Efficient Synthesis of PVDF/PI Side-by-Side Bicomponent Nanofiber Membrane with Enhanced Mechanical Strength and Good Thermal Stability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

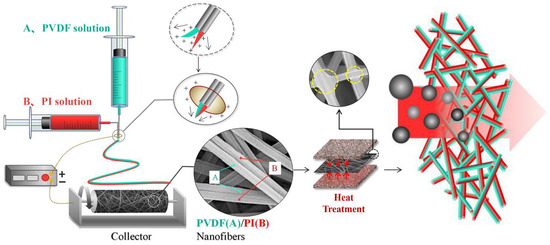

2.2. Side-by-Side Electrospinning

2.3. Measurement and Characterizations

3. Results and Discussion

3.1. Morphology and Chemical Structure

3.2. Thermal Stability

3.3. Thermo-Mechanical Properties

3.4. Filtration and Pore Size

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, S.H.; Chen, Y.M.; Duan, G.G.; Mei, C.T.; Greiner, A.; Agarwal, S. Electrospun nanofiber reinforced composites: A review. Polym. Chem. 2018, 9, 2685–2720. [Google Scholar] [CrossRef]

- Raja, S.N.; Olson, A.C.K.; Thorkelsson, K.; Luong, A.J.; Hsueh, L.; Chang, G.Q.; Gludovatz, B.; Lin, L.W.; Xu, T.; Ritchie, R.O.; et al. Tetrapod nanocrystals as fluorescent stress probes of electrospun nanocomposites. Nano Lett. 2013, 13, 3915–3922. [Google Scholar] [CrossRef] [PubMed]

- He, Y.X.; Yang, S.; Liu, H.; Shao, Q.; Chen, Q.Y.; Lu, C.; Jiang, Y.L.; Liu, C.T.; Guo, Z.H. Reinforced carbon fiber laminates with oriented carbon nanotube epoxy nanocomposites: Magnetic field assisted alignment and cryogenic temperature mechanical properties. J. Colloid Interface Sci. 2018, 517, 40–51. [Google Scholar] [CrossRef] [PubMed]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the right stuff: The trade-off between membrane permeability and selectivity. Science 2017, 356, 10. [Google Scholar] [CrossRef] [PubMed]

- Ayad, E.; Cayla, A.; Rault, F.; Gonthier, A.; LeBlan, T.; Campagne, C.; Devaux, E. Influence of rheological and thermal properties of polymers during melt spinning on bicomponent fiber morphology. J. Mater. Eng. Perform. 2016, 25, 3296–3302. [Google Scholar] [CrossRef]

- Naeimirad, M.; Zadhoush, A.; Kotek, R.; Neisiany, R.E.; Khorasani, S.N.; Ramakrishna, S. Recent advances in core/shell bicomponent fibers and nanofibers: A review. J. Appl. Polym. Sci. 2018, 135, 23. [Google Scholar] [CrossRef]

- Sibanda, M.; Focke, W.; Braack, L.; Leuteritz, A.; Brunig, H.; Tran, N.H.A.; Wieczorek, F.; Trumper, W. Bicomponent fibres for controlled release of volatile mosquito repellents. Mater. Sci. Eng. C Mater. Biol. Appl. 2018, 91, 754–761. [Google Scholar] [CrossRef] [PubMed]

- Afzal, A.; Drean, J.Y.; Harzallah, O.; Khenoussi, N.; Ahmad, S.; Akhtar, N.A. Development of multifunctional different cross-sectional shaped coaxial composite filaments for SMART textile applications. Text. Res. J. 2017, 87, 1991–2004. [Google Scholar] [CrossRef]

- Chen, S.L.; Hou, H.Q.; Hu, P.; Wendorff, J.H.; Greiner, A.; Agarwal, S. Effect of different bicomponent electrospinning techniques on the formation of polymeric nanosprings. Macromol. Mater. Eng. 2009, 294, 781–786. [Google Scholar] [CrossRef]

