Effect of Atmospheric Cold Plasma on the Aroma of Pineapple Juice: Improving Fresh and Fruity Notes and Reducing Undesired Pungent and Sulfurous Aromas

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Plasma Processing

2.3. Chromatographic Analysis

2.4. Reactive Oxygen Species Determination

2.5. Odor Activity Values (OAV) and Aroma Correlation

3. Results

3.1. Changes in Volatile Compounds Profile Induced by DBD Plasma

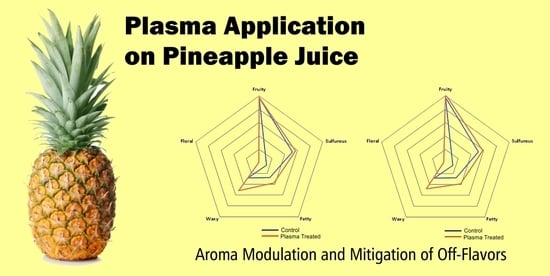

3.2. Changes in the Aroma Profile Induced by DBD Plasma

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Montero-Calderón, M.; Rojas-Graü, M.A.; Martín-Belloso, O. Aroma Profile and Volatiles Odor Activity Along Gold Cultivar Pineapple Flesh. J. Food Sci. 2010, 75, 506–512. [Google Scholar] [CrossRef] [PubMed]

- Petruzzi, L.; Campaniello, D.; Speranza, B.; Corbo, M.R.; Sinigaglia, M.; Bevilacqua, A. Thermal Treatments for Fruit and Vegetable Juices and Beverages: A Literature Overview. Compr. Rev. Food Sci. Food Saf. 2017, 16, 668–691. [Google Scholar] [CrossRef] [PubMed]

- Dhenge, R.; Langialonga, P.; Alinovi, M.; Lolli, V.; Aldini, A.; Rinaldi, M. Evaluation of Quality Parameters of Orange Juice Stabilized by Two Thermal Treatments (Helical Heat Exchanger and Ohmic Heating) and Non-Thermal (High-Pressure Processing). Food Control 2022, 141, 109150. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, P.; Zhan, P.; Tian, H.; Lu, C.; Tian, P. Aroma Characteristics of Cloudy Kiwifruit Juices Treated with High Hydrostatic Pressure and Representative Thermal Processes. Food Res. Int. 2021, 139, 109841. [Google Scholar] [CrossRef]

- De Vasconcelos Facundo, H.V.; De Souza Neto, M.A.; Maia, G.A.; Narain, N.; Dos Santos Garruti, D. Changes in Flavor Quality of Pineapple Juice during Processing. J. Food Process. Preserv. 2010, 34, 508–519. [Google Scholar] [CrossRef]

- Steinhaus, M.; Thomas, K.; Schieberle, P. Molecular Insights into Off-Flavor Formation during Pineapple Juice Processing. In Flavour Science; Academic Press: Cambridge, MA, USA, 2014; pp. 87–90. [Google Scholar]

- Steingass, C.B.; Glock, M.P.; Lieb, V.M.; Carle, R. Light-Induced Alterations of Pineapple (Ananas comosus [L.] Merr.) Juice Volatiles during Accelerated Ageing and Mass Spectrometric Studies into Their Precursors. Food Res. Int. 2017, 100, 366–374. [Google Scholar] [CrossRef]

- Ozen, E.; Singh, R.K. Atmospheric Cold Plasma Treatment of Fruit Juices: A Review. Trends Food Sci. Technol. 2020, 103, 144–151. [Google Scholar] [CrossRef]

- Laroque, D.A.; Seó, S.T.; Ayala Valencia, G.; Laurindo, B.; Augusto, B.; Carciofi, M. Cold Plasma in Food Processing: Design, Mechanisms, and Application. J. Food Eng. 2021, 312, 110748. [Google Scholar] [CrossRef]

