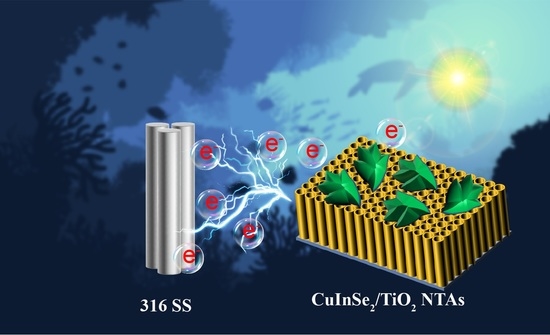

Highly Efficient CuInSe2 Sensitized TiO2 Nanotube Films for Photocathodic Protection of 316 Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Fabrication of CuInSe2/TiO2 Photoelectrodes

2.3. Characterization

2.4. Photoelectrochemical Measurements

3. Results and Discussion

3.1. Morphology and Chemical Compositions

3.2. Optical Properties Analysis

3.3. PCP Performance and Stability Evaluation

3.4. DFT Analysis and PCP Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akhtar, S.; Matin, A.; Kumar, A.; Brahim, A.; Laoui, I.T. Enhancement of anticorrosion property of 304 stainless steel using silane coatings. Appl. Surf. Sci. 2018, 440, 1286–1297. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, G.; Li, W.; Wu, D. Graphitic carbon nitride homojunction films for photocathodic protection of 316 stainless steel and Q235 carbon steel. J. Electroanal. Chem. 2020, 857, 113703. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, J.; Wu, B.; Guo, X.; Wang, Y.; Chen, D.; Zhang, Y.; Du, K.; Oguzie, E.; Ma, X. Unmasking chloride attack on the passive film of metals. Nat. Commun. 2018, 9, 2559. [Google Scholar] [CrossRef] [PubMed]

- El Ibrahimi, B.; Jmiai, A.; Bazzi, L.; El Issami, S. Amino acids and their derivatives as corrosion inhibitors for metals and alloys. Arab. J. Chem. 2020, 13, 740–771. [Google Scholar] [CrossRef]

- Hou, B.; Li, X.; Ma, X.; Du, C.; Zhang, D.; Zheng, M.; Xu, W.; Lu, D.; Ma, F. The cost of corrosion in China. NPJ Mater. Degrad. 2017, 1, 4. [Google Scholar] [CrossRef]

- Tan, B.; He, J.; Zhang, S.; Xu, C.; Chen, S.; Liu, H.; Li, W. Insight into anti-corrosion nature of Betel leaves water extracts as the novel and eco-friendly inhibitors. J. Colloid Interface Sci. 2021, 585, 287–301. [Google Scholar] [CrossRef]

- Mirhashemihaghighi, S.; Swiatowska, J.; Maurice, V.; Seyeux, A.; Klein, L.; Salmi, E.; Ritala, M.; Marcus, P. Interfacial native oxide effects on the corrosion protection of copper coated with ALD alumina. Electrochim. Acta 2016, 193, 7–15. [Google Scholar] [CrossRef]

- Kear, G.; Barker, B.; Stokes, K.; Walsh, F. Corrosion and impressed current cathodic protection of copper-based materials using a bimetallic rotating cylinder electrode (BRCE). Corros Sci. 2005, 47, 1694–1705. [Google Scholar] [CrossRef]

- Delfani, F.; Rahbar, N.; Aghanajafi, C.; Heydari, A.; KhalesiDoost, A. Utilization of thermoelectric technology in converting waste heat into electrical power required by an impressed current cathodic protection system. Appl. Energy 2021, 302, 117561. [Google Scholar] [CrossRef]

- Prasad, N.; Pathak, A.; Kundu, S.; Mondal, K. Highly active and efficient hybrid sacrificial anodes based on high p pig iron, Zn and Mg. J. Electrochem. Soc. 2021, 168, 111504. [Google Scholar] [CrossRef]

- Yuan, J.; Tsujikawa, S. Characterization of Sol-Gel-Derived TiO2 Coatings and Their Photoeffects on Copper Substrates. J. Electrochem. Soc. 1995, 142, 3444–3450. [Google Scholar] [CrossRef]

