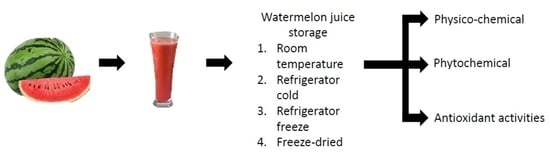

Effect of Storage Temperatures on Physico-Chemicals, Phytochemicals and Antioxidant Properties of Watermelon Juice (Citrullus lanatus)

Abstract

:1. Introduction

2. Results and Discussion

2.1. Weight Loss (%)

2.2. pH

2.3. Ash Content (%)

2.4. Moisture Content (%)

2.5. Total Soluble Solid

2.6. Browning Reaction

2.7. Turbidity

2.8. Total Phenolic Content (TPC)

2.9. Total Flavonoid Content (TFC)

2.10. Antioxidant Scavenging Activities Using DPPH

2.11. Lycopene and β-Carotene Quantification using HPLC-DAD

3. Materials and Methods

3.1. Chemicals and Reagents

3.2. Watermelon Collection

3.3. Preparation of Watermelon Juice

3.4. Weight Loss

3.5. pH

3.6. Ash Content (%)

3.7. Moisture Content (%)

3.8. Total Soluble Solid

3.9. Browning Reaction

3.10. Turbidity

3.11. Total Phenolic Content (TPC)

3.12. Total Flavonoid Content (TFC)

3.13. 2,2-1-Diphenyl-1-picrylhydrazyl (DPPH)

3.14. Extraction Procedure

3.15. Sample and Standard Preparation for HPLC

3.16. HPLC-DAD Analysis of Lycopene and β-Carotene

3.17. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saad, W.M.M.; Salin, N.S.; Ramzi, A.S.M.; Salim, F. Identification and Quantification of Fructose, Glucose and Sucrose in Watermelon Peel Juice. Malays. J. Anal. Sci. 2020, 24, 382–389. [Google Scholar]

- Liu, Y.; He, C.; Song, H. Comparison of fresh watermelon juice aroma characteristics of five varieties based on gas chromatography-olfactometry-mass spectrometry. Food Res. Int. 2018, 107, 119–129. [Google Scholar] [CrossRef]

- Lemos, Á.T.; Ribeiro, A.C.; Delgadillo, I.; Saraiva, J.A. Preservation of raw watermelon juice up to one year by hyperbaric storage at room temperature. LWT 2020, 117, 108695. [Google Scholar] [CrossRef]

- Putnik, P.; Kresoja, Ž.; Bosiljkov, T.; Režek Jambrak, A.; Barba, F.J.; Lorenzo, J.M.; Roohinejad, S.; Granato, D.; Žuntar, I.; Bursać Kovačević, D. Comparing the effects of thermal and non-thermal technologies on pomegranate juice quality: A review. Food Chem. 2019, 279, 150–161. [Google Scholar] [CrossRef]

- Ridwan, R.; Abdul Razak, H.R.; Adenan, M.I.; Md Saad, W.M. Development of isocratic RP-HPLC method for separation and quantification of L-citrulline and L-arginine in watermelons. Int. J. Anal. Chem. 2018, 2018, 4798530. [Google Scholar] [CrossRef] [Green Version]

- Noh, J.J.; Hur, O.S.; Ro, N.Y.; Lee, J.E.; Hwang, A.J.; Kim, B.S.; Rhe, J.S.; Yi, J.Y.; Kim, J.H.; Lee, H.S.; et al. Lycopene Content and Fruit Morphology of Red, Pink, Orange, and Yellow Fleshed Watermelon (Citrullus lanatus) Germplasm Collections. Korean J. Plant Resour. 2020, 33, 624–637. [Google Scholar] [CrossRef]

- Sabeetha, S.; Amin, I.; Nisak, M.Y.B. Physico-chemical characteristics of watermelon in Malaysia. Int. Food Res. J. 2017, 45, 209–223. [Google Scholar]

