Influence of Nanoparticle Pretreatment on the Thermal, Rheological and Mechanical Properties of PLA-PBSA Nanocomposites Incorporating Cellulose Nanocrystals or Montmorillonite

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of FD-CNC, SFD-CNC, FD-MMT & SFD-MMT

2.3. Preparation of PLA Nanocomposites

2.4. Characterization Methods

3. Results and Discussion

3.1. Morphology and Adsorption Analysis

3.2. Rheology Measurements

3.2.1. Small Amplitude Oscillatory Shear (SAOS) Behavior and Morphological Characteristics

3.2.2. Elongational Viscosity Behavior

3.2.3. Calorimetric Crystallization Properties

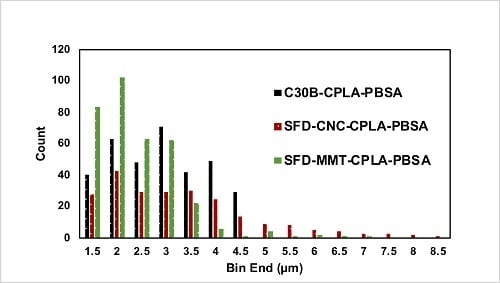

3.3. Particle and Cluster Size Distribution Study

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Iwatake, A.; Nogi, M.; Yano, H. Cellulose nanofiber-reinforced polylactic acid. Compos. Sci. Technol. 2008, 68, 2103–2106. [Google Scholar] [CrossRef]

- Sawyer, D.J. Bioprocessing—No Longer a Field of Dreams. Macromol. Symp. 2003, 201, 271–281. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Lin, S.; Guo, W.N.; Chen, C.Y.; Ma, J.L.; Wang, B.B. Mechanical properties and morphology of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends compatibilized by transesterification. Mater. Des. 2012, 36, 604–608. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Eslami, H.; Kamal, M.R. Elongational rheology of biodegradable poly(lactic acid)/poly[(butylene succinate)-co-adipate] binary blends and poly(lactic acid)/poly[(butylene succinate)-co-adipate]/clay ternary nanocomposites. J. Appl. Polym. Sci. 2012. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S.; Sadiku, R. Effect of Nanoclay Loading on the Thermal and Mechanical Properties of Biodegradable Polylactide/Poly[(butylene succinate)-co-adipate] Blend Composites. ACS Appl. Mater. Interfaces 2012, 4, 2395–2405. [Google Scholar] [CrossRef]

- Gui, Z.Y.; Wang, H.R.; Gao, Y.; Lu, C.; Cheng, S.J. Morphology and melt rheology of biodegradable poly(lactic acid)/poly(butylene succinate adipate) blends: Effect of blend compositions. Iran Polym. J. 2012, 21, 81–89. [Google Scholar] [CrossRef]

- Boujemaoui, A.; Mongkhontreerat, S.; Malmstrom, E.; Carlmark, A. Preparation and characterization of functionalized cellulose nanocrystals. Carbohydr. Polym. 2015, 115, 457–464. [Google Scholar] [CrossRef]

- Iyer, K.A.; Schueneman, G.T.; Torkelson, J.M. Cellulose nanocrystal/polyolefin biocomposites prepared by solid-state shear pulverization: Superior dispersion leading to synergistic property enhancements. Polymer 2015, 56, 464–475. [Google Scholar] [CrossRef]

- Favre, H.; Lagaly, G. Organo-bentonites with quaternary alkylammonium ions. Clay Miner. 1991, 26, 19–32. [Google Scholar] [CrossRef]

- Abdallah, W.; Yilmazer, U. Preparation and characterization of thermally stable phosphonium organoclays and their use in poly(ethylene terephthalate) nanocomposites. J. Appl. Polym. Sci. 2013, 128, 4283–4293. [Google Scholar] [CrossRef]

- Sapkota, J.; Jorfi, M.; Weder, C.; Foster, E.J. Reinforcing Poly(ethylene) with Cellulose Nanocrystals. Macromol. Rapid Commun. 2014, 35, 1747–1753. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Zhang, Y.; Wang, S. Preparation and characterization of acrylonitrile-butadiene-styrene nanocomposites reinforced with cellulose nanocrystal via solution casting method. Poly. Compos. 2015. [Google Scholar] [CrossRef]

- Voronova, M.I.; Surov, O.V.; Guseinov, S.S.; Barannikov, V.P.; Zakharov, A.G. Thermal stability of polyvinyl alcohol/nanocrystalline cellulose composites. Carbohydr. Polym. 2015, 130, 440–447. [Google Scholar] [CrossRef] [PubMed]