- Shao, J.; Wang, X.; Xu, H.; Zhao, X.; Niu, J.; Zhang, Z.; Huang, Y.; Duan, J. Photoelectrochemical Performance of SnS2 Sensitized TiO2 Nanotube for Protection of 304 Stainless Steel. J. Electrochem. Soc. 2021, 168, 016511. [Google Scholar] [CrossRef]

- Chen, R.; Xu, Y.; Xie, X.; Li, C.; Zhu, W.; Xiang, Q.; Li, G.; Wu, D.; Li, X.; Wang, L. Synthesis of TiO2 nanotubes/nickel-gallium layered double hydroxide heterostructure for highly-efficient photocathodic anticorrosion of 304 stainless steel. Surf. Coat. Technol. 2021, 424, 127641. [Google Scholar] [CrossRef]

- Jiang, X.; Sun, M.; Chen, Z.; Jing, J.; Lu, G.; Feng, C. Boosted photoinduced cathodic protection performance of ZnIn2S4/TiO2 nanoflowerbush with efficient photoelectric conversion in NaCl solution. J. Alloy Compd. 2021, 876, 160144. [Google Scholar] [CrossRef]

- Sood, S.; Mehta, S.; Sinha, A.; Kansal, S. Bi2O3/TiO2 heterostructures: Synthesis, characterization and their application in solar light mediated photocatalyzed degradation of an antibiotic, ofloxacin. Chem. Eng. J. 2016, 290, 45–52. [Google Scholar] [CrossRef]

- Wang, M.; Sun, L.; Lin, Z.; Cai, J.; Xie, K.; Lin, C. p-n Heterojunction photoelectrodes composed of Cu2O-loaded TiO2 nanotube arrays with enhanced photoelectrochemical and photoelectrocatalytic activities. Energy Environ. Sci. 2013, 6, 1211–1220. [Google Scholar] [CrossRef]

- Momeni, M.; Khansari-Zadeh, S.; Farrokhpour, H. Fabrication of tungsten-iron-doped TiO2 nanotubes via anodization: New photoelectrodes for photoelectrochemical cathodic protection under visible light. SN Appl. Sci. 2019, 1, 1160. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, C.; Feng, Z. Characteristics and anticorrosion performance of Fe-doped TiO2 films by liquid phase deposition method. Appl. Surf. Sci. 2014, 314, 392–399. [Google Scholar] [CrossRef]

- Sun, M.; Chen, Z.; Yu, J. Highly efficient visible light induced photoelectrochemical anticorrosion for 304 SS by Ni-doped TiO2. Electrochim. Acta. 2013, 109, 13–19. [Google Scholar] [CrossRef]

- Qiu, P.; Sun, X.; Lai, Y.; Gao, P.; Chen, C.; Ge, L. N-doped TiO2@TiO2 visible light active film with stable and efficient photocathodic protection performance. J. Electroanal. Chem. 2019, 844, 91–98. [Google Scholar] [CrossRef]

- Momeni, M.; Taghinejad, M.; Ghayeb, Y.; Bagheri, R.; Song, Z. Preparation of various boron-doped TiO2 nanostructures by in situ anodizing method and investigation of their photoelectrochemical and photocathodic protection properties. J. Iran. Chem. Soc. 2019, 16, 1839–1851. [Google Scholar] [CrossRef]

- Ma, X.; Ma, Z.; Lu, D.; Jiang, Q.; Li, L.; Liao, T.; Hou, B. Enhanced photoelectrochemical cathodic protection performance of MoS2/TiO2 nanocomposites for 304 stainless steel under visible light. J. Mater. Sci. Technol. 2021, 64, 21–28. [Google Scholar] [CrossRef]

- Lu, X.; Liu, L.; Ge, J.; Cui, Y.; Wang, F. Morphology controlled synthesis of Co(OH)2/TiO2 p-n heterojunction photoelectrodes for efficient photocathodic protection of 304 stainless steel. Appl. Surf. Sci. 2021, 537, 148002. [Google Scholar] [CrossRef]