- Rodríguez, Ó.; Gomes, W.F.; Rodrigues, S.; Fernandes, F.A.N. Effect of Indirect Cold Plasma Treatment on Cashew Apple Juice (Anacardium occidentale L.). LWT—Food Sci. Technol. 2017, 84, 457–463. [Google Scholar] [CrossRef]

- Alves Filho, E.G.; de Brito, E.S.; Rodrigues, S. Effects of Cold Plasma Processing in Food Components; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 9780128149218. [Google Scholar]

- Asl, P.J.; Rajulapati, V.; Gavahian, M.; Kapusta, I.; Putnik, P.; Mousavi Khaneghah, A.; Marszałek, K. Non-Thermal Plasma Technique for Preservation of Fresh Foods: A Review. Food Control 2022, 134, 108560. [Google Scholar] [CrossRef]

- Sruthi, N.U.; Josna, K.; Pandiselvam, R.; Kothakota, A.; Gavahian, M.; Mousavi Khaneghah, A. Impacts of Cold Plasma Treatment on Physicochemical, Functional, Bioactive, Textural, and Sensory Attributes of Food: A Comprehensive Review. Food Chem. 2022, 368, 130809. [Google Scholar] [CrossRef]

- Kopuk, B.; Gunes, R.; Palabiyik, I. Cold Plasma Modification of Food Macromolecules and Effects on Related Products. Food Chem. 2022, 382, 132356. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, F.A.N.; Rodrigues, S. Cold Plasma Processing on Fruits and Fruit Juices: A Review on the Effects of Plasma on Nutritional Quality. Processes 2021, 9, 2098. [Google Scholar] [CrossRef]

- Ma, T.J.; Lan, W.S. Effects of Non-Thermal Plasma Sterilization on Volatile Components of Tomato Juice. Int. J. Environ. Sci. Technol. 2015, 12, 3767–3772. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, S.; Fernandes, F.A.N. Glow Discharge Plasma Processing for the Improvement of Pasteurized Orange Juice’s Aroma and Off-Flavor. Processes 2022, 10, 1812. [Google Scholar] [CrossRef]

- Campelo, P.H.; Alves Filho, E.G.; Silva, L.M.A.; de Brito, E.S.; Rodrigues, S.; Fernandes, F.A.N. Modulation of Aroma and Flavor Using Glow Discharge Plasma Technology. Innov. Food Sci. Emerg. Technol. 2020, 62, 102363. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Zhu, X.; Yuan, Y.; Gao, Z.; Yue, T. Application of Electrical Discharge Plasma on the Inactivation of Zygosaccharomyces Rouxii in Apple Juice. LWT 2020, 121, 108974. [Google Scholar] [CrossRef]

- Rodrigues, S.; Fernandes, F.A.N. Changing Ready-to-Drink Coffee Aroma Using Dielectric Barrier Discharge Plasma. Processes 2022, 10, 2056. [Google Scholar] [CrossRef]

- Campelo, P.H.; Alves Filho, E.G.; Silva, L.M.A.; de Brito, E.S.; Rodrigues, S.; Fernandes, F.A.N. Modulation of Aroma and Flavor Using Dielectric Barrier Discharge Plasma Technology in a Juice Rich in Terpenes and Sesquiterpenes. LWT 2020, 130, 109644. [Google Scholar] [CrossRef]

- Elss, S.; Preston, C.; Hertzig, C.; Heckel, F.; Richling, E.; Schreier, P. Aroma Profiles of Pineapple Fruit (Ananas comosus [L.] Merr.) and Pineapple Products. LWT—Food Sci. Technol. 2005, 38, 263–274. [Google Scholar] [CrossRef]

- Vollmer, K.; Czerny, M.; Vásquez-Caicedo, A.L.; Varona Iglesias, S.; Frank, J.; Carle, R.; Steingass, C.B. Non-Thermal Processing of Pineapple (Ananas comosus [L.] Merr.) Juice Using Continuous Pressure Change Technology (PCT): HS-SPME-GC–MS Profiling, Descriptive Sensory Analysis, and Consumer Acceptance. Food Chem. 2021, 345, 128786. [Google Scholar] [CrossRef]

