Experimental Studies into the Analysis Required for the Durability Assessment of 7075 and 6061 Cold Spray Repairs to Military Aircraft

Abstract

:1. Introduction

- (i)

- How can we accurately compute crack growth in an AM or SPD repaired part when there is a residual stress field?

- (ii)

- How can we accurately compute crack growth in a cold spray repair where cracking can nucleate, either in the substructure being repaired, or at the intersection between the cold spray?

- (iii)

- How can we accurately perform a durability analysis for a cold spray repair if there are multiple collocated cracks?

- (iv)

- Can we relate da/dN versus ΔK equations, where da/dN is the crack growth rate per cycle and ΔK (= Kmax − Kmin) is the difference between the maximum and minimum values of the stress intensity factor in a load cycle, needed to perform items (i) through (iii) to the corresponding curves determined for the conventionally manufactured material? Here, a is the crack length and N is the number of cycles.

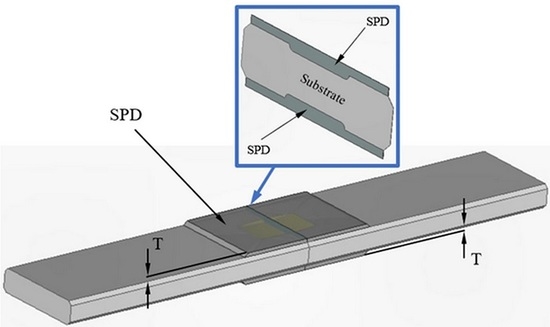

2. Fatigue Tests on 7075 Powder SPD Doublers on 2024-T3 Specimens

3. Repair of Simulated Corrosion in 7075-T7351 Panels

3.1. Test Specimen Geometry and Dimensions

3.2. Fatigue Test Results

3.3. Repair of Simulated Corrosion in a 7075-T6 Panel

4. Damage Tolerance of SPD Repaired Specimens

5. Conclusions

- (a)

- The post heat treatment of the 7075 powder coatings significantly reduced the fatigue life of repaired 7075-T7351 specimens. It is hypothesised that this may be due to its effect on the residual stresses in the repaired specimen.

- (b)

- When compared to the use of 7075 and 6061 powders, the use of AMC powder to repair simulated corrosion in the 7075-T7351 specimen tests led to lower fatigue lives.

Author Contributions

Funding

Conflicts of Interest

Appendix A. The Hartman–Schijve Variant of the Nasgro Crack Growth Equation

References

- Jones, R.; Matthews, N.; Baker, A.; Champagne, V. Aircraft Sustainment and Repair; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 978008100548. [Google Scholar]

- Champagne, V., Jr.; Matthews, N.; Champagne, V., III. Chapter 14: Introduction to Supersonic Particle Deposition. In Aircraft Sustainment and Repair; Jones, R., Matthews, N., Baker, A., Champagne, V., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; pp. 799–844. ISBN 9780081005408. [Google Scholar]

- Matthews, N. Chapter 15: Additive Metal Technologies for Aerospace Sustainment. In Aircraft Sustainment and Repair; Jones, R., Matthews, N., Baker, A., Champagne, V., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; pp. 845–862. ISBN 9780081005408. [Google Scholar]

- Bagherifard, S.; Guagliano, M. Fatigue performance of cold spray deposits: Coating, repair and additive manufacturing cases. Int. J. Fatigue 2020, 139, 105744. [Google Scholar] [CrossRef]

- Champagne, V.; Helfritch, D. Critical Assessment 11: Structural repairs by cold spray. Mater. Sci. Technol. 2015, 31, 627–634. [Google Scholar] [CrossRef]

- Leyman, P.F.; Champagne, V.K. Cold Spray Process Development for the Reclamation of the Apache Helicopter Mast Support, Army Research Laboratory, ARL-TR-4922. August 2009. Available online: https://apps.dtic.mil/sti/pdfs/ADA505530.pdf (accessed on 9 July 2020).