- Beuguel, Q.; Tavares, J.R.; Carreau, P.J.; Heuzey, M.-C. Ultrasonication of spray- and freeze-dried cellulose nanocrystals in water. J. Colloid Interface Sci. 2018, 516, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Beck, S.; Bouchard, J.; Berry, R. Dispersibility in Water of Dried Nanocrystalline Cellulose. Biomacromolecules 2012, 13, 1486–1494. [Google Scholar] [CrossRef] [PubMed]

- Abdallah, W.; Kamal, M.R. Influence of process variables on physical characteristics of spray freeze dried cellulose nanocrystals. Cellulose 2018, 25, 5711–5730. [Google Scholar] [CrossRef]

- Khoshkava, V.; Kamal, M.R. Effect of surface energy on dispersion and mechanical properties of polymer/nanocrystalline cellulose nanocomposites. Biomacromolecules 2013, 14, 3155–3163. [Google Scholar] [CrossRef]

- Zhang, W.; He, X.; Li, C.; Zhang, X.; Lu, C.; Zhang, X.; Deng, Y. High performance poly (vinyl alcohol)/cellulose nanocrystals nanocomposites manufactured by injection molding. Cellulose 2014, 21, 485–494. [Google Scholar] [CrossRef]

- Kamal, M.; Khoshkava, V. Spray Freeze-Dried Nanoparticles and Method of Use Thereof. Google Patents U.S. 9746236B2, 29 August 2017. [Google Scholar]

- Khoshkava, V.; Kamal, M.R. Effect of drying conditions on cellulose nanocrystal (CNC) agglomerate porosity and dispersibility in polymer nanocomposites. Powder Technol. 2014, 261, 288–298. [Google Scholar] [CrossRef]

- Khoshkava, V.; Kamal, M.R. Effect of Cellulose Nanocrystals (CNC) Particle Morphology on Dispersion and Rheological and Mechanical Properties of Polypropylene/CNC Nanocomposites. ACS Appl. Mater. Interfaces 2014, 6, 8146–8157. [Google Scholar] [CrossRef] [PubMed]

- Kamal, M.R.; Khoshkava, V. Effect of cellulose nanocrystals (CNC) on rheological and mechanical properties and crystallization behavior of PLA/CNC nanocomposites. Carbohydr. Polym. 2015, 123, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, E.M.; Moon, R.J.; Kalaitzidou, K.J.M. Processing and characterization of cellulose nanocrystals/polylactic acid nanocomposite films. Sci. J. 2015, 8, 8106–8116. [Google Scholar] [CrossRef] [PubMed]

- Krishnamachari, P.; Zhang, J.; Lou, J.; Yan, J.; Uitenham, L. Biodegradable Poly(Lactic Acid)/Clay Nanocomposites by Melt Intercalation: A Study of Morphological, Thermal, and Mechanical Properties. Int. J. Polym. Anal. Charact. 2009, 14, 336–350. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J.J. An investigation of melt rheology and thermal stability of poly (lactic acid)/poly (butylene succinate) nanocomposites. J. Appl. Polym. Sci. 2009, 114, 2837–2847. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Auras, R.A.; Lim, L.-T.; Selke, S.E.; Tsuji, H. Poly (Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 10. [Google Scholar]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.; Maspoch, M.L. Processing of poly (lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Petersson, L.; Kvien, I.; Oksman, K. Structure and thermal properties of poly (lactic acid)/cellulose whiskers nanocomposite materials. Compos. Sci. Technol. 2007, 67, 2535–2544. [Google Scholar] [CrossRef]

- Ogata, N.; Jimenez, G.; Kawai, H.; Ogihara, T. Structure and thermal/mechanical properties of poly(l-lactide)-clay blend. J. Polym. Sci. Pol. Phys. 1997, 35, 389–396. [Google Scholar] [CrossRef]

- Pei, A.; Zhou, Q.; Berglund, L.A. Functionalized cellulose nanocrystals as biobased nucleation agents in poly (l-lactide)(PLLA)–Crystallization and mechanical property effects. Compos. Sci. Technol. 2010, 70, 815–821. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Rouquerol, F.R.J.S.K.S.W. Adsorption by Powders and Porous Solids Principles, Methodology, and Applications. Available online: http://site.ebrary.com/id/10190030 (accessed on 27 November 2018).