- Mohd Ali, M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Pineapple (Ananas comosus): A Comprehensive Review of Nutritional Values, Volatile Compounds, Health Benefits, and Potential Food Products. Food Res. Int. 2020, 137, 109675. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Santos, V.O.; Rodrigues, S. Effects of Glow Plasma Technology on Some Bioactive Compounds of Acerola Juice. Food Res. Int. 2019, 115, 16–22. [Google Scholar] [CrossRef]

- Coutinho, N.M.; Silveira, M.R.; Fernandes, L.M.; Moraes, J.; Pimentel, T.C.; Freitas, M.Q.; Silva, M.C.; Raices, R.S.L.; Ranadheera, C.S.; Borges, F.O.; et al. Processing Chocolate Milk Drink by Low-Pressure Cold Plasma Technology. Food Chem. 2019, 278. [Google Scholar] [CrossRef]

- Grosch, W. Evaluation of the Key Odorants of Foods by Dilution Experiments, Aroma Models and Omission. Chem. Senses 2001, 26, 533–545. [Google Scholar] [CrossRef] [PubMed]

- Buttery, R.G.; Ling, L.C.; Light, D.M. Tomato Leaf Volatile Aroma Components. J. Agric. Food Chem. 1987, 35, 1039–1042. [Google Scholar] [CrossRef]

- Fazzalari, F.A. Compilation of Odor and Taste Threshold Values Data; American Society for Testing and Materials: Philadelphia, PA, USA, 1978. [Google Scholar]

- Padrayuttawat, A.; Yoshizawa, T.; Tamura, H.; Tokunaga, T. Optical Isomers and Odor Thresholds of Volatile Constituents in Citrus Sudachi. Food Sci. Technol. Int. 1997, 3, 402–408. [Google Scholar] [CrossRef] [Green Version]

- Qian, M.C.; Wang, Y. Seasonal Variation of Volatile Composition and Odor Activity Value of “Marion” (Rubus Spp. Hyb) and “Thornless Evergreen” (R. laciniatus L.) Blackberries. J. Food Sci. 2005, 70, 13–20. [Google Scholar] [CrossRef]

- Usami, A.; Ono, T.; Marumoto, S.; Miyazawa, M. Comparison of Volatile Compounds with Characteristic Odor in Flowers and Leaves of Nojigiku (Chrysanthemum japonense). J. Oleo Sci. 2013, 62, 631–636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiao, Z.; Chen, J.; Niu, Y.; Chen, F. Characterization of the Key Odorants of Fennel Essential Oils of Different Regions Using GC–MS and GC–O Combined with Partial Least Squares Regression. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2017, 1063, 226–234. [Google Scholar] [CrossRef]

- Company, T.G.S. The Good Scents Company Database; The Good Scents Company: Old Creek, WI, USA.

- Goiana, M.L.; de Brito, E.S.; Filho, E.G.A.; Miguel, E.D.C.; Fernandes, F.A.N.; de Azeredo, H.M.C.; Rosa, M.D.F. Corn Starch Based Films Treated by Dielectric Barrier Discharge Plasma. Int. J. Biol. Macromol. 2021, 183, 2009–2016. [Google Scholar] [CrossRef]

- Teixeira, M.A.; Barrault, L.; Rodríguez, O.; Carvalho, C.C.; Rodrigues, A.E. Perfumery Radar 2.0: A Step toward Fragrance Design and Classification. Ind. Eng. Chem. Res. 2014, 53, 8890–8912. [Google Scholar] [CrossRef]

- Pino, J.A. Odour-Active Compounds in Pineapple (Ananas comosus [L.] Merril Cv. Red Spanish). Int. J. Food Sci. Technol. 2013, 48, 564–570. [Google Scholar] [CrossRef]

