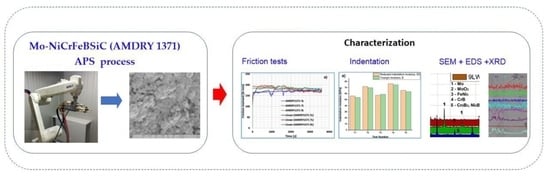

Microstructural Analysis and Tribological Behavior of AMDRY 1371 (Mo–NiCrFeBSiC) Atmospheric Plasma Spray Deposited Thin Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Surface Topography Measurement

2.2.2. Microhardness Measurements

2.2.3. Morphological and Structural Analyses

2.2.4. Tribological Friction and Wear Tests

3. Results

3.1. Surface Topography

3.2. Hardness and Elasticity Modulus

3.3. Morphological Analysis of Unworn Coatings

3.3.1. SEM Analysis

3.3.2. EDS Analysis

3.4. Friction Tests on AMSLER Machine

3.5. Wear Analysis of Coatings

3.5.1. SEM Analysis

3.5.2. EDS Point and Line Analysis of Worn Coatings

3.5.3. XRD Analysis of Coatings

3.5.4. Wear Profiles and Wear Rates

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Azarmi, F.; Coyle, T.; Mostaghimi, J. Optimization of atmospheric plasma spray process parameters using a design of experiment for alloy 625 coatings. J. Therm. Spray Technol. 2008, 17, 144–155. [Google Scholar] [CrossRef]

- Rico, A.; Rodriguez, J.; Otero, E.; Zeng, P.; Rainforth, W.M. Wear behaviour of nanostructured alumina–titania coatings deposited by atmospheric plasma spray. Wear 2009, 267, 1191–1197. [Google Scholar] [CrossRef]

- Deshpande, P.; Minfray, C.; Dassenoy, F.; Thiebaut, B.; Le Mogne, T.; Vacher, B.; Jarnias, F. Tribological behaviour of TiO2 atmospheric plasma spray (APS) coating under mixed and boundary lubrication conditions in presence of oil containing MoDTC. Tribol. Int. 2018, 118, 273–286. [Google Scholar] [CrossRef]

- Marquer, M.; Philippon, S.; Faure, L.; Chassaing, G.; Tardelli, J.; Demmou, K. Influence of two APS coatings on the high-speed tribological behavior of a contact between titanium alloys. Tribol. Int. 2019, 136, 13–22. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, C.; Sun, G.; Xiao, J.; Zhang, L.; Zhang, G. Role of SiC nanoparticles on tribological properties of atmospheric plasma sprayed 5 wt.% SiC–Ni60 coatings. Tribol. Int. 2020, 146, 106220. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, B.; Xu, J.; Cao, W.; Sun, G.; Xiao, J.; Yin, S. Effect of Mo on tribological behaviors of atmospheric plasma sprayed Al2O3-13%TiO2/Mo coatings under boundary lubrication condition. Ceram. Int. 2020, 46, 15066–15075. [Google Scholar] [CrossRef]

- Xiao, J.-K.; Wu, Y.-Q.; Chen, J.; Zhang, C. Microstructure and tribological properties of plasma sprayed FeCoNiCrSiAlx high entropy alloy coatings. Wear 2020, 448–449, 203209. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Parvin, N.; Valefi, Z.; Alishahi, M. Comparative study on tribological and corrosion protection properties of plasma sprayed Cr2O3–YSZ–SiC ceramic coatings. Ceram. Int. 2019, 45, 21108–21119. [Google Scholar] [CrossRef]

- Yang, X.; Zeng, J.; Zhang, H.; Wang, J.; Sun, J.; Dong, S.; Jiang, J.; Deng, L.; Zhou, X.; Cao, X. Correlation between microstructure, chemical components and tribological properties of plasma-sprayed Cr2O3-based coatings. Ceram. Int. 2018, 44, 10154–10168. [Google Scholar] [CrossRef]