- Mirzadeh, A.; Ghasemi, H.; Mahrous, F.; Kamal, M.R. Reactive extrusion effects on rheological and mechanical properties of poly(lactic acid)/poly[(butylene succinate)-co-adipate]/epoxy chain extender blends and clay nanocomposites. J. Appl. Polym. Sci. 2015. [Google Scholar] [CrossRef]

- Calderon, J.U.; Kamal, M.R. Influence of surface energy on dispersion and flexural properties of PS/phosphonium organoclay nanocomposites. Annu. Technol. Conf. Soc. Plast. Eng. 2007, 65, 85–89. [Google Scholar]

- Kamal, M.R.; Calderon, J.U.; Lennox, R.B. Surface energy of modified nanoclays and its effect on polymer/clay nanocomposites. J. Adhes. Sci. Technol. 2009, 23, 663–688. [Google Scholar] [CrossRef]

- Manevitch, O.L.; Rutledge, G.C. Elastic Properties of a Single Lamella of Montmorillonite by Molecular Dynamics Simulation. J. Phys. Chem. B 2004, 108, 1428–1435. [Google Scholar] [CrossRef]

- Ajji, A.; Choplin, L.; Prud’homme, R.E. Rheology and phase separation in polystyrene/poly(vinyl methyl ether) blends. J. Polym. Sci. Pol. Phys. 1988, 26, 2279–2289. [Google Scholar] [CrossRef]

- Eslami, H.; Kamal, M.R. Effect of a chain extender on the rheological and mechanical properties of biodegradable poly(lactic acid)/poly[(butylene succinate)-co-adipate] blends. J. Appl. Polym. Sci. 2013, 129, 2418–2428. [Google Scholar] [CrossRef]

- Hua, S.; Chen, F.; Liu, Z.-Y.; Yang, W.; Yang, M.-B. Preparation of cellulose-graft-polylactic acid via melt copolycondensation for use in polylactic acid based composites: Synthesis, characterization and properties. Rsc. Adv. 2016, 6, 1973–1983. [Google Scholar] [CrossRef]

- Sarasua, J.-R.; Prud’homme, R.E.; Wisniewski, M.; Le Borgne, A.; Spassky, N. Crystallization and Melting Behavior of Polylactides. Macromolecules 1998, 31, 3895–3905. [Google Scholar] [CrossRef]

- Lee, S.; Lee, J.W. Characterization and processing of biodegradable polymer blends of poly (lactic acid) with poly (butylene succinate adipate). Korea-Aust. Rheol. J. 2005, 17, 71–77. [Google Scholar]

- Charlon, S.; Follain, N.; Dargent, E.; Soulestin, J.; Sclavons, M.; Marais, S. Poly[(butylene succinate)-co-(butylene adipate)]-Montmorillonite Nanocomposites Prepared by Water-Assisted Extrusion: Role of the Dispersion Level and of the Structure-Microstructure on the Enhanced Barrier Properties. J. Phys. Chem. C 2016, 120, 13234–13248. [Google Scholar] [CrossRef]

- Lizundia, E.; Fortunati, E.; Dominici, F.; Vilas, J.L.; León, L.M.; Armentano, I.; Torre, L.; Kenny, J.M. PLLA-grafted cellulose nanocrystals: Role of the CNC content and grafting on the PLA bionanocomposite film properties. Carbohydr. Polym. 2016, 142, 105–113. [Google Scholar] [CrossRef] [PubMed]

| Material | BET | BJH Adsorption | BJH Desorption | ||||

|---|---|---|---|---|---|---|---|

| - | SBET (m2/g) | SBJH-Ads. (m2/g) | VP-Ads. (c.c./g) | rP-Ads. (nm) | SBJH-Des. (m2/g) | VP-Des. (c.c./g) | rP-Des. (nm) |

| SD-MMT | 20.9 | 26.22 | 0.0898 | 20.2 | 17.78 | 0.0916 | 13.9 |

| FD-MMT | 15.4 | 15.14 | 0.0585 | 15.5 | 17.14 | 0.0598 | 13.9 |

| SFD-MMT | 40.4 | 43.62 | 0.1473 | 13.5 | 45.34 | 0.1472 | 13.0 |

| Sample | (n) Pseudo-plasticity Index | (a) Carreau Constant | (η0) Zero-shear Viscosity (Pa·s) | (λ) RelaxationTime (s) |