- Wu, W.; Xiao, G.; Yu, Y.; Xu, Y.; Wu, J.; Peng, J.; Li, L. Effects of High Pressure and Thermal Processing on Quality Properties and Volatile Compounds of Pineapple Fruit Juice. Food Control 2021, 130, 108293. [Google Scholar] [CrossRef]

| Control | Dielectric Barrier Discharge Plasma Conditions (Frequency and Time) | ||||||

|---|---|---|---|---|---|---|---|

| 50 Hz 10 min | 50 Hz 20 min | 500 Hz 10 min | 500 Hz 20 min | 1000 Hz 10 min | 1000 Hz 20 min | ||

| Ethyl acetate | 3.48 ± 0.18 | 5.10 ± 0.20 | 6.95 ± 0.28 | 5.95 ± 0.24 | 2.31 ± 0.09 | 12.14 ± 0.49 | 12.20 ± 0.49 |

| Methyl butanoate | 1.70 ± 0.09 | 4.52 ± 0.18 | 0.81 ± 0.03 | 5.27 ± 0.21 | 1.02 ± 0.04 | 1.38 ± 0.06 | 0.79 ± 0.03 |

| Methyl 2-methyl butanoate | 7.84 ± 0.40 | 8.32 ± 0.33 | 3.70 ± 0.15 | 9.70 ± 0.39 | 9.81 ± 0.30 | 9.75 ± 0.39 | 5.14 ± 0.21 |

| Ethyl 2-methyl butanoate | 1.54 ± 0.08 | 1.82 ± 0.07 | 1.17 ± 0.05 | 2.13 ± 0.09 | 1.66 ± 0.07 | 2.09 ± 0.08 | 1.22 ± 0.05 |

| Methyl hexanoate | 53.16 ± 2.68 | 23.91 ± 0.96 | 11.65 ± 0.47 | 27.88 ± 1.12 | 27.53 ± 1.10 | 28.69 ± 1.15 | 18.68 ± 0.75 |

| Ethyl hexanoate | 10.00 ± 0.50 | 6.45 ± 0.26 | 1.98 ± 0.08 | 7.52 ± 0.30 | 8.33 ± 0.33 | 8.64 ± 0.35 | 8.42 ± 0.34 |

| Methyl 3-(methylthio)propanoate | 12.55 ± 0.63 | 16.14 ± 0.65 | 38.29 ± 1.53 | 18.82 ± 0.75 | 21.39 ± 0.86 | 16.97 ± 0.68 | 21.06 ± 0.84 |

| Ethyl 3-(methylthio)propanoate | 2.28 ± 0.04 | 3.71 ± 0.15 | 8.31 ± 0.33 | 4.33 ± 0.17 | 5.09 ± 0.20 | 4.36 ± 0.17 | 6.27 ± 0.25 |

| Methyl octanoate | 2.44 ± 0.11 | 0.42 ± 0.02 | 0.00 ± 0.00 | 0.49 ± 0.00 | 0.42 ± 0.02 | 0.29 ± 0.01 | 0.24 ± 0.01 |

| 1.3.5-Undecatriene | 0.56 ± 0.04 | 0.45 ± 0.02 | 0.00 ± 0.00 | 0.52 ± 0.00 | 1.49 ± 0.06 | 1.71 ± 0.07 | 1.07 ± 0.04 |

| Octanoic acid | 0.03 ± 0.01 | 0.47 ± 0.02 | 1.43 ± 0.06 | 0.54 ± 0.02 | 1.06 ± 0.04 | 1.12 ± 0.04 | 1.68 ± 0.07 |

| Ethyl octanoate | 0.07 ± 0.01 | 1.71 ± 0.07 | 0.14 ± 0.01 | 2.00 ± 0.02 | 1.27 ± 0.05 | 0.85 ± 0.03 | 0.28 ± 0.01 |

| Decanal | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.94 ± 0.04 | 0.00 ± 0.00 | 1.79 ± 0.07 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| 5-Hydroxymethyl-2-furaldehyde | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.66 ± 0.03 | 0.00 ± 0.00 | 0.11 ± 0.01 |

| Phenethyl acetate | 0.17 ± 0.01 | 0.62 ± 0.02 | 0.99 ± 0.04 | 0.72 ± 0.03 | 0.88 ± 0.04 | 0.66 ± 0.03 | 1.19 ± 0.05 |

