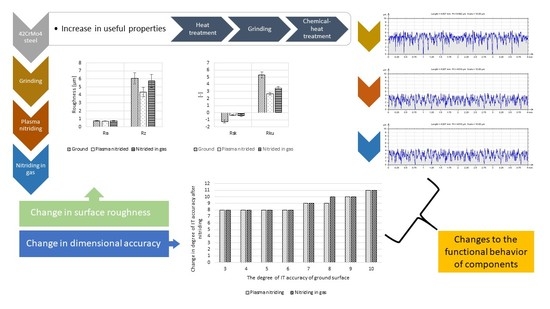

Change in Dimensions and Surface Roughness of 42CrMo4 Steel after Nitridation in Plasma and Gas

Abstract

:1. Introduction

- The pure nitride region (compound layer) is formed by nitrides, or carbonitrides of type ε (Fe2-3N) and γ’(Fe4N) of iron and alloying elements. Only exceptionally is ξ-type nitride (Fe2N) present. Its actual structure is influenced by the technology of the saturation process and the composition of the steel. A frequent phenomenon is its porosity as a result of the metastability of nitrides, the release of atomic nitrogen and the exothermic reaction during its fusion.

- The diffusion layer is the structure of the layer consisting of ferrite and nitrides (carbonitrides) of Fe and alloying elements, possibly carbides. The formation of nitrides is essentially a precipitation process from nitrogen-saturated ferrite. The consequence of its time-dependent progress in several stages is the formation of both coherent and incoherent nitrides.

2. Materials and Methods

3. Results

3.1. Metallographic Analysis

3.2. Measurement of Surface Hardness

3.3. Evaluation of the Depth of the Diffusion Layer

3.4. Surface Texture Analysis

3.5. Assessment of Surface Roughness

3.6. Dimensional Change after Nitriding

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naeem, M.; Diáz-Guillén, J.C.; Khalid, A.; Guzmán-Flores, I.; Muńoz-Arroyo, R.; Iqbal, J.; Sousa, R.R.M. Improved wear resistance of AISI-1045 steel by hybrid treatment of plasma nitriding and post-oxidation. Tribol. Int. 2022, 175, 107869. [Google Scholar] [CrossRef]

- Kumar, V.; Sinha, K.S.; Agarwal, A.K. Tribological studies of dual-coating (intermediate hard with top epoxy-graphene-base oil composite layers) on tool steel in dry and lubricated conditions. Tribol. Int. 2018, 127, 10–23. [Google Scholar] [CrossRef]

- Libório, M.S.; Almeida, E.O.; Alves, S.M.; Costa, T.H.C.; Feitor, M.C.; Nascimento, R.M.; Sousa, R.R.M.; Naeem, M.; Jelani, M. Enhanced surface properties of M2 steel by plasma nitriding pre-treatment and magnetron sputtered TiN coating. Int. J. Surf. Sci. Eng. 2020, 14, 288–306. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Lei, B.; Leng, Y.X.; Huang, N. Comparison of tribological behaviours of AlCrN and TiAlN coatings—Deposited by physical vapour deposition. Wear 2007, 263, 1423–1429. [Google Scholar] [CrossRef]

- Prochazka, J.; Pokorny, Z.; Dobrocky, D. Service behavior of nitride layers of steels for military applications. Coatings 2020, 10, 975. [Google Scholar] [CrossRef]

- Jing, J.; Dong, L.; Wang, H.D.; Jin, G. Influences of vacuum ion-nitriding on bending fatigue behaviors of 42CrMo4 steel: Experiment verification, numerical analysis and statistical approach. Int. J. Fatigue 2021, 142, 106104. [Google Scholar] [CrossRef]

- Terres, M.A.; Laalai, N.; Sidhom, H. Effect of nitriding and shot-peening on the fatigue behavior of 42CrMo4 steel: Experimental analysis and predictive approach. Mater. Des. 2012, 35, 741–748. [Google Scholar] [CrossRef]

