stylios. 2018. "One-Step Fabrication of Three-Dimensional Fibrous Collagen-Based Macrostructure with High Water Uptake Capability by Coaxial Electrospinning" Nanomaterials 8, no. 10: 803. https://doi.org/10.3390/nano8100803

APA StyleBazrafshan, Z., & Stylios, G. K. (2018). One-Step Fabrication of Three-Dimensional Fibrous Collagen-Based Macrostructure with High Water Uptake Capability by Coaxial Electrospinning. Nanomaterials, 8(10), 803. https://doi.org/10.3390/nano8100803