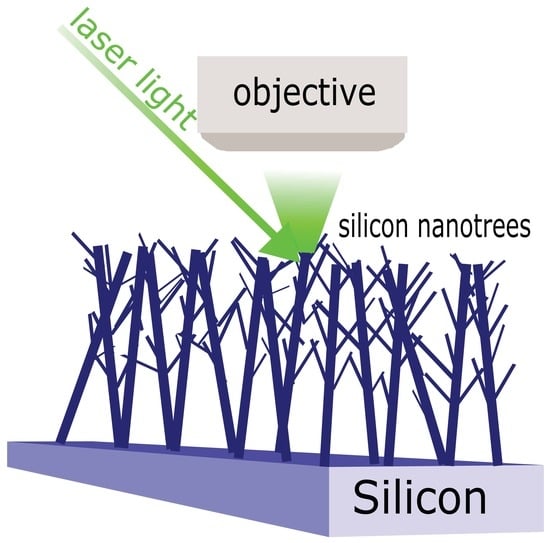

Engineering SERS Properties of Silicon Nanotrees at the Nanoscale

Abstract

:1. Introduction

2. Experimental

2.1. Substrate Preparation

2.2. Characterization Techniques

2.3. Silicon Nanotree Synthesis

- (a)

- High-density trunk nanostructure growth

- (b)

- Branch synthesis

3. Results

3.1. Morphology of SiNTR

3.1.1. Synthesis Method A—Temperature Dependence on SiNTr Growth

3.1.2. Synthesis Method B—Branch Density in Correlation with Cycle Numbers

3.2. The Flexibility of the Structure in Correlation with Metal Plating

3.3. SERS

4. Discussion

4.1. Discussion on NTr Nanostructure and SERS

4.2. Additional Optimization Parameters

4.3. Issues and Limitations

5. Conclusions

- Branches can be successfully synthesized during simultaneous temperature and gas pressure decrease

- The high number of trunks per unit area can be achieved using Ag-Au catalysts

- Forming gas improves branch synthesis

- The synthesis temperature for branch growth should be above 500 °C, while 0.25 mbar SiH4 shots are used

- Metal plating should be below 20 nm to preserve branch elasticity

- Trunk regrowth can be diminished by minimizing shot/cycle duration and number

- Branches contribute to SERS, however, there is a certain density that should not be traversed

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wagner, R.S.; Ooherty, C.J. Mechanism of Branching and Kinking during VLS Crystal Growth. J. Electrochem. Soc. 1968, 115, 93. [Google Scholar] [CrossRef]

- Cheng, C.; Fan, H.J. Branched nanowires: Synthesis and energy applications. Nano Today 2012, 7, 327–343. [Google Scholar] [CrossRef]

- Thissandier, F.; Gentile, P.; Brousse, T.; Bidan, G.; Sadki, S. Are tomorrow’s micro-supercapacitors hidden in a forest of silicon nanotrees? J. Power Sources 2014, 269, 740–746. [Google Scholar] [CrossRef]

- Xu, Q.; Meng, G.; Han, F. Porous AAO template-assisted rational synthesis of large-scale 1D hybrid and hierarchically branched nanoarchitectures. Prog. Mater. Sci. 2018, 95, 243–285. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H. Nanowires for high-efficiency, low-cost solar photovoltaics. Crystals 2019, 9, 87. [Google Scholar] [CrossRef] [Green Version]

- Dhalluin, F.; Desŕ, P.J.; den Hertog, M.I.; Rouvìre, J.L.; Ferret, P.; Gentile, P.; Baron, T. Critical condition for growth of silicon nanowires. J. Appl. Phys. 2007, 102, 094906. [Google Scholar] [CrossRef]

- Wan, Q.; Huang, J.; Xie, Z.; Wang, T.; Dattoli, E.N.; Lu, W. Branched SnO2 nanowires on metallic nanowire backbones for ethanol sensors application. Appl. Phys. Lett. 2008, 92, 102101. [Google Scholar] [CrossRef]

- Zhou, W.; Dai, X.; Lieber, C.M. Advances in nanowire bioelectronics. Rep. Prog. Phys. 2017, 80, 16701. [Google Scholar] [CrossRef] [Green Version]

- Jung, Y.; Ko, D.K.; Agarwal, R. Synthesis and structural characterization of single-crystalline branched nanowire heterostructures. Nano Lett. 2007, 7, 264–268. [Google Scholar] [CrossRef]

- Dick, K.A.; Deppert, K.; Larsson, M.W.; Mårtensson, T.; Seifert, W.; Wallenberg, L.R.; Samuelson, L. Synthesis of branched “nanotrees” by controlled seeding of multiple branching events. Nat. Mater. 2004, 3, 380–384. [Google Scholar] [CrossRef]

- Bierman, M.J.; Jin, S. Potential applications of hierarchical branching nanowires in solar energy conversion. Energy Environ. Sci. 2009, 2, 1050–1059. [Google Scholar] [CrossRef]