- Jones, R.; Matthews, N.; Peng, D.; Phan, N.; Nguyen, T. Chapter 16, Applications of SPD to enhance the structural integrity of corroded airframes. In Aircraft Sustainment and Repair; Jones, R., Matthews, N., Baker, A., Champagne, V., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; pp. 863–905. ISBN 9780081005408. [Google Scholar]

- Jones, R.; Peng, D.; Matthews, N. Chapter 18, Multiplicative Manufacturing and Aircraft Sustainment. In Aircraft Sustainment and Repair; Jones, R., Matthews, N., Baker, A.A., Champagne, V., Jr., Eds.; Elsevier Butterworth-Heinemann Press: Oxford, UK, 2018; pp. 931–938. ISBN 9780081005408. [Google Scholar]

- Kundu, S.; Jones, R.; Peng, D.; Matthews, N.; Alankar, A.; Singh, R.K.R.; Huang, P. Review of Requirements for the Durability and Damage Tolerance Certification of Additively Manufactured Aircraft Structural Parts and AM Repairs. Materials 2020, 13, 1341. [Google Scholar] [CrossRef] [Green Version]

- Jones, R.; Matthews, N.; Green, R.; Peng, D. On the potential of supersonic particle deposition to repair simulated corrosion damage. Eng. Fract. Mech. 2015, 137, 26–33. [Google Scholar] [CrossRef]

- Jones, R.; Matthews, N.; Rodopoulos, C.A.; Cairns, K.; Pitt, S. On the Use of Supersonic Particle Deposition to Restore the Structural Integrity of Damaged Aircraft Structures. Int. J. Fatigue 2011, 33, 1257–1267. [Google Scholar] [CrossRef]

- Jones, R.; Molent, L.; Barter, S.; Matthews, N.; Tamboli, D. Supersonic Particle Deposition as a Means for Enhancing the Structural Integrity of Aircraft Structures. Int. J. Fatigue 2014, 68, 260–268. [Google Scholar] [CrossRef]

- White, B.; Story, W.; Brewer, L.; Jordon, J.B. Fatigue behaviour of fastener holes in high-strength aluminum plates repaired by cold spray deposition. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 317–329. [Google Scholar] [CrossRef]

- Jones, R. Synchrotron radiation microcomputed tomography for assessing internal cracks in cold spray repairs. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 431–432. [Google Scholar] [CrossRef]

- Yandouzi, M.; Gaydos, S.; Guo, D.; Ghelichi, R.; Jodoin, B. Aircraft Skin Restoration and Evaluation. J. Therm. Spray Technol. 2006, 23, 1281–1290. [Google Scholar] [CrossRef]

- Sample, C.M.; Champagne, V.K.; Nardi, A.T.; Lados, D.A. Factors Governing Static Properties and Fatigue, Fatigue Crack Growth, and Fracture Mechanisms in Cold Spray Alloys and Coatings/Repairs: A Review. Addit. Manuf. 2020, 36, 101371. [Google Scholar] [CrossRef]

- Gavras, A.G.; Lados, D.A.; Champagne, V.K.; Warren, R.J.; Singh, D. Small Fatigue Crack Growth Mechanisms and Interfacial Stability in Cold-Spray 6061 Aluminum Alloys and Coatings. Met. Mater. Trans. A 2018, 49A, 6509–6520. [Google Scholar] [CrossRef] [Green Version]

- Ghelichi, R.; MacDonald, D.; Bagherifard, S.; Jahed, H.; Guagliano, M.; Jodoin, B. Microstructure and fatigue behavior of cold spray coated Al5052. Acta Mater. 2012, 60, 6555–6561. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Vezzú, S.; Trško, L.; Guagliano, M. Fatigue behavior of cold spray coatings: The effect of conventional and severe shot peening as pre-/post-treatment. Surf. Coat. Technol. 2015, 283, 247–254. [Google Scholar] [CrossRef]