- Wang, N.; Wang, J.; Liu, M.; Ge, C.; Hou, B.; Liu, N.; Ning, Y.; Hu, Y. Preparation of FeS2/TiO2 nanocomposite films and study on the performance of photoelectrochemistry cathodic protection. Sci. Rep. 2021, 11, 7509. [Google Scholar] [CrossRef] [PubMed]

- Aldakov, D.; Lefrançois, A.; Reiss, P. Ternary and quaternary metal chalcogenide nanocrystals: Synthesis, properties and applications. J. Mater. Chem. C. 2013, 1, 3756–3776. [Google Scholar] [CrossRef]

- Bhosale, R.; Agarkar, S.; Agrawal, I.; Naphade, R.; Ogale, S. Nanophase CulnS2 nanosheets/CuS composite grown by the SILAR method leads to high performance as a counter electrode in dye sensitized solar cells. Rsc. Adv. 2014, 4, 21989–21996. [Google Scholar] [CrossRef]

- Loo, A.; Bonanni, A.; Sofer, Z.; Pumera, M. Exfoliated transition metal dichalcogenides (MoS2, MoSe2, WS2, WSe2): An electrochemical impedance spectroscopic investigation. Electrochem. Commun. 2015, 50, 39–42. [Google Scholar] [CrossRef]

- Li, H.; Song, W.; Cui, X.; Li, Y.; Hou, B.; Zhang, X.; Wang, Y.; Cheng, L.; Zhang, P.; Li, J. AgInS2 and graphene co-sensitized TiO2 photoanodes for photocathodic protection of Q235 carbon steel under visible light. Nanotechnology 2020, 31, 305704. [Google Scholar] [CrossRef]

- Jiang, X.; Sun, M.; Chen, Z.; Jing, J.; Feng, C. High-efficiency photoelectrochemical cathodic protection performance of the TiO2/AgInSe2/In2Se3 multijunction nanosheet array. Corros. Sci. 2020, 176, 108901. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Y.; Li, Y.; Cui, X.; Zhang, Y.; Xiao, P. NiCo-selenide as a novel catalyst for water oxidation. J. Mater. Sci. 2016, 51, 3724–3734. [Google Scholar] [CrossRef]

- Jiang, Z.; Feng, L.; Zhu, J.; Liu, B.; Li, X.; Chen, Y.; Khan, S. Construction of a hierarchical NiFe2O4/CuInSe2 (p-n) heterojunction: Highly efficient visible-light-driven photocatalyst in the degradation of endocrine disruptors in an aqueous medium. Ceram. Int. 2021, 47, 8996–9007. [Google Scholar] [CrossRef]

- Wu, Z.; Tong, X.; Sheng, P.; Li, W.; Yin, X.; Zou, J.; Cai, Q. Fabrication of high-performance CuInSe2 nanocrystals-modified TiO2 NTs for photocatalytic degradation applications. Appl. Surf. Sci. 2015, 351, 309–315. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, H.; Zhong, Z.; Jia, L.; Bai, F.; Li, J.; Zhong, P.; Chen, H.; Zhang, J. Enhanced visible-photocatalytic activity of anodic TiO2 nanotubes film via decoration with CuInSe2 nanocrystals. ACS Appl. Mater. Interfaces 2013, 5, 11022–11028. [Google Scholar] [CrossRef]

- Yu, Y.; Chien, W.; Ko, Y.; Chen, S. Preparation and characterization of P3HT: CuInSe2: TiO2 thin film for hybrid solar cell applications. Thin Solid Film. 2011, 520, 1503–1510. [Google Scholar] [CrossRef]

- Zhang, T.; Rahman, Z.; Wei, N.; Liu, Y.; Liang, J.; Wang, D. In situ growth of single-crystal TiO2 nanorod arrays on Ti substrate: Controllable synthesis and photoelectro-chemical water splitting. Nano Res. 2017, 10, 1021–1032. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, H.; Guo, R.; Cui, Y.; Ma, Q.; Zhang, X.; Cheng, X.; Li, B.; Xie, M.; Cheng, Q. Effect of fabricating parameters on photoelectrocatalytic performance of CeO2/TiO2 nanotube arrays photoelectrode. Sep. Purif. Technol. 2018, 193, 264–273. [Google Scholar] [CrossRef]