- Song, M.; Zhang, Y.; Chun, J.; Hu, S.; Tang, M.; Li, D. Effects of catalyst droplets on wire growth and the resulting branched structures during VLS growth. Nanoscale 2020, 12, 7538–7543. [Google Scholar] [CrossRef]

- Yan, C.; Li, X.; Zhou, K.; Pan, A.; Werner, P.; Mensah, S.L.; Vogel, A.T.; Schmidt, V. Heteroepitaxial growth of GaSb nanotrees with an ultra-low reflectivity in a broad spectral range. Nano Lett. 2012, 12, 1799–1805. [Google Scholar] [CrossRef]

- Cheng, C.; Liu, B.; Yang, H.; Zhou, W.; Sun, L.; Chen, R.; Yu, S.F.; Zhang, J.; Gong, H.; Sun, H.; et al. Hierarchical assembly of ZnO nanostructures on SnO2 backbone nanowires: Low-temperature hydrothermal preparation and optical properties. ACS Nano 2009, 3, 3069–3076. [Google Scholar] [CrossRef]

- Zhang, C.; Tian, W.; Xu, Z.; Wang, X.; Liu, J.; Li, S.L.; Tang, D.M.; Liu, D.; Liao, M.; Bando, Y.; et al. Photosensing performance of branched CdS/ZnO heterostructures as revealed by in situ TEM and photodetector tests. Nanoscale 2014, 6, 8084–8090. [Google Scholar] [CrossRef]

- Dong, A.; Tang, R.; Buhro, W.E. Solution-based growth and structural characterization of homo- and heterobranched semiconductor nanowires. J. Am. Chem. Soc. 2007, 129, 12254–12262. [Google Scholar] [CrossRef]

- Gebavi, H.; Ristić, D.; Baran, N.; Mikac, L.; Mohaček-Grošev, V.; Gotić, M.; Šikić, M.; Ivanda, M. Horizontal silicon nanowires for surface-enhanced Raman spectroscopy. Mater. Res. Express. 2018, 5, 015015. [Google Scholar] [CrossRef]

- Risović, D.; Gebavi, H.; Ivanda, M. Influence of fractal and lacunar characteristic of a nanostructured substrate on SERS enhancement. Appl. Surf. Sci. 2021, 537, 147915. [Google Scholar] [CrossRef]

- Bousiakou, L.G.; Gebavi, H.; Mikac, L.; Karapetis, S.; Ivanda, M. Surface enhanced Raman spectroscopy for molecular identification- A review on surface plasmon resonance (SPR) and localised surface plasmon resonance (LSPR) in optical nanobiosensing. Croat. Chem. Acta 2019, 92, 479–494. [Google Scholar] [CrossRef]

- Gebavi, H.; Gašparić, V.; Risović, D.; Baran, N.; Albrycht, P.H.; Ivanda, M. Features and advantages of flexible silicon nanowires for SERS applications. Beilstein J. Nanotechnol. 2019, 10, 725–734. [Google Scholar] [CrossRef]

- Gebavi, H.; Ristić, D.; Baran, N.; Marciuš, M.; Gašparić, V.; Syed, K.; Ivanda, M. Development of silicon nanowires based on Ag-Au metal alloy seed system for sensing technologies. Sens. Actuators A Phys. 2021, 331, 112931. [Google Scholar] [CrossRef]

- den Hertog, M.I.; Rouviere, J.L.; Dhalluin, F.; Desré, P.J.; Gentile, P.; Ferret, P.; Oehler, F.; Baron, T. Control of gold surface diffusion on Si nanowires. Nano Lett. 2008, 8, 1544–1550. [Google Scholar] [CrossRef] [PubMed]

- Doerk, G.S.; Ferralis, N.; Carraro, C.; Maboudian, R. Growth of branching Si nanowires seeded by Au-Si surface migration. J. Mater. Chem. 2008, 18, 5376–5381. [Google Scholar] [CrossRef]

- Sadeghipari, M.; Mehrvar, L.; Hajmirzaheydarali, M.; Salehi, F.; Mohajerzadeh, S.; Tavassoli, H. Pressure-induced formation of highly controlled branched silicon nanowires suitable for broadband absorption. J. Mater. Sci. Mater. Electron. 2016, 27, 12903–12912. [Google Scholar] [CrossRef]

- Wang, D.; Qian, F.; Yang, C.; Zhong, Z.; Lieber, C.M. Rational growth of branched and hyperbranched nanowire structures. Nano Lett. 2004, 4, 871–874. [Google Scholar] [CrossRef]

- Gentile, P.; David, T.; Dhalluin, F.; Buttard, D.; Pauc, N.; den Hertog, M.; Ferret, P.; Baron, T. The growth of small diameter silicon nanowires to nanotrees. Nanotechnology 2008, 19, 125608. [Google Scholar] [CrossRef]

