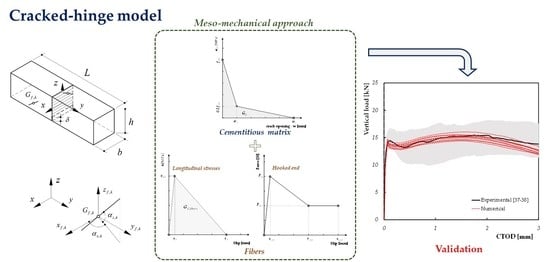

Meso-Scale Formulation of a Cracked-Hinge Model for Hybrid Fiber-Reinforced Cement Composites

Abstract

:1. Introduction

2. Formulation of a Meso-Mechanical Cracked-Hinge Model

2.1. Geometric Definition and Main Kinematic Assumptions

2.2. Equilibrium Equations

3. Numerical Implementation

3.1. Geometry of the FRCC Beam

3.2. Stress-Strain and Stress-Crack Opening for Cementitous Matrix

- -

- Ect is the tangent modulus of elasticity (expressed in MPa) in tension;

- -

- εct is the tensile strain,

- -

- σct is the tensile stress (expressed in MPa);

- -

- fctm is the tensile strength (expressed in MPa).

3.3. Bond of Spread Fiber Reinforcement Embedded within the Cementitius Matrix

- -

- the distributed bond throughout the lateral surface of the fiber, which is modelled through a bilinear bond-slip law (Figure 6a) which is defined by the three parameters τmax, sel and su and is governed by the fiber fracture energy (GF,fiber);

- -

- the concentrated force at the end hook (if present), which is described by a trilinear force-slip law (Figure 6b) defined by the maximum force Fsp attained at the slip se,sp, the residual force Fsp,r attained at a displacement sr,sp and sustained up to an ultimate slip value su,sp.

3.4. Force vs. Crack Opening Curves and Ductitlty Indices

4. Model Validation

- industrial steel fibers (ISF);

- recycled steel fibers (RSF);

- polypropylene fibers (PPF).

5. Conclusions

- -

- The obtained results show that the cracked-hinge model is able to represent quite faithfully the post-cracking behavior of the fiber-reinforced composites. Particularly, it has been shown that the load-COD curves (both in terms of CTOD and CMOD) are actually very close to the average experimental trend, especially for the mixtures reinforced with only industrial steel fibers.

- -

- For the hybrid mixtures, however, the results are certainly more than satisfactory, but could be further improved by further developing the model with the aim to take into account explicitly of the individual variation of geometric properties for recycled fibers.

- -

- The capability of the model to simulate the post-cracking behavior is clearly demonstrated. Further, the model is capable to reproduce the contribution of different types of fibers (either straight or hooked, made of steel or propylene) and this is a specific advantage of the proposed meso-mechanical approach;

- -

- The agreement obtained in terms of load-CMOD/CTOD curves is then reflected also in the characteristic parameters of the post-cracking behavior of the material. In fact, the values found are close to the experimental values in terms of work capacity and ductility indices.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yoo, D.Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Grabois, T.M.; Cordeiro, G.C.; Toledo Filho, R.D. Fresh and hardened-state properties of self-compacting lightweight concrete reinforced with steel fibers. Constr. Build. Mater. 2016, 104, 284–292. [Google Scholar] [CrossRef]

- da Silva, M.A.; Pepe, M.; de Andrade, R.G.M.; Pfeil, M.S.; Toledo Filho, R.D. Rheological and mechanical behavior of high strength steel fiber-river gravel self compacting concrete. Constr. Build. Mater. 2017, 150, 606–618. [Google Scholar] [CrossRef]

- Torres, J.A.; Lantsoght, E.O. Influence of Fiber Content on Shear Capacity of Steel Fiber-Reinforced Concrete Beams. Fibers 2019, 7, 102. [Google Scholar] [CrossRef] [Green Version]

- Karimi, M.M.; Darabi, M.K.; Jahanbakhsh, H.; Jahangiri, B.; Rushing, J.F. Effect of steel wool fibers on mechanical and induction heating response of conductive asphalt concrete. Int. J. Pavement Eng. 2019, 1–14. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, D.; Wang, T.; Wu, H.; Li, V.C. Mechanical and self-healing behavior of low carbon engineered cementitious composites reinforced with PP-fibers. Constr. Build. Mater. 2020, 259, 119805. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Tolêdo Filho, R.D. Influence of an impregnation treatment on the morphology and mechanical behaviour of flax yarns embedded in hydraulic lime mortar. Fibers 2019, 7, 30. [Google Scholar] [CrossRef] [Green Version]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef] [Green Version]

