Photostability of Oil-Coated and Stain-Coated Acetylated Hornbeam Wood against Natural Weather and Artificial Aging

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Coating

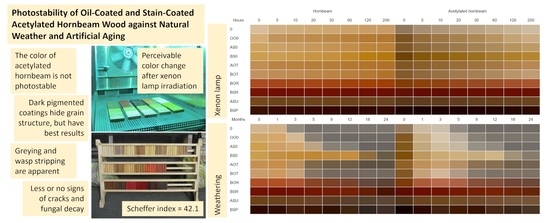

3.2. Xenon Lamp Irradiation

3.3. Weather Exposure

- –

- Uncoated hornbeam was the first to start greying among the tested samples–after about 21 days. Acetylated hornbeam started to grey after two months.

- –

- –

- OO0, AOT, and BOT started greying after three months due to no or low amounts of pigments, and not chemically bonding to the cell walls [24].

- –

- AS0 started to grey and crack after five months.

- –

- –

- BOR cracked after six months. It had a brightening interval until about five months, after which it starts to darken again while greying.

- –

- Cracks, flaking, chalking, and wasp marks became more apparent after nine months. Chalking was due to the photodegradation of the coating. The binder degraded where the film became thinner, and cracks appeared. Other researchers observed a similar process [20,21]. Wasps use the cellulose they strip from the wood surface to create nests. These marks were visible on almost all samples after one year of exposure.

- –

- –

- BSR and ASU withstood the weather exposure for two years.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teischinger, A.; Zukal, M.L.; Meints, T.; Hansmann, C.; Stingl, R. Colour characterization of various hardwoods. In Proceedings of the 5th Conference on Hardwood Research and Utilization in Europe, Sopron, Hungary, 10–11 September 2012; Németh, R., Teischinger, A., Eds.; University of West Hungary Press: Sopron, Hungary, 2012; pp. 180–188. [Google Scholar]

- Masuda, M. Why human loves wood grain figure? Extraction of vision-physical characteristics deeply related to impression. In Proceedings of the Fifth International Conference on the Development of Wood Science, Wood Technology and Forestry, Ljubljana, Slovenia, 5–7 September 2001; pp. 11–23. [Google Scholar]

- Molnár, S.; Bariska, M. Wood Species of Hungary; Szaktudás Kiadó Ház Zrt: Budapest, Hungary, 2002. [Google Scholar]

- Terziev, N.; Boutelje, J. Effect of felling time and kiln-drying on colour and susceptibility of wood to mold and fungal stain during an above-ground field test. Wood Fiber Sci. 1998, 30, 360–367. [Google Scholar]

- Mononen, K.; Alvila, L.; Tuula, T. CIEL*a*b* Measurements to Determine the Role of Felling Season, Log Storage and Kiln Drying on Colouration of Silver Birch Wood. Scand J. For. Res. 2002, 17, 179–191. [Google Scholar] [CrossRef]

- Jirouš-Rajković, V.; Ljuljka, B. Boja drva i njezine promjene prilikom izlaganja atmosferskim utjecajima. Drv. Ind. 1999, 50, 31–39. [Google Scholar]

- Straže, A.; Gorišek, Ž. Research colour variation of steamed cherrywood (Prunus avium L.). Wood Res. 2008, 53, 77–90. [Google Scholar]

- Bieske, K. Wahrnehmung von Farbunterschieden von Licht-und Körperfarben. In Tagung Licht- und Lebensqualität; Technical University of Ilmenau: Lüneburg, Germany, 2007; p. 11. [Google Scholar]

- Buchelt, B.; Wagenführ, A. Evaluation of colour differences on wood surfaces. Eur. J. Wood Wood Prod. 2011, 70, 389–391. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J. Prediction of service life—Does aesthetic matter? In Proceedings of the IRG48 Scientific Conference on Wood Protection, Ghent, Belgium, 4–8 June 2017. IRG/WP 17-20618. [Google Scholar]

- Péczely, G. Éghajlattan; Nemzeti Tankönyvkiadó Rt.: Budapest, Hungary, 1998. [Google Scholar]

- Sell, J.; Feist, W.C. U.S. and European finishes for weather-exposed wood, a comparison. For. Prod. J. 1986, 36, 37–41. [Google Scholar]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; Taylor and Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Kržišnik, D. Relationship between Laboratory and Field Tests in Service Life Assessment of Wood-Based Materials. Ph.D. Thesis, University of Ljubljana, Ljubljana, Slovenia, 2019. [Google Scholar]

