Ultra-Low Power Consuming Direct Radiation Sensors Based on Floating Gate Structures

Abstract

:1. Introduction

1.1. Radiation Sensing Techniques in CMOS Technology

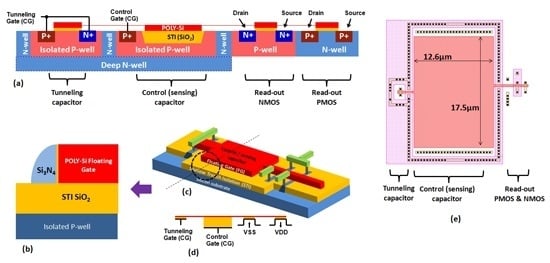

1.2. C-Sensor Principle, Structure and Operation

- The F-N injection occurs in the read-out NMOS transistor. The injection takes place in high electric fields and may cause damage to GOX by introducing charged traps. This charge is not stable, leading to Vt instabilities.

- The sensor requires very high voltages for charge injection into the FG, typically 12–14 V (110 A GOX). These voltages cannot be supplied using the main CMOS platform transistors (5 V), so that special high voltage devices are required to facilitate switching.

- Even if special high-voltage devices were fabricated in a certain CMOS process flavor, to select a sensor for charging in case when sensors are arranged in 2D array, HV devices have to be introduced into each cell.

1.3. Brief Review of Physical Mechanisms Involved in Sensor Operation

- “Emission”. Energetic electrons may transfer a part of their energy (directly or by secondary electrons or holes) to the charges in the FG (Polysilicon) or/and in the substrate. The transferred energy is sufficient for the electrons to overcome the oxide potential barrier, which leads to the discharge of the FG.

- “Separation”. The e-h pairs produced in the dielectric (STI) are separated in the electric field in this dielectric. Some of the electrons and holes reach the FG and discharge it.

2. Methods and Devices

- Single sensors.

- MOS transistors.

- Array sensors.

2.1. Single Sensors

2.2. MOS Transistors

2.3. Array Sensors

3. Experimental Results

3.1. Single Sensors Results

- “Linear” stage (UV irradiation):

- Impact of the periphery length (same FG footprint area): sensors with larger FG periphery (“Comb-FG”) showed higher discharge rate. This corresponds to a model where the FG discharge occurs by emission of electrons from the FG in contact with the STI where adsorption of UV photons takes place.

- Impact of doping: sensors with larger work function difference between FG to CG (with an account of the sign of this difference) showed higher discharge rate (Figure 8a). This observation is explained by two physical peculiarities. First, larger work function difference (between CG and FG) leads to higher electric field enhancing the flow rate of electrons from FG to CG. Secondly, the results suggest that dominating flow of electrons from the negatively charged FG is from the valence band, and not the conduction band. For example, the FG discharge rate is higher in the case of P+ to N− structure, even though the emission for N+ to P− could be assumed to happen from the conduction band of the strongly doped N+ FG.

- “Saturation” stage (UV irradiation):

- Impact of periphery length: the level of Vt saturation does not depend on periphery length. As was already mentioned in Introduction, the discharge kinetics of the FG discharge is connected with the balance of electrons flowing to and from the FG. The final FG charge depends on the electric field distribution, but not on the periphery length, which defines the FG charge decay kinetics.

- Impact of doping: the saturation level decreases as the work function difference between FG and CG decreases. This can be explained by the following mechanism: The intrinsic Vt of the readout transistor depends on the doping of substrate and the FG above it. In our layout, the FG doping over the readout transistor is always N+. The measured Vt of the C-sensor corresponds to a device with charged FG and can be both higher and lower than the intrinsic Vt, depending on the sign of charge in the FG. Let us consider, e.g., a situation when the FG in the control capacitor area is P+ and the opposite electrode (CG) is N−. In this case, there is an electric field in STI under the FG control capacitor area with lines of force starting at CG and terminating at the FG. Under irradiation, the mentioned field will result in continuous separation of the electrons and holes excited by the UV radiation. The electric field decreases to very small values, which corresponds to charging of the FG with positive charge. Actually, the voltage corresponding to this charging is ~0.7–0.8 V (difference between the Fermi levels of P+ and N− silicon). This voltage is connected in series with the gate of the read-out transistor and decreases its effective Vt by ~0.8 V. It is clear that with N+ to P− combination, the generated by radiation voltage will be opposite, and Vt would increase by ~0.7–0.8 V. These considerations explain the observed in Figure 8b ~1.5–1.6 V variation for the fabricated test-structures after prolonged irradiation with UV.