- Maoto, M.M.; Beswa, D.; Jideani, A.I. Watermelon as a potential fruit snack. Int. J. Food Prop. 2019, 22, 355–370. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Sánchez, A.; Alacid, F.; Rubio-Arias, J.A.; Fernández-Lobato, B.; Ramos-Campo, D.J.; Aguayo, E. Consumption of Watermelon Juice Enriched in l -Citrulline and Pomegranate Ellagitannins Enhanced Metabolism during Physical Exercise. J. Agric. Food Chem. 2017, 65, 4395–4404. [Google Scholar] [CrossRef] [PubMed]

- Shirzad, H.; Alirezalu, A.; Alirezalu, K.; Yaghoubi, M.; Ghorbani, B.; Pateiro, M.; Lorenzo, J.M. Effect of Aloysia citrodora Essential Oil on Biochemicals, Antioxidant Characteristics, and Shelf Life of Strawberry Fruit during Storage. Metabolites 2021, 11, 256. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, W.; Ma, Y.; Zhao, X.; Zhang, C. Effect of Thermal Treatments on Quality and Aroma of Watermelon Juice. J. Food Qual. 2018, 2018, 9242675. [Google Scholar] [CrossRef] [Green Version]

- Buvé, C.; Kebede, B.T.; De Batselier, C.; Carrillo, C.; Pham, H.T.T.; Hendrickx, M.; Grauwet, T.; Van Loey, A. Kinetics of colour changes in pasteurised strawberry juice during storage. J. Food Eng. 2018, 216, 42–51. [Google Scholar] [CrossRef]

- Gómez-López, V.M.; Buitrago, M.E.; Tapia, M.S.; Martínez-Yépez, A. Effect of ultrasonication on sensory and chemical stability of passion fruit juice during refrigerated storage. Emir. J. Food Agric. 2018, 30, 85–89. [Google Scholar] [CrossRef]

- Pinto, C.; Moreira, S.A.; Fidalgo, L.G.; Santos, M.D.; Delgadillo, I.; Saraiva, J.A. Shelf-life extension of watermelon juice preserved by hyperbaric storage at room temperature compared to refrigeration. LWT Food Sci. Technol. 2016, 72, 78–80. [Google Scholar] [CrossRef]

- Queirós, R.P.; Santos, M.D.; Fidalgo, L.G.; Mota, M.J.; Lopes, R.P.; Inácio, R.S.; Delgadillo, I.; Saraiva, J.A. Hyperbaric storage of melon juice at and above room temperature and comparison with storage at atmospheric pressure and refrigeration. Food Chem. 2014, 147, 209–214. [Google Scholar] [CrossRef]

- Guiné, R.; Barroca, M.J. Influence of processing and storage on fruit juices phenolic compounds. Int. J. Med. Biol. Front. 2014, 20, 45. [Google Scholar]

- Ktenioudaki, A.; O’Donnell, C.P.; Emond, J.P.; do Nascimento Nunes, M.C. Blueberry supply chain: Critical steps impacting fruit quality and application of a boosted regression tree model to predict weight loss. Postharvest Biol. Technol. 2021, 179, 111590. [Google Scholar] [CrossRef]

- Qian, L.; Yongbin, L.; Keying, S.; Simei, L.; Shiming, Z.; Ruiting, L.; Wanming, Z.; Shangzhen, H. Effect of drying methods on the texture properties and active ingredients in Longan flesh. E3S Web Conf. 2021, 251, 02049. [Google Scholar] [CrossRef]

- Nasrin, T.A.A.; Rahman, M.A.; Hossain, M.A.; Islam, M.N.; Arfin, M.S. Postharvest quality response of strawberries with aloe vera coating during refrigerated storage. J. Hortic. Sci. Biotechnol. 2017, 92, 598–605. [Google Scholar] [CrossRef]