- Borgioli, F.; Galvanetto, E.; Bacci, T. Low temperature nitriding of AISI 300 and 200 series austenitic stainless steels. Vacuum 2016, 127, 51–60. [Google Scholar] [CrossRef]

- Panfil, D.; Kulka, M.; Wach, P.; Michalski, J.; Przestacki, D. Nanomechanical properties of iron nitrides produced on 42CrMo4 steel by controlled gas nitriding and laser heat treatment. J. Alloys Compd. 2017, 706, 63–75. [Google Scholar] [CrossRef]

- Kumar, N.; Roy, B.; Ganguli, B.; Deb, B. Influence of treatment time and temperature on surface property of active screen plasma-nitrided EN24 low alloy steel. Trans. Indian Inst. Met. 2021, 74, 2027–2041. [Google Scholar] [CrossRef]

- Jessy Michla, J.R.; Ravikumar, B.; Prabhu, T.R.; Siengchin, S.; Kumar, M.A.; Rajini, R. Effect of nitriding on mechanical and microstructural properties of Direct Metal Laser Sintered 17-4PH stainless steel. J. Mater. Res. Technol. 2022, 19, 2810–2821. [Google Scholar] [CrossRef]

- Valdés, J.; Huape, E.; Oseguera, J.; Ruíz, A.; Ibarra, J.; Bernal, J.L.; Medina, A. Effect of plasma nitriding in the corrosion behavior of an AISI 4140 steel using a seawater medium solution. Mater. Lett. 2022, 316, 131991. [Google Scholar] [CrossRef]

- Jacobsen, S.D.; Hinrichs, R.; Aguzzoli, C.; Figueroa, C.A.; Baumvol, I.J.R.; Vasconcellos, M.A.Z. Influence of current density on phase formation and tribological behavior of plasma nitrided AISI H13 steel. Surf. Coat. Technol. 2016, 286, 129–139. [Google Scholar] [CrossRef]

- Karamis, M.B.; Gercekcioglu, E. Wear behavior of plasma nitride steels at ambient and elevated temperatures. Wear 2000, 243, 76–84. [Google Scholar] [CrossRef]

- Mittemeijer, E.J. Nitriding response of Cr alloyed steels. JOM 1985, 37, 16. [Google Scholar] [CrossRef]

- Shen, H.; Wang, L. Influence of temperature and duration on the nitriding behavior of 40Cr low alloy steel in mixture of NH3 and N2. Surf. Coat. Technol. 2019, 378, 124953. [Google Scholar] [CrossRef]

- Freudenberger, J.; Göllner, J.; Heilmaier, M.; Mook, G.; Saage, H.; Srivastava, V.; Wendt, U. Material Science and Engineering. In Springer Handbook of Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2009; pp. 73–222. [Google Scholar]

- Somers, M.A.J.; Mittemeijer, E.J. Verbindungsschichtbildung während des Gasnitrierens und des Gas- und Salzbadnitrocarburierens. Härt.-Tech. Mitt. 1992, 47, 5–12. [Google Scholar]

- Friehling, P.; Poulsen, F.; Somers, M.A.J. Nucleation of iron nitrides during gaseous nitriding of iron: The effect of a preoxidation treatment. Int. J. Mater. Res. 2001, 92, 589–595. [Google Scholar]

- Somers, M.A.J. Development of the compound layer during nitriding and nitrocarburizing of iron-carbon alloys. In Thermochemical Surface Engineering of Steels; Mittemeijer, E.J., Somers, M.A.J., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 341–372. [Google Scholar]

- Somers, M.A.J.; Mittemeijer, E.J. Layer growth kinetics on gaseous nitriding of pure iron: Evaluation of diffusion coefficients for nitrogen in iron nitrides. Metall. Mater. Trans. A 1995, 26, 57–74. [Google Scholar] [CrossRef]

