The Influence of Steady Air Jet on the Trailing-Edge Shock Loss in a Supersonic Compressor Cascade

Abstract

:1. Introduction

2. Numerical Methods and Validation

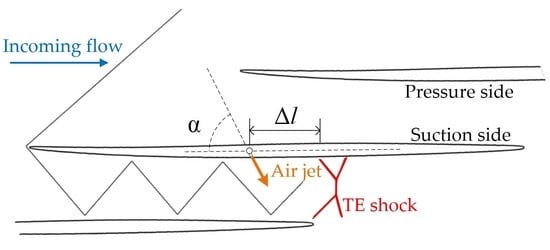

2.1. Physical Model

2.2. Turbulence Model Selection and Mesh Independent Validation

3. Results and Discussion

3.1. Analysis of the Effect of the Air Jet Control

3.2. Effect of Different Parameters

3.2.1. Effect of Strength of Air Jet

3.2.2. Effect of Air Jet Location

3.2.3. Effect of Angle of Air Jet

3.3. Discussion

4. Conclusions

- Under high back-pressure, a Mach reflection will form near the trailing edge of a “shock-in-type” supersonic cascade. The air jet upstream of the trailing-edge shock can effectively change the pattern of the trailing-edge shock, turning Mach reflection into regular reflection. It forms an oblique shock wave in the cascade passage, so that the airflow is decelerated and pressurized in advance, and the expansion wave downstream of the jet slot interferes with the trailing-edge shock and weakens the strength of the shock. The air jet can reduce the total pressure loss coefficient under the same pressure rise with a total pressure loss improvement effect of 7.29%.

- There is an optimal range for the strength of the air jet. Noticeable effect can be achieved when the total pressure of the air jet is in the range 160–180 kPa, corresponding to a mass flow rate ratio of 0.35–1.11%. The weak jet shock cannot decelerate and pressurize the airflow in the entire passage. As the strength increases, the pressure rise caused by the trailing-edge shock will be more moderate. Once the strength exceeds the range, the control effect is weakened.

- The location of the air jet determines the intersection location of the shock induced by the air jet and the trailing-edge shock. If the intersection is in the passage, the air jet cannot affect the trailing-edge fully. If the air jet is arranged far away from the trailing-edge shock, the airflow will re-accelerate after the jet shock and the control effect is weakened. The best control effect can be achieved when the distance from the jet slot to the shock foot of the trailing-edge shock is about five times the thickness of the boundary layer.

- The angle of the air jet has limited effect on loss control due to the weak penetration of the jet. As the direction of the air jet gradually deflects towards the incoming flow, the mass flow rate of injection increases slightly and the tangential momentum injected by the air jet into the downstream boundary layer increases. The negative impact of the air jet on the boundary layer decreases. The best control effect can be achieved at 30° to 40°.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- John, A.; Shahpar, S.; Qin, N. Alleviation of Shock-Wave Effects on a Highly Loaded Axial Compressor Through Novel Blade Shaping. In Turbomachinery; American Society of Mechanical Engineers: Seoul, Korea, 2016; Volume 2A, p. V02AT37A040. [Google Scholar] [CrossRef]

- Zhu, D.; Zheng, X. Fuel consumption and emission characteristics in asymmetric twin-scroll turbocharged diesel engine with two exhaust gas recirculation circuits. Appl. Energy 2019, 238, 985–995. [Google Scholar] [CrossRef]

- Cao, Z.; Gao, X.; Zhang, T.; Liu, B. Flow Mechanism and Aspiration Strategies in an Ultra-Highly Loaded Supersonic Compressor Cascade. Aerosp. Sci. Technol. 2020, 104, 105989. [Google Scholar] [CrossRef]

- Hubrich, K.; Bo¨lcs, A.; Ott, P. Boundary Layer Suction via a Slot in a Transonic Compressor: Numerical Parameter Study and First Experiments. In Turbo Expo 2004, Parts A and B; ASMEDC: Vienna, Austria, 2004; Volume 5, pp. 527–536. [Google Scholar] [CrossRef]