- Khaliq, G.; Mohamed, M.T.M.; Ding, P.; Ghazali, H.M.; Ali, A. Storage behaviour and quality responses of mango (Mangifera indica L.) fruit treated with chitosan and gum arabic coatings during cold storage conditions. Int. Food Res. J. 2016, 23, S141–S148. [Google Scholar]

- Suriati, L.; Utama, I.M.S.; Harjosuwono, B.A.; Wayan Gunam, I.B. Physicochemical characteristics of fresh-cut tropical fruit during storage. Int. J. Adv. Sci. Eng. Inf. Technol. 2020, 10, 1731–1736. [Google Scholar] [CrossRef]

- Kaddumukasa, P.P.; Imathiu, S.M.; Mathara, J.M.; Nakavuma, J.L. Influence of physicochemical parameters on storage stability: Microbiological quality of fresh unpasteurized fruit juices. Food Sci. Nutr. 2017, 5, 1098–1105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ngamwonglumlert, L.; Devahastin, S.; Chiewchan, N.; Raghavan, V. Plant carotenoids evolution during cultivation, postharvest storage, and food processing: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1561–1604. [Google Scholar] [CrossRef] [PubMed]

- Oyinloye, T.M.; Yoon, W.B. Effect of freeze-drying on quality and grinding process of food produce: A review. Processes 2020, 8, 354. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.K.; Sharma, M. Review on Biochemical Changes Associated with Storage of Fruit Juice. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 236–245. [Google Scholar] [CrossRef] [Green Version]

- Pico, J.; Xu, K.; Guo, M.; Mohamedshah, Z.; Ferruzzi, M.G.; Martinez, M.M. Manufacturing the ultimate green banana flour: Impact of drying and extrusion on phenolic profile and starch bioaccessibility. Food Chem. 2019, 297, 124990. [Google Scholar] [CrossRef]

- Liu, K. Effects of sample size, dry ashing temperature and duration on determination of ash content in algae and other biomass. Algal Res. 2019, 40, 101486. [Google Scholar] [CrossRef]

- Hou, C.; Wang, W.; Song, X.; Wu, L.; Zhang, D. Effects of drying methods and ash contents on heat-induced gelation of porcine plasma protein powder. Foods 2019, 8, 140. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.E.; Wang, C.L.; Shi, B.B.; Pan, X.J. Effect of storage temperature and time on the nutritional quality of walnut male inflorescences. J. Food Drug Anal. 2017, 25, 374–384. [Google Scholar] [CrossRef] [Green Version]

- Ali, S.; Khan, A.S.; Malik, A.U.; Shahid, M. Effect of controlled atmosphere storage on pericarp browning, bioactive compounds and antioxidant enzymes of litchi fruits. Food Chem. 2016, 206, 18–29. [Google Scholar] [CrossRef]

- Tahmasebian, M.; Mahmoudi, R.; Shakouri, M.J. Probiotic viability, physicochemical characterization and sensory properties of cornelian cherry (Cornus mas L.) juice supplemented with lactobacillus acidophilus and lactobacillus delbrueckii. J. Chem. Health Risks 2020, 10, 253–260. [Google Scholar] [CrossRef]

- Siti Mahirah, Y.; Rabeta, M.S.; Antora, R.A. Effects of different drying methods on the proximate composition and antioxidant activities of ocimum basilicum leaves. Food Res. 2018, 2, 421–428. [Google Scholar] [CrossRef]

- Ayomide, O.B.; Ajayi, O.O.; Ajayi, A.A. Advances in the development of a tomato postharvest storage system: Towards eradicating postharvest losses. J. Phys. Conf. Ser. 2019, 1378, 022064. [Google Scholar] [CrossRef]

- Razak, N.A.; Hamid, N.A.; Shaari, A.R. Effect of storage temperature on moisture content of encapsulated Orthosiphon stamineus spray-dried powder. AIP Conf. Proc. 2018, 2030, 020194. [Google Scholar] [CrossRef]