- Feist, W.C.; Hon, D.N.S. Chemistry of weathering and protection. In The Chemistry of Solid Wood, Advances in Chemistry; Series 207; Rowell, R.M., Ed.; American Chemical Society: Washington, DC, USA, 1984; pp. 401–454. [Google Scholar]

- Tolvaj, L.; Papp, G. Outdoor Weathering of Impregnated and Steamed Black Locust. In Proceedings of the 4th International Conference on the Development of Wood Science, Wood Technology and Forestry, Missenden Abbey, UK, 14–16 July 1999; pp. 112–115. [Google Scholar]

- Tolvaj, L.; Mitsui, K. Light source dependence of the photodegradation of wood. J. Wood Sci. 2005, 51, 468–473. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests 2018, 9, 488. [Google Scholar] [CrossRef]

- Shohet, I.M.; Rosenfeld, Y.; Puterman, M.; Gilboa, E. Deterioration patterns for maintenance management: A methodological approach. In Proceedings of the Eighth International Conference on Durability of Building Materials and Components, Vancouver, BC, Canada, 30 May–3 June 1999; pp. 1666–1678. [Google Scholar]

- Cogulet, A.; Blanchet, P.; Landry, V. The multifactorial aspect of wood weathering: A review based on a holistic approach of wood degradation protected by clear coating. J. Bioresour. 2018, 13, 2116–2138. [Google Scholar] [CrossRef]

- Jones, D.; Brischke, C. Performance of Bio-based Building Materials; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Nejad, M.; Cooper, P.A. Exterior Wood Coatings. In Wood in Civil Engineering; Concu, G., Ed.; IntechOpen: New York, NY, USA, 2017. [Google Scholar]

- Kataoka, Y.; Kiguchi, M.; Williams, R.S.; Evans, P.D. Violet light causes photodegradation of wood beyond the zone affected by ultraviolet radiation. Holzforschung 2007, 61, 23–27. [Google Scholar] [CrossRef]

- Lazzari, M.; Chiantore, O. Drying and oxidative degradation of linseed oil. Polym. Deg. Stab. 1999, 65, 303–313. [Google Scholar] [CrossRef]

- Teaca, C.A.; Roşu, D.; Mustaţă, F.; Rusu, T.; Roşu, L.; Roşca, I.; Varganici, C.D. Natural bio-based products for wood coating and protection against degradation: A Review. J. Biores. 2019, 14, 4873–4901. [Google Scholar] [CrossRef]

- Hon, D.N.S.; Chang, S.T. Surface degradation of wood by ultraviolet light. J. Polym. Sci. Polym. Chem. Ed. 1984, 22, 2227–2241. [Google Scholar] [CrossRef]

- Tolvaj, L.; Faix, O. Artificial ageing of wood monitored by DRIFT spectroscopy and CIE L*a*b* color measurements. I. effect of UV light. Holzforschung 1995, 49, 397–404. [Google Scholar] [CrossRef]

- Mohebby, B.; Saei, A.M. Effects of geographical directions and climatological parameters on natural weathering of fire wood. Constr. Build. Mater. 2015, 94, 684–690. [Google Scholar] [CrossRef]

- Dawson, B.; Singh, A.P.; Kroese, H.W.; Schwitzer, M.A.; Gallagher, S.; Riddiough, S.J.; Wu, S. Enhancing exterior performance of clear coatings through photostabilization of wood. Part 2: Coating and weathering performance. J. Coat. Technol. Res. 2008, 5, 207–219. [Google Scholar] [CrossRef]

- Davis, K.; Leavengood, S.; Morrell, J.J. Performance of Exterior Wood Coatings in Temperate Climates. Coatings 2021, 11, 325. [Google Scholar] [CrossRef]

- Evans, P.; Haase, J.; Seman, A.; Kiguchi, M. The search for durable exterior clear coatings for wood. Coatings 2015, 5, 830–864. [Google Scholar] [CrossRef]

- Plackett, D.V.; Dunningham, E.A.; Singh, A.P. Weathering of chemically modified wood. Accelerated weathering of acetylated radiata pine. Holz. Roh. Werkstoff 1992, 50, 135–140. [Google Scholar] [CrossRef]

- Leary, G.J. The yellowing of wood by light: Part II. Tappi 1968, 51, 257–260. [Google Scholar]