- Schuler, B.J.; Kerrebrock, J.L.; Merchant, A. Experimental Investigation of a Transonic Aspirated Compressor. J. Turbomach. 2005, 127, 340–348. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, X. Review of design optimization methods for turbomachinery aerodynamics. Prog. Aerosp. Sci. 2017, 93, 1–23. [Google Scholar] [CrossRef]

- Song, B.; Ng, W.; Sonoda, T.; Arima, T. Loss Mechanisms of High-Turning Supercritical Compressor Cascades. J. Propuls. Power 2008, 24, 416–423. [Google Scholar] [CrossRef]

- Liu, B.; Shi, H.; Yu, X. A New Method for Rapid Shock Loss Evaluation and Reduction for the Optimization Design of a Supersonic Compressor Cascade. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2018, 232, 2458–2476. [Google Scholar] [CrossRef]

- Sun, X.; Yang, S.; Zhao, Q. Shock Loss Model and Blade Profile Optimization Design of a Supersonic Cascade. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 1325–1329. [Google Scholar] [CrossRef]

- Sonoda, T.; Olhofer, M.; Arima, T.; Sendhoff, B. A New Concept of a Two-Dimensional Supersonic Relative Inlet Mach Number Compressor Cascade. In Turbomachinery, Parts A and B; ASMEDC: Orlando, FL, USA, 2009; Volume 7, pp. 555–565. [Google Scholar] [CrossRef]

- Song, P.; Sun, J. Blade Shape Optimization for Transonic Axial Flow Fan. J. Mech. Sci. Technol. 2015, 29, 931–938. [Google Scholar] [CrossRef]

- Razavi, S.R.; Sammak, S.; Boroomand, M. Multidisciplinary Design and Optimizations of Swept and Leaned Transonic Rotor. J. Eng. Gas Turbines Power 2017, 139, 122601. [Google Scholar] [CrossRef]

- Cao, Z.; Gao, X.; Zhang, X.; Zhang, F.; Liu, B. Effect of Endwall Passage Vortex Generator on Corner Stall of a Tandem Compressor Cascade. Int. J. Heat Fluid Flow 2022, 94, 108946. [Google Scholar] [CrossRef]

- John, A.; Qin, N.; Shahpar, S. Using Shock Control Bumps to Improve Transonic Fan/Compressor Blade Performance. J. Turbomach. 2019, 141, 081003. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Mao, X.; Liu, B. Numerical Investigation of Secondary Flow Control by Boundary Layer Suction on the End-Wall in a Highly-Loaded Axial Compressor Cascade. J. Aeronaut. Astronaut. Aviat. 2021, 53, 483–496. [Google Scholar] [CrossRef]

- Wang, Z.; Chang, J.; Zhang, J.; Ma, J. Investigations on Flowfield Behavior and Resistance Backpressure Characteristics of Supersonic Cascade with Boundary Layer Suction. Acta Astronaut. 2018, 152, 588–601. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Wu, Y.; Li, Y.; Zhu, Y. Supersonic Compressor Cascade Flow Control Using Plasma Actuation at Low Reynolds Number. Phys. Fluids 2022, 34, 027105. [Google Scholar] [CrossRef]

- Liu, Q.; Luo, Z.; Deng, X.; Wang, D.; Wang, L.; Zhou, Y.; Cheng, P. Fine Structures of Self-Sustaining Dual Jets in Supersonic Crossflow. Acta Astronaut. 2019, 164, 262–267. [Google Scholar] [CrossRef]

- Liu, Q.; Luo, Z.; Deng, X.; Zhou, Y.; Wang, L.; Cheng, P. Vortical Structures and Density Fluctuations Analysis of Supersonic Forward-Facing Step Controlled by Self-Sustaining Dual Synthetic Jets. Acta Mech. Sin. 2020, 36, 1215–1227. [Google Scholar] [CrossRef]