- Bhosale, D.G.; Rathod, W.S. Investigation on wear behaviour of SS 316L, atmospheric plasma and high velocity oxy-fuel sprayed WC–Cr3C2–Ni coatings for fracturing tools. Surf. Coat. Technol. 2020, 390, 125679. [Google Scholar] [CrossRef]

- Bolelli, G.; Bonferroni, B.; Laurila, J.; Lusvarghi, L.; Milanti, A.; Niemi, K.; Vuoristo, P. Micromechanical properties and sliding wear behaviour of HVOF-sprayed Fe-based alloy coatings. Wear 2012, 276–277, 29–47. [Google Scholar] [CrossRef]

- Bolelli, G.; Börner, T.; Milanti, A.; Lusvarghi, L.; Laurila, J.; Koivuluoto, H.; Vuoristo, P. Tribological behavior of HVOF- and HVAF-sprayed composite coatings based on Fe-Alloy+WC–12%Co. Surf. Coat. Technol. 2014, 248, 104–112. [Google Scholar] [CrossRef]

- Barba-Pingarrón, A.; Valdez-Navarro, R.; Sánchez-De Jesus, F.; Bolarín-Miró, A.M.; González-Parra, R.; Covelo-Villar, A.; Hernández-Gallegos, M.A.; Domínguez-Ríos, C. Enhancement of corrosion resistance of NiCrFeBSi coatings obtained by flame thermal spray process adding an electroless nickel coating Ni–P. J. Surf. Eng. Mater. Adv. Technol. 2017, 7, 86–97. [Google Scholar] [CrossRef] [Green Version]

- Miguel, J.M.; Guilemany, J.M.; Vizcaino, S. Tribological study of NiCrBSi coating obtained by different processes. Tribol. Int. 2003, 36, 181–187. [Google Scholar] [CrossRef]

- Sampath, S.; Wayne, S.F. Microstructure and properties of plasma-sprayed Mo–Mo2C composites. J. Therm. Spray Technol. 1994, 3, 282–288. [Google Scholar] [CrossRef]

- Yan, J.; He, Z.; Wang, Y.; Qiu, J.; Wang, Y. Microstructure and wear resistance of plasma-sprayed molybdenum coating reinforced by MoSi2 particles. J. Therm. Spray Technol. 2016, 25, 1322–1329. [Google Scholar] [CrossRef]

- Sampath, S.; Vanderpool, J.E. Advanced Mo-based composite powders for thermal spray applications. U.S. Patent 6,376,103, 4 April 2002. [Google Scholar]

- Yegunov, A.I.; Artemenko, Y.A.; Konoreva, N.A.; Usikova, N.Y. Technology of coaxial laser gas-powder surfacing of alloys of the Mo+NiCrBSi system. Weld. Int. 2014, 29, 481–483. [Google Scholar] [CrossRef]

- Niranatlumpong, P.; Koiprasert, H. The effect of Mo content in plasma-sprayed Mo–NiCrBSi coating on the tribological behavior. Surf. Coat. Technol. 2010, 205, 483–489. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, L.; Xu, H.; Xiao, J.; Zhang, G.; Liao, H. Role of Mo on tribological properties of atmospheric plasma-sprayed Mo–NiCrBSi composite coatings under dry and oil-lubricated conditions. J. Alloy. Compd. 2017, 727, 841–850. [Google Scholar] [CrossRef]

- Dilawary, S.A.A.; Motallebzadeh, A.; Atar, E.; Cimenoglu, H. Influence of Mo on the high temperature wear performance of NiCrBSi hardfacings. Tribol. Int. 2018, 127, 288–295. [Google Scholar] [CrossRef]

- Liu, L.; Xu, H.; Xiao, J.; Wei, X.; Zhang, G.; Zhang, C. Effect of heat treatment on structure and property evolutions of atmospheric plasma sprayed NiCrBSi coatings. Surf. Coat. Technol. 2017, 325, 548–554. [Google Scholar] [CrossRef]