- Feist, W.C.; Rowell, R.M.; Ellis, W.D. Moisture sorption and accelerated weathering of acetylated and methacrylated aspen. Wood Fib. Sci. 1991, 23, 128–136. [Google Scholar]

- Dawson, B.; Torr, K.; Plackett, D.V.; Cunningham, E.A. Spectroscopic and colour studies on acetylated radiata pine exposed to UV and visible light; FRI-Bulletin, No. 176. In Proceedings of the Pacific Rim Bio-Based Composites Symposium: Chemical Modification of Lignocellulosics, Rotorua, New Zealand, 7–8 November 1992; Plackett, D.V., Dunningham, E.A., Eds.; Forest Research Institute: Rotorua, New Zealand, 1992; pp. 41–51. [Google Scholar]

- Owen, J.A.; Owen, N.L.; Feist, W.C. Scanning electron microscope and infrared studies of weathering in southern pine. J. Mol. Struct. 1993, 300, 105–114. [Google Scholar] [CrossRef]

- Ota, M.; Abe, K.; Sekiguchi, T. Light-induced colour change of acetylated wood meal of kiri (Paulownia tomentosa Steud.). Mokuzai Gakkaishi 1996, 42, 216–221. [Google Scholar]

- Ota, M.; Ogata, H.; Jono, Y.; Hirota, K.; Abe, K. Light-induced colour changes of acetylated veneers of kiri (Paulownia tomentosa Steud.). Mokuzai Gakkaishi 1997, 43, 785–791. [Google Scholar]

- Ohkoshi, M. FTIR-PAS study of light-induced changes in the surface of acetylated or polyethylene glycol-impregnated wood. J. Wood Sci. 2002, 48, 394–401. [Google Scholar] [CrossRef]

- Bhat, I.; Khalil, A.H.P.S.; Awang, K.B.; Bakare, I.O.; Issam, A.M. Effect of weathering on physical, mechanical and morphological properties of chemically modified wood materials. Mater. Des. 2010, 31, 4363–4368. [Google Scholar] [CrossRef]

- Kalnins, M.A. Photochemical degradation of acetylated, methylated, phenylhydrazine-modified, and ACC-treated wood. J. Appl. Polym. Sci. 1984, 29, 105–115. [Google Scholar] [CrossRef]

- Dunningham, E.A.; Plackett, D.V.; Singh, A.P. Weathering of chemically modified wood: Natural weathering of acetylated radiata pine: Preliminary results. Holz. Roh. Werkstoff 1992, 50, 429–432. [Google Scholar] [CrossRef]

- Hon, D.N.S. Stabilization of wood colour: Is acetylation blocking effective? Wood Fib. Sci. 1995, 27, 360–367. [Google Scholar]

- Torr, K.M.; Dawson, B.S.W.; Ede, R.M.; Singh, J. Surface changes on acetylation and exposure to ultraviolet radiation of Pinus radiata using X-ray photo-electron spectroscopy. Holzforschung 1996, 50, 449–456. [Google Scholar] [CrossRef]

- Mitsui, K.; Tolvaj, L. Application of acetylation to photo-thermal treatment. In Proceedings of the 3rd International Symposium on Surfacing and Finishing of Wood, Kyoto, Japan, 24–26 November 2004; pp. 301–305. [Google Scholar]

- Mitsui, K.; Tolvaj, L. Colour changes in acetylated wood by the combined treatment of light and heat. Holz. Roh. Werkstoff 2005, 63, 392–393. [Google Scholar] [CrossRef]

- Lahtela, V.; Kärki, T. Determination and comparison of some selected properties of modified wood. Wood Res. 2015, 60, 763–772. [Google Scholar]

- Guo, M.; Guan, X. Effect of UV-irradiation on Surface Colour and Chemical Structure of Wood. Adv. Mater. Res. 2010, 113–116, 1624–1628. [Google Scholar] [CrossRef]

- Pu, Y.; Ragauskas, A.J. Structural analysis of acetylated hardwood lignins and their photoyellowing properties. Can. J. Chem. 2005, 83, 2132–2139. [Google Scholar] [CrossRef]

- Accoya Information Guide. Available online: https://www.accoya.com/app/uploads/2020/04/Accoya_WoodInfoGuide-1.pdf (accessed on 9 May 2022).