|---|---|---|---|---|

| PLA | 0.76 | 2.6 | 1160 | 0.048 |

| CPLA | 0.74 | 1.5 | 1264 | 0.057 |

| SFD-CNC-CPLA | 0.65 | 1.0 | 1912 | 0.070 |

| C30B-CPLA | 0.73 | 2.1 | 1409 | 0.099 |

| SFD-MMT-CPLA | 0.72 | 2.0 | 2048 | 0.126 |

| Material | Tc-onset | ΔHc | Tg | Tcc-onset | ΔHcc | Tm Peak | ΔHm | Xc |

|---|---|---|---|---|---|---|---|---|

| - | [°C] | [J/g] | [°C] | [°C] | [J/g] | [°C] | [J/g] | [%] |

| CPLA | 112.62 | - | 61.15 | 112.02 | −35.55 | 163.25 | 36.71 | 34.6 |

| C30B-CPLA | 108.2 | −2.20 | 60.63 | 97.87 | −31.04 | 166.25 | 35.31 | 33.3 |

| SFD-CNC-CPLA | 107.6 | −0.78 | 60.45 | 109.97 | −35.93 | 162.24/167.91 | 37.69 | 35.6 |

| SFD-MMT-CPLA | 110.4 | −0.72 | 58.88 | 111.66 | −32.79 | 162.55/167.56 | 37.80 | 35.7 |

| CPLA-PBSA | 106.7 | −1.33 | 55.47 | 96.75 | −31.15 | 166.87 | 35.13 | 33.1 |

| C30B-CPLA-PBSA | 107.6 | −7.00 | 55.95 | 89.89 | −26.10 | 165.21 | 39.36 | 37.1 |

| SFD-CNC-CPLA-PBSA | 109.3 | −2.32 | 53.63 | 92.68 | −30.92 | 166.22 | 37.18 | 35.1 |

| SFD-MMT-CPLA-PBSA | 112.0 | −2.28 | 55.10 | 97.15 | −26.94 | 166.24 | 35.28 | 33.3 |

| Material | Tensile Strength (MPa) | Young’s Modulus (MPa) | % Elongation at Break |

|---|---|---|---|

| CPLA | 51.5 ± 1.3 | 1029.2 ± 0.01 | 11.5 ± 0.2 |

| C30B-CPLA | 56.7 ± 1.5 | 1099.4 ± 0.03 | 6.8± 0.8 |

| SFD-CNC-CPLA | 56.8 ± 1.4 | 1057.2 ± 0.02 | 6.9 ± 0.2 |

| SFD-MMT-CPLA | 59.5 ± 0.6 | 1156.6 ± 0.03 | 8.4 ± 0.4 |

| C30B-CPLA-PBSA | 46.4 ± 0.8 | 966.1 ± 0.00 | 8.5 ± 0.2 |

| SFD-CNC-CPLA-PBSA | 45.4 ± 0.9 | 930.7 ± 0.03 | 21.1 ± 0.3 |

| SFD-MMT-CPLA-PBSA | 46.0 ± 0.1 | 894.9 ± 0.06 | 22.2 ± 0.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdallah, W.; Mirzadeh, A.; Tan, V.; Kamal, M.R. Influence of Nanoparticle Pretreatment on the Thermal, Rheological and Mechanical Properties of PLA-PBSA Nanocomposites Incorporating Cellulose Nanocrystals or Montmorillonite. Nanomaterials 2019, 9, 29. https://doi.org/10.3390/nano9010029

Abdallah W, Mirzadeh A, Tan V, Kamal MR. Influence of Nanoparticle Pretreatment on the Thermal, Rheological and Mechanical Properties of PLA-PBSA Nanocomposites Incorporating Cellulose Nanocrystals or Montmorillonite. Nanomaterials. 2019; 9(1):29. https://doi.org/10.3390/nano9010029

Chicago/Turabian StyleAbdallah, Wissam, Amin Mirzadeh, Victor Tan, and Musa R. Kamal. 2019. "Influence of Nanoparticle Pretreatment on the Thermal, Rheological and Mechanical Properties of PLA-PBSA Nanocomposites Incorporating Cellulose Nanocrystals or Montmorillonite" Nanomaterials 9, no. 1: 29. https://doi.org/10.3390/nano9010029

APA StyleAbdallah, W., Mirzadeh, A., Tan, V., & Kamal, M. R. (2019). Influence of Nanoparticle Pretreatment on the Thermal, Rheological and Mechanical Properties of PLA-PBSA Nanocomposites Incorporating Cellulose Nanocrystals or Montmorillonite. Nanomaterials, 9(1), 29. https://doi.org/10.3390/nano9010029