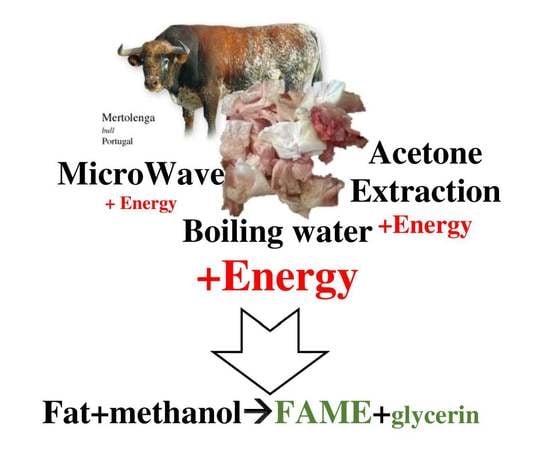

Rendering of Beef Tallow for Biodiesel Production: Microwave versus Boiling Water and Acetone Fat Extraction

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shan, R.; Zhao, C.; Lv, P.; Yuan, H.; Yao, J. Catalytic applications of calcium rich waste materials for biodiesel: Current state and perspectives. Energy Convers. Manag. 2016, 127, 273–283. [Google Scholar] [CrossRef]

- Luque, R.; Lovett, J.C.; Datta, B.; Clancy, J.; Campelo, J.M.; Romero, A.A. Biodiesel as feasible petrol fuel replacement: A multidisciplinary overview. Energy Environ. Sci. 2010, 3, 1706–1721. [Google Scholar] [CrossRef]

- Gasparatos, A.; Stromberg, P.; Takeuchi, K. Sustainability impacts of first-generation biofuels. Anim. Front. 2013, 3, 12–26. [Google Scholar] [CrossRef]

- Chong, C.T.; Loe, T.Y.; Wong, K.Y.; Ashokkumar, V.; Lam, S.S.; Chong, W.T.; Borrion, A.; Tian, B.; Ng, J.H. Biodiesel sustainability: The global impact of potential biodiesel production on the energy–water–food (EWF) nexus. Environ. Technol. Innov. 2021, 22, 101408. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Adamu, A.; Zhu, Z. Economic evaluation and production process simulation of biodiesel production from waste cooking oil. Curr. Res. Green Sustain. Chem. 2021, 4, 100091. [Google Scholar] [CrossRef]

- Festel, G.; Bellof, M.; Würmseher, M.; Rammer, C.; Boles, E. Calculation of raw material prices and conversion costs for biofuels. Lect. Notes Energy 2014, 27, 93–115. [Google Scholar] [CrossRef]

- Bashir, M.A.; Wu, S.; Zhu, J.; Krosuri, A.; Khan, M.U.; Ndeddy Aka, R.J. Recent development of advanced processing technologies for biodiesel production: A critical review. Fuel Process. Technol. 2022, 227, 107120. [Google Scholar] [CrossRef]

- Sander, A.; Antonije Košćak, M.; Kosir, D.; Milosavljević, N.; Parlov Vuković, J.; Magić, L. The influence of animal fat type and purification conditions on biodiesel quality. Renew. Energy 2018, 118, 752–760. [Google Scholar] [CrossRef]

- Habib, M.S.; Tayyab, M.; Zahoor, S.; Sarkar, B. Management of animal fat-based biodiesel supply chain under the paradigm of sustainability. Energy Convers. Manag. 2020, 225, 113345. [Google Scholar] [CrossRef]

- UFOP Report on Global Market Supply European and World Demand for Biomass for the Purpose of Biofuel Production in Relation to Supply in the Food and Feedstuff Markets; UFOP: Ouro Preto, Brazil, 2018.

- Stojković, I.J.; Miladinović, M.R.; Stamenković, O.S.; Banković-Ilić, I.B.; Povrenović, D.S.; Veljković, V.B. Biodiesel production by methanolysis of waste lard from piglet roasting over quicklime. Fuel 2016, 182, 454–466. [Google Scholar] [CrossRef]

- Mata, T.M.; Mendes, A.M.; Caetano, N.S.; Martins, A.A. Properties and sustainability of biodiesel from animal fats and fish oil. Chem. Eng. Trans. 2014, 38, 175–180. [Google Scholar]

- Vafakish, B.; Barari, M. Biodiesel production by transesterification of tallow fat using heterogeneous Catalysis. Kem. Ind. 2017, 66, 47–52. [Google Scholar] [CrossRef] [Green Version]