- Jiang, X.; Sun, M.; Chen, Z.; Jing, J.; Feng, C. An ultrafine hyperbranched CdS/TiO2 nanolawn photoanode with highly efficient photoelectrochemical performance. J. Alloy. Compd. 2020, 816, 152533. [Google Scholar] [CrossRef]

- Antony, R.; Mathews, T.; Dash, S.; Tyagi, A.; Raj, B. X-ray photoelectron spectroscopic studies of anodically synthesized self aligned TiO2 nanotube arrays and the effect of electrochemical parameters on tube morphology. Mater. Chem. Phys. 2012, 132, 957–966. [Google Scholar] [CrossRef]

- Anuroop, R.; Pradeep, B. Structural, optical, ac conductivity and dielectric relaxation studies of reactively evaporated In6Se7 thin films. J. Alloy. Compd. 2017, 702, 432–441. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, W.; Wang, W.; Qian, N.; Ji, X. Highly Efficient Zn-Cu-In-Se Quantum Dot-Sensitized Solar Cells through Surface Capping with Ascorbic Acid. ACS Appl. Mater. Interfaces 2019, 11, 6927–6936. [Google Scholar] [CrossRef]

- Jia, H.; Cheng, S.; Zhang, H.; Yu, J.; Lai, Y. Band alignment at the Cu2SnS3/In2S3 interface measured by X-ray photoemission spectroscopy. Appl. Surf. Sci. 2015, 353, 414–418. [Google Scholar] [CrossRef]

- Dai, G.; Yu, J.; Liu, G. Synthesis and Enhanced Visible-Light Photoelectrocatalytic Activity of p-n Junction BiOI/TiO2 Nanotube Arrays. J. Phys. Chem. C 2011, 115, 7339–7346. [Google Scholar] [CrossRef]

- Tauc, J. Optical Properties and Electronic Structure of Amorphous Ge and Si. Mater. Res. Bull. 1968, 3, 37–46. [Google Scholar] [CrossRef]

- Lu, X.; Liu, L.; Xie, X.; Cui, Y.; Oguzie, E.; Wang, F. Synergetic effect of graphene and Co(OH)2 as cocatalysts of TiO2 nanotubes for enhanced photogenerated cathodic protection. J. Mater. Sci. Technol. 2020, 37, 55–63. [Google Scholar] [CrossRef]

- Sun, Z.; Li, F.; Zhao, M.; Xu, L.; Fang, S. A comparative study on photoelectrochemical performance of TiO2 photoanodes enhanced by different polyoxometalates. Electrochem. Commun. 2013, 30, 38–41. [Google Scholar] [CrossRef]

- Saha, S.; Dutta, A.; Ghosh, P.; Sukul, D.; Banerjee, P. Adsorption and corrosion inhibition effect of Schiff base molecules on the mild steel surface in 1 M HCl medium: A combined experimental and theoretical approach. Phys. Chem. Chem. Phys. 2015, 17, 5679–5690. [Google Scholar] [CrossRef]

- Solmaz, R.; Kardaş, G.; Çulha, M.; Yazıcı, B.; Erbil, M. Investigation of adsorption and inhibitive effect of 2-mercaptothiazoline on corrosion of mild steel in hydrochloric acid media. Electrochim. Acta 2008, 53, 5941–5952. [Google Scholar] [CrossRef]

- Özcan, M.; Dehri, İ.; Erbil, M. Organic sulphur-containing compounds as corrosion inhibitors for mild steel in acidic media: Correlation between inhibition efficiency and chemical structure. Appl. Surf. Sci. 2004, 236, 155–164. [Google Scholar] [CrossRef]

- Tong, X.; Shen, W.; Chen, X. Enhanced H2S sensing performance of cobalt doped free-standing TiO2 nanotube array film and theoretical simulation based on density functional theory. Appl. Surf. Sci. 2019, 469, 414–422. [Google Scholar] [CrossRef]

- Zhou, M.; Hou, Z.; Chen, X. Graphitic-C3N4 nanosheets: Synergistic effects of hydrogenation and n/n junctions for enhanced photocatalytic activities. Dalton Trans. 2017, 46, 10641–10649. [Google Scholar] [CrossRef]