- Wang, K.; Liu, X.K.; Chen, X.H.; Yu, D.G.; Yang, Y.Y.; Liu, P. Electrospun hydrophilic janus nanocomposites for the rapid onset of therapeutic action of helicid. ACS Appl. Mater. Interfaces 2018, 10, 2859–2867. [Google Scholar] [CrossRef]

- Dong, R.H.; Qin, C.C.; Qiu, X.; Yan, X.; Yu, M.; Cui, L.; Zhou, Y.; Zhang, H.D.; Jiang, X.Y.; Long, Y.Z. In situ precision electrospinning as an effective delivery technique for cyanoacrylate medical glue with high efficiency and low toxicity. Nanoscale 2015, 7, 19468–19475. [Google Scholar] [CrossRef] [PubMed]

- Tijing, L.D.; Choi, W.; Jiang, Z.; Amarjargal, A.; Park, C.H.; Pant, H.R.; Im, I.T.; Kim, C.S. Two-nozzle electrospinning of (MWNT/PU)/PU nanofibrous composite mat with improved mechanical and thermal properties. Curr. Appl. Phys. 2013, 13, 1247–1255. [Google Scholar] [CrossRef]

- Wang, X.F.; Ding, B.; Yu, J.Y.; Wang, M.R. Engineering biomimetic superhydrophobic surfaces of electrospun nanomaterials. Nano Today 2011, 6, 510–530. [Google Scholar] [CrossRef]

- Wang, N.; Cai, M.; Yang, X.; Yang, Y.Y. Electret nanofibrous membrane with enhanced filtration performance and wearing comfortability for face mask. J. Colloid Interface Sci. 2018, 530, 695–703. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; You, M.H.; Lou, T.; Yu, M.; Zhang, J.C.; Gong, M.G.; Lv, F.Y.; Huang, Y.Y.; Long, Y.Z. Colorful hydrophobic poly(vinyl butyral)/cationic dye fibrous membranes via a colored solution electrospinning process. Nanoscale Res. Lett. 2016, 11, 9. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.J.; Ma, Q.L.; Yu, W.S.; Wang, T.T.; Dong, X.T.; Wang, J.X.; Liu, G.X. Magnetism and white-light-emission bifunctionality simultaneously assembled into flexible Janus nanofiber via electrospinning. J. Mater. Sci. 2015, 50, 7884–7895. [Google Scholar] [CrossRef]

- Gernhardt, M.; Peng, L.; Burgard, M.; Jiang, S.H.; Forster, B.; Schmalz, H.; Agarwal, S. Tailoring the morphology of responsive bioinspired bicomponent fibers. Macromol. Mater. Eng. 2018, 303, 8. [Google Scholar] [CrossRef]

- Guarino, V.; Cirillo, V.; Ambrosio, L. Bicomponent electrospun scaffolds to design extracellular matrix tissue analogs. Expert Rev. Med. Devices 2016, 13, 83–102. [Google Scholar] [CrossRef] [PubMed]

- Gai, G.Q.; Wang, L.Y.; Dong, X.T.; Zheng, C.M.; Yu, W.S.; Wang, J.X.; Xiao, X.F. Electrospinning preparation and properties of magnetic-photoluminescent bifunctional bistrand-aligned composite nanofibers bundles. J. Nanopart. Res. 2013, 15, 9. [Google Scholar] [CrossRef]

- Chen, S.L.; Hou, H.Q.; Hu, P.; Wendorff, J.H.; Greiner, A.; Agarwal, S. Polymeric nanosprings by bicomponent electrospinning. Macromol. Mater. Eng. 2009, 294, 265–271. [Google Scholar] [CrossRef]

- Peng, L.; Jiang, S.; Seuss, M.; Fery, A.; Lang, G.; Scheibel, T.; Agarwal, S. Two-in-one composite fibers with side-by-Side arrangement of silk fibroin and poly(l-lactide) by electrospinning. Macromol. Mater. Eng. 2016, 301, 48–55. [Google Scholar] [CrossRef]

- Gupta, P.; Wilkes, G.L. Some investigations on the fiber formation by utilizing a side-by-side bicomponent electrospinning approach. Polymer 2003, 44, 6353–6359. [Google Scholar] [CrossRef]