- Price, T.S.; Shipway, P.H.; McCartney, D.G. Effect of Cold Spray Deposition of a Titanium Coating on Fatigue Behavior of a Titanium Alloy. J. Therm. Spray Technol. 2006, 15, 507–512. [Google Scholar] [CrossRef]

- Cizek, J.; Matejkova, M.; Dlouhy, I.; Siska, F.; Kay, C.M.; Karthikeyan, S.J.; Kuroda, S.; Kovarik, O.; Siegl, J.; Loke, K.; et al. Influence of Cold-Sprayed, Warm-Sprayed, and Plasma-Sprayed Layers Deposition on Fatigue Properties of Steel Specimens. J. Therm. Spray Technol. 2015, 25, 758–768. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, M.E.; Zhang, W.Z.L. Nondestructive inspection of fatigue crack propagation beneath supersonic particle deposition coatings during fatigue testing. Int. J. Fatigue 2017, 102, 149–157. [Google Scholar] [CrossRef]

- Structures Bulletin EZ-SB-19-01. Durability and Damage Tolerance Certification for Additive Manufacturing of Aircraft Structural Metallic Parts; Wright Patterson Air Force Base: Montgomery, OH, USA, 2019; Available online: https://daytonaero.com/usaf-structures-bulletins-library/ (accessed on 2 February 2020).

- MIL-STD-1530D. Department of Defense Standard Practice Aircraft Structural Integrity Program (ASIP). 13 October 2016. Available online: http://everyspec.com/MIL-STD/MIL-STD/download.php?spec=MIL-STD-1530D (accessed on 2 February 2020).

- Department of Defense Joint Service Specification Guide, Aircraft Structures, JSSG-2006, October 1998. Available online: http://everyspec.com/USAF/USAF-General/JSSG-2006_10206/ (accessed on 2 February 2020).

- Jones, R. Fatigue crack growth and damage tolerance. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 463–483. [Google Scholar] [CrossRef]

- Schijve, J. Fatigue crack growth, physical understanding and practical application. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 867–871. [Google Scholar] [CrossRef]

- Kirby, B.R.; Beevers, C.J. Slow fatigue crack growth and threshold behaviour in air and vacuum of commercial aluminium alloys. Fatigue Eng. Mater. Struct. 1979, 1, 203–215. [Google Scholar] [CrossRef]

- Petit, J.; Ranganathan, N.; de Fouquet, J. Vacuum Effect on Propagation at Fatigue Crack Low Rate, Fracture and Fatigue: Elasto-Plasticity, Thin Sheet and Micromechanisms Problems, Proceedings of the Third Colloqium on Fracture, ECF 3, London, UK, 8–10 September 1980; Radon, J., Ed.; Elsevier: Oxford, UK, 1980; pp. 329–337. ISBN 0-08-026161-2. Available online: https://books.google.com.au/books?id=_jkvBQAAQBAJ&pg=PA329&lpg=PA329&dq=Petit+Vacuum+effect+on+fatigue+crack+propagation&source=bl&ots=OPiIUu29IJ&sig=ACfU3U3MGo1vbmnH1gUczwoTv-LDCaeo6Q&hl=en&sa=X&ved=2ahUKEwjOoM6H1cTqAhVNU30KHfd-BxcQ6AEwAnoECAsQAQ#v=onepage&q=Petit%20Vacuum%20effect%20on%20fatigue%20crack%20propagation&f=false (accessed on 11 July 2020).