- Jalali, A.; Rux, G.; Linke, M.; Geyer, M.; Pant, A.; Saengerlaub, S.; Mahajan, P. Application of humidity absorbing trays to fresh produce packaging: Mathematical modeling and experimental validation. J. Food Eng. 2019, 244, 115–125. [Google Scholar] [CrossRef]

- FDA Inspection Guides. Guide to Inspections of Lyophilization of Parenterals. Lyophilization Parenter. 2015, 7, 1–23. [Google Scholar]

- Rongtong, B.; Suwonsichon, T.; Ritthiruangdej, P.; Kasemsumran, S. Determination of water activity, total soluble solids and moisture, sucrose, glucose and fructose contents in osmotically dehydrated papaya using near-infrared spectroscopy. Agric. Nat. Resour. 2018, 52, 557–564. [Google Scholar] [CrossRef]

- Mishra, R.; Kar, A. Effect of storage on the physicochemical and flavour attributes of two cultivars of strawberry cultivated in Northern India. Sci. World J. 2014, 2014, 794926. [Google Scholar] [CrossRef]

- Ampofo-Asiama, J.; Quaye, B. The Effect of Pasteurisation on the Physicochemical and Nutritional Quality of Soursop (Annona muricata L.) Juice. Asian Food Sci. J. 2019, 6, 1–8. [Google Scholar] [CrossRef]

- Jerry, A.-A.; Bright, Q. Effect of storage temperature on the physicochemical, nutritional and microbiological quality of pasteurised soursop (Annona muricata L.) Juice. Afr. J. Food Sci. 2019, 13, 38–47. [Google Scholar] [CrossRef]

- Al-Amrani, M.; Al-Alawi, A.; Al-Marhobi, I. Assessment of Enzymatic Browning and Evaluation of Antibrowning Methods on Dates. Int. J. Food Sci. 2020, 2020, 8380461. [Google Scholar] [CrossRef]

- Selli, S.; Canbas, A.; Unal, U. Effect of bottle colour and storage conditions on browning of orange wine. Food/Nahrung 2002, 46, 64–67. [Google Scholar] [CrossRef]

- Donno, D.; Mellano, M.G.; Riondato, I.; De Biaggi, M.; Andriamaniraka, H.; Gamba, G.; Beccaro, G.L. Traditional and unconventional dried fruit snacks as a source of health-promoting compounds. Antioxidants 2019, 8, 396. [Google Scholar] [CrossRef] [Green Version]

- Espley, R.V.; Leif, D.; Plunkett, B.; McGhie, T.; Henry-Kirk, R.; Hall, M.; John, J.W.; Punter, M.P.; Boldingh, H.; Nardozza, S.; et al. Red to brown: An elevated anthocyanic response in apple drives ethylene to advance maturity and fruit flesh browning. Front. Plant Sci. 2019, 10, 1248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chia, S.L.; Rosnah, S.; Noranizan, M.A.; Wan Ramli, W.D. The effect of storage on the quality attributes of ultraviolet-irradiated and thermally pasteurised pineapple juices. Int. Food Res. J. 2012, 19, 1001–1010. [Google Scholar]

- Oziyci, H.R.; Karhan, M.; Tetik, N.; Turhan, I. Effects of processing method and storage temperature on clear pomegranate juice turbidity and color. J. Food Processing Preserv. 2013, 37, 899–906. [Google Scholar] [CrossRef]

- Aghajanzadeh, S.; Kashaninejad, M.; Ziaiifar, A.M. Cloud stability of sour orange juice as affected by pectin methylesterase during come up time: Approached through fractal dimension. Int. J. Food Prop. 2018, 20, S2508–S2519. [Google Scholar] [CrossRef] [Green Version]