- Sang, P.; Chen, L.-Y.; Zhao, C.; Wang, Z.-X.; Wang, H.; Lu, S.; Zhang, L.-C. Particle size-dependent microstructure, hardness and electrochemical corrosion behavior of atmospheric plasma sprayed NiCrBSi coatings. Metals 2019, 9, 1342. [Google Scholar] [CrossRef] [Green Version]

- Cîrlan Paleu, C.; Istrate, B.; Paleu, V.; Munteanu, C. Technological and structural analysis of Al2O3 40TiO2 coating deposited on a shaft sleeve of hydraulic pump. IOP Conf. Series: Mater. Sci. Eng. 2020, 724, 012063. [Google Scholar] [CrossRef]

- Istrate, B.; Rau, J.V.; Munteanu, C.; Antoniac, I.V.; Saceleanu, V. Properties and in vitro assessment of ZrO2-based coatings obtained by atmospheric plasma jet spraying on biodegradable Mg–Ca and Mg–Ca–Zr alloys. Ceram. Int. 2020, 46, 15897–15906. [Google Scholar] [CrossRef]

- Doxey, R.C. Use of an AMSLER Wear Testing Machine to Investigate the Wear of Steel. Master of Science in Mechanical Engineering Thesis, United States Naval Postgraduate School, Monterey, CA, USA, 1956. Available online: https://core.ac.uk/download/pdf/36708066.pdf. (accessed on 1 March 2020).

- Paulin, C.; Chicet, D.; Paleu, V.; Benchea, M.; Lupescu, Ş.; Munteanu, C. Dry friction aspects of Ni-based self-fluxing flame sprayed coatings. IOP Conf. Ser. Mater. Sci. Eng. 2017, 227, 012091. [Google Scholar] [CrossRef] [Green Version]

- Paleu, V.; Georgescu, S.; Baciu, C.; Istrate, B.; Baciu, E.R. Preliminary experimental research on friction characteristics of a thick gravitational casted babbit layer on steel substrate. IOP Conf. Ser. Mater. Sci. Eng. 2016, 147, 012028. [Google Scholar] [CrossRef] [Green Version]

- Paleu, C.C.; Paleu, V.; Istrate, B.; Cimpoesu, N.; Munteanu, C. Thin coatings for pumping station mechanical components. IOP Conf. Ser. Mater. Sci. Eng. 2019, 591, 012007. [Google Scholar] [CrossRef] [Green Version]

- Paleu, V.; Cîrlan Paleu, C.; Istrate, B.; Bhaumik, S.; Munteanu, C. Friction and wear resistance of Al2O3 40TiO2 (AMDRY 6250) coating of a pump shaft sleeve bearing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724, 012064. [Google Scholar] [CrossRef]

- Mrdak, M.; Vencl, A.; Ćosić, M. Microstructure and mechanical properties of the Mo–NiCrBSi coating deposited by atmospheric plasma spraying. FME Trans. 2009, 37, 27–32. [Google Scholar]

- Planche, M.P.; Liao, H.; Normand, B.; Coddet, C. Relationships between NiCrBSi particle characteristics and corresponding coating properties using different thermal spraying processes. Surf. Coat. Technol. 2005, 200, 2465–2473. [Google Scholar] [CrossRef]

- Krbata, M.; Eckert, M.; Majerik, J.; Barenyi, I. Wear Behaviour of high strength tool steel 90MnCrV8 in contact with Si3N4. Metals 2020, 10, 756. [Google Scholar] [CrossRef]