- Ritchie, R.O. Near-threshold fatigue-crack propagation in steels. Int. Met. Rev. 1979, 5–6, 205–230. [Google Scholar]

- Wanhill, R.H.; Barter, S.; Molent, L. Fatigue Crack Growth Failure and Lifing Analyses for Metallic Aircraft Structures and Components; Springer: Dordrecht, The Netherlands, 2019; ISBN 978-94-024-1673-2. [Google Scholar]

- Molent, L.; Dixon, B. Airframe metal fatigue revisited. Int. J. Fatigue 2020, 131, 105323. [Google Scholar] [CrossRef]

- Molent, L.; Barter, S.A.; Wanhill, R.J.H. The lead crack fatigue lifing framework. Int. J. Fatigue 2011, 33, 323–331. [Google Scholar] [CrossRef]

- Manning, S.D.; Yang, Y.N. USAF Durability Design Handbook: Guidelines for the Analysis and Design of Durable Aircraft Structures, AFWAL-TR-83-3027, Flight Dynamics Directorate, Wright Laboratory, Air Force Systems Command, Wright-Patterson Air Force Base, January 1984. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a206286.pdf (accessed on 16 May 2020).

- Berens, A.P.; Hovey, P.W.; Skinn, D.A. Risk Analysis for Aging Aircraft Fleets–Volume 1: Analysis, WL-TR-91-3066, Flight Dynamics Directorate, Wright Laboratory, Air Force Systems Command, Wright-Patterson Air Force Base, October 1991. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a252000.pdf (accessed on 26 June 2020).

- Gallagher, J.P.; Molent, L. The Equivalence of EPS and EIFS Based on the Same Crack Growth Life Data. Int. J. Fatigue 2015, 80, 162–170. [Google Scholar] [CrossRef]

- Jones, R.; Peng, D.; McMillan, A. Chapter 5, Crack growth from naturally occurring material discontinuities. In Aircraft Sustainment and Repair; Jones, R., Matthews, N., Baker, A.A., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; pp. 129–190. ISBN 9780081005408. [Google Scholar]

- Jones, R.; Singh Raman, R.K.; McMillan, A.J. Crack growth: Does microstructure play a role? Eng. Fract. Mech. 2018, 187, 190–210. [Google Scholar] [CrossRef]

- Jones, R.; Tamboli, D. Implications of the lead crack philosophy and the role of short cracks in combat aircraft. Eng. Fail. Anal. 2013, 29, 149–166. [Google Scholar] [CrossRef]

- Caton, M.J.; John, R.; Porter, W.J.; Burb, M.E. Stress ratio effects on small fatigue crack growth in Ti-6Al-4V. Int. J. Fatigue 2012, 138, 36–45. [Google Scholar] [CrossRef]

- Hu, X.T.; Zhu, L.; Jiang, R.; Song, Y.D.; Qu, S.D. Small fatigue crack growth behavior of titanium alloy TC4 at different stress ratios. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 339–351. [Google Scholar] [CrossRef] [Green Version]

- Dowson, A.L.; Hollis, A.C.; Beevers, C.J. The effect of the alpha phase volume fraction and stress ratio on the fatigue crack growth characteristics of the near? alpha IMI 834 Ti alloy. Int. J. Fatigue 1992, 14, 261–270. [Google Scholar] [CrossRef]

- Masuda, K.; Oguma, N.; Ishihara, S.; McEvily, A.J. Investigation of subsurface fatigue crack growth behavior of D2 tool steel (JIS SKD11) based on a novel measurement method. Int. J. Fatigue 2020, 133, 105395. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Nakamura, T.; Takeuchi, A.; Uesugi, M.; Uesugi, K. Initiation and growth behaviour of small internal fatigue cracks in Ti-6Al-4V via synchrotron radiation microcomputed tomography. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2093–2105. [Google Scholar] [CrossRef]

- Virkler, D.A.; Hillberry, B.M.; Goel, P.K. The statistical nature of fatigue crack propagation. Trans. ASME 1979, 101, 148–153. [Google Scholar] [CrossRef]

- ASTM. Measurement of Fatigue Crack Growth Rates; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Molent, L.; Jones, R. The influence of cyclic stress intensity threshold on fatigue life scatter. Int. J. Fatigue 2016, 82, 748–756. [Google Scholar] [CrossRef]