- “Linear” stage (Gamma irradiation):

- Impact of periphery length: the discharge rate in “area-FG” case is higher than in “Comb-FG” case, for all combinations of FG and CG doping. This indicates, first, that edge fields at Poly fingers are not critical in the discharge mechanism. The vertical field under the charged continuous FG in corresponding specimens is higher than for finger type counterparts. Increasing the periphery length of FG did not result in faster discharge. Thus, “separation” mechanism dominates over “emission” mechanism. It is worth mentioning that it could be expected that more sparse Poly fingers would result in increased sensitivity. Nevertheless, such effect was not observed, and even a certain sensitivity decrease was registered. This leads to a conclusion that reduction of STI thickness in “area” type C-Sensor could provide an improvement in its response to radiation.

- Impact of doping: the systematic dependence of discharge rate on doping of CG and FG is observed, mainly in “area-FG” structures: faster discharge corresponds to higher difference between Conduction (or Valence) band energy level of CG and FG (arrow “A” in Figure 10): for higher EC,CG-EC,FG (or EV,CG-EC,FG), the higher response is observed. The weaker dependence on doping in “comb-FG” structures can be explained by lower electrical fields.

- ”Saturation” stage (Gamma irradiation): no dependence of Vt level on FG shape was observed: “comb” and “area” type sensors reached the same level of Vt after continuous discharge. The explanation of this result is similar to the case of UV irradiation. In the case of Gamma rays, electrons and holes can be created inside STI or diffused from the adjacent solid state areas into the STI. Nevertheless, the final state of the system is the same, since the discharge continues up to the stage when the electric field in the control capacitor becomes very small.

3.2. MOS Structures Results

3.3. Array Sensors Results

3.4. Spectral Response

3.4.1. X-ray (100 kVp) vs. Gamma (Co-60) experiment

3.4.2. X-ray Energy Experiment Using 4K Arrays of C-Sensors

3.5. Direct Gamma Imaging

3.6. Energetic Ions Detection

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Auricchioa, N.; Carolia, E.; Donatia, A.; Dusib, W.; Fougeresc, P.; Landinia, G. Thin CdTe detectors mounted in back-to-back confguration: Spectroscopic performance for low-energy X- and Gamma-rays. Radiat. Meas. 2001, 33, 867–872. [Google Scholar] [CrossRef]

- Carroll-Ramsey Associates. Silicon PIN Diode Radiation Detectors; Carroll-Ramsey Associates: Berkeley, CA, USA, 1999; Available online: http://www.carroll-ramsey.com/detect.htm (accessed on 28 July 2017).

- Oliveira, F.; Amaral, L.L.; Costa, A.M.; Netto, T.G. In vivo dosimetry with silicon diodes in total body irradiation. Radiat. Phys. Chem. 2014, 95, 230–232. [Google Scholar] [CrossRef]

- Jackson, T.; Fine, L. Dosimeter Charging and/or Reading Apparatus. U.S. Patent 4,224,522, 23 September 1980. [Google Scholar]

- Rosenfeld, A.B.; Tavernier, S.; Gektin, A.; Grinyov, B.; Moses, W.W. Semiconductor detectors in radiation medicine: Radiotherapy and related applications. In Radiation Detectors for Medical Applications; Springer: New York, NY, USA, 2006; pp. 111–147. [Google Scholar]

