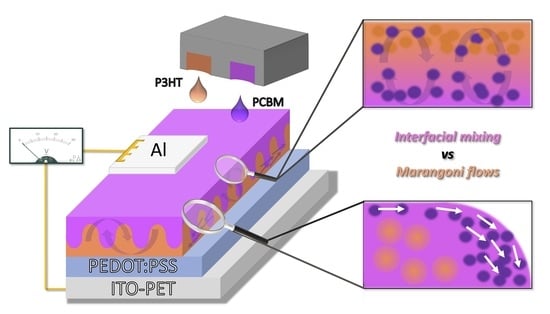

Pseudo-Planar Organic Heterojunctions by Sequential Printing of Quasi-Miscible Inks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Inks Preparation

2.3. ITO/Glass and ITO/PET Substrate Preparation

2.4. Fabrication of PHJs and BHJs by Inkjet Printing

2.5. Spectroscopic and Morphological Characterization

2.6. Atomic Force Microscopy (AFM)

2.7. X-ray Photoelectron Spectroscopy (XPS)

2.8. Electrical Measurements

3. Results

3.1. Inkjet Printing P3HT:PCBM Inks

3.2. Morphological and Chemical Characterization of the Printed P3HT/PCBM Interface

3.3. Electrical Characterization of the Photovoltaic Devices

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carpenter, A. Oil pollution in the north sea: The impact of governance measures on oil pollution over several decades. Hydrobiologia 2019, 845, 109–127. [Google Scholar] [CrossRef] [Green Version]

- Ahmadi, F.; Samlali, K.; Vo, P.Q.N.; Shih, S.C.C. An integrated droplet-digital microfluidic system for on-demand droplet creation, mixing, incubation, and sorting. Lab Chip 2019, 19, 524–535. [Google Scholar] [CrossRef] [PubMed]

- Kaminski, T.S.; Garstecki, P. Controlled droplet microfluidic systems for multistep chemical and biological assays. Chem. Soc. Rev. 2017, 46, 6210–6226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fortelný, I.; Jůza, J. Description of the droplet size evolution in flowing immiscible polymer blends. Polymers 2019, 11, 761. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goodarzi, F.; Zendehboudi, S. A comprehensive review on emulsions and emulsion stability in chemical and energy industries. Can. J. Chem. Eng. 2019, 97, 281–309. [Google Scholar] [CrossRef] [Green Version]

- Ai, Y.; Xie, R.; Xiong, J.; Liang, Q. Microfluidics for biosynthesizing: From droplets and vesicles to artificial cells. Small 2019, 1903940, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Arrabito, G.; Ferrara, V.; Bonasera, A.; Pignataro, B. Artificial biosystems by printing biology. Small 2020, 16, 1907691. [Google Scholar] [CrossRef] [PubMed]

- Mouhamad, Y.; Mokarian-Tabari, P.; Clarke, N.; Jones, R.A.L.; Geoghegan, M. Dynamics of polymer film formation during spin coating. J. Appl. Phys. 2014, 116, 123513. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, P. Large-scale colloidal self-assembly by doctor blade coating. Langmuir 2010, 26, 13173–13182. [Google Scholar] [CrossRef] [PubMed]

- Jagadamma, L.K.; Al-Senani, M.; El-Labban, A.; Gereige, I.; Ngongang Ndjawa, G.O.; Faria, J.C.D.; Kim, T.; Zhao, K.; Cruciani, F.; Anjum, D.H.; et al. Polymer solar cells with efficiency >10% enabled via a facile solution-processed Al-doped zno electron transporting layer. Adv. Energy Mater. 2015, 5, 1500204. [Google Scholar] [CrossRef]

- Arrabito, G.; Cavaleri, F.; Montalbano, V.V.; Vetri, V.; Leone, M.; Pignataro, B. Monitoring few molecular binding events in scalable confined aqueous compartments by raster image correlation spectroscopy (CADRICS). Lab Chip 2016, 16, 4666–4676. [Google Scholar] [CrossRef] [PubMed]