- Jones, R.; Huang, P.; Peng, D. Crack growth from naturally occurring material discontinuities under constant amplitude and operational loads. Int. J. Fatigue 2016, 91, 434–444. [Google Scholar] [CrossRef]

- Jones, R.; Molent, L.; Barter, S. Calculating crack growth from small discontinuities in 7050-T7451 under combat aircraft spectra. Int. J. Fatigue 2013, 55, 178–182. [Google Scholar] [CrossRef]

- Carlson, R.L.; Cappelli, M.D.; Kardomateas, G.A. An investigation of the growth of multi-site fatigue cracks. Int. J. Fracture 2007, 145, 329–332. [Google Scholar] [CrossRef]

- Suh, C.M.; Kitagawa, H. Crack growth behaviour of fatigue microcracks in low carbon steels. Fatigue Fract. Eng. Mater. Struct. 1987, 9, 409–424. [Google Scholar] [CrossRef]

- Larsen, J.M.; Jha, S.K.; Szczepanski, C.J.; Caton, M.J.; John, R.; Rosenberger, A.H.; Buchanan, D.J.; Golden, P.J.; Jira, J.R. Reducing uncertainty in fatigue life limits of turbine engine alloys. Int. J. Fatigue 2013, 57, 103–112. [Google Scholar] [CrossRef] [Green Version]

- Mayén, J.; Abúndez, A.; Pereyra, I.; Colín, J.; Blanco, A.; Serna, S. Comparative analysis of the fatigue short crack growth on Al 6061-T6 alloy by the exponential crack growth equation and a proposed empirical model. Eng. Fract. Mech. 2017, 177, 203–217. [Google Scholar] [CrossRef]

- Carlson, R.L.; Steadman, D.L.; Dancila, D.S.; Kardomateas, K.A. An experimental investigation of the growth of small corner fatigue cracks in aluminium 6061-T651. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 403–409. [Google Scholar] [CrossRef]

- McEvily, A.J.; Eifler, D.; Macherauch, E. An analysis of the growth of short fatigue cracks. Eng. Fract. Mech. 1991, 40, 571–584. [Google Scholar] [CrossRef]

- Endo, M.; McEvily, A.J. Prediction of the behaviour of small fatigue cracks. Mater. Sci. Eng. A 2007, 468–470, 51–58. [Google Scholar] [CrossRef]

- Little, R.; Ekvall, J. ASTM E 739-80: Standard Practice for Statistical Analysis of Linearized Stress-Life (S-N) and Strain-Life (E-N) Fatigue Data. In Annual Book of ASTM Standards; ASTM International: Philadelphia, PA, USA, 1989. [Google Scholar]

- Monsalve, A.; Paez, M.; Toledano, M.; Artigas, A.; Sepulveda, Y.; Valencia, Y.N. S-N-P curves in 7075 T7351 and 2024 T3 aluminium alloys subjected to surface treatments. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 748–758. [Google Scholar] [CrossRef]

- Forman, R.G.; Mettu, S.R. Behavior of Surface and Corner Cracks Subjected to Tensile and Bending Loads in Ti-6Al-4V Alloy, Fracture Mechanics 22nd Symposium; Ernst, H.A., Saxena, A., McDowell, D.L., Eds.; American Society for Testing and Materials: Philadelphia, PA, USA, 1992; Volume 1. ASTM STP 1131. [Google Scholar]

- Elber, W. The Significance of Fatigue Crack Closure, Damage Tolerance in Aircraft Structures; American Society for Testing and Materials: Philadelphia, PA, USA, 1971; Volume ASTM STP 486, pp. 230–242. [Google Scholar]

- Ritchie, R.O.; Yu, W.; Blom, A.F.; Holm, D.K. An analysis of crack tip shielding in aluminium alloy 2124: A comparison of large, small through-crack and surface fatigue cracks. Fatigue Fract. Eng. Mater. Struct. 1987, 10, 343–363. [Google Scholar] [CrossRef]