- Kim, A.N.; Kim, H.J.; Chun, J.; Heo, H.J.; Kerr, W.L.; Choi, S.G. Degradation kinetics of phenolic content and antioxidant activity of hardy kiwifruit (Actinidia arguta) puree at different storage temperatures. LWT 2018, 89, 535–541. [Google Scholar] [CrossRef]

- Lekjing, S.; Venkatachalam, K. Influences of storage time and temperature on sensory and measured quality of green gram savory crackers. LWT 2019, 113, 108310. [Google Scholar] [CrossRef]

- Ho, L.H.; Ramli, N.F.; Tan, T.C.; Muhamad, N.; Haron, M.N. Effect of extraction solvents and drying conditions on total phenolic content and antioxidant properties of watermelon rind powder. Sains Malays. 2018, 47, 99–107. [Google Scholar] [CrossRef]

- Ali, A.; Chong, C.H.; Mah, S.H.; Abdullah, L.C.; Choong, T.S.Y.; Chua, B.L. Impact of storage conditions on the stability of predominant phenolic constituents and antioxidant activity of dried Piper betle extracts. Molecules 2018, 23, 484. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panche, A.N.; Diwan, A.D.; Chandra, S.R. Flavonoids: An overview. J. Nutr. Sci. 2016, 5, e47. [Google Scholar] [CrossRef] [Green Version]

- Hamidu, L.; Ahmad, A.R.; Najib, A. Qualitative and quantitative test of total flavonoid buni fruit (Antidesma bunius (L.) Spreng) with UV-Vis spectrophotometry method. Pharmacogn. J. 2018, 10, 60–63. [Google Scholar] [CrossRef] [Green Version]

- Giuffrè, A.M.; Louadj, L.; Rizzo, P.; De Salvo, E.; Sicari, V. The influence of film and storage on the phenolic and antioxidant properties of red raspberries (Rubus idaeus L.) cv. Erika. Antioxidants 2019, 8, 254. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yadav, A.; Kumari, R.; Yadav, A.; Mishra, J.P.; Srivatva, S.; Prabha, S. Antioxidants and its functions in human body-A Review. Res. Environ. Life Sci. 2016, 9, 1328–1331. [Google Scholar]

- Gouot, J.C.; Smith, J.P.; Holzapfel, B.P.; Walker, A.R.; Barril, C. Grape berry flavonoids: A review of their biochemical responses to high and extreme high temperatures. J. Exp. Bot. 2019, 70, 397–423. [Google Scholar] [CrossRef]

- Margraf, T.; Karnopp, A.R.; Rosso, N.D.; Granato, D. Comparison between Folin-Ciocalteu and Prussian Blue assays to estimate the total phenolic content of juices and teas using 96-well microplates. J. Food Sci. 2015, 80, C2397–C2403. [Google Scholar] [CrossRef]

- Fallik, E.; Ilić, Z. The Influence of Physical Treatments on Phytochemical Changes in Fresh Produce after Storage and Marketing. Agronomy 2021, 11, 788. [Google Scholar] [CrossRef]

- Lin, Y.S.; Huang, W.Y.; Ho, P.Y.; Hu, S.Y.; Lin, Y.Y.; Chen, C.Y.; Chang, M.Y.; Huang, S.L. Effects of Storage Time and Temperature on Antioxidants in Juice from Momordica charantia L. and Momordica charantia L. var. abbreviata Ser. Molecules 2020, 25, 3614. [Google Scholar] [CrossRef] [PubMed]

- Zorić, Z.; Pelaić, Z.; Pedisić, S.; Elez Garofulić, I.; Bursać Kovačević, D.; Dragović–Uzelac, V. Effect of storage conditions on phenolic content and antioxidant capacity of spray dried sour cherry powder. LWT Food Sci. Technol. 2017, 79, 251–259. [Google Scholar] [CrossRef]

- Zhang, Y.; Truzzi, F.; D’amen, E.; Dinelli, G. Effect of storage conditions and time on the polyphenol content of wheat flours. Processes 2021, 9, 248. [Google Scholar] [CrossRef]