- Arrabito, G.; Pignataro, B. Solution processed micro- and nano-bioarrays for multiplexed biosensing. Anal. Chem. 2012, 84, 5450–5462. [Google Scholar] [CrossRef] [PubMed]

- Miccichè, C.; Arrabito, G.; Amato, F.; Buscarino, G.; Agnello, S.; Pignataro, B. Inkjet printing Ag nanoparticles for SERS hot spots. Anal. Methods 2018, 10, 3215–3223. [Google Scholar] [CrossRef]

- Singh, B.M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet printing-process and its applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef] [PubMed]

- Alamán, J.; Alicante, R.; Peña, J.I.; Sánchez-Somolinos, C. Inkjet printing of functional materials for optical and photonic applications. Materials 2016, 9, 910. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, D.-O.; Rokoni, A.; Kaneelil, P.; Cui, C.; Han, L.-H.; Sun, Y. Role of surfactant in evaporation and deposition of bisolvent biopolymer droplets. Langmuir 2019, 35, 12773–12781. [Google Scholar] [CrossRef] [PubMed]

- Sowade, E.; Ramon, E.; Mitra, K.Y.; Martínez-Domingo, C.; Pedró, M.; Pallarès, J.; Loffredo, F.; Villani, F.; Gomes, H.L.; Terés, L.; et al. All-inkjet-printed thin-film transistors: Manufacturing process reliability by root cause analysis. Sci. Rep. 2016, 6, 33490. [Google Scholar] [CrossRef]

- Grubb, P.M.; Subbaraman, H.; Park, S.; Akinwande, D.; Chen, R.T. Inkjet printing of high performance transistors with micron order chemically set gaps. Sci. Rep. 2017, 7, 1202. [Google Scholar] [CrossRef] [Green Version]

- Seol, M.-L.; Han, J.-W.; Moon, D.-I.; Yoon, K.J.; Hwang, C.S.; Meyyappan, M. All-printed triboelectric nanogenerator. Nano Energy 2018, 44, 82–88. [Google Scholar] [CrossRef]

- Saha, M.S.; Malevich, D.; Halliop, E.; Pharoah, J.G.; Peppley, B.A.; Karan, K. Electrochemical activity and catalyst utilization of low Pt and thickness controlled membrane electrode assemblies. J. Electrochem. Soc. 2011, 158, B562–B567. [Google Scholar] [CrossRef]

- Shukla, S.; Domican, K.; Karan, K.; Bhattacharjee, S.; Secanell, M. Analysis of low platinum loading thin polymer electrolyte fuel cell electrodes prepared by inkjet printing. Electrochim. Acta 2014, 156, 289–300. [Google Scholar] [CrossRef]

- Yeh, N.; Yeh, P. Organic solar cells: Their developments and potentials. Renew. Sustain. Energy Rev. 2013, 21, 421–431. [Google Scholar] [CrossRef]

- Lange, A.; Wegener, M.; Fischer, B.; Janietz, S.; Wedel, A. Solar cells with inkjet printed polymer layers. Energy Procedia 2013, 31, 150–158. [Google Scholar] [CrossRef]

- Teichler, A.; Eckardt, R.; Hoeppener, S.; Friebe, C.; Perelaer, J.; Senes, A.; Morana, M.; Brabec, C.J.; Schubert, U.S. Combinatorial screening of polymer: Fullerene blends for organic solar cells by inkjet printing. Adv. Energy Mater. 2011, 1, 105–114. [Google Scholar] [CrossRef]

- Eom, S.H.; Senthilarasu, S.; Uthirakumar, P.; Yoon, S.C.; Lim, J.; Lee, C.; Lim, H.S.; Lee, J.; Lee, S.H. Polymer solar cells based on inkjet-printed PEDOT:PSS layer. Org. Electron. 2009, 10, 536–542. [Google Scholar] [CrossRef]

- Jung, S.; Sou, A.; Banger, K.; Ko, D.H.; Chow, P.C.Y.; McNeill, C.R.; Sirringhaus, H. All-inkjet-printed, all-air-processed solar cells. Adv. Energy Mater. 2014, 4, 1–9. [Google Scholar] [CrossRef]