- Schwalbe, K.H. On the Beauty of Analytical Models for Fatigue Crack Propagation and Fracture-A Personal Historical Review; Fatigue and Fracture Mechanics; ASTM International: West Conshohocken, PA, USA, 2011; Volume 37, pp. 3–73. [Google Scholar] [CrossRef]

- Main, B.; Evans, R.; Walker, K.; Yu, X.; Molent, L. Lessons from a Fatigue Prediction Challenge for an Aircraft Wing Shear Tie Post. Int. J. Fatigue 2019, 123, 53–65. [Google Scholar] [CrossRef]

- Jones, R.; Peng, D.; Singh Raman, R.K.; Huang, P. Computing the growth of small cracks in the assist round robin helicopter challenge. Metals 2020, 10, 944. [Google Scholar] [CrossRef]

- Jones, R.; Matthews, N.; Peng, D.; Phan, N.; Nguyen, T.T. Damage Tolerant Assessment of Additively Manufactured Replacement Parts. In Proceedings of the 13th International Conference on the Mechanical Behaviour of Materials (ICM13), Melbourne, Australia, 11–14 June 2019; pp. 384–393, ISBN 978-1-922016-65-2. [Google Scholar]

| Specimen | SPD Powder | Heat Treated | Cycles to Failure | Description |

|---|---|---|---|---|

| 7075_F_1 | 7075 | NO | 71,408 | Multiple cracks |

| 7075_F_2 | 62,488 | Multiple cracks | ||

| 7075_F_3 | 83,590 | Multiple cracks | ||

| 7075_F_4 | 70,754 | Multiple cracks | ||

| 6061_F_1 | 6061 | NO | 121,467 | Multiple cracks |

| 6061_F_2 | 87,958 | Multiple cracks | ||

| 6061_F_3 | 82,409 | Multiple cracks | ||

| 6061_F_4 | 79,384 | Multiple cracks | ||

| 7075HT_F_1 | 7075 | YES | 36,284 | Multiple cracks |

| 7075HT_F_2 | 36,677 | Multiple cracks | ||

| 7075HT_F_3 | 32,847 | Multiple cracks | ||

| AMC_F_1 | AMC | NO | 38,677 | Multiple cracks |

| AMC_F_2 | 33,103 | Multiple cracks | ||

| AMC_F_3 | 48,638 | Multiple cracks | ||

| AMC LT-NGB_1 * | AMC | NO | 54,801 | Multiple cracks |

| AMC LT **-NGB_2 | 56,790 | Multiple cracks |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jones, R.; Matthews, N.; Peng, D.; Raman, R.K.S.; Phan, N. Experimental Studies into the Analysis Required for the Durability Assessment of 7075 and 6061 Cold Spray Repairs to Military Aircraft. Aerospace 2020, 7, 119. https://doi.org/10.3390/aerospace7090119

Jones R, Matthews N, Peng D, Raman RKS, Phan N. Experimental Studies into the Analysis Required for the Durability Assessment of 7075 and 6061 Cold Spray Repairs to Military Aircraft. Aerospace. 2020; 7(9):119. https://doi.org/10.3390/aerospace7090119

Chicago/Turabian StyleJones, Rhys, Neil Matthews, Daren Peng, R. K. Singh Raman, and Nam Phan. 2020. "Experimental Studies into the Analysis Required for the Durability Assessment of 7075 and 6061 Cold Spray Repairs to Military Aircraft" Aerospace 7, no. 9: 119. https://doi.org/10.3390/aerospace7090119

APA StyleJones, R., Matthews, N., Peng, D., Raman, R. K. S., & Phan, N. (2020). Experimental Studies into the Analysis Required for the Durability Assessment of 7075 and 6061 Cold Spray Repairs to Military Aircraft. Aerospace, 7(9), 119. https://doi.org/10.3390/aerospace7090119