- Wang, B.L.; Ahmad, Z.; Huang, J.; Li, J.S.; Chang, M.W. Development of random and ordered composite fiber hybrid technologies for controlled release functions. Chem. Eng. J. 2018, 343, 379–389. [Google Scholar] [CrossRef]

- Jing, P.P.; Du, J.L.; Wang, J.B.; Lan, W.; Pan, L.N.; Li, J.A.; Wei, J.W.; Cao, D.R.; Zhang, X.L.; Zhao, C.B.; et al. Hierarchical SrTiO3/NiFe2O4 composite nanostructures with excellent light response and magnetic performance synthesized toward enhanced photocatalytic activity. Nanoscale 2015, 7, 14738–14746. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, Y.G.; Zhang, Q.H.; Wang, H.Z. Well-dispersed Pt nanocrystals on the heterostructured TiO2/SnO2 nanofibers and the enhanced photocatalytic properties. Appl. Surf. Sci. 2014, 319, 21–28. [Google Scholar] [CrossRef]

- Lv, N.; Wang, Z.G.; Bi, W.Z.; Li, G.M.; Zhang, J.L.; Ni, J.Z. C8-modified CeO2//SiO2 janus fibers for selective capture and individual MS detection of low-abundance peptides and phosphopeptides. J. Mater. Chem. B 2016, 4, 4402–4409. [Google Scholar] [CrossRef]

- Zhang, B.F.; Li, C.J.; Chang, M. Curled poly(ethylene glycol terephthalate)/poly(ethylene propanediol terephthalate) nanofibers produced by side-by-side electrospinning. Polym. J. 2009, 41, 252–253. [Google Scholar] [CrossRef]

- Zhu, C.Q.; Deng, W.; Pan, J.Q.; Lu, B.G.; Zhang, J.W.; Su, Q.; Xie, E.Q.; Lan, W. Structure effect of dual-spinneret on the preparation of electrospun composite nanofibers with side-by-side heterojunctions. J. Mater. Sci. Mater. Electron. 2013, 24, 2287–2291. [Google Scholar] [CrossRef]

- Yu, D.G.; Li, J.J.; Zhang, M.; Williams, G.R. High-quality Janus nanofibers prepared using three-fluid electrospinning. Chem. Commun. 2017, 53, 4542–4545. [Google Scholar] [CrossRef] [Green Version]

- Jin, S.; Yu, J.; Zheng, Y.; Wang, W.-Y.; Xin, B.; Kan, C.-W. Preparation and characterization of electrospun PAN/PSA carbonized nanofibers: Experiment and simulation study. Nanomaterials 2018, 8. [Google Scholar] [CrossRef]

- Roche, R.; Yalcinkaya, F. Incorporation of PVDF nanofibre multilayers into functional structure for filtration applications. Nanomaterials 2018, 8. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, C.; Costa, C.M.; Correia, D.M.; Nunes-Pereira, J.; Oliveira, J.; Martins, P.; Goncalves, R.; Cardoso, V.F.; Lanceros-Mendez, S. Electroactive poly(vinylidene fluoride)-based structures for advanced applications. Nat. Protoc. 2018, 13, 681–704. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.L.; Li, Y.Y.; Hua, T.; Jiang, P.; Yin, X.; Yu, J.Y.; Ding, B. Low-resistance dual-purpose air filter releasing negative ions and effectively capturing PM2.5. ACS Appl. Mater. Interfaces 2017, 9, 12054–12063. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.C.; Hou, H.Q.; Zhao, Y.; Zhu, Z.T.; Fong, H. Electrospun polyimide nanofibers and their applications. Prog. Polym. Sci. 2016, 61, 67–103. [Google Scholar] [CrossRef]

- Guo, Y.Q.; Xu, G.J.; Yang, X.T.; Ruan, K.P.; Ma, T.B.; Zhang, Q.Y.; Gu, J.W.; Wu, Y.L.; Liu, H.; Guo, Z. Significantly enhanced and precisely modeled thermal conductivity in polyimide nanocomposites with chemically modified graphene via in situ polymerization and electrospinning-hot press technology. J. Mater. Chem. C 2018, 6, 3004–3015. [Google Scholar] [CrossRef]