- Rosenfeld, A.; Holmes-Siedle, A.; Cornelius, I.M. Edge-on Face-to-Face MOSFET for Synchrotron Microbeam Dosimetry: MC modeling. IEEE Trans. Nucl. Sci. 2005, 22, 2562–2569. [Google Scholar] [CrossRef]

- Holmes-Siedle, A.; Adams, L. RADFET: A review of the use of metal-oxide-silicon devices as integrating dosimeters. Radiat. Phys. Chem. 1986, 28, 235–244. [Google Scholar] [CrossRef]

- Sarrabayrouse, G.; Siskos, S. Low dose measurement with thick gate oxide MOSFETs. Radiat. Phys. Chem. 2012, 81, 339–344. [Google Scholar] [CrossRef]

- Hsieh, W.-C.; Lee, H.-T.D.; Jong, F.-C.; Wu, S.-C. Performance Improvement of Total Ionization Dose Radiation Sensor Devices Using Fluorine-Treated MOHOS. Sensors 2016, 16, 450. [Google Scholar] [CrossRef] [PubMed]

- Scheik, L.Z.; McNulty, P.J.; Roth, D.R. Dosimetry based on the erasure of floating gates in the natural radiation environments in space. IEEE Trans. Nucl. Sci. 1998, 45, 2681–2688. [Google Scholar] [CrossRef]

- Fullem, T.Z.; Lehman, L.P.; Cotts, E.J. Examination of the utility of commercial-off-the-shelf memory devices as X-ray detectors. In Proceedings of the 2007 IEEE Nuclear Science Symposium Conference Record, Honolulu, HI, USA, 26 October–3 November 2007. [Google Scholar]

- Scheick, L.Z.; McNulty, P.J.; Roth, D.R.; Davis, M.; Mason, B.E. Measurements of dose with individual FAMOS transistors. IEEE Trans. Nucl. Sci. 1999, 46, 1751–1756. [Google Scholar] [CrossRef]

- Roizin, Y.; Aloni, E.; Birman, A.; Dayan, V.; Fenigstein, A.; Nahmad, D.; Pikhay, E.; Zfira, D. C-Flash: An Ultra-Low Power Single Poly Logic NVM. In Proceedings of the 2008 Joint Non-Volatile Semiconductor Memory Workshop and International Conference on Memory Technology and Design, Opio, France, 18–21 May 2008; pp. 90–92. [Google Scholar]

- Dagan, H.; Shapira, A.; Teman, A.; Mordakhay, A.; Jameson, S.; Pikhay, E.; Dayan, V.; Roizin, Y.; Socher, E.; Fish, A. A Low-Power Low-Cost 24 GHz RFID Tag With a C-Flash Based Embedded Memory. IEEE J. Solid-State Circuits 2014, 49, 1942–1957. [Google Scholar] [CrossRef]

- Dagan, H.; Teman, A.; Fish, A.; Pikhay, E.; Dayan, V.; Roizin, Y. A Low-Cost Low-Power Non-Volatile Memory for RFID Applications. In Proceedings of the 2012 IEEE International Symposium on Circuits and Systems (ISCAS 2012), Seoul, Korea, 20–23 May 2012. [Google Scholar]

- Tarr, N.G.; Mackay, G.F.; Shortt, K.; Thomson, I. A Floating Gate MOSFET Dosimeter Requiring No External Bias Supply. In Proceedings of the Fourth European Conference on Radiation and Its Effects on Components and Systems (RADECS 1997), Cannes, France, 15–19 September 1997. [Google Scholar]

- Garcia-Moreno, E.; Picos, R.; Isern, E.; Roca, M.; Font, J.; Suenaga, K. CMOS Current Source Based Radiation Sensors. In Proceedings of the 2010 10th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT 2010), Shanghai, China, 1–4 November 2010. [Google Scholar]