- Abulikemu, M.; Da’as, E.H.; Haverinen, H.; Cha, D.; Malik, M.A.; Jabbour, G.E. In situ synthesis of self-assembled gold nanoparticles on glass or silicon substrates through reactive inkjet printing. Angew. Chem. 2014, 126, 430–433. [Google Scholar] [CrossRef]

- Teo, M.Y.; Stuart, L.; Aw, K.C.; Stringer, J. Micro-reactive inkjet printer for 2D and 3D hydrogel structures. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; pp. 569–573. [Google Scholar] [CrossRef]

- Wei, Z.; Li, Y.; Cooks, R.G.; Yan, X. Accelerated reaction kinetics in microdroplets: Overview and recent developments. Annu. Rev. Phys. Chem. 2020, 71, 31–51. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, X.; Yuan, J.; Shen, S.; Gao, M.; Chesman, A.S.R.; Yin, H. Perovskite and organic solar cells fabricated by inkjet printing: Progress and prospects. Adv. Funct. Mater. 2017, 27, 1703704. [Google Scholar] [CrossRef]

- Karunakaran, S.K.; Arumugam, G.M.; Yang, W.; Ge, S.; Khan, S.N.; Lin, X.; Yang, G. Recent progress in inkjet-printed solar cells. J. Mater. Chem. A 2019, 7, 13873–13902. [Google Scholar] [CrossRef]

- Bonasera, A.; Giuliano, G.; Arrabito, G.; Pignataro, B. Tackling performance challenges in organic photovoltaics: An overview about compatibilizers. Molecules 2020, 25, 2200. [Google Scholar] [CrossRef] [PubMed]

- Syu, Y.-W.; Huang, P.-Y.; Li, H.-D.; Hsu, C.-L.; Chiu, K.-C.; Kim, C.; Chen, M.-C.; Chao, Y.-C. Enhanced performance of pseudo-bilayer organic photovoltaic devices via small molecule doping. J. Phys. Chem. C 2014, 118, 9958–9965. [Google Scholar] [CrossRef]

- Lee, J.; Jung, Y.K.; Lee, D.Y.; Jang, J.-W.; Cho, S.; Son, S.; Jeong, J.; Park, S.H. Enhanced efficiency of bilayer polymer solar cells by the solvent treatment method. Synth. Met. 2015, 199, 408–412. [Google Scholar] [CrossRef]

- Tada, A.; Geng, Y.; Wei, Q.; Hashimoto, K.; Tajima, K. Tailoring organic heterojunction interfaces in bilayer polymer photovoltaic devices. Nat. Mater. 2011, 10, 450. [Google Scholar] [CrossRef] [PubMed]

- Kitchen, B.; Awartani, O.; Kline, R.J.; Mcafee, T.; Ade, H.; O’Connor, B.T. Tuning open-circuit voltage in organic solar cells with molecular orientation. ACS Appl. Mater. Interfaces 2015, 7, 13208–13216. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Jiang, P.; Zhang, Y.; Zhang, L.; Yu, Z.; He, Q.; Zhou, W.; Tan, L.; Chen, Y. Unraveling the morphology in solution-processed pseudo-bilayer planar heterojunction organic solar cells. ACS Appl. Mater. Interfaces 2019, 11, 26213–26221. [Google Scholar] [CrossRef]

- Sartorio, C.; Scaramuzza, S.; Cataldo, S.; Vetri, V.; Scopelliti, M.; Leone, M.; Amendola, V.; Pignataro, B.; Scienze, V.; Ii, O. Donor−acceptor interfaces by engineered nanoparticles assemblies for enhanced efficiency in plastic planar heterojunction solar cells. J. Phys. Chem. C 2016, 120, 26588–26599. [Google Scholar] [CrossRef]

- Wan, J.; Zhang, L.; He, Q.; Liu, S.; Huang, B.; Hu, L.; Zhou, W.; Chen, Y. High-performance pseudoplanar heterojunction ternary organic solar cells with nonfullerene alloyed acceptor. Adv. Funct. Mater. 2020, 30, 1–9. [Google Scholar] [CrossRef]