- Alexander, J. Accoya™. An opportunity for improving perceptions of timber joinery. In Proceedings of the Third European Conference on Wood Modification, Cardiff, Wales, 15–16 October 2007. [Google Scholar]

- Beckers, E.P.J.; Meijer, M.; Militz, H.; Stevens, M. Performance of finishes on wood that is chemically modified by acetylation. J. Coat. Technol. 1998, 70, 59–67. [Google Scholar] [CrossRef]

- Schaller, D.R. New approaches in wood coating stabilization. J. Coat. Technol. Res. 2007, 4, 401–409. [Google Scholar] [CrossRef]

- Rowell, R.M.; Bongers, F. Coating acetylated wood. Coatings 2015, 5, 792–801. [Google Scholar] [CrossRef]

- Rowell, R.M.; Bongers, F. Role of Moisture in the Failure of Coatings on Wood. Coatings 2017, 7, 219. [Google Scholar] [CrossRef]

- Fodor, F.; Lankveld, C.; Németh, R. Testing common hornbeam (Carpinus betulus L.) acetylated with the Accoya method under industrial conditions. iForest 2017, 10, 948–954. [Google Scholar] [CrossRef]

- Scheffer, T.C. A Climate Index for Estimating Potential for Decay in Wood Structures Above Ground. For. Prod. J. 1971, 21, 25–31. [Google Scholar]

- Carll, C.G. Decay Hazard (Scheffer) Index Values Calculated from 1971–2000 Climate Normal Data; General Technical Report; Forest Products Laboratory: Madison, WI, USA, 2009. [Google Scholar]

- Brischke, C.; Selter, V. Mapping the Decay Hazard of Wooden Structures in Topographically Divergent Regions. Forests 2020, 11, 510. [Google Scholar] [CrossRef]

- Nobbs, J. Colour4Free. Available online: www.colour4free.org.uk (accessed on 9 May 2022).

- Fodor, F.; Ábrahám, J.; Németh, R. Bonding acetylated hornbeam wood (Carpinus betulus L.). Pro. Ligno. 2018, 14, 31–38. [Google Scholar]

- Fodor, F.; Németh, R.; Lankveld, C.; Hofmann, T. Effect of acetylation on the chemical composition of hornbeam (Carpinus betulus L.) in relation with the physical and mechanical properties. Wood Mater. Sci. Eng. 2018, 13, 271–278. [Google Scholar] [CrossRef]

- Brischke, C.; Frühwald, H.E.; Kavurmaci, D.; Thelandersson, S. Decay hazard mapping for Europe. In Proceedings of the International Research Group on Wood Protection Annual Meeting, Queenstown, New Zealand, 8–12 May 2011. [Google Scholar]

- Frühwald, H.E.; Brischke, C.; Meyer, L.; Isaksson, T.; Thelandersson, S.; Kavurmaci, D. Durability of timber outdoor structures: Modelling performance and climate impacts. In Proceedings of the World Conference on Timber Engineering, Auckland, New Zealand, 15–19 July 2012; Quenneville, P., Ed.; New Zealand Timber Design Society: Wellington, New Zealand, 2012; pp. 295–303. [Google Scholar]

- Niklewski, J.; Brischke, C.; Hansson, E.F. Numerical study on the effects of macro climate and detailing on the relative decay hazard of Norway spruce. Wood Mat. Sci. Eng. 2021, 16, 12–20. [Google Scholar] [CrossRef]

- Van Niekerk, P.; Marais, B.; Brischke, C.; Borges, L.; Kutnik, M.; Niklewski, J.; Ansard, D.; Humar, M.; Cragg, S.; Militz, H. Mapping the biotic degradation hazard of wood in Europe—Biophysical background, engineering applications, and climate change-induced prospects. Holzforschung 2022, 76, 188–210. [Google Scholar] [CrossRef]

- Csizmadia, P. Weathering Tests of Heat-Treated and Untreated Wood Species. Bachelor’s Thesis, University of West Hungary, Sopron, Hungary, 2015. [Google Scholar]

- Nógrádi, B. Investigation of Color Change of Heat-Treated Wood Species, with Special Focus on the Time of Weathering. Bachelor’s Thesis, University of Sopron, Sopron, Hungary, 2018. [Google Scholar]

- Stefanich, A. Weather Resistance of Beech and Poplar Wood Heat-Treated in Paraffin. Bachelor’s Thesis, University of West Hungary, Sopron, Hungary, 2009. [Google Scholar]