- Wang, C.; Long, X.; Wei, S.; Wang, T.; Li, F.; Gao, L.; Hu, Y.; Li, S.; Jin, J. Conformally Coupling CoAl-LDH on Fluorine-Doped Hematite: Surface and Bulk Co-modification for Enhanced Photoelectrochemical Water Oxidation. ACS Appl. Mater. Interfaces 2019, 11, 29799–29806. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Lei, J.; Shao, Q.; Li, X.; Ning, X.; Shao, J.; Duan, J.; Hou, B. Preparation of ZnWO4/TiO2 composite film and its photocathodic protection for 304 stainless steel under visible light. Nanotechnology 2019, 30, 045710. [Google Scholar] [CrossRef] [PubMed]

| Samples | τ1 | B1 | τ2 | B2 | t |

|---|---|---|---|---|---|

| TiO2 | 1.26 | 202.54 | 1.26 | 245.59 | 1.26 |

| CuInSe2/TiO2 | 1.32 | 308.75 | 1.32 | 362.61 | 1.32 |

| Samples | Ecorr (V vs. SCE) | Jcorr (μA cm−2) |

|---|---|---|

| 316 SS | −0.19 | 1.58 |

| TiO2 dark | −0.44 | 5.22 |

| CuInSe2/TiO2-B dark | −0.47 | 5.31 |

| TiO2 illumination | −0.59 | 32.31 |

| CuInSe2/TiO2-B illumination | −0.76 | 76.26 |

| Samples | Rs (Ω·cm2) | Qf | Rf (Ω·cm2) | Qdl | Rp (Ω·cm2) | ||

|---|---|---|---|---|---|---|---|

| Y01 (Sn·Ω−1 cm−2) | n1 | Y02 (Sn·Ω−1 cm−2) | n2 | ||||

| 316 | 5.559 | - | - | - | 2.186 × 10−5 | 0.9232 | 1.001 × 105 |

| TiO2 a | 7.558 | 4.984 × 10−4 | 1.00 | 22.190 | 3.232 × 10−4 | 0.7796 | 4.357 × 104 |

| CuInSe2/TiO2-B a | 4.869 | 1.912 × 10−3 | 0.8027 | 1.948 × 103 | 6.390 × 10−4 | 0.8369 | 2.840 × 104 |

| TiO2 b | 3.567 | 2.879 × 10−7 | 0.99 | 3.636 | 6.784 × 10−4 | 0.7243 | 3.783 × 103 |

| CuInSe2/TiO2-B b | 6.677 | 3.167 × 10−3 | 0.8916 | 1.616 × 103 | 9.438 × 10−4 | 0.7958 | 20.990 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Li, H.; Cui, X.; Zhu, J.; Li, Y.; Zhang, P.; Li, J. Highly Efficient CuInSe2 Sensitized TiO2 Nanotube Films for Photocathodic Protection of 316 Stainless Steel. Coatings 2022, 12, 1448. https://doi.org/10.3390/coatings12101448

Yang Z, Li H, Cui X, Zhu J, Li Y, Zhang P, Li J. Highly Efficient CuInSe2 Sensitized TiO2 Nanotube Films for Photocathodic Protection of 316 Stainless Steel. Coatings. 2022; 12(10):1448. https://doi.org/10.3390/coatings12101448

Chicago/Turabian StyleYang, Zhanyuan, Hong Li, Xingqiang Cui, Jinke Zhu, Yanhui Li, Pengfei Zhang, and Junru Li. 2022. "Highly Efficient CuInSe2 Sensitized TiO2 Nanotube Films for Photocathodic Protection of 316 Stainless Steel" Coatings 12, no. 10: 1448. https://doi.org/10.3390/coatings12101448

APA StyleYang, Z., Li, H., Cui, X., Zhu, J., Li, Y., Zhang, P., & Li, J. (2022). Highly Efficient CuInSe2 Sensitized TiO2 Nanotube Films for Photocathodic Protection of 316 Stainless Steel. Coatings, 12(10), 1448. https://doi.org/10.3390/coatings12101448