- Frazão, C.M.V.; Barros, J.A.O.; Bogas, J.A. Durability of Recycled Steel Fiber Reinforced Concrete in Chloride Environment. Fibers 2019, 7, 111. [Google Scholar] [CrossRef] [Green Version]

- Banthia, N.; Sappakittipakorn, M. Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. Cem. Concr. Res. 2007, 37, 1366–1372. [Google Scholar] [CrossRef]

- Mobasher, B.; Yao, Y.; Soranakom, C. Analytical solutions for flexural design of hybrid steel fiber reinforced concrete beams. Eng. Struct. 2015, 100, 164–177. [Google Scholar] [CrossRef]

- Farina, I.; Fabbrocino, F.; Carpentieri, G.; Modano, M.; Amendola, A.; Goodall, R.; Fraternali, F. On the reinforcement of cement mortars through 3D printed polymeric and metallic fibers. Compos. Part B Eng. 2016, 90, 76–85. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Chi, Y.; Yu, M.; Huang, L.; Xu, L. Finite element modeling of steel-polypropylene hybrid fiber reinforced concrete using modified concrete damaged plasticity. Engineering Structures 2017, 148, 23–35. [Google Scholar] [CrossRef]

- Bošnjak, J.; Sharma, A.; Grauf, K. Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures. Fibers 2019, 7, 9. [Google Scholar] [CrossRef] [Green Version]

- Othman, H.; Marzouk, H.; Sherif, M. Effects of variations in compressive strength and fibre content on dynamic properties of ultra-high performance fibre-reinforced concrete. Constr. Build. Mater. 2019, 195, 547–556. [Google Scholar] [CrossRef]

- Carvalho, M.R.; Barros, J.A.; Zhang, Y.; Dias-da-Costa, D. A computational model for simulation of steel fibre reinforced concrete with explicit fibres and cracks. Comput. Methods Appl. Mech. Eng. 2020, 363, 112879. [Google Scholar] [CrossRef]

- Farina, I.; Modano, M.; Zuccaro, G.; Goodall, R.; Colangelo, F. Improving flexural strength and toughness of geopolymer mortars through additively manufactured metallic rebars. Compos. Part B Eng. 2018, 145, 155–161. [Google Scholar] [CrossRef]

- Abed, F.; Alhafiz, A.R. Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars. Compos. Struct. 2019, 215, 23–34. [Google Scholar] [CrossRef]

- ASTM C1018-97. Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- RILEM-TC-162-TDF. Test and design methods for steel fibre reinforced concrete–bending test, final recommendation. Mater. Struct. 2002, 35, 579–582. [Google Scholar] [CrossRef]

- EN 14651. Test Method for Metallic Fibred Concrete-Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual); CEN: Brussels, Belgium, 2005. [Google Scholar]

- UNI 11039-1. Steel Fiber Reinforced Concrete-Definitions, Classification and Designation; UNI: Milan, Italy, 2003. [Google Scholar]

- UNI 11039-2. Steel Fiber Reinforced Concrete-Test Method to Determine the First Crack Strength and Ductility Indexes; UNI: Milan, Italy, 2003. [Google Scholar]

- Code, M. Fib Model Code for Concrete Structures 2010. Fédération Internationale du Béton; Ernst & Sohn: Berlin, Germany, 2013; p. 434. [Google Scholar]

- Hu, X.D.; Day, R.; Dux, P. Biaxial failure model for fiber reinforced concrete. J. Mater. Civ. Eng. 2003, 15, 609–615. [Google Scholar] [CrossRef]

- Li, F.; Li, Z. Continuum damage mechanics based modeling of fiber reinforced concrete in tension. Int. J. Solids Struct. 2001, 38, 777–793. [Google Scholar] [CrossRef]

- Beghini, A.; Bažant, Z.P.; Zhou, Y.; Gouirand, O.; Caner, F.C. Microplane model M5f for multiaxial behavior and fracture of fiber-reinforced concrete. J. Eng. Mech. 2007, 133, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Ramm, E.; Hund, A.; Hettich, T. A variational multiscale model for composites with special emphasis on the X-FEM and level sets. In Computational Modelling of Concrete Structures: Proceedings of the EURO-C; CRC Press: Boca Raton, FL, USA, 2006; pp. 27–30. [Google Scholar]

- Caggiano, A.; Etse, G.; Martinelli, E. Zero-thickness interface model formulation for failure behavior of fiber-reinforced cementitious composites. Comput. Struct. 2012, 98, 23–32. [Google Scholar] [CrossRef]