- Ma, J.; Yang, G.; Zhou, L.; Ji, L.; Zhang, C. Effect of a Blade End Slot on Supersonic Compressor Cascade Hub-Corner Separation. Aerosp. Sci. Technol. 2021, 118, 107032. [Google Scholar] [CrossRef]

- Benini, E.; Biollo, R.; Ponza, R. Efficiency Enhancement in Transonic Compressor Rotor Blades Using Synthetic Jets: A Numerical Investigation. Appl. Energy 2011, 88, 953–962. [Google Scholar] [CrossRef]

- Klinner, J.; Hergt, A.; Grund, S.; Willert, C.E. Experimental Investigation of Shock-Induced Separation and Flow Control in a Transonic Compressor Cascade. Exp. Fluids 2019, 60, 96. [Google Scholar] [CrossRef]

- Telisinghe, J.C.; Ireland, P.T.; Jones, T.V.; Barrett, D.; Son, C. Comparative Study Between a Cut-Back and Conventional Trailing Edge Film Cooling System. In Heat Transfer, Parts A and B; ASMEDC: Barcelona, Spain, 2006; Volume 3, pp. 983–993. [Google Scholar] [CrossRef]

- Bernardini, C.; Salvadori, S.; Martelli, F.; Paniagua, G.; Saracoglu, B.H. Pulsating Coolant Ejection Effects Downstream of Supersonic Trailing Edge. Eng. Appl. Comput. Fluid Mech. 2013, 7, 250–260. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Wei, M.; Fu, W.; Zheng, Q.; Yue, G. Experimental and Numerical Investigations of Trailing Edge Injection in a Transonic Turbine Cascade. Aerosp. Sci. Technol. 2019, 92, 258–268. [Google Scholar] [CrossRef]

- Szwaba, R. Influence of Air-Jet Vortex Generator Diameter on Separation Region. J. Therm. Sci. 2013, 22, 294–303. [Google Scholar] [CrossRef]

- Szwaba, R. Shock Wave Induced Separation Control by Streamwise Vortices. J. Therm. Sci. 2005, 14, 249–253. [Google Scholar] [CrossRef]

- Souverein, L.J.; Debiève, J.-F. Effect of Air Jet Vortex Generators on a Shock Wave Boundary Layer Interaction. Exp. Fluids 2010, 49, 1053–1064. [Google Scholar] [CrossRef] [Green Version]

- Verma, S.B.; Manisankar, C. Control of Compression-Ramp-Induced Interaction with Steady Microjets. AIAA J. 2019, 57, 2892–2904. [Google Scholar] [CrossRef]

- Verma, S.B.; Manisankar, C. Shockwave/Boundary-Layer Interaction Control on a Compression Ramp Using Steady Micro Jets. AIAA J. 2012, 50, 2753–2764. [Google Scholar] [CrossRef]

- Liu, Y.Z. Investigation on the Organization Method of Passage Shock Wave and Control of Leading-Edge Passage Shock Wave/Boundary-Layer Interaction within “Shock-in-Type” Supersonic Compressor; University of Chinese Academy of Sciences, Institute of Engineering: Beijing, China, 2021. (In Chinese) [Google Scholar]

- Kazuyasu, M.; Yoshiaki, M.; Heuy-Dong, K. Shock train and pseudo-shock phenomena in internal gas flows. Prog. Aerosp. Sci. 1999, 35, 33–100. [Google Scholar] [CrossRef]