- Banković-Ilić, I.B.; Stojković, I.J.; Stamenković, O.S.; Veljkovic, V.B.; Hung, Y.T. Waste animal fats as feedstocks for biodiesel production. Renew. Sustain. Energy Rev. 2014, 32, 238–254. [Google Scholar] [CrossRef] [Green Version]

- Ramos, M.; Dias, A.P.S.; Puna, J.F.; Gomes, J.; Bordado, J.C. Biodiesel production processes and sustainable raw materials. Energies 2019, 12, 4408. [Google Scholar] [CrossRef] [Green Version]

- Adewale, P.; Dumont, M.J.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- Wyatt, V.T.; Hess, M.A.; Dunn, R.O.; Foglia, T.A.; Haas, M.J.; Marmer, W.N. Fuel properties and nitrogen oxide emission levels of biodiesel produced from animal fats. J. Am. Oil Chem. Soc. 2005, 82, 585–591. [Google Scholar] [CrossRef]

- Ikura, M.; Kouchachvili, L.; Caravaggio, G. Production of biodiesel from waste fat and grease. Lect. Notes Energy Environ. 2007, 25–30. [Google Scholar]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Trends in biodiesel production from animal fatwaste. Appl. Sci. 2020, 10, 3644. [Google Scholar] [CrossRef]

- Woodgate, S.; van der Veen, J. The role of fat processing and rendering in the European Union animal production industry. Biotechnol. Agron. Soc. Environ. 2004, 8, 283–294. [Google Scholar]

- Meeker, D.L. ESSENTIAL Rendering All About The Animal By-Products Industry; The National Renderers Association The Fats and Proteins Research Foundation The Animal Protein Producers Industry: Alexandria, VA, USA, 2006; ISBN 0965466035. [Google Scholar]

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kazimierowicz, J.; Zieliński, M.; Dębowski, M. Influence of the heating method on the efficiency of biomethane production from expired food products. Fermentation 2021, 7, 12. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Kazimierowicz, J. The effect of electromagnetic microwave radiation on methane fermentation of selected energy crop species. Process 2022, 10, 45. [Google Scholar] [CrossRef]

- Jákói, Z.; Lemmer, B.; Hodúr, C.; Beszédes, S. Microwave and ultrasound based methods in sludge treatment: A review. Appl. Sci. 2021, 11, 7067. [Google Scholar] [CrossRef]

- Quesada-Salas, M.C.; Delfau--bonnet, G.; Willig, G.; Préat, N.; Allais, F.; Ioannou, I. Optimization and comparison of three cell disruption processes on lipid extraction from microalgae. Process 2021, 9, 369. [Google Scholar] [CrossRef]

- Aguado-Deblas, L.; Estevez, R.; Russo, M.; La Parola, V.; Bautista, F.M.; Testa, M.L. Microwave-assisted glycerol etherification over sulfonic acid catalysts. Materials 2020, 13, 1584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nomanbhay, S.; Ong, M.Y. A review of microwave—Assisted reactions for biodiesel production. Bioengineering 2017, 4, 57. [Google Scholar] [CrossRef] [Green Version]

- Sharma, H.; Giriprasad, R.; Goswami, M. Animal fat-processing and its quality control. J. Food Process. Technol. 2013, 4, 8. [Google Scholar] [CrossRef] [Green Version]

- Lin, L.; Liu, D.; Chen, M.; Kuo, H.; Tan, F. Influence of rendering methods on the yield and quality characteristics of chicken fat from broiler skin fat. Asian-Australas J. Anim. Sci. 2013, 30, 2011–2013. [Google Scholar]

- Sheu, K.S.; Chen, T.C. Yield and quality characteristics of edible broiler skin fat as obtained from five rendering methods. J. Food Eng. 2002, 55, 263–269. [Google Scholar] [CrossRef]

- Hewavitharana, G.G.; Perera, D.N.; Navaratne, S.B.; Wickramasinghe, I. Extraction methods of fat from food samples and preparation of fatty acid methyl esters for gas chromatography: A review. Arab. J. Chem. 2020, 13, 6865–6875. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Allen, J.D.; Kanitkar, A.; Boldor, D. Oil extraction from Scenedesmus obliquus using a continuous microwave system—design, optimization, and quality characterization. Bioresour. Technol. 2011, 102, 3396–3403. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Badruddin, I.A.; Mahlia, T.M.I.; Masjuki, H.H.; Mekhilef, S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev. 2012, 16, 2070–2093. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Hagos, F.Y.; Mamat, R.; Adam, A.A.; Ishak, W.F.W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sustain. Energy Rev. 2017, 72, 497–509. [Google Scholar] [CrossRef]