- Zhang, C.-R.; Aldosari, S.A.; Vidyasagar, P.S.P.V.; Shukla, P.; Nair, M.G. Determination of the variability of sugars in date fruit varieties. J. Plant. Crops 2015, 43, 53–61. [Google Scholar]

- Patanè, C.; Malvuccio, A.; Saita, A.; Rizzarelli, P.; Siracusa, L.; Rizzo, V.; Muratore, G. Nutritional changes during storage in fresh-cut long storage tomato as affected by biocompostable polylactide and cellulose based packaging. LWT 2019, 101, 618–624. [Google Scholar] [CrossRef]

- Park, M.H.; Sangwanangkul, P.; Baek, D.R. Changes in carotenoid and chlorophyll content of black tomatoes (Lycopersicone sculentum L.) during storage at various temperatures. Saudi J. Biol. Sci. 2018, 25, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Mezzomo, N.; Ferreira, S.R. Carotenoids functionality, sources, and processing by supercritical technology: A review. J. Chem. 2016, 2016, 3164312. [Google Scholar] [CrossRef] [Green Version]

- Bollinedi, H.; Dhakane-Lad, J.; Gopala Krishnan, S.; Bhowmick, P.K.; Prabhu, K.V.; Singh, N.K.; Singh, A.K. Kinetics of β-carotene degradation under different storage conditions in transgenic Golden Rice® lines. Food Chem. 2019, 278, 773–779. [Google Scholar] [CrossRef]

- Okokon, E.J.; Okokon, E.O. Proximate analysis and sensory evaluation of freshly produced apple fruit juice stored at different temperatures and treated with natural and artificial preservatives. Glob. J. Pure Appl. Sci. 2019, 25, 31. [Google Scholar] [CrossRef]

- Paravisini, L.; Peterson, D.G. Role of Reactive Carbonyl Species in non-enzymatic browning of apple juice during storage. Food Chem. 2018, 245, 1010–1017. [Google Scholar] [CrossRef] [PubMed]

- Amini, M.H.; Kalsi, V.; Kaur, B.; Khatik, G.L.; Lobo, R.; Singh, G.; Agarharu, U.C.; Yele, S.; Suttee, A. Phytochemical screening and antioxidant activity of Heracleum afghanicum Kitamura leaves. Res. J. Pharm. Technol. 2017, 10, 3498–3502. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamad Salin, N.S.; Md Saad, W.M.; Abdul Razak, H.R.; Salim, F. Effect of Storage Temperatures on Physico-Chemicals, Phytochemicals and Antioxidant Properties of Watermelon Juice (Citrullus lanatus). Metabolites 2022, 12, 75. https://doi.org/10.3390/metabo12010075

Mohamad Salin NS, Md Saad WM, Abdul Razak HR, Salim F. Effect of Storage Temperatures on Physico-Chemicals, Phytochemicals and Antioxidant Properties of Watermelon Juice (Citrullus lanatus). Metabolites. 2022; 12(1):75. https://doi.org/10.3390/metabo12010075

Chicago/Turabian StyleMohamad Salin, Nur Shafinaz, Wan Mazlina Md Saad, Hairil Rashmizal Abdul Razak, and Fatimah Salim. 2022. "Effect of Storage Temperatures on Physico-Chemicals, Phytochemicals and Antioxidant Properties of Watermelon Juice (Citrullus lanatus)" Metabolites 12, no. 1: 75. https://doi.org/10.3390/metabo12010075

APA StyleMohamad Salin, N. S., Md Saad, W. M., Abdul Razak, H. R., & Salim, F. (2022). Effect of Storage Temperatures on Physico-Chemicals, Phytochemicals and Antioxidant Properties of Watermelon Juice (Citrullus lanatus). Metabolites, 12(1), 75. https://doi.org/10.3390/metabo12010075