- Tarr, N.; Thomson, I. Method of Monitoring Radiation Using a Floating Gate Field Effect Transistior Dosimeter, and Dosimeter for Use Therein. U.S. Patent 6,172,368, 9 January 2001. [Google Scholar]

- Arsalan, M.; Shamim, A.; Tarr, N.; Roy, L. Miniaturized, Low Power FGMOSFET Radiation Sensor and Wireless Dosimeter System. U.S. Patent 12/580,670, 27 August 2013. [Google Scholar]

- Knoll, M.; Braunig, D. MOS Dosimeter. U.S. Patent 4,788,581, 29 November 1988. [Google Scholar]

- Isern, E.; Roca, M.; Garcia-Moreno, E.; Font, J.; Cesari, J.; Pineda, A. Characterization of a floating-gate radiation sensor for X-ray dose detection. In Proceedings of the Radiation and Its Effects on Components and Systems (RADECS 2013), Oxford, UK, 23–27 September 2013. [Google Scholar]

- Cesari, J.; Gómez, D.; Roca, M.; Isern, E.; Pineda, A.; García-Moreno, E. Floating Gate P-MOS Radiation Sensor Charging Cycles Characterization. In Proceedings of the IEEE Radiation Effects Data Workshop (REDW 2014), Paris, France, 14–18 July 2014. [Google Scholar]

- Wang, Y.; Tatv, G.; Wang, Y. A Novel Fully Integrated Floating-Gate MOSFET Radiation Dosimeter Using VTH Extractor. In Proceedings of the 2nd Annual IEEE Northeast Workshop on Circuits and Systems (NEWCAS 2004), Montreal, QC, Canada, 20–23 June 2004. [Google Scholar]

- Martin, M.N.; Roth, D.R.; Garrison-Darrin, A.; McNulty, P.J.; Andreou, A.G. FGMOS dosimetry: Design and implementation. IEEE Trans. Nucl. Sci. 2002, 48, 2050–2055. [Google Scholar] [CrossRef]

- Tarr, N.G.; Shortt, K.; Wang, Y.; Thomson, I. A Sensitive, Temperature-Compensated, Zero-Bias Floating Gate MOSFET Dosimeter. IEEE Trans. Nucl. Sci. 2004, 51, 1277–1282. [Google Scholar] [CrossRef]

- Braunig, D.; Wulf, F. Atomic displacement and total ionizing dose damage in semiconductors. Radiat. Phys. Chem. 1994, 43, 105–127. [Google Scholar] [CrossRef]

- Benedetto, J.; Hughes, H.L. Radiation Effects and Hardening of MOS Technology: Devices and Circuits. IEEE Trans. Nucl. Sci. 2003, 50, 500–521. [Google Scholar]

- Snyder, E.S.; McWhorter, P.J.; Dellin, T.A.; Sweetrnant, J.D. Radiation response of floating gate EEPROM memory cells. IEEE Trans. Nucl. Sci. 1989, 36, 2131–2139. [Google Scholar] [CrossRef]

- McNulty, P.J.; Yow, S.; Scheick, L.Z.; Abdel-Kader, W.G. Charge Removal From FGMOS Floating Gates. IEEE Trans. Nucl. Sci. 2002, 49, 3016–3021. [Google Scholar] [CrossRef]

- Bagatin, M.; Gerardin, S.; Cellere, G.; Paccagnella, A.; Visconti, A.; Bonanomi, M.; Beltrami, S. Error Instability in Floating Gate Flash Memories Exposed to TID. IEEE Trans. Nucl. Sci. 2009, 56, 3267–3273. [Google Scholar] [CrossRef]

- Naumova, O.V.; Fomin, B.I.; Ilnitsky, M.A.; Popov, V.P. Charge accumulation in the buried oxide of SOI structures with the bonded Si/SiO2 interface under γ-irradiation: Effect of preliminary ion implantation. Semicond. Sci. Technol. 2012, 27, 065014. [Google Scholar] [CrossRef]