- Mittemeijer, E.J.; Somers, M.A.J. Thermodynamics, kinetics and process control of nitriding. Surf. Eng. 1997, 16, 483–497. [Google Scholar] [CrossRef]

- Odvody, V. An opinion on the relationship between surface roughness and the prescribed dimensional tolerance of machine parts. Precis. Mach. Parts 1982, 1, 34–42. [Google Scholar]

- Bumbalek, B.; Odvody, V.; Ostadal, B. Surface Roughness; SNTL: Prague, Czechoslovakia, 1989; pp. 233–243. [Google Scholar]

- Cep, R.; Petru, J. Introduction to Machining Theory; Technical University of Ostrava: Ostrava, Czech Republic, 2013; 103p. [Google Scholar]

- Klanica, O.; Svoboda, E. Influence of the ratio gases and duration of the plasma nitriding on the changes texture of the surface34CrAl6 steel. Coat. Layers 2014, 12, 89–95. [Google Scholar]

- Pokorny, Z.; Dobrocky, D.; Studeny, Z. Influence of chemical composition on layer properties of barrel steels. Manuf. Technol. 2018, 18, 1007–1010. [Google Scholar] [CrossRef]

- Lamim, T.d.S.; Salvaro, D.; Giacomelli, R.O.; Binder, R.; Binder, C.; Klein, A.N.; de Mello, J.D.B. Plasma nitride compound layers in sintered parts: Microstructures and wear mechanisms. Wear 2021, 477, 203810. [Google Scholar] [CrossRef]

- Pokorny, Z. The Possibilities of Influencing the Basic Characteristics of the Layers during the Chemical-Thermal Treatment of Steels. Habilitation Thesis, University of Defence, Brno, Czech Republic, 2017. [Google Scholar]

- Pokorny, Z.; Studeny, Z.; Hruby, V. Effect of nitrogen on surface morphology of layers. Met. Mater. 2016, 54, 119–124. [Google Scholar] [CrossRef] [Green Version]

- Mittemeijer, E.; Somers, M. Thermochemical Surface Engineering of Steels: Improving Materials Performance; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing: Kidlington, UK, 2015; Volume 62, 816p. [Google Scholar]

- Sommer, M. Variation of the compound layer structure by controlled gas nitriding and nitrocarburizing. HTM J. Heat Treat. Mater. 2022, 77, 214–227. [Google Scholar] [CrossRef]

- Ahangarani, S.; Sabour, A.R.; Mahboubi, F.; Shahrabi, T. The influence of active screen plasma nitriding parameters on corrosion behavior of a low-alloy steel. J. Alloys Compd. 2009, 484, 222–229. [Google Scholar] [CrossRef]

- Bergelt, T.; Landgraf, P.; Grund, T.; Bräuer, G.; Lampke, T. Modelling of layer development and nitrogen distribution on different microstructures during plasma nitriding. Surf. Coat. Technol. 2022, 447, 128813. [Google Scholar] [CrossRef]

- Pye, D. Practical Nitriding and Ferritic Nitrocarburizing; ASM International: Materials Park, OH, USA, 2003; pp. 65–70. [Google Scholar]

- Genel, K.; Demirkol, M. A method to predict effective case depth in ion nitrided steels. Surf. Coat. Technol. 2005, 195, 116–120. [Google Scholar] [CrossRef]

- Díaz-Guillén, J.C.; Vargas-Gutiérrez, G.; Granda-Gutiérrez, E.E.; Zamarripa-Piňa, J.S.; Pérez-Aguilar, S.I.; Candelas-Ramírez, J.; Álvarez-Contreras, L. Surface properties of Fe4N compounds layer on AISI 4340 steel modified by pulsed plasma nitriding. J. Mater. Sci. Technol. 2013, 29, 287–290. [Google Scholar] [CrossRef]