- Nebolsin, V.A. Critical parametres of quasi-one-dimensional growth of nanowires according to the scheme vapor→ liquid drop → crystal. Mater. Res. Soc. Symp. Proc. 2011, 1350, 24–29. [Google Scholar] [CrossRef]

- Schmidt, M.S.; Hübner, J.; Boisen, A. Large area fabrication of leaning silicon nanopillars for Surface Enhanced Raman Spectroscopy. Adv. Mater. 2012, 24, OP11–OP18. [Google Scholar] [CrossRef]

- Doerk, G.S.; Radmilovic, V.; Maboudian, R. Branching induced faceting of Si nanotrees. Appl. Phys. Lett. 2010, 96, 2012–2015. [Google Scholar] [CrossRef]

- Gaboriau, D.; Aradilla, D.; Brachet, M.; le Bideau, J.; Brousse, T.; Bidan, G.; Gentile, P.; Sadki, S. Silicon nanowires and nanotrees: Elaboration and optimization of new 3D architectures for high performance on-chip supercapacitors. RSC Adv. 2016, 6, 81017–81027. [Google Scholar] [CrossRef]

- Kern, W. The Evolution of Silicon Wafer Cleaning Technology. J. Electrochem. Soc. 1990, 137, 1887. [Google Scholar] [CrossRef]

- Liu, M.; Sun, L.; Cheng, C.; Hu, H.; Shen, Z.; Fan, H.J. Nanoscale Highly effective SERS substrates based on an atomic-layer-deposition- tailored nanorod array scaffold. Nanoscale 2011, 3, 3627–3630. [Google Scholar] [CrossRef] [Green Version]

- Pal, P.; Bonyár, A.; Veres, M.; Himics, L.; Balázs, L.; Juhász, L.; Csarnovics, I. A generalized exponential relationship between the surface-enhanced Raman scattering (SERS) efficiency of gold/silver nanoisland arrangements and their non-dimensional interparticle distance/particle diameter ratio. Sens. Actuators A Phys. 2020, 314, 112225. [Google Scholar] [CrossRef]

- le Ru, E.C.; Etchegoin, P.G. Quantifying SERS enhancements. MRS Bull. 2013, 38, 631–640. [Google Scholar] [CrossRef]

- Li, S.; Zhang, N.; Zhang, N.; Lin, D.; Hu, X.; Yang, X. Three-dimensional ordered Ag/ZnO/Si hierarchical nanoflower arrays for spatially uniform and ultrasensitive SERS detection. Sens. Actuators B Chem. 2020, 321, 128519. [Google Scholar] [CrossRef]

- Chen, Y.C.; Hsu, J.H.; Hsu, Y.K. Branched silver nanowires on fluorine-doped tin oxide glass for simultaneous amperometric detection of H2O2 and of 4-aminothiophenol by SERS. Microchim. Acta 2018, 185, 106. [Google Scholar] [CrossRef]

- Zalaffi, M.S.; Litti, L.; Canton, P.; Meneghetti, M.; Moretto, L.M.; Ugo, P. Preparation and characterization of Ag-nanostars@Au-nanowires hierarchical nanostructures for highly sensitive surface enhanced Raman spectroscopy. Nano Express 2020, 1, 020006. [Google Scholar] [CrossRef]

- Khan, M.A.; Hogan, T.P.; Shanker, B. Gold-coated zinc oxide nanowire-based substrate for surface-enhanced Raman spectroscopy. J. Raman Spectrosc. 2009, 40, 1539–1545. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.B.; Gong, Q.H.; Teng, J.H.; Hong, M.H. High aspect ratio SiNW arrays with Ag nanoparticles decoration for strong SERS detection. Nanotechnology 2014, 25, 465707. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gebavi, H.; Pál, P.; Csarnovics, I.; Gašparić, V.; Ivanda, M. Engineering SERS Properties of Silicon Nanotrees at the Nanoscale. Chemosensors 2022, 10, 534. https://doi.org/10.3390/chemosensors10120534

Gebavi H, Pál P, Csarnovics I, Gašparić V, Ivanda M. Engineering SERS Properties of Silicon Nanotrees at the Nanoscale. Chemosensors. 2022; 10(12):534. https://doi.org/10.3390/chemosensors10120534

Chicago/Turabian StyleGebavi, Hrvoje, Petra Pál, István Csarnovics, Vlatko Gašparić, and Mile Ivanda. 2022. "Engineering SERS Properties of Silicon Nanotrees at the Nanoscale" Chemosensors 10, no. 12: 534. https://doi.org/10.3390/chemosensors10120534

APA StyleGebavi, H., Pál, P., Csarnovics, I., Gašparić, V., & Ivanda, M. (2022). Engineering SERS Properties of Silicon Nanotrees at the Nanoscale. Chemosensors, 10(12), 534. https://doi.org/10.3390/chemosensors10120534