- Brown, D.B.; Saks, N.S. Time dependence of radiation-induced interface trap formation in metal-oxide-semiconductor devices as a function of oxide thickness and applied field. J. Appl. Phys. 1991, 70, 3734–3747. [Google Scholar] [CrossRef]

- Katznelson, R.; Frohman-Bentchkovsky, D. An Erase Model for FAMOS EPROM Devices. IEEE Trans. Electron Devices 1980, 27, 1744–1752. [Google Scholar] [CrossRef]

- Jafari, H.; Feghhi, S.; Boorboor, S. The effect of interface trapped charge on threshold voltage shift estimation for gamma irradiated MOS device. Radiat. Meas. 2015, 73, 69–77. [Google Scholar] [CrossRef]

- Witczak, S.C.; Lacoe, R.C.; Mayer, D.C.; Fleetwood, D.M.; Schrimpf, R.; Galloway, K.F. Space Charge Limited Degradation of Bipollar Oxides at Low Electric Fields. IEEE Trans. Nucl. Sci. 1998, 45, 2339–2351. [Google Scholar] [CrossRef]

- Miyata, B.; Tawa, N.; Mukai, K.; Tsunemi, H.; Miyaguchi, K. High Resolution X-ray Photon-Counting Detector with Scintillator-deposited Charge-coupled Device. In Proceedings of the IEEE Nuclear Science Symposium Conference Record, Rome, Italy, 16–22 October 2004. [Google Scholar]

- Cha, A.K.; Kim, B.-J.; Cho, G.; Jeon, S.C.; Bae, J.H.; Chi, Y.K.; Lim, G.-H.; Kim, Y.-H. A Pixelated CsI (Tl) Scintillator for CMOS-based X-ray Image Sensor. In Proceedings of the IEEE Nuclear Science Symposium Conference, San Diego, CA, USA, 29 October–1 November 2006. [Google Scholar]

- Spartiotis, K.; Durrant, R.; Leppänen, A.; Lohman, H.; Männistö, O.; Pantsar, T.; Pyyhtiä, J.; Schulman, T. X- and Gamma ray Imaging Systems based on CdTe-CMOS Detector Technology. In Proceedings of the IEEE Nuclear Science Symposium Conference Record, Dresden, Germany, 19–25 October 2008. [Google Scholar]

- Dupont, B.; Dierickx, B.; Ahmed, N. Photon Counting and Color X-ray Imaging in Standard cis Technology. Available online: http://www.caeleste.com/caeleste_publications/Caeleste_photon_counting_color_xray_web.pdf (accessed on 28 July 2017).

- Audzeyeu, M.; Makarevich, Y.; Shvedau, S.; Belous, A.; Pikhay, E.; Dayan, V.; Roizin, Y. Floating Gate Inverter Type Memory Cell and Array. U.S. Patent 8,378,407, 24 June 2010. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pikhay, E.; Roizin, Y.; Nemirovsky, Y. Ultra-Low Power Consuming Direct Radiation Sensors Based on Floating Gate Structures. J. Low Power Electron. Appl. 2017, 7, 20. https://doi.org/10.3390/jlpea7030020

Pikhay E, Roizin Y, Nemirovsky Y. Ultra-Low Power Consuming Direct Radiation Sensors Based on Floating Gate Structures. Journal of Low Power Electronics and Applications. 2017; 7(3):20. https://doi.org/10.3390/jlpea7030020

Chicago/Turabian StylePikhay, Evgeny, Yakov Roizin, and Yael Nemirovsky. 2017. "Ultra-Low Power Consuming Direct Radiation Sensors Based on Floating Gate Structures" Journal of Low Power Electronics and Applications 7, no. 3: 20. https://doi.org/10.3390/jlpea7030020

APA StylePikhay, E., Roizin, Y., & Nemirovsky, Y. (2017). Ultra-Low Power Consuming Direct Radiation Sensors Based on Floating Gate Structures. Journal of Low Power Electronics and Applications, 7(3), 20. https://doi.org/10.3390/jlpea7030020