- Dias, A.P.S.; Ramos, M.; Catarino, M.; Puna, J.; Gomes, J. Towards biodiesel sustainability: Solvent assisted biodiesel production by co-processing beef tallow and soybean oil over calcium catalysts. Energy Fuels 2020, 11, 6249–6259. [Google Scholar]

- Marwaha, A.; Rosha, P.; Mohapatra, S.K.; Mahla, S.K.; Dhir, A. Waste materials as potential catalysts for biodiesel production: Current state and future scope. Fuel Process. Technol. 2018, 181, 175–186. [Google Scholar] [CrossRef]

- Soares Dias, A.P.; Puna, J.; Neiva Correia, M.J.; Nogueira, I.; Gomes, J.; Bordado, J. Effect of the oil acidity on the methanolysis performances of lime catalyst biodiesel from waste frying oils (WFO). Fuel Process. Technol. 2013, 116, 94–100. [Google Scholar] [CrossRef]

- EN 14214:2003; Automotive Fuels—Fatty acid Methyl Esters (FAME) for Diesel Engines—Requirements. European Committee for Standardization (Comité Européen de Normalisation): Brussel, Belgium, 2003.

- Dias, A.P.S.; Puna, J.; Gomes, J.; Ramos, M.; Rijo, B.; Bordado, J. The role of alkali dopants on the oil methanolysis behavior of lime catalyst: Activity & stability. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 748–757. [Google Scholar] [CrossRef]

- Soares Dias, A.P.; Catarino, M.; Gomes, J. Co-processing lard/soybean oil over Ca-based catalysts to greener biodiesel. Environ. Technol. Innov. 2021, 21, 101220. [Google Scholar] [CrossRef]

- Soares Dias, A.P.; Puna, J.; Gomes, J.; Neiva Correia, M.J.; Bordado, J. Biodiesel production over lime. Catalytic contributions of bulk phases and surface Ca species formed during reaction. Renew. Energy 2016, 99, 622–630. [Google Scholar] [CrossRef]

- Soares Dias, A.P.; Ramos, M.; Catarino, M.; Costa Pereira, M.F. Biodiesel by Co-processing animal fat/vegetable oil mixtures over basic heterogeneous Ca catalyst. Clean. Eng. Technol. 2020, 1, 100012. [Google Scholar] [CrossRef]

- Jayakumar, M.; Karmegam, N.; Gundupalli, M.P.; Bizuneh Gebeyehu, K.; Tessema Asfaw, B.; Chang, S.W.; Ravindran, B.; Kumar Awasthi, M. Heterogeneous base catalysts: Synthesis and application for biodiesel production—A review. Bioresour. Technol. 2021, 331, 125054. [Google Scholar] [CrossRef] [PubMed]

- Catarino, M.; Ramos, M.; Dias, A.P.S.; Santos, M.T.; Puna, J.F.; Gomes, J.F. Calcium rich food wastes based catalysts for biodiesel production. Waste Biomass Valorization 2017, 8, 1699–1707. [Google Scholar] [CrossRef]

- Dias, A.P.S.; Ramos, M. On the storage stability of CaO biodiesel catalyst. Hydration and carbonation poisoning. J. Environ. Chem. Eng. 2021, 9, 104917. [Google Scholar] [CrossRef]

- Xing, R.; Qin, Y.; Guan, X.; Liu, S.; Yu, H.; Li, P. Comparison of antifungal activities of scallop shell, oyster shell and their pyrolyzed products. Egypt. J. Aquat. Res. 2013, 39, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Odetoye, T.E.; Agu, J.O.; Ajala, E.O. Biodiesel production from poultry wastes: Waste chicken fat and eggshell. J. Environ. Chem. Eng. 2021, 9, 105654. [Google Scholar] [CrossRef]

- Iasmin, M.; Dean, L.O.; Ducoste, J.J. Quantifying fat, oil, and grease deposit formation kinetics. Water Res. 2016, 88, 786–795. [Google Scholar] [CrossRef]

- Demirbas, A. Thermal degradation of fatty acids in biodiesel production by supercritical methanol. Energy Explor. Exploit. 2007, 25, 63–70. [Google Scholar] [CrossRef] [Green Version]