- Bak, M. The Effect of Oil-Heat-Treatment on Some Major Properties of Poplar Wood. Ph.D. Thesis, University of West Hungary, Sopron, Hungary, 2012. [Google Scholar]

- Győri, I. Investigating the Properties of Oil-Heat-Treated Beech and Oak. Bachelor’s Thesis, University of West Hungary, Sopron, Hungary, 2012. [Google Scholar]

- Zöld, F. Examination of Oil-Impregnated Exterior Wooden Flooring. Bachelor’s Thesis, University of West Hungary, Sopron, Hungary, 2015. [Google Scholar]

- Németh, R.; Tolvaj, L.; Bak, M.; Alpár, T.L. Colour stability of oil-heat treated black locust and poplar wood during short-term UV radiation. J. Photochem. Photobiol. A Chem. 2016, 329, 287–292. [Google Scholar] [CrossRef]

- Takács, D. Increasing the Color-Stability of Wood with Nanoparticles. Bachelor’s Thesis, University of Sopron, Sopron, Hungary, 2019. [Google Scholar]

- Demjén, A. Increasing the Outdoor Photostability of Wood Using Iron Nanoparticles. Bachelor’s Thesis, University of Sopron, Sopron, Hungary, 2021. [Google Scholar]

- Fodor, F.; Németh, R. Testing the Photostability of Acetylated and Boiled Linseed Oil-coated Common Hornbeam (Carpinus betulus L.). Wood. Acta Silv. Lignaria Hung. 2017, 13, 81–94. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, H.; Li, K.; Yang, Z. Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light. Polymers 2019, 11, 709. [Google Scholar] [CrossRef]

| Product Name, Type and Marking | Ingredients |

|---|---|

Oli-Natura Yacht and Teak Oil

| Modified vegetable oils such as linseed oil; isoparaffinic hydrocarbon of pharmaceutical quality; lead-free drying agents, non-fading earth and mineral pigments, micronized titan oxide. |

Auro Garden Furniture Oil No. 102

| Fatty acids, lecithin, linseed oil, mineral pigments, orange terpene, silica, tung oil, drying agents (cobalt-free). |

Auro Wood stain No. 160

| Water, linseed oil, colophonium glycerine ester with organic acids (as ammonium soaps), mineral fillers and pigments, surfactants made from rapeseed and Ricinus oil, silicic acid, dryers (cobalt-free), castor stand oil, sunflower oil, cellulose, fatty acids. |

Biopin Weather Protection Stain

| Binding agents (polymer made from natural oils, fatty acids, and resins), solvent (water), pigments and fillers (earth and mineral pigments), additives (vegetable-based emulsifier, lead and barium-free stabilizers and drying agents, methyl cellulose, film treaters (3-iodine-2-propynyl butylcarbamate (max. 0.2%), and 2-octyl-2H-isothiazol-3-one (<0.01%)). |

Biopin Terrace Oil

| Binding agents (polymer made from natural oils, fatty acids, and resins), solvent (isoparaffin), pigments (mineral pigments), additives (silicic acid, lead-free drying agent). |

Biopin Natural Impregnating Oil and 20% K.O.S. Natural Pigment Paste

| Binding agents (polymer made from natural oils, fatty acids, and resins), solvent (isoaliphate), additives (lead and barium-free drying agents), and non-toxic natural mineral pigments prepared in vegetable oil. |

| Marking | Volume Solids (%) | Density (g/cm3) | Drying Time (Hours) | Full Hardness (Day) | Number of Layers | Application Amount (g/m2) |