- Ahmed, K.A.; Moody, J.K.; Forliti, D.J. The Effect of Slot Jet Size on the Confined Transverse Slot Jet. Exp. Fluids 2008, 45, 13–26. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Chord (mm) | 155 |

| Pitch (mm) | 70 |

| Incoming Mach number | 1.75 |

| Leading-edge radius (mm) | 0.2 |

| Trailing-edge radius (mm) | 0.2 |

| Stagger angle (°) | 70 |

| Geometric inlet angle (°) | 70.5 |

| Geometric outlet angle (°) | 72 |

| Case Number | Total Pressure of Air Jet (kPa) | mr (%) | J | ω (%) | ωj (%) | Δωj (%) |

|---|---|---|---|---|---|---|

| Case 0 | / | / | / | 16.56 | 16.56 | / |

| Case 1 | 130 | 0.07 | 0.014 | 16.47 | 16.43 | 0.78 |

| Case 2 | 145 | 0.18 | 0.051 | 16.24 | 16.13 | 2.57 |

| Case 3 | 165 | 0.45 | 0.066 | 15.82 | 15.56 | 6.01 |

| Case 4 | 175 | 0.84 | 0.070 | 15.79 | 15.35 | 7.29 |

| Case 5 | 210 | 1.84 | 0.172 | 16.44 | 15.65 | 5.58 |

| Case Number | Location of Air Jet () | mr (%) | ω (%) | ωj (%) | Δωj (%) |

|---|---|---|---|---|---|

| Case 6 | 2 | 0.45 | 15.99 | 15.75 | 4.91 |

| Case 3 | 5 | 0.45 | 15.82 | 15.56 | 6.01 |

| Case 7 | 8 | 0.45 | 16.02 | 15.77 | 4.79 |

| Case 8 | 10 | 0.45 | 16.28 | 16.03 | 3.22 |

| Case Number | Angle of Air Jet (°) | Total Pressure of Air Jet (kPa) | mr (%) | ω (%) | ωj (%) | Δωj (%) |

|---|---|---|---|---|---|---|

| Case 9 | 20 | 165 | 5.83 | 15.82 | 15.49 | 6.43 |

| Case 10 | 30 | 165 | 6.78 | 15.76 | 15.39 | 7.09 |

| Case 11 | 40 | 165 | 6.66 | 15.76 | 15.39 | 7.06 |

| Case 12 | 50 | 165 | 6.17 | 15.77 | 15.43 | 6.84 |

| Case 13 | 60 | 165 | 5.69 | 15.78 | 15.47 | 6.59 |

| Case 14 | 70 | 165 | 5.26 | 15.79 | 15.50 | 6.38 |

| Case 15 | 90 | 165 | 4.54 | 15.82 | 15.56 | 6.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Luo, Z.; Peng, W.; Liu, Q.; Zhou, Y.; Xie, W.; Cheng, P.; Ma, Z.; Xie, X. The Influence of Steady Air Jet on the Trailing-Edge Shock Loss in a Supersonic Compressor Cascade. Aerospace 2022, 9, 713. https://doi.org/10.3390/aerospace9110713

Zhu Y, Luo Z, Peng W, Liu Q, Zhou Y, Xie W, Cheng P, Ma Z, Xie X. The Influence of Steady Air Jet on the Trailing-Edge Shock Loss in a Supersonic Compressor Cascade. Aerospace. 2022; 9(11):713. https://doi.org/10.3390/aerospace9110713

Chicago/Turabian StyleZhu, Yinxin, Zhenbing Luo, Wenqiang Peng, Qiang Liu, Yan Zhou, Wei Xie, Pan Cheng, Zhengxue Ma, and Xuzhen Xie. 2022. "The Influence of Steady Air Jet on the Trailing-Edge Shock Loss in a Supersonic Compressor Cascade" Aerospace 9, no. 11: 713. https://doi.org/10.3390/aerospace9110713

APA StyleZhu, Y., Luo, Z., Peng, W., Liu, Q., Zhou, Y., Xie, W., Cheng, P., Ma, Z., & Xie, X. (2022). The Influence of Steady Air Jet on the Trailing-Edge Shock Loss in a Supersonic Compressor Cascade. Aerospace, 9(11), 713. https://doi.org/10.3390/aerospace9110713