- Harris, T.A. Roller Bearings Analysis, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2001; pp. 183–205. [Google Scholar]

| Product | Nominal Chemical Composition (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| AMDRY 1371 | Mo | Ni | Cr | Fe | B | Si | C | Others |

| Balance | 17.5 | 4.0 | 1.0 | 0.85 | 1.0 | 0.25 | <0.3 | |

| AISI 304 (EN 1.4301) | C% | Si% | Mn% | P% | S% | Cr% | Ni% | N% |

| ≤0.07 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.015 | 17.5–19.5 | 8.0–10.5 | ≤0.11 | |

| Sample | 5L | 7L | 9L | Disc AISI 52100 |

|---|---|---|---|---|

| Longitudinal roughness, Ra [μm] | 8.228 ± 0.43 | 4.819 ± 0.24 | 6.741 ± 0.34 | 1.0 ± 0.1 |

| Transversal roughness, Ra [μm] | 9.236 ± 0.48 | 5.670 ± 0.29 | 6.030 ± 0.27 | 1.2 ± 0.1 |

| Parameter | AMDRY 1371 | Confidence Limits |

|---|---|---|

| Microhardness, HR0.5 [GPa] | 0.464 | −31.21% + 34.32% |

| Young modulus, E [GPa] | 64 | −15.03% + 18.14% |

| Reduced modulus, E0 [GPa] | 65.5 | −14.28% + 16.94% |

| Elements wt.% | Samples | ||||

|---|---|---|---|---|---|

| Mean Values (Test 1–Test 4) | Test 1 | Test 2 | Test 3 | Test 4 | |

| Mo | 79.248 | 77.57 | 80.33 | 81.62 | 77.47 |

| Ni | 5.605 | 6.37 | 3.15 | 5.63 | 7.27 |

| Cr | 1.323 | 1.29 | 0.93 | 1.31 | 1.76 |

| Fe | 0.825 | 0.67 | 0.96 | 0.99 | 0.68 |

| O | 6.267 | 7.38 | 7.64 | 3.49 | 6.56 |

| Si | 0.318 | 0.33 | 0.25 | 0.20 | 0.49 |

| B | 6.418 | 6.40 | 6.74 | 6.76 | 5.77 |

| Elements wt.% | Sample 7L | |

|---|---|---|

| Light Zone | Dark Zone | |

| Mo | 59.38 | 6.89 |

| Ni | 4.66 | 1.69 |

| Cr | 2.15 | 1.68 |

| Fe | 14.31 | 64.15 |

| O | 19.21 | 2.58 |

| Si | 0.29 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paleu, C.C.; Munteanu, C.; Istrate, B.; Bhaumik, S.; Vizureanu, P.; Bălţatu, M.S.; Paleu, V. Microstructural Analysis and Tribological Behavior of AMDRY 1371 (Mo–NiCrFeBSiC) Atmospheric Plasma Spray Deposited Thin Coatings. Coatings 2020, 10, 1186. https://doi.org/10.3390/coatings10121186

Paleu CC, Munteanu C, Istrate B, Bhaumik S, Vizureanu P, Bălţatu MS, Paleu V. Microstructural Analysis and Tribological Behavior of AMDRY 1371 (Mo–NiCrFeBSiC) Atmospheric Plasma Spray Deposited Thin Coatings. Coatings. 2020; 10(12):1186. https://doi.org/10.3390/coatings10121186

Chicago/Turabian StylePaleu, Cornelia Cîrlan, Corneliu Munteanu, Bogdan Istrate, Shubrajit Bhaumik, Petrică Vizureanu, Mădălina Simona Bălţatu, and Viorel Paleu. 2020. "Microstructural Analysis and Tribological Behavior of AMDRY 1371 (Mo–NiCrFeBSiC) Atmospheric Plasma Spray Deposited Thin Coatings" Coatings 10, no. 12: 1186. https://doi.org/10.3390/coatings10121186

APA StylePaleu, C. C., Munteanu, C., Istrate, B., Bhaumik, S., Vizureanu, P., Bălţatu, M. S., & Paleu, V. (2020). Microstructural Analysis and Tribological Behavior of AMDRY 1371 (Mo–NiCrFeBSiC) Atmospheric Plasma Spray Deposited Thin Coatings. Coatings, 10(12), 1186. https://doi.org/10.3390/coatings10121186