- Keddam, M. Characterization of the nitrided layers of XC38 carbon steel obtained by R.F. plasma nitriding. Appl. Surf. Sci. 2008, 254, 2276–2280. [Google Scholar] [CrossRef]

- Meireles, A.B.; Bastos, F.d.S.; Cornacchia, T.P.; Ferreira, J.A.; de Las Casas, E.B. Enamel wear characterization based on a skewness and kurtosis surface roughness evaluation. Biotribology 2015, 1–2, 35–41. [Google Scholar] [CrossRef]

- Tayebi, N.; Polycarpou, A.A. Modeling the effect of skewness and kurtosis on the static friction coefficient of rough surfaces. Tribol. Int. 2004, 37, 491–505. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Correlation between standard roughness parameters skewness and kurtosis and tribological behavior of contact surfaces. Tribol. Int. 2012, 48, 102–112. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V. Effect of directionality of unidirectional grinding marks on friction and transfer layer formation of Mg on steel using inclined scratch test. Mater. Sci. Eng. A 2006, 429, 149–160. [Google Scholar] [CrossRef]

- Nogueira, I.; Dias, A.M.; Gras, R.; Progri, R. An experimental model for mixed friction during running-in. Wear 2002, 253, 541–549. [Google Scholar] [CrossRef] [Green Version]

- Menezes, P.L.; Kishore; Kailas, S.V. Effect of roughness parameter and grinding angle on coefficient of friction when sliding of Al-Mg alloy over EN8 steel. J. Tribol. 2006, 128, 697–704. [Google Scholar] [CrossRef]

- Chlebinova, L. Research on the Change in Dimension and Surface Roughness after Plasma Nitriding. Ph.D. Thesis, Trenčianska Univerzita Alexandra Dubčeka, Trenčín, Slovakia, 2016. [Google Scholar]

- Karamis, M.B. Some effects of the plasma nitriding process on layer properties. Thin Solid Films 1992, 217, 38–47. [Google Scholar] [CrossRef]

- Karamis, M.B. Wear properties of steel plasma nitrided at high temperatures. Mater. Sci. Eng. A 1993, 168, 49–53. [Google Scholar] [CrossRef]

- Fontalvo, G.A.; Mitterer, C.; Reithofer, G. Tribological behaviour of plasma nitrided and plasma sulfonitrided cold work steels. Surf. Eng. 2004, 20, 474–478. [Google Scholar] [CrossRef]

- Terčelj, M.; Smolej, A.; Fajfar, P.; Turk, R. Laboratory assessment of wear on nitrided surfaces of dies for hot extrusion of aluminium. Tribol. Int. 2007, 40, 374–384. [Google Scholar] [CrossRef]

- Castro, G.; Fernández-Vicente, A.; Cid, J. Influence of the nitriding time in the wear behaviour of an AISI H13 steel during a crankshaft forging process. Wear 2007, 263, 1375–1385. [Google Scholar] [CrossRef]

- Karamis, M.B.; Yildizli, K.; Aydin, G.C. Sliding/rolling wear performance of plasma nitrided H11 hot working steel. Tribol. Int. 2012, 51, 18–24. [Google Scholar] [CrossRef]

- Mohammadzadeh, R.; Akbari, A.; Drouet, M. Microstructure and wear properties of AISI M2 tool steel on RF plasma nitriding at different N2-H2 gas compositions. Surf. Coat. Technol. 2014, 258, 566–573. [Google Scholar] [CrossRef]

- Das, K.; Joseph, A.; Ghosh, M.; Mukherjee, S. Microstructure and wear behaviour of pulsed plasma nitrided AISI H13 tool steel. Can. Metall. Q. 2016, 55, 402–408. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, X.; Li, W.; Qin, M.; Gu, J. Effect of nitrided-layer microstructure control on wear behavior of AISI H13 hot work die steel. Appl. Surf. Sci. 2018, 431, 39–43. [Google Scholar] [CrossRef]