- Saluja, R.K.; Kumar, V.; Sham, R. Stability of biodiesel—A review. Renew. Sustain. Energy Rev. 2016, 62, 866–881. [Google Scholar] [CrossRef]

- Joseph, P. Oxidative Stability and Shelf Life of Bulk Animal Fats and Poultry Fats; Elsevier Inc.: Amsterdam, The Netherlands, 2016; ISBN 9781630670566. [Google Scholar]

- Borchman, D.; Sinha, S. Determination of products of lipid oxidation by infrared spectroscopy. Methods Mol. Biol. 2002, 186, 21–28. [Google Scholar] [CrossRef]

- Christy, A.A.; Egeberg, P.K. Quantitative determination of saturated and unsaturated fatty acids in edible oils by infrared spectroscopy and chemometrics. Chemom. Intell. Lab. Syst. 2006, 82, 130–136. [Google Scholar] [CrossRef]

- Nina Naquiah, A.N.; Marikkar, J.M.N.; Mirghani, M.E.S.; Nurrulhidayah, A.F.; Yanty, N.A.M. Differentiation of fractionated components of lard from other animal fats using different analytical techniques. Sains Malays. 2017, 46, 209–216. [Google Scholar]

- Bobroff, V.; Rubio, C.; Vigier, V.; Petibois, C. FTIR spectroscopy characterization of fatty-acyl-chain conjugates. Anal. Bioanal. Chem. 2016, 408, 319–326. [Google Scholar] [CrossRef]

- Yang, J.; Astatkie, T.; He, Q.S. A comparative study on the effect of unsaturation degree of camelina and canola oils on the optimization of bio-diesel production. Energy Rep. 2016, 2, 211–217. [Google Scholar] [CrossRef] [Green Version]

- Catarino, M.; Ferreira, E.; Soares Dias, A.P.; Gomes, J. Dry washing biodiesel purification using fumed silica sorbent. Chem. Eng. J. 2020, 386, 123930. [Google Scholar] [CrossRef]

| Fat | EUR per Metric Ton |

|---|---|

| Soybean oil | 184–450 |

| Rapeseed oil | 230–583 |

| Palm oil (crude) | 138–238 |

| UCO | 137–200 |

| Tallow (category 1) | 100–148 |

| Rendering Process | Equipment | Power (W) | Time (min) | Energy (kWh/100 g Raw Fat) | Fat Yield (g/100 g Raw Fat) | Fat Acidity (%) |

|---|---|---|---|---|---|---|

| Microwave | MW oven | 1400 | 3 | 0.070 | 60 ± 3 | 0.81 |

| Boiling water | Stove | 2800 | 40 | 1.868 | 30 * ± 3 | 1.96 |

| Acetone extraction | Heating mantle | 325 | 240 | 1.300 | 15 ± 1 | 2.39 |

| Catalyst | %Wcat (Fat Basis) | Methanol/Fat (Molar Ratio) | Reaction Temperature; Time | FAME Yield (%) |

|---|---|---|---|---|

| H2SO4 | 1.25 | 30 | 60 °C; 24 h | 93.2 |

| KOH | 0.8 | 6 | 60 °C; 2 h | 90.8 |

| Immobilized lipase | 20 | 12 | 50 °C; 48 h | 89.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soares Dias, A.P.; Ramos, M.; Rijo, B. Rendering of Beef Tallow for Biodiesel Production: Microwave versus Boiling Water and Acetone Fat Extraction. Processes 2022, 10, 666. https://doi.org/10.3390/pr10040666

Soares Dias AP, Ramos M, Rijo B. Rendering of Beef Tallow for Biodiesel Production: Microwave versus Boiling Water and Acetone Fat Extraction. Processes. 2022; 10(4):666. https://doi.org/10.3390/pr10040666

Chicago/Turabian StyleSoares Dias, Ana Paula, Marta Ramos, and Bruna Rijo. 2022. "Rendering of Beef Tallow for Biodiesel Production: Microwave versus Boiling Water and Acetone Fat Extraction" Processes 10, no. 4: 666. https://doi.org/10.3390/pr10040666

APA StyleSoares Dias, A. P., Ramos, M., & Rijo, B. (2022). Rendering of Beef Tallow for Biodiesel Production: Microwave versus Boiling Water and Acetone Fat Extraction. Processes, 10(4), 666. https://doi.org/10.3390/pr10040666