|---|---|---|---|---|---|---|

| OO0 | 68.39 | 0.875 | 1–2 | 2–3 | 2 | 40–80 |

| AOT | 90.53 | 0.95 | 24 | 28 | 2 | 38 |

| AS0 | 12.78 | 1.065 | 24 | 28 | 3 | 75–96 |

| ASU | 31.96 | 1.065 | 24 | 21 | 3 | 75–96 |

| BS0 | 58.59 | 0.98 | 24 | 14 | 3 | 69–83 |

| BSP | 50.97 | 0.98 | 24 | 14 | 3 | 69–83 |

| BSR | 59.15 | 0.98 | 24 | 14 | 3 | 69–83 |

| BOT | 72.94 | 0.84 | 4–6 | 14 | 3 | 55–105 |

| BOR | 50.26 | 0.86 | 6–8 | 14 | 3 | 60–69 |

| Marking | Hornbeam | Acetylated Hornbeam | ||||

|---|---|---|---|---|---|---|

| L * | a * | b * | L * | a * | b * | |

| 0 | 78.73 | 4.06 | 19.70 | 58.31 | 5.38 | 15.94 |

| OO0 | 73.09 | 7.39 | 29.48 | 47.36 | 10.48 | 23.90 |

| AS0 | 76.06 | 5.55 | 32.66 | 49.40 | 11.42 | 25.00 |

| BS0 | 75.56 | 5.41 | 29.96 | 49.91 | 9.63 | 24.96 |

| AOT | 67.34 | 11.69 | 33.42 | 50.46 | 8.52 | 22.87 |

| ASU | 40.57 | 10.62 | 17.53 | 36.87 | 8.09 | 11.76 |

| BSP | 32.87 | 8.17 | 6.18 | 30.31 | 6.31 | 5.06 |

| BSR | 38.50 | 28.22 | 17.81 | 35.50 | 23.74 | 15.10 |

| BOT | 69.59 | 9.94 | 27.14 | 47.35 | 9.87 | 21.18 |

| BOR | 49.60 | 31.08 | 27.86 | 42.19 | 21.19 | 21.07 |

| Marking | Hornbeam | Acetylated Hornbeam | ||

|---|---|---|---|---|

| Before | After 200 h | Before | After 200 h | |

| 0 | 1.80 | 18.30 | 1.84 | 25.70 |

| OO0 | 4.07 | 25.47 | 3.96 | 36.92 |

| AS0 | 1.49 | 26.78 | 3.12 | 27.41 |

| BS0 | 2.71 | 26.92 | 1.78 | 22.80 |

| AOT | 2.66 | 16.53 | 3.09 | 20.46 |

| BOT | 3.87 | 19.95 | 5.10 | 27.32 |

| BOR | 3.07 | 7.28 | 1.94 | 15.22 |

| BSR | 1.57 | 3.16 | 1.09 | 6.72 |

| ASU | 2.09 | 3.27 | 1.54 | 6.27 |

| BSP | 1.23 | 2.14 | 1.27 | 14.98 |

| 2018–2020 | J | F | M | A | M | J | J | A | S | O | N | D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) AVG: 13 | 1 | 6 | 8 | 14 | 16 | 22 | 22 | 23 | 17 | 13 | 7 | 3 |

| Precipitation (mm) SUM: 625 AVG: 51 | 20 | 11 | 26 | 23 | 125 | 78 | 61 | 52 | 84 | 32 | 70 | 43 |

| Max temperature AVG: 25 | 13 | 20 | 22 | 27 | 28 | 33 | 35 | 35 | 32 | 24 | 19 | 14 |

| Sunshine duration (hours) SUM: 2548 AVG: 216 | 100 | 173 | 217 | 296 | 243 | 316 | 309 | 297 | 244 | 188 | 89 | 79 |

| Solar irradiance (MJ/m2) SUM: 4895 AVG: 415 | 123 | 241 | 390 | 584 | 585 | 710 | 699 | 618 | 443 | 281 | 123 | 99 |

| Relative humidity (%) AVG: 69 | 81 | 63 | 59 | 55 | 72 | 67 | 61 | 64 | 70 | 77 | 88 | 80 |

| Number of days with precipitation above 0.25 mm SUM: 83 | 1 | 6 | 8 | 14 | 16 | 22 | 22 | 23 | 17 | 13 | 7 | 3 |

| Marking | Hornbeam | Acetylated Hornbeam | ||||

|---|---|---|---|---|---|---|

| 0 Year | 1 Year | 2 Years | 0 Year | 1 Year | 2 Years | |

| 0 | 2.22 | 3.68 | 3.68 | 6.07 | 18.08 | 18.08 |

| OO0 | 3.59 | 2.67 | 2.67 | 5.94 | 2.67 | 2.67 |

| AS0 | 2.86 | 2.73 | 3.91 | 5.30 | 3.12 | 2.73 |

| BS0 | 2.47 | 2.55 | 5.37 | 7.27 | 2.89 | 3.05 |

| AOT | 3.05 | 3.54 | 6.20 | 2.80 | 4.08 | 5.78 |

| BOT | 2.93 | 3.42 | 3.42 | 4.71 | 3.21 | 3.21 |

| BOR | 3.24 | 3.92 | 10.31 | 3.00 | 5.00 | 6.30 |

| BSR | 2.39 | 1.77 | 6.82 | 1.77 | 1.73 | 3.08 |

| ASU | 2.08 | 4.12 | 2.13 | 2.70 | 3.31 | 2.15 |

| BSP | 9.93 | 6.14 | 13.06 | 2.65 | 6.67 | 8.07 |

| Marking | After 200 h of Xenon Lamp Irradiation | After Weather Exposure | ∆E * | |||||