- El-Helou, R.G.; Moen, C.D.; Lale, E.; Cusatis, G. Lattice discrete particle modeling of buckling deformation in thin ultra-high-performance fiber-reinforced concrete plates. Comput. Model. Concr. Struct. 2014, 1, 365–371. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modeer, M.; Petersson, P.E. Analysis of Crack Formation and Crack Growth in Concrete by Means of Fracture Mechanics and Finite Elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Olesen, J.F. Fictitious crack propagation in fiber-reinforced concrete beams. J. Eng. Mech. 2001, 127, 272–280. [Google Scholar] [CrossRef]

- Armelin, H.S.; Banthia, N. Predicting the flexural postcracking performance of steel fiber reinforced concrete from the pullout of single fibers. Mater. J. 1997, 94, 18–31. [Google Scholar]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of hybrid fiber reinforced concrete with recycled and industrial steel fibers. Constr. Build. Mater. 2017, 147, 286–295. [CrossRef]

- Caggiano, A.; Gambarelli, S.; Martinelli, E.; Nisticò, N.; Pepe, M. Experimental characterization of the post-cracking response in hybrid steel/polypropylene fiber-reinforced concrete. Constr. Build. Mater. 2016, 125, 1035–1043. [Google Scholar] [CrossRef]

- Farina, I.; Goodall, R.; Hernández-Nava, E.; di Filippo, A.; Colangelo, F.; Fraternali, F. Design, microstructure and mechanical characterization of Ti6Al4V reinforcing elements for cement composites with fractal architecture. Mater. Des. 2019, 172, 107758. [Google Scholar] [CrossRef]

- Khoshhesab, M.M.; Li, Y. Mechanical behavior of 3D printed biomimetic koch fractal contact and interlocking. Extreme Mech. Lett. 2018, 24, 58–65. [Google Scholar] [CrossRef]

- Li, Y.; Ortiz, C.; Boyce, M.C. A generalized mechanical model for suture inter-faces of arbitrary geometry. J. Mech. Phys. Solids 2013, 61, 1144–1167. [Google Scholar] [CrossRef]

- Farina, I.; Fabbrocino, F.; Colangelo, F.; Feo, L.; Fraternali, F. Surface roughness effects on the reinforcement of cement mortars through 3D printed metallic fibers. Compos. Part B Eng. 2016, 99, 305–311. [Google Scholar] [CrossRef]

| Fiber Type | df (mm) | lf (mm) | Hooked End | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| ISF | 0.550 | 33 | Yes | >1200 | 210 |

| RSF | 0.255 | 26 | Yes | >1200 | 210 |

| PPF | 0.032 | 12 | No | 400–500 | 3.5–3.9 |

| Mixture | ISF (kg/m3) | RSF (kg/m3) | PPF (kg/m3) | ISF (%) | RSF (%) | PPF (%) |

|---|---|---|---|---|---|---|

| ISF-FRC | 60.0 | - | - | 0.750 | - | - |

| RSF-FRC | - | 60.0 | - | - | 0.750 | - |

| PPF-FRC | - | - | 6.8 | - | - | 0.750 |

| Hybrid ISF-RSF FRC | 30.0 | 30.0 | 30.0 | 0.375 | 0.375 | - |

| Hybrid ISF-PPF FRC | 45.0 | - | 1.7 | 0.550 | - | 0.200 |

| Parameter | ISF | RSF | PPF |

|---|---|---|---|

| τmax (MPa) | 3.8 | 2.8 | 0.9 |

| sel (mm) | 0.125 | 0.130 | 0.04 |

| su (mm) | 20.0 | 20.0 | 8.0 |

| Fsp (N) | 160 | 36 | - |

| Fsp,r (N) | 140 | 30 | - |

| se,sp (mm) | 6.0 | 6.0 | - |

| se,sp (mm) | 15.0 | 13.0 | - |

| su,sp (mm) | 25.0 | 20.0 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinelli, E.; Pepe, M.; Fraternali, F. Meso-Scale Formulation of a Cracked-Hinge Model for Hybrid Fiber-Reinforced Cement Composites. Fibers 2020, 8, 56. https://doi.org/10.3390/fib8090056

Martinelli E, Pepe M, Fraternali F. Meso-Scale Formulation of a Cracked-Hinge Model for Hybrid Fiber-Reinforced Cement Composites. Fibers. 2020; 8(9):56. https://doi.org/10.3390/fib8090056

Chicago/Turabian StyleMartinelli, Enzo, Marco Pepe, and Fernando Fraternali. 2020. "Meso-Scale Formulation of a Cracked-Hinge Model for Hybrid Fiber-Reinforced Cement Composites" Fibers 8, no. 9: 56. https://doi.org/10.3390/fib8090056

APA StyleMartinelli, E., Pepe, M., & Fraternali, F. (2020). Meso-Scale Formulation of a Cracked-Hinge Model for Hybrid Fiber-Reinforced Cement Composites. Fibers, 8(9), 56. https://doi.org/10.3390/fib8090056