- Shan, T.; Hong, Y.; Zhu, L.; Wang, X.; Zhang, Y.; Ding, K.; Liu, F.; Chen, C.C.; Zhong, H. Achieving optimal bulk heterojunction in all-polymer solar cells by sequential processing with nonorthogonal solvents. ACS Appl. Mater. Interfaces 2019, 11, 42438–42446. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Öberg, V.A.; Du, J.; Liu, J.; Johansson, E.M.J. Extremely lightweight and ultra-flexible infrared light-converting quantum dot solar cells with high power-per-weight output using a solution-processed bending durable silver nanowire-based electrode. Energy Environ. Sci. 2018, 11, 354–364. [Google Scholar] [CrossRef] [Green Version]

- Carlé, J.E.; Helgesen, M.; Hagemann, O.; Hösel, M.; Heckler, I.M.; Bundgaard, E.; Gevorgyan, S.A.; Søndergaard, R.R.; Jørgensen, M.; García-Valverde, R.; et al. Overcoming the scaling lag for polymer solar cells. Joule 2017, 1, 274–289. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Xu, G.; Cui, C.; Li, Y. Flexible and semitransparent organic solar cells. Adv. Energy Mater. 2018, 8, 1701791. [Google Scholar] [CrossRef]

- Schubert, M.B.; Werner, J.H. Flexible solar cells for clothing. Mater. Today 2006, 9, 42–50. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Ramakrishna, S.; Aberle, A.G. Recent progress in flexible–wearable solar cells for self-powered electronic devices. Energy Environ. Sci. 2020, 13, 685–743. [Google Scholar] [CrossRef]

- Nečas, D.; Klapetek, P. Gwyddion: An open-source software for spm data analysis. Cent. Eur. J. Phys. 2012, 10, 181–188. [Google Scholar] [CrossRef]

- Srivastava, R.; Natarajan, G.; Smith, B.D. Total pressure vapor-liquid equilibrium data for binary systems of diethylether with acetone, acetonitrile, and methanol. J. Chem. Eng. Data 1986, 31, 89–93. [Google Scholar] [CrossRef]

- Srivastava, R.; Smith, B.D. Total pressure vapor-liquid equilibrium data for binary systems of dichloromethane with benzene, toluene, nitromethane, and chlorobenzene. J. Chem. Eng. Data 1985, 30, 313–318. [Google Scholar] [CrossRef]

- Dong, H.; Carr, W.W.; Morris, J.F. An experimental study of drop-on-demand drop formation. Phys. Fluids 2006, 18, 072102. [Google Scholar] [CrossRef]

- Sartorio, C.; Giuliano, G.; Scopelliti, M.; Vetri, V.; Leone, M.; Pignataro, B. Synergies and compromises between charge and energy transfers in three-component organic solar cells. Phys. Chem. Chem. Phys. 2020, 22, 8344–8352. [Google Scholar] [CrossRef] [PubMed]

- Kadem, B.Y.; Al-Hashimi, M.K.; Hassan, A.K. The effect of solution processing on the power conversion efficiency of P3HT-based organic solar cells. Energy Procedia 2014, 50, 237–245. [Google Scholar] [CrossRef] [Green Version]

- Sartorio, C.; Campisciano, V.; Chiappara, C.; Cataldo, S.; Scopelliti, M.; Gruttadauria, M.; Giacalone, F.; Pignataro, B. Enhanced power-conversion efficiency in organic solar cells incorporating copolymeric phase-separation modulators. J. Mater. Chem. A 2018, 6, 3884–3894. [Google Scholar] [CrossRef]

- Burgués-Ceballos, I.; Hermerschmidt, F.; Akkuratov, A.V.; Susarova, D.K.; Troshin, P.A.; Choulis, S.A. High-performing polycarbazole derivatives for efficient solution-processing of organic solar cells in air. Chemsuschem 2015, 8, 4209–4215. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Larson, R.G. Evaporation of a sessile droplet on a substrate. J. Phys. Chem. B 2002, 106, 1334–1344. [Google Scholar] [CrossRef]

