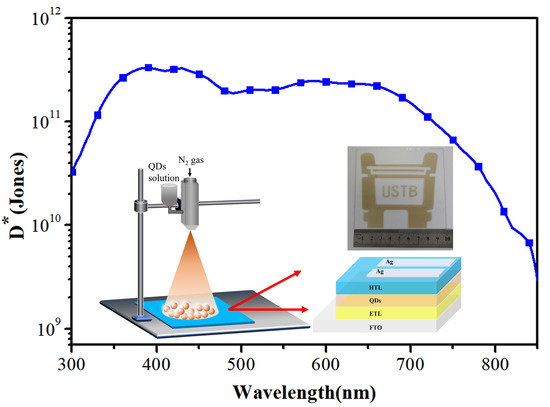

Spray Coated Colloidal Quantum Dot Films for Broadband Photodetectors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. CdSeTe QD Synthesis

2.3. Device Fabrication

2.4. Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kim, J.Y.; Voznyy, O.; Zhitomirsky, D.; Sargent, E.H. 25th Anniversary Article: Colloidal Quantum Dot Materials and Devices: A Quarter-Century of Advances. Adv. Mater. 2013, 3, 4986–5010. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, Y.; Cao, W.; Titov, A.; Hyvonen, J.; Manders, J.R.; Xue, J.; Holloway, P.H.; Qian, L. High-efficiency light-emitting devices based on quantum dots with tailored nanostructures. Nat. Photonics 2015, 9, 259–266. [Google Scholar] [CrossRef]

- Shen, T.; Li, B.; Zheng, K.; Pullerits, T.; Cao, G.; Tian, J. Surface Engineering of Quantum Dots for Remarkably High Detectivity Photodetectors. J. Phys. Chem. Lett. 2018, 9, 3285–3294. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, W.; Wang, W.; Qian, N.; Ji, X. Highly Efficient Zn-Cu-In-Se Quantum Dot-Sensitized Solar Cells through Surface Capping with Ascorbic Acid. ACS Appl. Mater. Interfaces 2019, 11, 6927–6936. [Google Scholar] [CrossRef]

- Kagan, C.R.; Lifshitz, E.; Sargent, E.H.; Talapin, D.V. Building devices from colloidal quantum dots. Science 2016, 353, aac5523. [Google Scholar] [CrossRef]

- Guo, R.; Shen, T.; Tian, J. Broadband hybrid organic/CuInSe2 quantum dot photodetectors. J. Mater. Chem. C 2018, 6, 2573–2579. [Google Scholar] [CrossRef]

- Guo, R.; Huang, F.; Zheng, K.; Pullerits, T.; Tian, J. CuInSe2 Quantum Dots Hybrid Hole Transfer Layer for Halide Perovskite Photodetectors. ACS Appl. Mater. Interfaces 2018, 10, 35656–35663. [Google Scholar] [CrossRef]

- Bi, C.; Kershaw, S.V.; Rogach, A.L.; Tian, J. Improved Stability and Photodetector Performance of CsPbI3 Perovskite Quantum Dots by Ligand Exchange with Aminoethanethiol. Adv. Funct. Mater. 2019, 29, 1902446. [Google Scholar] [CrossRef]

- Wang, S.; Bi, C.; Yuan, J.; Zhang, L.; Tian, J. Original Core–Shell Structure of Cubic CsPbBr3@Amorphous CsPbBrx Perovskite Quantum Dots with a High Blue Photoluminescence Quantum Yield of over 80%. ACS Energy Lett. 2018, 3, 245–251. [Google Scholar] [CrossRef]

- Stiff-Roberts, A.D. Quantum-dot infrared photodetectors: A review. J. Nanophotonics 2009, 3, 031607. [Google Scholar] [CrossRef]

- Dou, L.; Yang, Y.; You, J.; Hong, Z.; Chang, W.H.; Li, G. Solution-processed hybrid perovskite photodetectors with high detectivity. Nat. Commun. 2014, 5, 5404. [Google Scholar] [CrossRef] [PubMed]

- Hafiz, S.B.; Scimeca, M.R.; Zhao, P.; Paredes, I.J.; Sahu, A.; Ko, D.K. Silver Selenide Colloidal Quantum Dots for Mid-Wavelength Infrared Photodetection. ACS Appl. Nano Mater. 2019, 2, 1631–1636. [Google Scholar] [CrossRef]

- Tan, C.L.; Mohseni, H. Emerging technologies for high performance infrared detectors. Nanophotonics 2018, 7, 169–197. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Ren, Z.; Zhang, A.; Mao, P.; Li, H.; Zhong, X.; Li, W.; Yang, S.; Wang, J. Hybrid Organic/PbS Quantum Dot Bilayer Photodetector with Low Dark Current and High Detectivity. Adv. Funct. Mater. 2018, 28, 1706690. [Google Scholar] [CrossRef]