- Czerwiec, T.; Tsareva, S.; Andrieux, A.; Bruyére, S.; Marcos, G. Effect of surface topography at different scales on the dispersion of the wetting data for sessile water droplets on nitrided austenitic stainless steels. Surf. Coat. Technol. 2022, 441, 128510. [Google Scholar] [CrossRef]

- Taktak, S.; Gunes, I.; Ulker, S.; Yalcin, Y. Effect of N2 + H2 gas mixtures in plasma nitriding on tribological properties of duplex surface treated steels. Mater. Charact. 2008, 59, 1784–1791. [Google Scholar] [CrossRef]

- Kucharska, B.; Michalski, J.; Wójcik, G. Mechanical and microstructural aspects of C20-steel blades subjected to gas nitriding. Arch. Civ. Mech. Eng. 2019, 19, 147–156. [Google Scholar] [CrossRef]

- Sankar, S.L.; Kumar, G.A.; Kuppusami, P.; Singh, A.A.M.M.; Nithin, B.S.; Karimulla, S.K. Tribological analysis of plasma nitrided SS310 steel material for different proces parameters. Mater. Proc. 2021, 44, 3678–3685. [Google Scholar]

- Pye, D. Nitriding Techniques and Methods. In Steel Heat Treatment Handbook; Totten, G.E., Ed.; Marcel Dekker, Inc.: New York, NY, USA, 1997; pp. 721–764. [Google Scholar]

- Graf, M.; Holm, T. Furnace Atmospheres No. 3: Gas Nitriding and Nitrocarburizing; Linde AG: Unterschleissheim, Germany, 2006; pp. 1–52. [Google Scholar]

- Totten, G.E.; Howes, M. Distortion of Heat-Treated Components. In Steel Heat Treatment Handbook; Totten, G.E., Ed.; Marcel Dekker, Inc.: New York, NY, USA, 1997; pp. 251–292. [Google Scholar]

- Mittemeijer, E.J. Fundamentals of Nitriding and Nitrocarburizing. In ASM Handbook 4A: Steel Heat Treatment Handbook; Dosset, J., Totten, G.E., Eds.; ASM International: Material Park, OH, USA, 2013; pp. 619–646. [Google Scholar]

- Dobrocky, D. Verification of Selected Mechanical Properties of Nitrided Layers of Structural Steels in a Wide Range of Temperatures. Ph.D. Thesis, University of Defence, Brno, Czech Republic, 2015. [Google Scholar]

- Steiner, T.; Mittemeijer, E.J. Alloying element nitride development in ferritic Fe-based materials upon nitriding: A review. J. Mater. Eng. Perform. 2016, 25, 2091–2102. [Google Scholar] [CrossRef] [Green Version]

- Duo, A.; Basagoiti, R.; Arrazola, P.J.; Cuesta, M.; Illarramendi, M. Surface roughness assessment on hole drilled trough the identification and clustering of relevant external and internal signal statistical features. CIRP J. Manuf. Sci. Technol. 2022, 36, 143–157. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, W.; Zhao, Z. The effect of surface roughness characteristics on the elastic-plastic contact performance. Tribol. Int. 2014, 79, 59–73. [Google Scholar] [CrossRef]

- Amor, M.B.H.; Belghith, S.; Mezlini, S.; Salah, H.B.H. Effect of Skewness and Roughness Level on the Mechanical Behavior of a Rough Contact. In Design and Modeling of Mechanical Systems—II, Proceedings of the Sixth Conference on Design and Modeling of Mechanical Systems, CMSM’2015, Hammamet, Tunisia, 23–25 March 2015; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2015; Volume 789, pp. 377–386. [Google Scholar]

- Borgioli, F.; Galvanetto, E.; Bacci, T. Influence of surface morphology and roughness on water wetting properties of low temperature nitrided auastenitic stainless steels. Mater. Charact. 2014, 95, 278–284. [Google Scholar] [CrossRef]