- Belmiloud, N.; Tamaddon, A.H.; Mertens, P.W.; Struyf, H.; Xu, X. Dynamics of the drying defects left by residual ultra-pure water droplets on silicon substrate. ECS J. Solid State Sci. Technol. 2012, 1, 34–39. [Google Scholar] [CrossRef]

- Hattori, Y.; Haruna, Y.; Otsuka, M. Dissolution process analysis using model-free noyes-whitney integral equation. Colloids Surf. B 2013, 102, 227–231. [Google Scholar] [CrossRef] [PubMed]

- Treat, N.D.; Mates, T.E.; Hawker, C.J.; Kramer, E.J.; Chabinyc, M.L. Temperature dependence of the diffusion coefficient of PCBM in poly(3-hexylthiophene). Macromolecules 2013, 46, 1002–1007. [Google Scholar] [CrossRef]

- Machui, F.; Langner, S.; Zhu, X.; Abbott, S.; Brabec, C.J. Determination of the P3HT:PCBM solubility parameters via a binary solvent gradient method: Impact of solubility on the photovoltaic performance. Sol. Energy Mater. Sol. Cells 2012, 100, 138–146. [Google Scholar] [CrossRef]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Capillary flow as the cause of ring stains from dried liquid drops. Nature 1997, 389, 827. [Google Scholar] [CrossRef]

- Eales, A.D.; Dartnell, N.; Goddard, S.; Routh, A.F. Thin, binary liquid droplets, containing polymer: An investigation of the parameters controlling film shape. J. Fluid Mech. 2016, 794, 200–232. [Google Scholar] [CrossRef] [Green Version]

- Suri, S.K.; Ramakrishna, V. Surface tension of some binary liquid mixtures. J. Phys. Chem. 1968, 72, 3073–3079. [Google Scholar] [CrossRef]

| Inkjet-Printed Component | Jsc (mA·cm−2) | Voc (V) | FF - | PCE (%) |

|---|---|---|---|---|

| P3HT:PCBM PHJ | 0.82 | 0.31 | 0.30 | 0.08 |

| P3HT:PCBM BHJ | 2.99 | 0.60 | 0.34 | 0.61 |

| PEDOT:PSS HTL+ P3HT:PCBM BHJ | 4.60 | 0.53 | 0.27 | 0.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gereanu, A.-G.; Sartorio, C.; Bonasera, A.; Giuliano, G.; Cataldo, S.; Scopelliti, M.; Arrabito, G.; Pignataro, B. Pseudo-Planar Organic Heterojunctions by Sequential Printing of Quasi-Miscible Inks. Coatings 2021, 11, 586. https://doi.org/10.3390/coatings11050586

Gereanu A-G, Sartorio C, Bonasera A, Giuliano G, Cataldo S, Scopelliti M, Arrabito G, Pignataro B. Pseudo-Planar Organic Heterojunctions by Sequential Printing of Quasi-Miscible Inks. Coatings. 2021; 11(5):586. https://doi.org/10.3390/coatings11050586

Chicago/Turabian StyleGereanu, Ana-Gianina, Camillo Sartorio, Aurelio Bonasera, Giuliana Giuliano, Sebastiano Cataldo, Michelangelo Scopelliti, Giuseppe Arrabito, and Bruno Pignataro. 2021. "Pseudo-Planar Organic Heterojunctions by Sequential Printing of Quasi-Miscible Inks" Coatings 11, no. 5: 586. https://doi.org/10.3390/coatings11050586

APA StyleGereanu, A. -G., Sartorio, C., Bonasera, A., Giuliano, G., Cataldo, S., Scopelliti, M., Arrabito, G., & Pignataro, B. (2021). Pseudo-Planar Organic Heterojunctions by Sequential Printing of Quasi-Miscible Inks. Coatings, 11(5), 586. https://doi.org/10.3390/coatings11050586