- Peng, M.; Xie, X.; Zheng, H.; Wang, Y.; Zhuo, Q.; Yuan, G.; Ma, W.; Shao, M.; Wen, Z.; Sun, X. PbS Quantum Dots/2D Nonlayered CdSxSe1−x Nanosheet Hybrid Nanostructure for High-Performance Broadband Photodetectors. ACS Appl. Mater. Interfaces 2018, 10, 43887–43895. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Song, X.; Yu, Y.; Cao, M.; Che, Y.; Zhang, Z.; Dai, H.; Yang, J.; Zhang, G.; et al. Highly Photosensitive Vertical Phototransistors Based on a Poly(3-hexylthiophene) and PbS Quantum Dot Layered Heterojunction. ACS Photonics 2017, 4, 584–592. [Google Scholar] [CrossRef]

- Peng, M.; Wang, Y.; Shen, Q.; Xie, X.; Zheng, H.; Ma, W.; Wen, Z.; Sun, X. High-performance flexible and broadband photodetectors based on PbS quantum dots/ZnO nanoparticles heterostructure. Sci. China Mater. 2018, 62, 225–235. [Google Scholar] [CrossRef] [Green Version]

- Shen, T.; Binks, D.; Yuan, J.; Cao, G.; Tian, J. Enhanced-performance of self-powered flexible quantum dot photodetectors by a double hole transport layer structure. Nanoscale 2019, 11, 9626–9632. [Google Scholar] [CrossRef]

- Konstantatos, G.; Sargent, E.H. Solution-Processed Quantum Dot Photodetectors. Proc. IEEE 2009, 97, 1666–1683. [Google Scholar] [CrossRef]

- Zabihi, F.; Xie, Y.; Gao, S.; Eslamian, M. Morphology, conductivity, and wetting characteristics of PEDOT:PSS thin films deposited by spin and spray coating. Appl. Surf. Sci. 2015, 338, 163–177. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, M.; Li, J.; Dou, J.; Qiu, H.; Shao, J. Spray-Coated CsPbBr3 Quantum Dot Films for Perovskite Photodiodes. ACS Appl. Mater. Interfaces 2018, 10, 26387–26395. [Google Scholar] [CrossRef] [PubMed]

- Shen, T.; Yuan, J.; Zhong, X.; Tian, J. Dip-coating colloidal quantum dot film for high-performance broadband photodetector. J. Mater. Chem. C 2019, 7, 6266–6272. [Google Scholar] [CrossRef]

- Kramer, I.J.; Minor, J.C.; Moreno-Bautista, G.; Rollny, L.; Kanjanaboos, P.; Kopilovic, D.; Thon, S.M.; Carey, G.H.; Chou, K.W.; Zhitomirsky, D.; et al. Efficient spray-coated colloidal quantum dot solar cells. Adv. Mater. 2015, 27, 116–121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, H.; Lee, J.G.; Mai, X.D.; Beard, M.C.; Yoon, S.S.; Jeong, S. Supersonically Spray-Coated Colloidal Quantum Dot Ink Solar Cells. Sci. Rep. 2017, 7, 622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, Y.H.; Im, S.H.; Rhee, J.H.; Lee, J.H.; Seok, S.I. Performance enhancement through post-treatments of CdS-sensitized solar cells fabricated by spray pyrolysis deposition. ACS Appl. Mater. Interfaces 2010, 2, 1648–1652. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Lv, T.; Pan, L.; Sun, Z.; Sun, C. All spray pyrolysis deposited CdS sensitized ZnO films for quantum dot-sensitized solar cells. J. Alloy. Compd. 2011, 509, 362–365. [Google Scholar] [CrossRef]

- Ji, W.; Liu, S.; Zhang, H.; Wang, R.; Xie, W.; Zhang, H. Ultrasonic Spray Processed, Highly Efficient All-Inorganic Quantum-Dot Light-Emitting Diodes. ACS Photonics 2017, 4, 1271–1278. [Google Scholar] [CrossRef]

- Han, J.; Bong, J.; Lim, T.; Lee, K.-H.; Yang, H.; Ju, S. Water repellent spray-type encapsulation of quantum dot light-emitting diodes using super-hydrophobic self-assembled nanoparticles. Appl. Surf. Sci. 2015, 353, 338–341. [Google Scholar] [CrossRef]

- Lee, J.; Jang, E.-H.; Chang, W.S.; Jeong, S.; Lee, E.; Jeong, J.-H.; Choi, J.-H. High performance ultraviolet photodetector based on a spray-coated nanocrystal quantum dots layer and Si photodiode. Sens. Actuators A Phys. 2018, 273, 182–188. [Google Scholar] [CrossRef]

- Benavides, C.M.; Rechberger, S.; Spiecker, E.; Berlinghof, M.; Unruh, T.; Biele, M.; Schmidt, O.; Brabec, C.J.; Tedde, S.F. Improving spray coated organic photodetectors performance by using 1,8-diiodooctane as processing additive. Org. Electron. 2018, 54, 21–26. [Google Scholar] [CrossRef]

- Yen, C.T.; Huang, Y.C.; Yu, Z.L.; Cha, H.C.; Hsiao, H.T.; Liang, Y.T.; Chien, F.S.S.; Tsao, C.S. Performance Improvement and Characterization of Spray-Coated Organic Photodetectors. ACS Appl. Mater. Interfaces 2018, 10, 33399–33406. [Google Scholar] [CrossRef] [PubMed]