| 5-Butyldihydro-2(3H)-furanone | 0.17 ± 0.01 | 0.44 ± 0.02 | 0.91 ± 0.04 | 0.51 ± 0.02 | 0.60 ± 0.02 | 0.48 ± 0.02 | 0.74 ± 0.03 |

| Methyl linoleate | 0.98 ± 0.01 | 1.42 ± 0.06 | 2.18 ± 0.09 | 1.66 ± 0.07 | 1.72 ± 0.07 | 1.56 ± 0.06 | 1.42 ± 0.03 |

| Frequency (Hz) | Hydroxyl Radical | Hydrogen Peroxide | Superoxide Anion |

|---|---|---|---|

| 50 | 1.0 ± 0.0 | 0.9 ± 0.1 | 0.3 ± 0.1 |

| 500 | 0.9 ± 0.1 | 1.0 ± 0.0 | 1.0 ± 0.0 |

| 1000 | 0.4 ± 0.1 | 1.0 ± 0.0 | 0.2 ± 0.1 |

| Primary Odor Description | Secundary Odor Description | Odor Threshold (mg/L Water) | |

|---|---|---|---|

| Ethyl acetate | ethereo | - | 25 |

| Methyl butanoate | fruity | apple/ sweet | 0.076 |

| Methyl 2-methyl butanoate | fruity | ethereal | 0.00025 |

| Ethyl 2-methyl butanoate | fruity | sharp/sweet | 0.0003 |

| Methyl hexanoate | fruity | ethereal | 0.084 |

| Ethyl hexanoate | fruity | sweet | 0.001 |

| Methyl 3-(methylthio)propionate | sulfurous | - | 0.180 |

| Ethyl 3-(methylthio)propanoate | sulfurous | - | 0.007 |

| Methyl octanoate | waxy | - | 0.200 |

| 1.3.5-undecatriene | fruity | fresh/green | 0.00002 |

| Octanoic acid | fatty | - | 0.910 |

| Ethyl octanoate | waxy | - | 0.005 |

| Decanal | aldehydic | - | 0.030 |

| 5-Hydroxymethyl-2-furaldehyde | fatty | - | 100 |

| Phenethyl acetate | floral | - | 0.650 |

| 5-Butyldihydro-2(3H)-furanone | fatty | - | 0.007 |

| Methyl linoleate | ethereo | - | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porto, E.C.M.; de Brito, E.S.; Rodrigues, S.; Fernandes, F.A.N. Effect of Atmospheric Cold Plasma on the Aroma of Pineapple Juice: Improving Fresh and Fruity Notes and Reducing Undesired Pungent and Sulfurous Aromas. Processes 2023, 11, 2303. https://doi.org/10.3390/pr11082303

Porto ECM, de Brito ES, Rodrigues S, Fernandes FAN. Effect of Atmospheric Cold Plasma on the Aroma of Pineapple Juice: Improving Fresh and Fruity Notes and Reducing Undesired Pungent and Sulfurous Aromas. Processes. 2023; 11(8):2303. https://doi.org/10.3390/pr11082303

Chicago/Turabian StylePorto, Elaine C. M., Edy S. de Brito, Sueli Rodrigues, and Fabiano A. N. Fernandes. 2023. "Effect of Atmospheric Cold Plasma on the Aroma of Pineapple Juice: Improving Fresh and Fruity Notes and Reducing Undesired Pungent and Sulfurous Aromas" Processes 11, no. 8: 2303. https://doi.org/10.3390/pr11082303

APA StylePorto, E. C. M., de Brito, E. S., Rodrigues, S., & Fernandes, F. A. N. (2023). Effect of Atmospheric Cold Plasma on the Aroma of Pineapple Juice: Improving Fresh and Fruity Notes and Reducing Undesired Pungent and Sulfurous Aromas. Processes, 11(8), 2303. https://doi.org/10.3390/pr11082303