- Singh, G.P.; Alphonsa, J.; Barhai, P.K.; Rayjada, P.A.; Raole, P.M.; Mukherjee, S. Effect of surface roughness on the properties of the layer formed on AISI 304 stainless steel after plasma nitriding. Surf. Coat. Technol. 2006, 200, 5807–5811. [Google Scholar] [CrossRef]

- Durst, O.; Ellermeier, J.; Berger, C. Influence of plasma-nitriding and surface roughness on the wear and corrosion resistance of thin films (PVD/PECVD). Surf. Coat. Technol. 2008, 203, 848–854. [Google Scholar] [CrossRef]

- Dobrocky, D.; Joska, Z.; Prochazka, J.; Svoboda, E.; Dostal, P. Evaluation of structural and mechanical properties of the nitrided layer on steel for weapons. Manuf. Technol. 2021, 21, 184–192. [Google Scholar] [CrossRef]

- Atáide, A.R.P.; Alves, C.J.J.; Hajek, V.; Leite, J.P. Effects during plasma nitriding of shaped materials of different sizes. Surf. Coat. Technol. 2003, 167, 52–58. [Google Scholar] [CrossRef]

| Parameter Designation | Parameter Name | Unit |

|---|---|---|

| Ra | Arithmetic mean height | μm |

| Rsk | Skewness | - |

| Rku | Kurtosis | - |

| Rz | Maximum height per section | μm |

| Nitriding Process | Dimension Change (mm) |

|---|---|

| Plasma nitriding | +0.032 ± 0.001 |

| Gaseous nitriding | +0.036 ± 0.002 |

| Tolerance | Ground | Plasma Nitriding | Gaseous Nitriding |

|---|---|---|---|

| Max (mm) | 90.054 | 90.079 | 90.086 |

| Min (mm) | 90.051 | 90.077 | 90.081 |

| IT (-) | 8 | 9 | 9 |

| The Degree of Accuracy IT for the Ground Component | Coefficient kzIT (-) |

|---|---|

| 3 | 2.48 |

| 4 | 1.93 |

| 5 | 1.57 |

| 6 | 1.38 |

| 7 | 1.26 |

| 8 | 1.16 |

| 9 | 1.11 |

| 10 | 1.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrocky, D.; Pokorny, Z.; Joska, Z.; Sedlak, J.; Zouhar, J.; Majerik, J.; Studeny, Z.; Prochazka, J.; Barenyi, I. Change in Dimensions and Surface Roughness of 42CrMo4 Steel after Nitridation in Plasma and Gas. Coatings 2022, 12, 1481. https://doi.org/10.3390/coatings12101481

Dobrocky D, Pokorny Z, Joska Z, Sedlak J, Zouhar J, Majerik J, Studeny Z, Prochazka J, Barenyi I. Change in Dimensions and Surface Roughness of 42CrMo4 Steel after Nitridation in Plasma and Gas. Coatings. 2022; 12(10):1481. https://doi.org/10.3390/coatings12101481

Chicago/Turabian StyleDobrocky, David, Zdenek Pokorny, Zdenek Joska, Josef Sedlak, Jan Zouhar, Jozef Majerik, Zbynek Studeny, Jiri Prochazka, and Igor Barenyi. 2022. "Change in Dimensions and Surface Roughness of 42CrMo4 Steel after Nitridation in Plasma and Gas" Coatings 12, no. 10: 1481. https://doi.org/10.3390/coatings12101481

APA StyleDobrocky, D., Pokorny, Z., Joska, Z., Sedlak, J., Zouhar, J., Majerik, J., Studeny, Z., Prochazka, J., & Barenyi, I. (2022). Change in Dimensions and Surface Roughness of 42CrMo4 Steel after Nitridation in Plasma and Gas. Coatings, 12(10), 1481. https://doi.org/10.3390/coatings12101481