- Inamdar, S.I.; Rajpure, K.Y. High-performance metal–semiconductor–metal UV photodetector based on spray deposited ZnO thin films. J. Alloy. Compd. 2014, 595, 55–59. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Zhao, K.; Izuishi, T.; Li, Y.; Shen, Q.; Zhong, X. CdSeTe/CdS Type-I Core/Shell Quantum Dot Sensitized Solar Cells with Efficiency over 9%. J. Phys. Chem. C 2015, 119, 28800–28808. [Google Scholar] [CrossRef]

- Wei, H.; Wang, G.; Luo, Y.; Li, D.; Meng, Q. Investigation on Interfacial Charge Transfer Process in CdSex Te1-x Alloyed Quantum Dot Sensitized Solar Cells. Electrochim. Acta 2015, 173, 156–163. [Google Scholar] [CrossRef]

- Ren, Z.; Sun, J.; Li, H.; Mao, P.; Wei, Y.; Zhong, X.; Hu, J.; Yang, S.; Wang, J. Bilayer PbS Quantum Dots for High-Performance Photodetectors. Adv. Mater. 2017, 29, 1702055. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Yao, J.S.; Liang, L.; Tong, X.W.; Lin, Y.; Liang, F.X.; Yao, H.B.; Luo, L.B. High-Performance Photocoupler Based on Perovskite Light Emitting Diode and Photodetector. ACS Appl. Mater. Interfaces 2018, 10, 39441–39447. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhuge, F.; Wang, Y.; Zhang, J.; Gan, L.; Zhou, X.; Li, H.; Zhai, T. Decorating Perovskite Quantum Dots in TiO2 Nanotubes Array for Broadband Response Photodetector. Adv. Funct. Mater. 2017, 27, 1703115. [Google Scholar] [CrossRef]

- Aher, R.; Bhorde, A.; Nair, S.; Borate, H.; Pandharkar, S.; Naik, D.; Vairale, P.; Karpe, S.; Late, D.; Prasad, M.; et al. Solvothermal Growth of PbBi2Se4 Nano-Flowers: A Material for Humidity Sensor and Photodetector Applications. Phys. Status Solidi A 2019, 26, 1900065. [Google Scholar] [CrossRef]

- García de Arquer, F.P.; Armin, A.; Meredith, P.; Sargent, E.H. Solution-processed semiconductors for next-generation photodetectors. Nat. Rev. Mater. 2017, 2, 16100. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.A.; Yu, Z.; Khan, U.; Dong, L. Solution Processed Trilayer Structure for High-Performance Perovskite Photodetector. Nanoscale Res. Lett. 2018, 13, 399. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.; Yoon, S.; Cho, J.; Kim, J.; Chung, D.S. Reactive Dedoping of Polymer Semiconductors To Boost Self-Powered Schottky Diode Performances. ACS Appl. Mater. Interfaces 2019, 11, 8365–8373. [Google Scholar] [CrossRef] [PubMed]

| Chemicals | Reagent Purity | Manufacturer |

|---|---|---|

| selenium powder (Se) | 99.0% | Alfa Aesar (shanghai, China) |

| cadmium oxide (CdO) | 99.99% | Aladdin (shanghai, China) |

| tellurium powder (Te) | 99.99% | Aladdin (shanghai, China) |

| paraffin liquid | 99.0% | Aladdin (shanghai, China) |

| oleic acid (OA) | 99.0% | Guoyao China (shanghai, China) |

| trioctylphosphine (TOP) | 90.0% | Aladdin (shanghai, China) |

| oleylamine (OAm) | 80–90% | Aladdin (shanghai, China) |

| mercapto acetic acid (TGA) | 90.0% | Alfa Aesar (shanghai, China) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, K.; Yuan, J.; Shen, T.; Du, J.; Guo, R.; Pullerits, T.; Tian, J. Spray Coated Colloidal Quantum Dot Films for Broadband Photodetectors. Nanomaterials 2019, 9, 1738. https://doi.org/10.3390/nano9121738

Song K, Yuan J, Shen T, Du J, Guo R, Pullerits T, Tian J. Spray Coated Colloidal Quantum Dot Films for Broadband Photodetectors. Nanomaterials. 2019; 9(12):1738. https://doi.org/10.3390/nano9121738

Chicago/Turabian StyleSong, Kaixuan, Jifeng Yuan, Ting Shen, Jiuyao Du, Ruiqi Guo, Tönu Pullerits, and Jianjun Tian. 2019. "Spray Coated Colloidal Quantum Dot Films for Broadband Photodetectors" Nanomaterials 9, no. 12: 1738. https://doi.org/10.3390/nano9121738

APA StyleSong, K., Yuan, J., Shen, T., Du, J., Guo, R., Pullerits, T., & Tian, J. (2019). Spray Coated Colloidal Quantum Dot Films for Broadband Photodetectors. Nanomaterials, 9(12), 1738. https://doi.org/10.3390/nano9121738