|---|---|---|---|---|---|---|---|---|

| L * | a * | b * | L * | a * | b * | Duration (Month) | ||

| Untreated hornbeam | ||||||||

| 0 | 67.59 | 10.64 | 34.27 | 73.98 | 5.46 | 25.20 | 0–1 | 12.24 |

| OO0 | 55.14 | 16.91 | 48.41 | 71.96 | 9.53 | 39.01 | 0–1 | 20.63 |

| AS0 | 58.92 | 15.52 | 49.36 | 69.52 | 9.47 | 38.05 | 0–1 | 16.64 |

| AOT | 53.41 | 18.82 | 50.86 | 63.45 | 14.64 | 44.32 | 0–1 | 12.70 |

| ASU | 31.93 | 15.14 | 31.48 | 31.66 | 15.18 | 32.12 | 1 | 0.69 |

| BS0 | 55.45 | 17.91 | 68.43 | 61.43 | 14.11 | 53.22 | 5 | 16.77 |

| BSP | 6.76 | 25.07 | 11.50 | 6.41 | 20.53 | 10.90 | 0–1 | 4.59 |

| BSR | 21.42 | 43.76 | 36.78 | 22.19 | 44.33 | 38.11 | 3 | 1.64 |

| BOT | 54.12 | 17.98 | 49.27 | 67.41 | 12.61 | 38.63 | 0–1 | 17.86 |

| BOR | 39.60 | 38.57 | 50.08 | 45.44 | 37.75 | 46.33 | 0–1 | 6.99 |

| Acetylated hornbeam | ||||||||

| 0 | 77.32 | 2.20 | 15.51 | 77.15 | 2.01 | 15.35 | 1 | 0.30 |

| OO0 | 72.74 | 4.12 | 25.71 | 72.76 | 3.91 | 25.07 | 1 | 0.68 |

| AS0 | 66.39 | 5.29 | 32.76 | 70.19 | 3.83 | 25.97 | 0–1 | 7.92 |

| AOT | 60.41 | 11.12 | 36.13 | 63.76 | 11.36 | 37.21 | 0–1 | 3.53 |

| ASU | 32.21 | 14.09 | 31.19 | 31.69 | 13.72 | 31.54 | 1 | 0.73 |

| BS0 | 59.15 | 9.97 | 52.19 | 65.87 | 5.42 | 37.03 | 0–1 | 17.20 |

| BSP | 4.81 | 17.72 | 8.13 | 5.62 | 20.85 | 9.53 | 0–1 | 3.53 |

| BSR | 21.28 | 43.05 | 36.54 | 21.29 | 43.13 | 36.55 | 1 | 0.09 |

| BOT | 67.30 | 7.42 | 26.20 | 68.91 | 7.33 | 25.77 | 1 | 1.67 |

| BOR | 45.75 | 32.43 | 38.06 | 48.00 | 31.05 | 36.86 | 0–1 | 2.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fodor, F.; Bak, M.; Németh, R. Photostability of Oil-Coated and Stain-Coated Acetylated Hornbeam Wood against Natural Weather and Artificial Aging. Coatings 2022, 12, 817. https://doi.org/10.3390/coatings12060817

Fodor F, Bak M, Németh R. Photostability of Oil-Coated and Stain-Coated Acetylated Hornbeam Wood against Natural Weather and Artificial Aging. Coatings. 2022; 12(6):817. https://doi.org/10.3390/coatings12060817

Chicago/Turabian StyleFodor, Fanni, Miklós Bak, and Róbert Németh. 2022. "Photostability of Oil-Coated and Stain-Coated Acetylated Hornbeam Wood against Natural Weather and Artificial Aging" Coatings 12, no. 6: 817. https://doi.org/10.3390/coatings12060817

APA StyleFodor, F., Bak, M., & Németh, R. (2022). Photostability of Oil-Coated and Stain-Coated Acetylated Hornbeam Wood against Natural Weather and Artificial Aging. Coatings, 12(6), 817. https://doi.org/10.3390/coatings12060817