- Jin, G.; Lee, S.; Kim, S.H.; Kim, M.; Jang, J.H. Bicomponent electrospinning to fabricate three-dimensional hydrogel-hybrid nanofibrous scaffolds with spatial fiber tortuosity. Biomed. Microdevices 2014, 16, 793–804. [Google Scholar] [CrossRef] [PubMed]

- Hou, D.Y.; Lin, D.C.; Ding, C.L.; Wang, D.W.; Wang, J. Fabrication and characterization of electrospun superhydrophobic PVDF-HFP/SiNPs hybrid membrane for membrane distillation. Sep. Purif. Technol. 2017, 189, 82–89. [Google Scholar] [CrossRef]

- Li, J.; Song, G.C.; Yu, J.R.; Wang, Y.; Zhu, J.; Hu, Z.M. Preparation of solution blown polyamic acid nanofibers and their imidization into polyimide nanofiber mats. Nanomaterials 2017, 7, 15. [Google Scholar] [CrossRef]

- Jiang, S.H.; Duan, G.G.; Chen, L.L.; Hu, X.W.; Ding, Y.H.; Jiang, C.G.; Hou, H.Q. Thermal, mechanical and thermomechanical properties of tough electrospun poly(imide-co-benzoxazole) nanofiber belts. New J. Chem. 2015, 39, 7797–7804. [Google Scholar] [CrossRef]

- Chen, W.Y.; Liu, Y.B.; Ma, Y.; Yang, W.X. Improved performance of lithium ion battery separator enabled by co-electrospinnig polyimide/poly(vinylidene fluoride-co-hexafluoropropylene) and the incorporation of TiO2-(2-hydroxyethyl methacrylate). J. Power Sources 2015, 273, 1127–1135. [Google Scholar] [CrossRef]

| Samples | Thickness (μm) | Maximum Pore Size (μm) | Average Pore Size (μm) | ||||

|---|---|---|---|---|---|---|---|

| 25 °C | 140 °C | 230 °C | 25 °C | 140 °C | 230 °C | ||

| PVDF | 29.7 ± 1.2 | 1.968 | 1.755 | - | 1.402 | 0.818 | - |

| PI | 30.5 ± 2.3 | 5.463 | 5.977 | 6.301 | 3.241 | 3.886 | 3.971 |

| PVDF/PI | 31.3 ± 1.9 | 5.662 | 5.463 | 5.324 | 3.587 | 3.171 | 2.903 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, M.; He, H.; Zhang, X.; Yan, X.; Li, J.; Chen, F.; Yuan, D.; Ning, X. Efficient Synthesis of PVDF/PI Side-by-Side Bicomponent Nanofiber Membrane with Enhanced Mechanical Strength and Good Thermal Stability. Nanomaterials 2019, 9, 39. https://doi.org/10.3390/nano9010039

Cai M, He H, Zhang X, Yan X, Li J, Chen F, Yuan D, Ning X. Efficient Synthesis of PVDF/PI Side-by-Side Bicomponent Nanofiber Membrane with Enhanced Mechanical Strength and Good Thermal Stability. Nanomaterials. 2019; 9(1):39. https://doi.org/10.3390/nano9010039

Chicago/Turabian StyleCai, Ming, Hongwei He, Xiao Zhang, Xu Yan, Jianxin Li, Fuxing Chen, Ding Yuan, and Xin Ning. 2019. "Efficient Synthesis of PVDF/PI Side-by-Side Bicomponent Nanofiber Membrane with Enhanced Mechanical Strength and Good Thermal Stability" Nanomaterials 9, no. 1: 39. https://doi.org/10.3390/nano9010039

APA StyleCai, M., He, H., Zhang, X., Yan, X., Li, J., Chen, F., Yuan, D., & Ning, X. (2019). Efficient Synthesis of PVDF/PI Side-by-Side Bicomponent Nanofiber Membrane with Enhanced Mechanical Strength and Good Thermal Stability. Nanomaterials, 9(1), 39. https://doi.org/10.3390/nano9010039